Escolar Documentos

Profissional Documentos

Cultura Documentos

Kera Valves ML

Enviado por

Sharon LambertDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kera Valves ML

Enviado por

Sharon LambertDireitos autorais:

Formatos disponíveis

The AYLESBURY Float Valve Range

Delayed Action Float Valves for Water Storage Tanks

Reliable long life cycle Ideal for pumped systems Improve water turnover Reduce legionella risk Save energy with positive pump control High performance and high quality

Size shown 40mm (SF)

Size shown 25mm

Full flow during fill Tank capacity maximised Fixed & variable level differential No dribble No water hammer No valve bounce Maintenance free Suitable for type AA, AB, AF & AG air gaps

W WITH O

Size shown 40mm (HF)

ARRAN

TY

ERAFLO

The Professionals Choice

The range of delayed action Aylesbury Float Valves manufactured in the UK by Keraflo Ltd are especially designed to provide an accurate and efficient method of controlling the level of stored water in tanks with or without raised valve chambers. All types of valve are constructed to operate over a long period without requiring maintenance.

The AYLESBURY Float Valve Range

NOW AVAIL A IN STA BLE INLESS STEEL

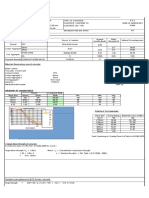

AYLESBURY K TYPE

The Aylesbury Float Valve is easy to install; with the up and over discharge arrangement facilitating either Type AA, AB, AF or AG air gap requirements under the New Water Regulations.

The weighted key-shaped float which is supplied with Aylesbury K, KX & KA Type float valves can be accurately set in a number of positions on the brass float arm, actuating the valve at a predetermined difference in water level, driving it fully open or fully closed without water hammer. This positive action avoids dribble, reduces noise and allows full flow until the selected closed level is reached. Inherent in the design is a nonadjustable operating differential in water level between opening and closing of approximately 75mm.

OPEN POSITION

Sizes:

1

/2

/4

1

25mm

11 /4

32mm

11 /2 (SF)

40mm

11 /2 (HF)

40mm

2 (SF)

50mm

15mm

20mm

SF - Standard Flow

HF - High Flow

AYLESBURY KA KX & KAX TYPE

Identical in operation to the K Type, the Aylesbury KA KX & KAX Type Valves have extended drops and are suitable for raised valve chambers. They are primarily designed to fit into chambers or boxes in the covers of tanks calling for air gaps or where maximum tank capacity is required. To assist with compliance of air gap requirements the valve discharge is further raised above the centre line.The KAX is especially suitable for Type AA & AB air gaps where valve sizes greater than 1 are needed. KA & KX Sizes:

3

/4

1

25mm

20mm

KAX Sizes:

11 /4

32mm

11 /2 (SF)

40mm

11 /2 (HF)

40mm

2 (SF)

50mm

SF - Standard Flow

HF - High Flow

C LO SE D

The Aylesbury Float Valve is ideal for pumped systems as the open to closed on/off operation of the valve avoids pump hunting and water hammer.The set level is unaffected by pressure fluctuation and there is no seat or washer to wear.

The AYLESBURY Float Valve Range

AYLESBURY KB TYPE

The standard DZR brass-bodied valve is common to all valve types. The radical design of the puncture proof float, combined with the unique technology of the valve almost entirely eliminates stress on the tank wall fixing point and can be readily fitted to maximise tank capacity.

The Aylesbury KB Type Valve offers fully variable operating differential between opening and closing water level settings. The valve is operated by a transfer of weight in an actuator tube which causes the valve to open or close.The arrangement of the float and buoy assembly produces a delayed change of balance in the actuator as the water level alters. As the total assembly is relatively light and there are no pressure related stresses there is no need for supporting structures. The versatility of the Aylesbury KB Type makes it suitable for installation either direct into a tank or into a raised valve chamber particularly where air gaps are required. Changes in water levels and differentials can be made quickly by the installer or maintenance engineer without tools.This feature is particularly useful where water demand changes either due to seasonal factors, building occupancy or where the commissioning of a facility is phased, as it reduces the risks associated with excess water being stored for too long.

Variable CLOSED POSITION OPEN POSITION

The unique design makes this valve ideal for use with pumped systems, water treatment plants and many other applications including: Industrial tanks Pumped systems Rain (grey) water tanks and reservoirs Process tanks Industrial feed and expansion tanks Underground tanks

Delayed Action

Sizes:

3

/4

1

25mm

11 /4

32mm

11 /2 (SF)

40mm

11 /2 (HF)

40mm

2 (SF)

50mm

2 (HF)

50mm

21 /2 (SF)

65mm

3 (RB)

80mm

20mm

SF - Standard Flow

HF - High Flow

RB - Reduced Bore

AYLESBURY KB TYPE Type Valves Applications

Aylesbury 'KB' Type valves have a variable delayed action and feature a chain in place of a rigid float arm - enabling virtually unlimited opening and closing levels. This allows for a considerable drop from the valve to the water level overcoming the problems associated with drop arms. 'KB' Valves are particularly suitable to meet the requirements of the New Water Regulations where air gaps are required. In addition their flexibility can assist with Improving water quality where Buildings are partially commissioned or Occupancy varies.

Air gaps for Industrial tanks - The 'KB' Type is ideal for fitting into a tank without a lid or raised valve chamber and where the vertical drop from the valve to the water level may be considerable. Pumped systems - The adjustable and potentially large difference between opening and closing levels can allow an immense volume of water to be admitted to the tank each filling cycle. Pumps and pump sets are often controlled to run for a minimum of 3 minutes. If the water demand is satisfied before this time and an auxiliary hydraulic accumulator is not fitted, the pumps will run against a closed valve at 0% efficiency. The fill volume can be set to equal or exceed this volume thereby ensuring the pump(s) run for at least 3 minutes. Where a pump set is used solely for transferring water from a break tank to an elevated storage tank the KB Valve can dispense with the need for an auxiliary hydraulic accumulator. Pump efficiency and initial sizing can be further enhanced using a float valve with little internal resistance. Consequently the High Flow version is often better suited to these applications than the Standard Flow version which is ideal for mains applications. Rain (Grey) water tanks and reservoirs - For economy and environmental reasons, rain water is increasingly being used for applications where drinking water standards are not required. At times of inadequate rainfall, there is no choice but to use mains water. A valve is therefore required to admit mains water when the level in the rain water tank is low. The KB valve is ideal due to a 2 m long chain allowing for a low opening level and the correct air gap requirement. Process tanks - Tanks storing water in industrial processes are fluid category 5 requiring a Type AA or AB air gap. They may be small and irregular and the flow through the float valve may also need to be constant. KB valves are ideal in these instances. Industrial feed and expansion tanks - The water level in a large LTHW F&E tank can rise and fall several feet. Since non-domestic F&E tanks are a fluid category 5 risk, they require a Type AA air gap. The KB valve is perfect because it can be mounted high in the tank (maximising the air gap) and the opening level can be set low, allowing sufficient volume for expansion. Maximum temperature 60C. Underground tanks - Water storage tanks can be buried underground. Facilitating access to a float valve in this situation is difficult, so it is desirable to mount the valve above ground. Provided the water is ducted from the valve, a KB valve can be mounted above ground with only the closing float and opening buoy in the tank.

The AYLESBURY Float Valve Range

Hygienic air gap - Occasionally water needs to be stored to drinking water standards but is considered to be a fluid category 4 or 5 risk. Such an arrangement is described as a "hygienic air gap" and is to be found in dental surgeries and food processing equipment. The height required to accommodate:screened slots, free board, overflow, warning pipe and air gap to water level is considerable and often beyond the reach of conventional ball valves. Fitting a "drop arm" can provide the necessary drop but these suffer from a range of problems including the unscrewing of the drop arm or at the valve connection and failure of the valve to close due to reduced leverage in the open position.

CLOSED POSITION OPEN POSITION Variable Delayed Action

IMPROVED WATER QUALITY In addition to the benefits of having the facility to match stored capacity to occupancy, the KB valve also reduces the risk of stagnation and stratification due to its high discharge velocity. This, in turn, assists in reducing the risk of levels of bacteria, including legionellae bacterium. The valve discharge diameter is optimised to provide a vertical jet that stirs up the stored water. Partially commissioned buildings - Water over capacity during initial construction and prior to full occupancy can cause problems. KB valves allow the depth (hence volume) of water in the tank to be set according to the occupancy. Varying occupancy - Water storage capacity is calculated according to the type of building and occupancy. For example, the required water capacity for peak season in tourist hotels or during term time in educational establishments is vastly more than that required during low season or holidays. During these lower demand times the stored water is not consumed and replenished every day; indeed it may well take weeks for the water to be turned over. Naturally this can lead to stagnation and a temperature rise in excess of 20C where the legionellae bacterium can proliferate increasing the risk of legionnaires disease and Pontiac fever. The KB valve is the simple solution since open and closing levels can be simultaneously adjusted by raising or lowering the chain attached to the valve actuator. This operation is quick and does not require tools.

The KP TYPE Float Valve Kit

The KP Type Float Valve Kit comprises an in-line control valve together with an Aylesbury KB Type Valve acting as a pilot.The Aylesbury valve offers almost infinitely variable independent opening and closing water level settings.With the delayed action and on/off operation it is ideal for mains or pumped systems.

Control Valve - Flexible installation: Can be mounted in one of three positions. Outside the tank at floor level. Outside the tank above the tank water level. Inside the tank above the tank water level. High kv Value: The standard KP Control Valve offers excellent flow rate performance. Raised Valve Chamber: Can be small as it only has to accommodate a 3/4 KB and discharge assembly. Facilitates Air gaps: The Aylesbury KB Valve is supplied with 2m long adjustable chain as standard allowing the closing level to be set below any combination of Weir Slot, Overflow and Warning device. Quiet operation Valves are quieter than conventional valves due to the elimination of Water Hammer,Valve Bounce, Hiss and Dribble. Ease of Installation Conventional Float Valves above 3 are heavy and cumbersome often necessitating two installers. When the KP Control Valve is mounted outside the tank at floor level, no heavy lifting is required. Accessibility An externally mounted Control Valve can be easily inspected, adjusted and if required serviced. Re-chlorination of the tank is not necessary provided the tank lid is not removed. Multiple Discharges To reduce the risk of stagnation two or more discharges can be connected to the outlet of the control valve. Since the Filling Pipe is only subjected to low pressure, thin wall PVC pipe can be used.The KP Valve can also be configured to service twin/partitioned tanks. Shallow tanks KP valves can operate in tanks of only 1 metre in depth. Deep tanks The standard Aylesbury KB Pilot valve enables an opening level 2m below the Pilot valve. A longer chain can be supplied to control levels greater than 2m. Optional Extras - A range of accessories are available as original equipment or as retrofits. Including Upstream Pressure Sustaining Regulator - the Control Valve will regulate itself to leave the desired minimum upstream pressure (Adjustable 1 - 6 Bar). This can also be used to provide a constant flow rate. Check Valve can be fitted to the Pilot System causing the Control Valve to act as a check valve and float valve. Electrical solenoids, pressure gauges and other options are available.

Control Valve Fitted with upstream sustaining valve

Delayed Action Valves for

Water Storage Tanks

Aylesbury KB Type Valve

No Water Hammer No Valve Bounce Full Flow During Fill No Dribble Maximises Tank Capacity Delayed Action Maintenance Free Tank Wall Stress negligible No backing plate required Ideal for Fire Sprinkler Systems Suitable for all types of Air gap applications

Sizes: 4 100mm

6 150mm

8 200mm

The KP TYPE Float Valve Kit

The AYLESBURY Float Valve Range

All the advantages of

Filterball Service Valves

Incorporating coarse particle strainer with easy clean facility

Equilibrium Valves Plus

Virtually Indestructible: The heart of the valve incorporates pressure compensated rotating ceramic discs with ports where in open position the actuator aligns ports and in closed position the actuator misaligns ports. Revolutionary Shaped Puncture Proof Float: Made from Polyethylene closed cell PE foam which is CFC Free and chemically and biologically inert. Extended Durability: Non-wearing ceramic disc seal. Water Pressure: Suitable for 0 -10 Bar. Temperature Range: 1 - 60 C Maintenance Free: Designed to operate over a long period without requiring maintenance. Backsiphonage Protection: Up and Over discharge as for BS1212 part 2 to facilitate easier Air gap compliance. Delayed Action: K KA KX & KAX Types: Non adjustable operating differential between opening and closing of 75mm. KB & KP Type: Fully variable operating differential between opening and closing up to 1820mm as standard.

The Filterball service valve is an on-off spherical valve with integral conical strainer which is easy to inspect and remove for normal maintenance operations without draining down. In the open position, the valve has two important functions.The supply water passes through the strainer safeguarding the storage vessel and the Aylesbury float valve against the ingress of coarse undesirable particles. All parts conform to requirements for potable water systems. Available in sizes 1/2 (15mm) to 2 (50mm) WBS Approved product. The fitting of a service valve in conjunction with a float valve is mandatory.

The AYLESBURY Float Valve Range

Delayed Action Float Valves for Water Storage Tanks

Full Technical Specifications or advice on the New Water Regulations available on request from Keraflo: Tel: 01296 435785 Fax: 01296 395522 E-mail: info@keraflo.co.uk Web: www.keraflo.co.uk

Keraflo Ltd, Griffin Lane, Aylesbury, Bucks. UK. HP19 8BF

ERAFLO

Keraflo and Aylesbury are registered trade marks. The Aylesbury valve is a patented product Keraflo Ltd reserve the right to alter designs without prior notice

Keraflo Ltd manufacturers of the Aylesbury Float Valve Range and suppliers of specialist equipment for cold water services.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- JournalofBuildingPhysics 2012 Younes 267 302Documento37 páginasJournalofBuildingPhysics 2012 Younes 267 302Sharon LambertAinda não há avaliações

- Hvac Basics 4Documento74 páginasHvac Basics 4Sharon LambertAinda não há avaliações

- 20170706140654483Documento66 páginas20170706140654483Sharon LambertAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 20170706140756729Documento36 páginas20170706140756729Sharon LambertAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- HVAC Chilled Water Distribution SchemesDocumento56 páginasHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hvac BasicsDocumento73 páginasHvac BasicsSharon LambertAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Background Noise Rating Calculator: InstructionsDocumento29 páginasBackground Noise Rating Calculator: InstructionsSharon LambertAinda não há avaliações

- REQ 15 Sizing of Oil and Grease TrapsDocumento40 páginasREQ 15 Sizing of Oil and Grease TrapsSharon LambertAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Commercial Kitchen Design PDFDocumento21 páginasCommercial Kitchen Design PDFRocky WidjajaAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Fundamentals of Water Distribution: TopicsDocumento89 páginasFundamentals of Water Distribution: TopicsRonald Kahora0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Calculating Sump VolumeDocumento2 páginasCalculating Sump VolumeSharon LambertAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Pertes de Charge (Fluide Compressibles) V2Documento20 páginasPertes de Charge (Fluide Compressibles) V2Sharon LambertAinda não há avaliações

- HVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationDocumento4 páginasHVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationSharon LambertAinda não há avaliações

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocumento17 páginasAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Temperature Expansion PipesDocumento2 páginasTemperature Expansion PipesSharon LambertAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- How To Size and Design DuctsDocumento91 páginasHow To Size and Design DuctsPrabir Bhowmik100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Duct SilencersDocumento125 páginasDuct SilencersesagcojrAinda não há avaliações

- Grease Trap Calculator 03Documento2 páginasGrease Trap Calculator 03Sharon LambertAinda não há avaliações

- MD He Tema Asme v0.1Documento31 páginasMD He Tema Asme v0.1Sharon Lambert100% (1)

- MD He Tema Asme v0.1Documento31 páginasMD He Tema Asme v0.1Sharon Lambert100% (1)

- Pipe and Fitting Calcs MasterDocumento8 páginasPipe and Fitting Calcs MasterSharon LambertAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Importance of Drying Compressed Air - Paerker BalstonDocumento12 páginasThe Importance of Drying Compressed Air - Paerker Balstonppluis90Ainda não há avaliações

- Piping Pressure Drop Functions by Stephen Hall, PE: Pipe DataDocumento4 páginasPiping Pressure Drop Functions by Stephen Hall, PE: Pipe DataSharon LambertAinda não há avaliações

- Red Cells Contain Parameters That You Can Change To Test Different ConfigurationsDocumento3 páginasRed Cells Contain Parameters That You Can Change To Test Different ConfigurationsSharon Lambert100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Expansion LoopDocumento54 páginasExpansion Loopsteepa22Ainda não há avaliações

- Wap 3 Ventilation WksheetDocumento7 páginasWap 3 Ventilation WksheetSharon LambertAinda não há avaliações

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocumento3 páginasPressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- Emergency Vent Flam LiquidsDocumento3 páginasEmergency Vent Flam LiquidsSharon LambertAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Recommended Fluid VelocitiesDocumento5 páginasRecommended Fluid Velocitiesger80100% (1)

- Equivalent Length Calculator - RevADocumento10 páginasEquivalent Length Calculator - RevArkrajan1502Ainda não há avaliações

- Mechatronics Electronic Control Systems in Mechanical and Electrical EngineeringDocumento19 páginasMechatronics Electronic Control Systems in Mechanical and Electrical EngineeringTanAinda não há avaliações

- Automobile Waste and Its Management PDFDocumento7 páginasAutomobile Waste and Its Management PDFBojan TanaskovskiAinda não há avaliações

- BT134WDocumento7 páginasBT134WMiloud ChouguiAinda não há avaliações

- Rf00025-Quantitative Fractography and Modelling of FatiguDocumento14 páginasRf00025-Quantitative Fractography and Modelling of Fatiguzixin chenAinda não há avaliações

- 2 - Conservation and The Use of Secondary and Recycled Materials PDFDocumento16 páginas2 - Conservation and The Use of Secondary and Recycled Materials PDFfa_fa67Ainda não há avaliações

- E SN752Documento3 páginasE SN752hasan_676489616Ainda não há avaliações

- TMMDocumento21 páginasTMMAkash LohiAinda não há avaliações

- Algal Bio PlasticsDocumento4 páginasAlgal Bio PlasticsBala JiAinda não há avaliações

- 01CB1S01Documento5 páginas01CB1S01raobabar21Ainda não há avaliações

- tp6140 PDFDocumento72 páginastp6140 PDFjohnAinda não há avaliações

- Engineering Standards SAEC Waste Disposal LandfillsDocumento17 páginasEngineering Standards SAEC Waste Disposal LandfillsAhmad RazaAinda não há avaliações

- Prestartup Check List of HRSGDocumento3 páginasPrestartup Check List of HRSGmd abAinda não há avaliações

- Item Description UOM Quantity Unit Rate in Amount inDocumento35 páginasItem Description UOM Quantity Unit Rate in Amount inIshwar AltAinda não há avaliações

- High-Temperature Corrosion and Materials Applications George Y. Lai, Editor, p1 DOI: 10.1361/hcma2007p001 All Rights ReservedDocumento445 páginasHigh-Temperature Corrosion and Materials Applications George Y. Lai, Editor, p1 DOI: 10.1361/hcma2007p001 All Rights ReservedFaraj HaiderAinda não há avaliações

- Tpi183 de en PDFDocumento40 páginasTpi183 de en PDFAGNALDOJULIOAinda não há avaliações

- BD 4415 ADocumento130 páginasBD 4415 Akhx2Ainda não há avaliações

- Ductless Fume Hood Brochure - FEB19Documento2 páginasDuctless Fume Hood Brochure - FEB19Musz MusaAinda não há avaliações

- Project Report On GearsDocumento40 páginasProject Report On Gearsjai70% (27)

- K 5 Premium Full Control Plus: Operating InstructionsDocumento84 páginasK 5 Premium Full Control Plus: Operating Instructionsronald DAinda não há avaliações

- Manual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Documento2 páginasManual For Accessory Kit To Electromagnetic Vibrator No. 2185.55Harry RamzaAinda não há avaliações

- Miniature Lamp GuideDocumento3 páginasMiniature Lamp GuideKAZIMALI25Ainda não há avaliações

- CH312 Experiment 3 - Soil Chemistry ReportDocumento5 páginasCH312 Experiment 3 - Soil Chemistry ReportNarelle Iauma100% (1)

- Ped Asme ComparisionDocumento31 páginasPed Asme ComparisionJose A ManciniAinda não há avaliações

- MOJAVE Single Wide 2015Documento16 páginasMOJAVE Single Wide 2015Donnarose DiBenedettoAinda não há avaliações

- Weldspec ASME WPS ASME IXDocumento2 páginasWeldspec ASME WPS ASME IXPadmanabhan VenkateshAinda não há avaliações

- Thermal Lab PPT - Heat Balance SheetDocumento10 páginasThermal Lab PPT - Heat Balance SheetAyush SinghalAinda não há avaliações

- Sheet Metal Forming PDFDocumento8 páginasSheet Metal Forming PDFAlpha WolfAinda não há avaliações

- New Text DocumentDocumento6 páginasNew Text DocumentsadsdAinda não há avaliações

- Frictional Losses in Circular PipeDocumento5 páginasFrictional Losses in Circular PipeVrushiket PatilAinda não há avaliações

- M25 (PPC)Documento2 páginasM25 (PPC)Jagdev GuleriaAinda não há avaliações