Escolar Documentos

Profissional Documentos

Cultura Documentos

Proyecto

Enviado por

Crack_09Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Proyecto

Enviado por

Crack_09Direitos autorais:

Formatos disponíveis

UNIVERSIDAD LATINA DE PANAM SEDE VERAGUAS COMUNICACIONES I III CUATRIMESTRE DEL 2013 PROYECTO CIRCUITO LEVITADOR ELECTROMAGNETICO Profesor

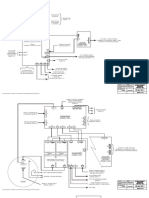

Guillermo Herrera Indicaciones: el siguiente proyecto se realizara en grupo de tres estudiantes como mximo y se entregara el da del examen cuatrimestral. ;El informe del proyecto debe tener: portada, introduccin, objetivos, lista de materiales, diagrama esquemtico, circuito impreso, colusin, bibliografa. Cotizacin en Panam o por Mailbox. Comenzar trabajar desde la primera semana de clases. Tienen 15 semanas. Nota: Traduzca el contenido que est en Ingles e incluya en el informe. Diagrama No 1

Lista de Materiales Partes R1 R2 R3 R4 R5, R6, R14, R16 R7 R8, R10 R9 R11 R12 R13 R15 C1 C2 C3 D1 D2 D3 Q1 Q2 Q3, Q4 Q6 Q7 U1 U2 L1 S1 MISC Cantidad Descripcion

1 2K 1/4W Resistor 1 560 Ohm 1/2W Resistor 1 3.3K 1/4W Resistor 1 12K 1/4W Resistor 4 1K 1/4W Resistor 1 470K 1/4W Resistor 2 100K 1/4W Resistor 1 10K Linear Pot 1 150K 1/4W Resistor 1 360K 1/4W Resistor 1 82 Ohm 1/4W Resistor 1 2.2K 1/4W Resistor 1 330uF 25V Electrolytic Capacitor 1 0.1uF Ceramic Disc Capacitor 1 0.22uF 50V Polyester Capacitor 1 TLN110 IR LED 1 1N4001 Silicon Rectifier Diode 1N4004, 1N4007 1 Red LED 1 IRD500 NPN Phototransistor 1 2N3906 PNP Transistor 2 2N3904 NPN Transistor 1 2N2907 PNP Transistor 1 TIP41A NPN Power Transistor 1 LM78L09 9V Linear Regulator IC 1 LM358N Dual Op-Amp IC 1 Potter & Brumfield KUP11D15-6VDC Relay Coil (See Text) 1 SPST Switch 1PC Board, Sockets For ICs, 12VDC 500mA Power Adapter, Wire, Knob For R9, Heatsink For Q7, Holder For D1 and Q1, DC Power Jack

Circuit Assembly

This project is built in two sections; the circuit and then the enclosure/base. Assembly of the circuit should take place on a printed circuit board to minimize the chance of oscillation and to keep the assembly need and compact. A printed circuit board pattern is provided below. Before using it as a template for your board (using either a photographic or laser process) it is important to check its dimensions when printed. Make a test print on regular paper and then measure the result, comparing it to the measurement shown on the board pattern. If they don't match, you will need to adjust your printing settings or scale the pattern in the photo editing software of your choice. While a tiny amount of variance will not make much of a difference, about 1MM is enough to make fitting ICs very difficult. Once you are satisfied your pattern is correct, etch the board using the method of your choice and then drill out component lead holes. Assemble the parts onto the board using the parts placement diagram shown below. Make sure to check the position of all polarized parts against the schematic before they are soldered into the board. ICs, diodes, transistors, electrolytic capacitors and LEDs must be placed properly or they will not function and may be damaged. As the board will be mounted into a case, some components are mounted off board with wire leads connecting them to the PCB. D1, D3, Q1, R9, L1 and S1 should be connected to the board via wire leads. S1, R9 and D3 should be on leads about 6" to allow mounting on the front of the case. Q1 and D1 will require longer leads (about 8-10") as they will be mounted on the bracket supporting the electromagnet. L1, the magnet, needs enough lead length to get it to the top of that bracket so use between 12" and 14" of wire. L1 is the electromagnet coil assembly from a Potter & Brumfield KUP11D15-6VDC relay. Pull the relay casing off and then remove the coil assembly by snapping its bracket from the plastic bottom. Be careful not to damage the coil windings or the fragile leads connecting the coil to the pins. The KUP11D15 is available from many online suppliers and quite likely through your local electronics store. It was commonly used in HVAC so if you are having trouble locating it through an electronics supplier, try a heating and cooling supplier. The relay is in a socket type case with a clear plastic cover. Substitutions are also available from several manufacturers and most relays having similar physical dimensions will also work as long as the coil voltage is the same. If you can't find the P&B relay or you wish to experiment you can of course wind your own coil. Use very thin magnet wire (34 or 35 gauge) and wind about 100 feet onto a 1/4" bolt which has been cut to a lenth of 1.5". By chucking the bolt into an electric drill you can make winding easy but be very careful to control the wire speed as it will turn into a razor blade if moving quickly. The circuit runs on 12V supplied from a 12VDC 500MA "wall wart" power adapter. This keeps the size of the base small and desk-friendly.

Enclosure and Base Aessembly

With the circuit complete, the next task is to assemble the physical structure. It is divided into two parts; the enclosure (which houses the magnet) and the base (which houses the circuit). The enclosure is built out of a 1" wide section of 4" OD 1/8" wall aluminum square tubing. You can find this tubing at the local metal supplier but you may be forced to buy a 10, 12 or 20 foot length. Most communities have a retail metal shop that will sell in smaller quantities. These same shops will often also cut to the dimensions you need for free or a small fee. If you don't have a retail metal shop handy then check out the big box home improvement stores, or a local farm supplier. Drill a hole of an appropriate diameter (this depends on your coil) in the middle of the top of the tubing. Now mount the coil, running the wires down the back of the tubing. Then, drill a hole on each side 1" down from the top. Size the hole according to the LED holder you are using as this size can vary. Be sure to keep the holes as perfectly aligned as possible. If you are going to experiment with a different electromagnet or objects of various sizes, it will be helpful to make two slots instead of holes so that the LED and photo transistor can be moved up and down. Lighter objects can float farther from the coil which requires the optical components to be moved down to the same level. Mount the LED and photo transistor in their respective holders and secure them to the tubing using the nut or snap ring supplied with the holder. Drill the front of your base to accept S1, R9 and D3 and mount the components. The exact project case you choose for your base will depend on your individual tastes and how you wish to decorate the bracket. Wherever you position these components, make sure they will not interfere with the top of the base or your ability to mount the circuit board. Mount a jack to match your DC power adapter at the back of the base.

Final Assembly Mount the enclosure assembly to the top of your base using two small bolts and appropriate nuts. Whether you chose to center it or mount if off to one side will depend on how you intend to decorate it. Left raw, the enclosure is best positioned in the center as the exposed machinery will create a more precise look. If decoration is used, turning the levitator into a pencil holder for example, the enclosure is best mounted to one side so the pencil cup can be placed beside it. Using a bit of creativity, covers for the exposed tubing and mechanical components can be made using many common materials. Cardboard, Plexiglas, Lexan, wood, glass and stone are some possibilities. Chose your material based on the types of objects you are most likely to float. Testing And Operation The Electromagnetic Levitator is best operated in a location away from strong light sources that may interfere with the optical components. Enclosing them in some kind of decoration will go a long way to both improving the aesthetics and minimizing interference. Make sure that S1 is turned off, then plug in the power adapter and turn R9 fully counterclockwise. D3 should be of at this point. Slowly turn R9 and observe D3. At some point, D3 should turn on. If you keep turning R9, it will turn off again. Adjust R9 just to the point where the LED is off, which should be about half way. You need an object to levitate so find a small and light steel object. Something like a key chain trinket, small hallow steel globe or beer bottle cap is ideal. The size of the object will depend on how close you are willing to keep it to the coil (by adjusting the position of D1 and Q1) and the coil you use. The specified relay coil is best suited for very light objects. Slowly lift your object towards the coil while making sure not to block the IR beam with your fingers. If R9 is adjusted properly the object will be lifted from your hand as you bring it near the coil, and suspended in mid air. If it oscillates up and down, back off on R9 slowly. Non-metallic and heavier objects can be levitated by attaching a small magnet. Remember that the polarity of the magnet must be opposite of the coil as to be attracted and not repelled so if your object is shot away from the coil, reverse the magnet.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- TPB 10en101 PDFDocumento5 páginasTPB 10en101 PDFJoseph BoshehAinda não há avaliações

- TM221CE24RDocumento19 páginasTM221CE24RRefaldyAinda não há avaliações

- F60fd한글설명서Documento135 páginasF60fd한글설명서Danbi YooAinda não há avaliações

- Little Fuse Powersafe Littelfuse Fuse Holder LPSM LPSCDocumento1 páginaLittle Fuse Powersafe Littelfuse Fuse Holder LPSM LPSCnickelchowAinda não há avaliações

- Design and Modeling of Photovoltaic Water Pumping System: Dr. C.K. Panigrahi, Pradosh Ranjan Parida, M. Das, J.PatiDocumento4 páginasDesign and Modeling of Photovoltaic Water Pumping System: Dr. C.K. Panigrahi, Pradosh Ranjan Parida, M. Das, J.PatiTarek BouallegAinda não há avaliações

- Rudder Angle Instruction ManualDocumento37 páginasRudder Angle Instruction ManualtosveAinda não há avaliações

- WWW Coilws ComDocumento2 páginasWWW Coilws ComClerk LoloAinda não há avaliações

- Cqc1103u Auto RadioDocumento30 páginasCqc1103u Auto RadioMilutinAinda não há avaliações

- Compact DX Training Manual PDFDocumento239 páginasCompact DX Training Manual PDFChrisAinda não há avaliações

- Onda Service Manual SM116x1_G.V02 Table of Contents and Component ReplacementDocumento69 páginasOnda Service Manual SM116x1_G.V02 Table of Contents and Component ReplacementSoporte BiomedicoAinda não há avaliações

- Three-Phase Motor - TroubleshootingDocumento3 páginasThree-Phase Motor - TroubleshootingEbi Eldho50% (2)

- Control Systems Viva VoiceDocumento10 páginasControl Systems Viva VoiceSunil MotepalliAinda não há avaliações

- Half & Full Wave Rectifier Circuits, Zener Diode Voltage Regulator ExperimentDocumento22 páginasHalf & Full Wave Rectifier Circuits, Zener Diode Voltage Regulator ExperimentHardik RangwaniAinda não há avaliações

- Critical Components Table Rev35Documento5 páginasCritical Components Table Rev35ashishtrueAinda não há avaliações

- Electrical Design AnalysisDocumento2 páginasElectrical Design AnalysisMaritel SumatraAinda não há avaliações

- Electrode IDentificationDocumento3 páginasElectrode IDentificationAmit AgarwalAinda não há avaliações

- Lab Module Electrical Resistivity Imaging (Eri)Documento13 páginasLab Module Electrical Resistivity Imaging (Eri)Liyana LisaAinda não há avaliações

- Usb ShieldDocumento4 páginasUsb ShieldnecrodruciferAinda não há avaliações

- 30HXCHXY - ph3 - Pro-Dialogue - IOMDocumento36 páginas30HXCHXY - ph3 - Pro-Dialogue - IOMallah ditta shafiAinda não há avaliações

- DC Bus Diagram for Dual Speed Starter InverterDocumento63 páginasDC Bus Diagram for Dual Speed Starter InverterВладимир МалининAinda não há avaliações

- Operating Instructions: Reactive Power Control Relay EMR 1100 /-SDocumento42 páginasOperating Instructions: Reactive Power Control Relay EMR 1100 /-SJafet Chambi HurtadoAinda não há avaliações

- 14 XS DLX 15 - 11039691Documento22 páginas14 XS DLX 15 - 11039691Ramdek Ramdek100% (1)

- Pplication OTE: Low Voltage DC Supply Dimmable Ballast For 1 X 36W T8 LampDocumento13 páginasPplication OTE: Low Voltage DC Supply Dimmable Ballast For 1 X 36W T8 LampBravo MacAinda não há avaliações

- Delta TDocumento3 páginasDelta Tvinny7531Ainda não há avaliações

- Testing of TransformersDocumento5 páginasTesting of Transformersjinojk100% (1)

- Features:: Powered LoudspeakerDocumento6 páginasFeatures:: Powered LoudspeakerYerko LucoAinda não há avaliações

- Lessonsections 2Documento12 páginasLessonsections 2Ghazi DallyAinda não há avaliações

- Technical data - VV fuse-links specificationsDocumento9 páginasTechnical data - VV fuse-links specificationsYben ZutaAinda não há avaliações

- USB Charging Port Power Switch and Controller: Features DescriptionDocumento42 páginasUSB Charging Port Power Switch and Controller: Features DescriptionJagopati Jr.Ainda não há avaliações

- NikolsddDocumento1 páginaNikolsddMaissyAinda não há avaliações