Escolar Documentos

Profissional Documentos

Cultura Documentos

Detailed Calculation For Box Girder Design

Enviado por

leodegarioporralTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Detailed Calculation For Box Girder Design

Enviado por

leodegarioporralDireitos autorais:

Formatos disponíveis

REFERENCES

1. BS 5400 Part 2: 1978, Steel, Concrete and Composite Bridges- Specification for loads.

2. BS 5400 Part 4: 1990 Steel, Concrete and Composite Bridges- Code of Practice for

Design of Concrete Bridges.

3. Jayasinghe M.T.R., Lecture Notes given forM. Eng. Degree Course in Structural

Engineering Design.

4. Clark L.A., 1981 ,Concrete Bridge design to BS 5400, Construction Press London and

New York.

5. Hurst M.K., Nanyang, Pre-Stresses Concrete Design, Technological Institute Singapore

6. User Manual, SAP 2000 V14 Integrated Solution for Structural Analysis and Design.

7. :; \' ',(.

8.

9.

1 !5orgicdc

!

II U.

10. Gee, A.F., "Bridge winners and losers", The Structural Engineer, Vol: 65 A, No 4, pp

141-145, 1987.

11. Burgoyne, C.J ., Jayasinghe, M. T.R., Rationalization of section design philosophy for

prismatic pre-stressed concrete beams.

12. Swann, R.A ( 1972), "A future survey of concrete box spine-beam bridges", Technical

Report 469, Cement and Concrete Association, London, 1972.

13. Podonly, W. & Muller, J.M., Construction and design of pre-stressed concrete segmental

bridges, John Wiley & Sons, New York, 1982.

36

APPENDIXES

APPENDIX 1- Manual calculation for box girder

APPENDIX 2- Computer output of the box girder

APPENDIX 3- Computer output of the doubleT beam

APPENDIX 4- Comparison of the forces bending moment and stresses

37

CONTENTS OF MANUAL CALCULATION

A. Notations and their descriptions

B. Load calculations

C. Design of pre-stressed concrete Box Girder

1. Magnal Diagram

2. Calculation of number of ducts

3. Profile of individual ducts

4. Analysis of the Box Girder

5. Losses

6. Check for ultimate limit state

7. Design of End Blok and transverse reinforcement.

~ f r nee

Description

s 540

199(

I able

::) 540

199(

324

; 5401.)

199l

3.2.4

3.2 <

)ble,

5400

1990

3.2.2

1ble 2

Data

Density of Concrete,

Pc

= 24 kN/m

3

Density of Screed Concrete,

P.vc = 24

kN/m

3

Density of Asphalt Concrete,

Pac = 23.6 kN/m

3

Pre stress Loss ratio,

R = 0.8

Span of the bridge, I

30

m

Effective span of the bridge,

/e = 29 m

Carriageway width,

= 7.4 m

Number of lanes

= 2

0-4 Width of the foot walk

= 1500 mm

Characteristic Concrete cube strength of the beam, feu

= 50 N/mm

2

20

Concrete strength at (initial) transfer( at the age of 7 < fc; s = 36

N/mm

2

Characteristic strenght of high yield bars fyv

= 460 N/mm

2

Modulus of Elasticity of grade 50 concrete

Ec = 34000

N/mm

2

Characteristic strenght of mild steel bars

fy

= 250 N/mm

2

1-4

Permissible stresses for class 2 member

a (2' Allowable tensile stress at service,

larrin = 0.36xvfcu N/mm

3

Characteristic Concrete cube strength of the beam, feu

= 50 N/mm2

= o.36xv5o

farrin = 2.55

N/mm2

4

Allowable tensile stress at transfer,

farrint = 1 N/mm2

(1)

Allowable compressive stress at service,

fatmX = Design load in Bending

(a)

= 0.4xfcu

= 0.4x50 N/mm2

farmx = 20

N/mm2

4

Allowable compressive stress at transfer,

!, _ Triangular or near Triangular

DIIBX t - rfic::trin11tinn nf c:tr<=>c::c::

= 0.5xfci

buts 0.4xfcu

:b)

= 0.5x36

farmxt = 18 N/mm2

s 0.4x50

s 20

Output

farrin

2.55

N/mm2

fanint

1

N/mm2

fatmX

20

N/mm2

farm.xt

18

N/mm2

Reference I

Description

I

Output

Details of Precast section

Thckness of bottom flange

tb = 200 mm

Thckness of top flange

II = 250 mm

Thckness of one web

I,.

= 350 mm

Width of the cantilever overhang

we

= 1000 mm

Width of bottom flange

wb

= 3200 mm

Width of top flange

WI

= 4400 mm

Overall depth of beam (Pre cast section)

hp

= 1667 mm

Number of web

N = 2

Cross section of the brigde

1.500M --1 __r_!l.225M

E5 f I r=}-

. M I

_L

o.2sor0 o.200M

0.350M 2.500M ------j

0.200M 1

0.200..;-r- 3.200M

Figure 1

Details of the Precast Section after grouting

I

4.400M

I

r

-J

Q.200M

::Jf290M

r

-r[

0.350r1=

0.3 50 M +----il------

2.5001'1

Q.200M

0.200!'1 1

1-

I

Q.200M J

3.2001'1

Figure 2

.. ___ .___t_:_ ________________ __:_ __________ ..J_ __ ____.

---- -

Reference 1

Description

I

Output

Cross sectional Area,

AP

= 2.740E+06 mm

2

Total Depth, hp

= 1.667E+03

mm

Total width of the top flange

wt

= 4.400E+03 mm

Total width of the bottom flange

wb = 3.200E+03 mm

Height to the top fiber from the neutral axis.

Ypt = 7.150E+02

mm

Height to the bottom fiber from the neutral axis,

Ypb = 9.520E+02 mm

Second Moment of Inertia along x axis,

Jxp

= 1.016E+12 mm

4

Sectional Modulus of the top fiber,

zpt = 1.421E+09 mm

3

Sectional Modulus of the bottom fiber

zpb

= 1.067E+09

mm

3

Weight of the beam per unit length, w - A xp xi

I

wpgl

pgl - c c

wpgl = 65.76

kN/m

65.76

kN/m

Details of the Composite Sections

1.Edge beam

I

5.200M

. O.OF-

1

-

---------.......

t

I

_(r 0.200M

Q.J50M

2.500M

__r__9.200M

0.200M

1-

I

I

. :)UM L_Q.132M

c--- f250M

f.- 1.000M

0.200;-r-

3.200M

I

l

Figure 3

Cross sectional Area,

Ac = 3.45E+06 mm

2

Total Depth,

hcl = 1764 mm

Total width of the top flange,

welt

= 5200 mm

Total width of the bottom flange wclb

= 3200 mm

Height to the top fiber from the neutral axis,

Yc1t

= 665 mm

Height to the bottom fiber from the neutral axis,

Yclb

= 1099 mm

Moment of Inertia,

/xcl

= 1.31E+12 mm

4

Seactional Modulus of the top fiber,

zeit = 1.97E+09 mm

3

Sectional Modulus of the bottom fiber,

zclb = 1.19E+09 mm

3

I

Weigl

Weight of the beam per unit length,

welgl =A P x p c x 1 kN/m 82.80

Weigl = 82.80 kN/m I kN/m

Refer, :mce

) 5400

1990

I 6.2

-4

Description

Load CaJcuJations

Dead Loads

Dead Loads due to grecast beam

Weight of the beam per unit length, wpgl = 65.76 kN/m

Dead Loads due to comgosite beams

1.Edge beam

Weight of the beam per unit length, Weigl = 82.80 kN/m

Cross sectional Area of the Screed concrete,

Asci

= 7.15E+05 mm

2

Weight of the screed concrete per unit length of bea w sci = AscxPscx1

wscl = 17.16 kN/m

Super imposed dead loads

Super imposed dead loads on edge beam

Cross sectional Area of the Asphalt concrete, Aocl = 1.85E+05 mm

2

Weight of the Asphalt concrete, woe!

= Aocl X Poe X 1

woe! = 4.37 kN/m

Weight of the hand railings per unit length of beam, whr = 0.585 kN/m

Cross sectonal area of the footwalk, Afw = 3.38E+05 mm

2

Weight of the footwalk, wfw = AfwxPscx1

= 8.10 kN/m

Weight of the kerb per unit length of beam,

W.v

= 0.85 kN/m

HA Loading

HA Uniformly Distributed Load (UDL)

Carriage way width = 7.4 m

Number of notional lanes

= 2

For loaded length up to 30 m HA UDL = 30 kN/mllane

HA UDL per unit width of the beam = 30x2x29

7.4x29

= 8.11 kN/m

2

Output

wpgl

65.76

kN/m

Weigl

82.80

kN/m

wscl

17.16

kN/m

woe)

4.37

kN/m

whr

0.585

kN/m

wfw

8.10

kN/m

Akr

0.85

kN/m

--

ence

's 54

19'

d 6

S54

199

7 1

s 54

199

d6.

00-4

'()

{ 2

)0-4

D

1 (a)

10-4

I

.;

1

Description

Output

Effective width for edge beam = 3700 mm

HA UDL on the edge beam = 8.11x3.7 HAUDL

= 30.00 kN/m 30.00

kN/m

HA Knife Edge Load (KEL)

KEL Load for per notional lane = 120 kN/Iane

KEL for a meter width of road = 120x2

7.4

= 32.43 kN/m

Effective width for edge beam = 3700 mm KEL

HA KEL on the edge beam = 120.00 kN 120.00

kN

Pedestrian Load

Pedestrian load per beam

= 5

kN/m

2

Pedestrian load per beam per unit length of bear = 5x1.5

I

= 7.5 kN/m 7.5

kN/m

HB Loading

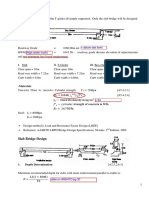

Case I 300 300 300 300

0

:1.8:

tR1

... 1.8 ...

6.0

i R2

Figure 4

Where, 0 - Bridge Centre

300

a

...

b

v

...

-

l

... _

Figure 5

From the theory ;

q1

=

Pab I (a+b)

=

30

2218

=

2217.6 kNm

kNm

--- ------- - -

~ e f e r e n e

From Figure 5;

From Figure 6;

Description

qo1 = (q1 * Ll2)1b

=

1980 kNm

300

Q02=CI29

L

Figure 6

q2 = qo2 =

=

(P * L/2 * L/2) I L

2250 kNm

......

~ a ~

? ~ b

" > :

From the theory;

From Figure 7 ;

L

Figure 7

q3 =

=

=

qo3 =

=

Pab I (a+b)

300*21*(30-21!

30

1890 kNm

(q3 * U2)1b

1350 kNm

300

a ~ b .,

~

L

.....

Figure 8

From the theory;

q4 = Pab I (a+b)

= 300*22.8*(30-22.8)

30

= 1641.6 kNm

Output

1980

kNm

2250

kNm

1890

kNm

1350

kNm

1642

kNm

----- -

teference

From Figure 8;

Moment @ mid span 0 ;

Similarlly;

Case II

1R1

300

Moment @ mid span 0 ;

Case Ill

~

.1.8

Description

qo4 = (q4 * U2)/b

=

1080 kNm

mq1

=

qo1 + qo2 + qo3 + qo4

=

6660 kNm

300 300 300

i 0

u

.. 3.0 ~ ~ 3.0

~ 1.8 ...

Figure 9

mq2 = qo'1 + qo'2 + qo'3 + qo'4

qo4

=

6660 kNm

300 300 300 300

LAo

u

i R2

1R1

... 1 8 ~ 1 5 ~ ~ 4.5 .. 1.8 ... j R2

Moment @ mid span 0 ;

Similarfly;

Moment @ mid span A ;

Section Check

1.Edge beam

Figure 10

mq3 = qo"1 + qo"2 -t qo"3 ; qo"4

= 6660 kNm

mq4 = qo"11 +qo"22 qo"33 . +qo"44

= 6750

kNm

Moment at mid span due to self weight of the beam, M gi = Wc

1

g

1

x 1

2

8

Moment at mid span due to screed concrete,

M gl = 65. 76x29

2

8

= 6913.02 kNm

Mg2 = wscl xP

8

Output

1080

kNm

6660

kNm

6660

kNm

6660

kNm

6750

kNm

Mg2

6913.02

kNm

_____ ....._ ___________________________ .....J...-----1

-

Reference

Description Output

Mcz = 17.16x29

2

8

Mcz

= 1803.95 kNm 1803.95

kNm

Moment at mid span due to Asphalt concrete

Macl =

Wacl X /2

8

= 4.37x29

2

8

Macl

= 458.98 kNm 458.98

kNm

Moment at mid span due to hand railings

M = whr x/2

hr

8

= 0.585x29

2

8

Mhr

= 61.50 kNm 61.50

kNm

Moment at mid span due to footwalk

Mfw = wfw x/2

8

= 8.10x29

2

8

Mfw

= 851.51 kNm 851.51

kNm

Moment at mid span due to kerbs

~ c r = wkr x/2

8

= 0.85x29

2

8

Mkr

= 89.36 kNm 89.36

kNm

Moments due to HA

MHAUDLCI

Moment at mid span due to HA UDL, M HAUDLCI = 3153.75

kNm 3153.75

kNm

Moment at mid span due to HA KEL, M HAKELCI = 870.00 kNm

MHAKELCI

870.00

Moment at mid span due to pedestrian load, M PL = 788.44 kNm

kNm

MPL

788.44

kNm

-

.

-----

Reference Description

Output

Load Amount (KN/m) Moment at mid span

(KNm)

"01/) Unit weight of pre cast section, wpg

1

65.76 6913.02

ro-o

G> ro

Unit weight of screed concrete, W

5

c 17.16 1803.95

o.3

"0

Unit weight of Asphalt concrete, Wac

Q)

4.37 458.98

If)

0 If)

a.."'

E ro

Unit weight of handrails, Whr 0.585 61.50

- 0

L.

...J

Unit weight of kerbs, Wkr 0.85 89.36

Q)"'

a..ro -

:::s Q)

Unit weight of foot walk, Wrw 8.10 851.51 U)Q

Uniformly distributed pedestrian live load 7.50 788.44

HA UDL on the beam 30.00 3153.75

If)

HA KEL on the beam

u

120.00 870.00

ro

0

...J

HB Loading - Case I 6660.00

Q)

>

::::;

HB Loading- Case II 6660.00

HB Loading- Case Ill(@ mid span) 6660.00

HB Loading -Case Ill(@ point "A") 6750.00

Table 1

Table 1 Total moment due to HA loading

=

4023.75 kNm

'

Maximum moment due to HB loading

=

6750.00 kNm

If compare the moments due to HA and HB, moment due to HB is the higher value than the

moment due to HA loading. But for the design purpose should use moment due to HA loading.

By using Table 1

M gl = 6913.02 kNm Mgl

6913.02

Mg2 = 1803.95 kNm kNm

( M.., + M" + M

1

+ M,,J

Mg2

Mq

= x120 1803.95

MHA UDL + MHAKEL

kNm

+MPL xl.OO

Mq

= 7370.55 kNm 7370.55

kNm

-

L_ _____

.

.

-- ---------- -

Description

Design of prestressed concrete beam

Design criterian:Stress in concrete should not exceed the allowable values during the life time of

structure.

Sign convention:

Axial compressive force positive

Distances measured upwards from the neutral axis positive

Compresive stress positive

Transfer condition stresses

Top fiber (fur tensi on)

(

p) (-PxeJ (Mg

1

J

A + Z pi + z pi 2:: -fa mini

( :) -( J + ( J / .. ,., .......... .............. (!)

Bottom fiber (fur compressio n)

(

p) (PxeJ (-Mg

1

J

A + Z ph + Z ph < fa maxi

(:)+ ( J-( J < fomnr .............. (2)

Service condition stresses

Top fiber (for compressio n)

( R:P)+( -R;:xe ]+( M,,;#M,

2

J+( ::) < fomn

( R: p) -( R X:,x e J +( M ';#M,, ]+( ::) < / .......... .... (J)

Bottom fiber (fur temi on)

(

RxP)+(RxPxeJ+(-(Mg

1

+Mg

2

)J+(-MqJ>- .

A Z z z famm

ph ph ph

( R p)+( J-( M,,

2

+"M,, J-( J > _ / , .................................. ( 4)

.

Output

< ____

teference

Description

Output

M gl + M g2 - R X M gl

Mq

= 1.87E+08

R X famin t + famax - z

cit

= 1.87E+08

< zp,

1.42E+09

Section is ok at the top fiber

M gl + M g2 - R X M gl

Mq

= 2.96E+08

R X famaxt + famin- z

clh

= 2.96E+08

<Zpb

1.07E+09

Section is ok at the bottom fiber

---- -

!terence Description

Output

Magnel digram at the mid span of the bridge

(1) =>

e ( ]+ zpl X:anint +;I .............. (S)

(2) =>

e -( J + z ph x;armx I+ M;l .................... .... (6)

(3) =>

Mq x(____e_)

J- Rx:ct .................................. (?)

[ z l

(4)=>

M X ( ______e_)

J- qRx!ch .................................. (8)

[ z l

1.Edge Beam

farrin

= 2.55 N/mm

2

fanint

= 1 N/mm

2

hrmx

=

20 N/mm

2

hrraxt

=

18 N/mm

2

R

=

0.80

AP

= 2.74E+06 mm

2

zpl

= 1.42E+09 mm

3

zph

= 1.07E+09 mm

3

zeit

= 1.97E+09 mm

3

zclb

= 1.19E+09 mm

3

Mgi

=

6913.02 kNm

Mg2

=

1803.95 kNm

'

Mq

=

7370.55 kNm

e/(mm)

-665 0 1099 2500

1/P1

-1.12E-07 -4.92E-08 5.51E-08 1.88E-07

1/P2

-1.05E-08 1.49E-08 5.70E-08 1.11E-07

11P3

6.58E-08 2.88E-08 -3.23E-08 -1.10E-07

11P4

-1.75E-08 2.47E-08 9.45E-08 1.83E-07

.

---

I

-665

em ax

1/P

-1.5E-07

lemin

1099

1/P

-1.5E-07

3.E-07 1

2.E-071

2.E-07

l.E-07

-1000

-2.E-07

-2.E-07

-665

1.6E-07

1099

1.6E-07

z

:::::::

a.

-

....

Description

Chosen1/P

4.00E-08 4E-08

e

0 1000

-+-1/Pl

--a--1/P2

__._1/P3

""""*'-1/P4

Eccentricity,e/(m"!),

------,-- -r--- --- , E max

I

2000 2500 3000 .

!!!- Emrn

- -6 - Chosenl/P

Chosen e

Prestressing force for the section,P = 2s,ooo,ooo N

Eccentricity,e = 500 mm

Feasible Tendon Profile Zone

Bendingmomentat a point x from one support in a simply supportedbeamof due to a uniformly

distributerlload w, M ..u

wxlxx wxx

2

IM =-----

xudl

2 2

! Bendingmomentat a point x from one supportin a simply supportedbeamof length I due to a point load load P, Mxpr

Pxx(l-x)

Mrpl= [

j1.Edge Beam

l,

= 29 m

Weigl

= 65.76 kN/m

wscl

= 17.16 kN/m

wac!

= 4.37 kN/m

whr

= 0.585 kN/m

wfo'

= 8.10 kN/m

WAr = 0.85 kN/m

HA UDL on the edge beam = 30.00 kN/m

HA KEL on the edge beam = 120.00 kN

udl due to pedestrian load = 7.5 kN/m

Output

p

25000000

N

---

Ference Description Output

Length along the Beam /(m),X 0 3.625 7.25 10.875 14.5

Moment due to self wt of the beam,Mg1 /(Nmm) 0 3.0E+09 5.2E+09 6.5E+09 6.9E+09

Moment due to Screed Concrete,Mg2/(Nmm) 0 7.9E+08 1.4E+09 1.7E+09 1.8E+09

Total Moment due to dead load/(Nmm) 0 3.8E+09 6.5E+09 8.2E+09 8.7E+09

Moment due to Asphalt Concrete, /(Nmm) 0 2.0E+08 3.4E+08 4.3E+08 4.6E+08

Moment due to hand raii/(Nmm) 0 2.7E+07 4.6E+07 5.8E+07 6.1E+07

Moment due to footwalki(Nmm) 0 3.7E+08 6.4E+08 8.0E+08 8.5E+08

Moment due to pedestrian load/I(Nmm) 0 3.4E+08 5.9E+08 7.4E+08 7.9E+08

Moment due to kerb/(Nmm) 0 3.9E+07 6.7E+07. 8.4E+07 8.9E+07

Total Moment due to super imposed load/(Nmm) 0 9.5E+08 1.6E+09 2.0E+09 2.2E+09

Moment due to live loads,HAUDL/(Nmm) 0 1.4E+09 2.4E+09 3.0E+09 3.2E+09

Moment due to live loads,HA KEL/(Nmm) 0 3.8E+08 6.5E+08 8.2E+08 8.7E+08

Total Moment due to live loads 0 1.8E+09 3.0E+09 3.8E+09 4.0E+09

Eccentricity,e1/(mm) 575 696 783 835 852

Eccentricity,e2/(mm) 379 500 586 638 655

Eccentricity,e3/(mm) -902 -613 -406 -281 -240

Eccentricity,e4/(mm) -525 -212 12 147 192

Emin/(mm) -902 -613 -406 -281 -240

Emax/(mm) 575 696 783 835 852

i

----

l

Cable Zone

1 0 0 0 ~

--+- Emin/(mm)

-Emax/(mm)

E

-500

~

E

:::::::::

2 4 6 8 lU 16

cu

ChianagiaT'ong the beam/(m)

~ 0

;::;

.:

....

c

cu

500 L

u

u

LLI

-

- -

-

-

1000-

. -"

i

---

~ e f e r e n e

:s 5896

1980

-able 6

.cl. 20

s 5400

199l'

16.i '

'--

I

i

Calculation of number of ducts

1.Edge beam

Prestressing force,P

Type of strand

Nominal tensile strength

Nominal steel area

Description

Specified characteristic breaking load

= 25,000,000 N

= BS 5896-3 super strand-1770-15. 7 -relax 1

= 1770

= 150

= 265,500

N/mm

2

mm

2

N

Output

Maximum prestress force allowed for tendons = 70%xCharacteristic strength

Number of tendons needed

External diametre of duct

Internal diametre of duct

Number of strands per duct

Number of ducts

:n

he

h

BJ I

le

X

= 185,850 N

= Prestressing force

Maximum prestress force allowed for tendons

= 25.000.000

185850

= 135 Nos.

= 60

=50

=7

= 135

7

= 20

t y

0

ho

/A

mm

mm

Nos.

Nos.

Number of,

ducts

20

Nos.

ference

>40(

90

! 36

e 371

Description

Output

Assumed equation for parabolic portion

Y=aX

2

+hX+c

I

At A; X = O,Y = ho

X

= 0 dy = 0

'dx

At 8;

X

= l dy = _!__

'dx n

So;

b = 0

c = ho

i

dy = 2ax

dx

At 8;

dy = _!__

dx n

1

- = 2ax

n

1

a =

2nl

Assumed equation for straight portion;

Y=mX+c

At 8;

dy 1

X=l-=m=-

'dx n

X= lc,Y =he

Straight

y = (X - le) + he

n

Curve

xz

Y=--+ho

2nl

At 8;

X= l,and,Y = h

n=

(2le -!)

2(he-ho)

. . (he- ho) 2

Equation of Parabolic curve Y = ( ) X + ho

l 2/e -I

Equation of Straight line

y = 2(he-hoXX-le) +he

2/e-1

Minimum cover to the ducts at the end of parabolic section =

50 mm

Minimum spacing between the centrelines of ducts at the = 140 mm

end of the parabolic section

------.-------------------------------------,.-----,

1ference Description

Profiles of individual ducts

:; 5400 I Cover to ducts

tart 4 I Minimum cover to ducts

3.8.2 3

Clear distance between ducts

Maximum size of coarse aggregate, hagg

hagg +5mm

. 5400 I vertical internal dimension of the duct

art 4 I Horizontal internal dimension of the duct

i.8 3 3 I Clear distance between ducts

Height to centorid of a duct from bottom fibre at level n

Cross sectional area of a duct at level n

=50

= 19

= 24

=50

=50

=50

= Yn

= AJn

Height to the bottom fiber from the neutral axis (Composite = Y pb -

Output

Cover

mm 50

mm

mm

mm

Clear

mm spacing

mm 50

mm mm

i :

:.. t.'

Centroid of all ducts from the bottom fibre,

y

= (Adl x Yt + Ad2 x Y2 + + Adn x Y I)

Eccentricity of all ducts in the section considered,e

At mid span

Chainage

Eccentricity obtained from the Magnel Diagram

External diametre of the duct

Number of ducts

Strands/duct

Height to the bottom fiber from the neutral axis,

--t

(Adl + Ad2 + + Adn)

= y ph - y

=0

= 500

=50

= 20

=7

Ypb = 952

m

mm

mm

= 25,000,000 N

tference Description

Output

Duct

Cross sectional

Duds No. of duds No of Strands

area of a

position

ducU(mm

2

)

y1 100 12 84 1963

y2 300 2 14 1963

y3 500 2 14 1963

-

y4 700 2 14 1963

y5 900 2 14 1963

Total 20

Centrad of all ducts from bottom fiber = 300 mm

Resultant Eccentricity of all tendons,e = 652 mm

Profile5

Profile 3 -------

Profile 2

r--!---

-

lo

lp Is

Zone I

Zone2 Zone3

Length of

Eccentricity at

Length of

Eccentricity at end

Length of Zone Lenth up to mid Number of

start of zone 1 of zone 2 (mid Number of ducts

Zone 1/(m)

/(mm)

Zone 2/(m)

span) /(mm)

3/(m) span /(m) strands

Profile 1 1 852 8 852 5.5 14.5 12 84

Profile 2 1 542 8 652 5.5 14.5 2 14

Profile 3 1 232 8 452 5.5 14.5 2 14

Profile 4 1 -78 8 252 5.5 14.5 2 14

Profile 5 1 -388 8 52 5.5 14.5 2 14

Total 20 140

tferen ce Description

Output

Chainage

Eccentricity/(mm)

I (m)

Profile 1 Profile 2 Profile 3 Profile 4 Profile 5 Resultant

0 852 542 232 -78 -388 542

1 852 564 276 -12 -300 564

2 852 585 317 50 -218 585

3 852 603 353 104 -146 603

4 852 618 383 149 -86 618

5 852 630 408 186 -36 630

6 852 640 427 215 3 640

7 852 647 441 236 30 647

8 852 651 449 248 47 651

9 852 652 452 252 52 652

!

10 852 652 452 252 52 652

I

11 852 652 452 252 52 652

I

12 852 652 452 252 52 652

13 852 652 452 252 52 652

14 852 652 452 252 52 652

14.5 852 652 452 252 52 652

100 410 720 1030 1340

I

'

-1000

Eccentricity of cables along the beam Emin

..

- - Emax

-800 ......

..

--600

.. ..

---ts- Profile 1

...

E

.. ..

... ...

-)'(

Profile 2

E-400

.....

-

6

"1 "14 -

--------Profile 3

Cl)-200

0

--1-Profile 4

(.)

-ProfileS

:s 200

c::

G) 400

-

.....

"'

....

-

.....

(.)

JJ 600)

1- ; - ': "'' . +-

800 - -.A. - - _Ill -

- - - -

- - - - - - - -

1000

i - ------

terence

Description

Output

--

Analysis of the beam

-------- -- ----- --- ------ ---------- ------------- ---------- 1----------

Post tensioning sequence

feu

=50 N/mm

2

Stage 1 Stage 2 Stage 3 Stage4 Stage 5

Age 14 days 1 month

5400-4 Strength 36 50

990

Jle 20

When cables are prestressed,all cables are not stresses at once.Differents cable sets are chosen for

stressing procedure.A post tensioning seaquence is introduced and cables are stressed taking each set

of cables at once.At each stage after tensioning stresses are checked at top and bottom fiber.

Number of cables in each set of cables

Total no of

Cable

cables

profile

Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6

Profile 1

8 4 12

Profile 2

2 2

Profile 3

2 2

Profile 4

2 2

Profile 5

2 2

Total 20

Cables are stressed according to the the sequence chosen in the above table

The sectional properties at diifferent sections of the beam changes according to the tendon profiles at

each section of the beam. Therefore the section properties has to be found at each section of the beam

before grouting of the beam.when tendons are stressed at stage one( cable set 1) at transfer the

section will have all the ducts without grout. But when the stressing is done at stage two in cable set

two,the the ducts which consists of the cables that are stresses at stage one wil be grouted,thus

section properties will be changed. Therefore section properties at each stage of stressing has to be

calculated as well.

Calculation of sectional l!rol!erties

L

J

0

- Cl

0

-

C2

Y5

0

Y4

Y3

0 G--

Y2

!fl

-------------

tference I Description I Output

Cross sectional Area of the pre cast section AP' = A - A - A - - A

. d! d2 dn

before groutmg P

Height to the centriod of precast section after grouting y

p

Height to the centriod of precast section before grouting

Y' -

Centroidof the precast section before grouting cl

Centroidof the precast section after grouting

c2

Y' = (Ap X Yp- Adl X Y1- Ad2 X Y2.Adn X Yn)

,

- AP

Y' = (A p X y p - L A di X y i)

Ap

LAd; xy; = Adl xyl +Ad2 xy2 + ..... +An xyn

I xp - Moment of inertia of precat section after grouting

,

fxp - Moment of inertia of precat section before grouting

From parallel axis theorem

Ixp'= Ixp + (Y'- Y)2 x Ap -{(Idl + Adl x (i''- ~ 2 + ~ 2 + Ad2 x (i''- y2)2}

+

1

dn + Ad2 x (Y'- Yn)

Lfdi = Jdl +fd2 + ... +fdn

LAd; X (Y'- y;)2 = Adl X (Y'- YI}2 + A2 X (Y'- Y2)2 + .. + Adn X (Y'- Yn)2

, - -

fxp = fxp +(Y' -Y)

2

X Ap- Lfdi- 'LAd;

moment of inertia of a duct of diametre d I d

with respect to x axis

Area of a duct of diametre d Ad

= mf4

-

64

mf2

=

- ~

4

L - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ~ - - - - ~

eference Description

1.Edge beam

At mid span (Chainage 14.5 m)

Cross sectional

Ducts

Duct

I No.ofducts INoofStrands Externaldiametre, areaofa ITotaiAreaofthel

Ad;XY;

position at one level,n of duct/(mm)

2

ducts /(mm2)

ductl(mm)

Ad

y1 100 12 84 60

I

2827

I

33929

I

3,392,920

y2 300 2 14 60

I

2"827

I

5655

I

1,696,460

y3 500 2 14 60

I

2827

I

5655

I

2,827,433

y4 700 2 14 60

I

2827

I

5655

I

3,958,407

y5 900 2 14 60

I

2827

I

5655

I

5,089,380

Total I 20 I 140 I I 56549 I 16964600

IAd;XY;

I

Ixp

= I xp + ( y I - y) 2 X A p - L I di - L Adi X (Y I - y i) 2

yl = (A p X y p - I A di X y i)

I

Cross sectional Area of the pre cast section

after grouting

yp

AP

Adl + Ad2 + + Adn

Height to the centriod of precast section

before grouting

~

IAd;XY;

Y'

y ~ _ y

Second moment of area of a circle with diametre d around

= Ypb

= 952

= 2.74E+06

= 56549

AP

mm

mm

2

= A P - Ad! - Ad2 - - Adn

= 2.68E+06 mm2

= 16,964,600 mm

3

= 966 mm

= 14

mm

its centre =

7ld4

64

External diametre of a duct = 60

Second moment of area of a duct around its centre = 636,173 mm

4

Output

Y'

966

mm

----

eference

Description

Output

Duct No. of ducts

External

Id

nxld

(Y'- y;)z

Adi X (Y'- y;)

Ducts

position at one level,n

diametre of

ducU(mm) /(mm

4

)

y1 100 12 60 636,173

7634070 749505 25430111423

y2 300 2 60 636,173

1272345 443209 2506289580

y3 500 2 60 636,173

1272345 216913 1226616598

y4 700 2 60 636,173

1272345 70618 399332958

y5 900 2 60 636,173

1272345 4322 24438660

Total 20

12723450 29586789218

IIdi L(Adi x(Y'- Y;)2)

_LJdi

= 12,723,450

mm

4

L(Ad; x(Y'- Y;)2) = 3.0.E+10

mm

4

Jxp

= 1.0E+12

mm

4

,

= Ixp + (Y'- .YY X Ap- L Idi- L Adi X (Y'- Y;)2

Jxp

,,

9.87E+11

,

Jxp

= 9.87E+11

mm

4

mm

4

,

Ypb

Total depth of the precast section = 1667 mm

966

I

Y' mm Ypb

=

= 966

mm

Ypt

I

Ypt

1

= 701

mm

701

,

mm

, I

zp, = ~

Ypt

z p ~

= 1.41E+09 mm

3

1.41E+09

,

mm

3

' Jxp

zpb =--,

Ypb

zpb

I

= 1.02E+09 mm

3

1.02E+09

mm

3

tference Description Output

Similarly,

when stressing is done at stage 1

Mid Span

At qarter At edge of

span beam

14.5 7.25 0

Cross sectonal area of the precast section before

~

2.68E+06 2.68E+06 2.68E+06

grouting/(mm

2

)

,

9.87E+11 9.87E+11 9.96E+11

Second moment of area before grouting/(mm

4

)

Jxp

Heght to the top fiber from the neutral axis/(mm)

Ypt

I 701 701 704

Heght to the bottom fiber from the neutral axis/(mm)

966 966 963

Ypb

I

Sectional modulus at the top fiber of the section before

1.41E+09 1.41E+09 1.42E+09

grouting/(mm

3

)

-

zptl

Sectional modulus at the bottom fiber of the section before

1.02E+09 1.02E+09 1.03E+09

grouting/(mm

3

)

zpb

I

Moment due to self weight before grouting/(kNm)

Mgl

6770 5078 0

when stressing is done at stage 2

Mid Span

At qarter At edge of

span beam

14.5 7.25 0

Cross sectonal area of the precast section before

~

2.72E+06 2.72E+06 2.72E+06

grouting/(mm

2

)

Second moment of area before grouting/(mm

4

)

,

1.01E+12 1.01E+12 1.01E+12

]xp

Heght to the top fiber from the neutral axis/(mm)

711 711 712

Ypt

1

Heght to the bottom fiber from the neutral axis/(mm) y

1

956 956 955

pb

Sectional modulus at the top fiber of the section before

1.42E+09 1.42E+09 1.42E+09

grouting/(mm

3

)

zpll

Sectional modulus at the bottom fiber of the section before

1.05E+09 1.05E+09 1.05E+09

grouting/(mm

3

)

zpb

I

,

Moment due to self weight before grouting/(kNm) Mel 6870 5153 0

'

i

l

I

-------.-------------------------------------------------------------------------------.-------,

eference

Description

Prestressing force along a cable changes from point to pont because of friction present Therefore the

prestressing force along the cable is calculated as follows

Friction in the duct due to unintentional variation from the specified profile

: 5400-4

1990 I Prestressing force at distance x from the jack ~ = Poe -Kx Equation 31

67 3 3j where

Kx 0.2,e-Kx = 1-Kx

P. Pre stressing force in the tendon at the

0

- jacking end

K - constant depending on the type of duct

Friction in the duct due to curvature of the tendon

5400-4

990 I Prestressing force at distance x from the jack

3.7.3.4

Prestressing force alonQ the profile 1

I I

Start Zone

Chainage length

Zone 1 0 1

Zone2 1 8

~ n e 9 5.5

-px

px = Poe rP,

where

Equation 32

-px

J.LX ~ 0.2, e rps =I- J.LX

rps rps

(Kx + px) ~ 0.2,

rps

-(Kx+JLX)

e rps = 1- (Kx + JlX)

End

rps

J.l - Coefficient of friction

rps - Radius of curvature,R

Chanage

1

9

14.5

Output

eferem.e

540u--

199t

" ..,

J,l

i400

390

733

&

734

i

4j

t

I

I

I

I

Description Output

Zone 1 is a staright section

px = Poe-Kx

Equation 31 ,

where

Kx :S: 0.2,e-Kx = 1- Kx

Po

= 1300950

N

Start Chainage

X

:0

m

-

K = 0.0033

Kx = 0.000 < 0.2

Therefore,

1-kx

= 1.000

p =

X

Prestressing force at the beam edge px = 1300950 N 1,300,950

N

End Chanage X = 1 m

Kx

= 0.0033 < 0.2 ok

eKx = 1-Kx

= 0.9967

p =

X

px = 1296657

N 1,296,657

N

Zone 2 has a curvature

-( J.IX +Kx)

~ = P o e

rps

Equation 31 and 32,

where

(Kx+ ~ :s:; 0.2, e

-(Kx+JIX)

rp, = 1-(Kx+ ,ux)

rps

rps

Start Chainage = 1 m

Po

= 1296657 N

for steel moving on steel

J.L

= 0.3

rps

=R

Radius of curvature at the end of zone 2 =

I

-

R

1

-

R = 2.70E-06 mm

eferenc e Description

Output

Therefore,

R

= 370.37 m

At the end of zone 2, Chainage = 9 m

X

f..K

-+Kx = 0.0065

< 0.2 ok

rps

-(Kx + JiX)

- ( J.iX

e

rps

-1- Kx+-)

p =

rps

X

1,288,255

px = 1 ,288,255 N N

i

Zone 3 is a straight section px = Poe-Kx

I

where

Kx 0.2,e-Kr = 1- Kx

I

Po

= 1,288,255

N

1

At the end of zone 3,

Chianage = 14.5

m

i

X = 5.50

m

Kx

= 0.01815

< 0.2 ok

P=

X 1264873

N

Chianage/(_mj_

0 1 9 14.5

t-'restressmg rorce or

1,300,950 1,296,657 1,288,255 1,264,873

the orofile 2HN}

t

Beam edg_e Quarter span Midspan

!

Chianage/(m) 0.0 2.0 7.25 12.0 14.5

t

-

0

Profile 1 1300950 1292364 1269825 1249432 1238700

Q) ...--.

oZ

._ ........

Profile 2 1300950 1295607 1290093 1275501 1264873 o--

- ..--

OlQ)

1289803 ~ li= Profile 3 1300950 1295560 1275134 1264509

en o

en ._

Q)O.

Profile 4 1300950 1295045 1286584 1271054 1260463

-= Q)

en..c

Q) ......

Profile 5 1300950 1294524 1283324 1266923 1256366

._

a_

_j_

,-

Reference I Description

At mid span

Chosen cables for tension in 1

Profile I

Duct

Number of cables

Prestressing

1

T t

1

t

tensioned from each

. o a orce

position

force 1n one t

1 1

1 Force X y

name

y/(mm)

profile in stage 1

cable a one eve

Profile 1 I 100 I

8

1,238,700 I 9909596.341 990959634

Profile 2 I 300 I

2

1,264,873 I 2529745.4 I 758923620

Profile 3 I 500 I

2

1,264,509 12529017.4511264508723

Profile 4 I 700 I

0

1,260,463 J

0

0 I 0

Profile 5 I 900 I

2

1,256,366 12512732.6712261459407

Total

I 17481092 15275851385

Total prestressing force at stage one= 17,481,092 N

Centroid of forces from the bottom of the beam = L Force x Y

Totalforce

= 5275851385

17481091.9

yf = 302 mm

Eccentricity = Y'-Y

f

Y'

=966 mm

Eccentricity of force = 664 mm

Calculation of stresses

Stage 1

Pre-cats section before grouting at transfer condition-Mid span

Neutral Axis

Level

PIA

8

8

-Pxe/Zpt' Mg l/Zpt'

Pxe/Zpb'

-Mgl/Zpb'

6.514 O.OOOE+OO 4.80

Stress at top most fibre = _!_ _ P x e + M gl

, , ,

Ap zpt zpt

I

Output

.Reference

Description

P = 17,481,092 N

Eccentricity of force = 664

mm

,

A ,

1

( l,x x' J

Mg,

= xp X X---

p c 2 2

A ~

= 2.68E+06 mm

2

Pc

= 24 kN/m

3

[e = 29 m

At mid span x = 14.5

,

Mg,

= 6770

zpr'

= 1.41E+09

zpb

'

= 1.02E+09

Stress at top most fibre = 3.08

Allowable tensile stress at transfer, = -1

m

kNm

mm

3

mm

3

N/mm

2

N/mm

2

Stress at the bottom most fibre= P P x e M gl

--+ ---

1 I 1

AP z pb Z pb

Stress at the bottom most fibre = 11.26

Allowable compressive stress at transfer, = 18

N/mm

2

N/mm

2

P Pxe Mgl

Stress at tendon level ----, + , - --,

,

Z pe

AP Zpe Zpe

- J xp

e

,

= 1.49E+09 mm

3

Stress at tendon level = 9. 77

N/mm

2

Output

3.08

N/mm

2

11.26

N/mm

2

10

N/mm

2

~ j _ _ _j

----

~ e f e r e n c e

Description Output

Similarly

Stage 1

Midspan Quarter Span Beam Edge

Prestressing force,P/(N)

17481091.9 17,885,037 18,213,300

,

Moment due to self weight before grouting/(kNm} Mal

6770 5078 0

Eccentricity of the force,e/(mm)

664 660 553

Sectional modulus at the top fiber of the section before

1.41E+09 1.41E+09 1.42E+09

grouting/(mm

3

)

zpt,

Sectional modulus at the bottom fiber of the section before

-

1.02E+09 1.02E+09 1.03E+09

grouting/(mm

3

)

zpb

'

,

9.87E+11 9.87E+11 9.96E+11

Second moment of area before grouting/(mm

4

)

/xp

Sectional modulus at the centroid of force before

1.49E+09 1.50E+09 1.80E+09

grouting/(mm

3

)

Cross sectonal area of the precast section before

~

2.68E+06 2.68E+06 2.68E+06

grouting/(mm

2

)

Stress at the top most fibre/(N/mm

2

)

3.08 1.88 -0.33

Stress at bottom most fiber/(N/mm

2

)

11.25 13.25 16.53

Stress at tendon leveV(N/mm

2

)

9.77 11.16 12.39

Stage 2

Midspan Quarter Span Beam Edge

Prestressing force,P/(N)

7475724.28 7,652;467 7,805,700

Moment due to self weight before grouting!(kNm} M _,'

6870 5153 0

Eccentricity of the force of stage 2,e/(mm)

654 650 545

Sectional modulus at the top fiber of the section before

1.42E+09 1.42E+09 1.42E+09

grouting/(mm

3

) zpt,

Sectional modulus at the bottom fiber of the section before

1.05E+09 1.05E+09 1.05E+09

grouting/(mm

3

)

zpb

I

,

9.87E+11 9.87E+11 9.96E+11

Second moment of area before grouting/(mm

4

)

/xp

Sectional modulus at the centroid of force before

1.51E+09 1.52E+09 1.83E+09

grouting/(mm

3

)

Cross sectonal area of the precast section before

~

2.72E+06 2.72E+06 2.72E+06

grouting/(mm

2

)

Stress at the top most fibre/(N/mm

2

)

-0.70 -0.70 -0.14

Stress at bottom most fiber/(N/mm

2

)

7.38 7.53 6.90

Stress at tendon level of the cables in stage 2/(N/mm

2

)

5.98 6.09 5.20

Eccentricity of the force of stage 1 ,e/(mm) 654 650 545

Stress at tendon level of the cables in stage1/(N/mm

2

) 5.99 6.09 5.20

r . ~ ~

Description

.,Reference

BS 5400

Part 4

1990

ci.6J.2. &

cl.6. 7.2.3

Short term prestress losses

A. loss of Prestress due to elastc defonnaion of concrete

Strain in concrete, =

8

c

(J"c

&c=E

_c

O" c - Stress of concrete

& c - Strain in concrete

Ec - Modulus of Elasticity of concrete

Strain in concrete = &s

/l(J" s

& =---

s E

s

& s - Strain in concrete

llO" s - Loss of prestress in steel

Es

- Modulus of Elasticity of steel

At the tendon level Strain in steel = Strain in concrete

&s =Ec

/l(J"s = (J"c

Es E

c

Loss of force in the steel, llP = !lO" x A

s s

Cross sectional area of steel = As

= (J"c x-As XEs

Ec

.......... ()

Since the tensioning of the steel is done gradually during post tensioning, the stress in tendons are

taken as the half of the stress in the steel for calculation of prestress loss

Loss of prestressing force= O.S x O"c x As xEs

Ec

Output

3S 5400-4

1990

I

Table3

;r.4.3.2.2.

Figure2

Stage 1

Chainage/(m)

14.5 (mid span)

7.25 (quarter span)

0 (beam edge)

Average stress along

the cable/Nmm, u

c

Description

Stress in concete

at tendon level

/(N/mm

2

)

9.77

11.16

12.39

11

Cross sectional area of steel = Cross sectional area of one tendon X

A number of tendons stresses

s

Cross sectional area of one tendon = 150 mm

2

Number of tendons needed = 98

As = 14700 mm

2

Characteristic Concrete cube strength at transfer = 36

Modulus of Elasticity of concrete E c = 29.8

= 29,800

Modulus of Elasticity of steel Es = 200

= 200,000

N/mm

2

kN/mm

2

N/mm

2

KN/mm

2

N/mm

2

Loss of prestressing force = 0.5 x Uc x As xEs

Ec

Loss of pre stress

= 547,823 N

Loss of stress due to direct force loss = AP

A'

p

= 547,823

2.68E+06

= 0.20

loss of stress due to loss of moment at the top fiber = AP x e

zp,'

N/mm

2

after 7 days

Output

AP

547,823

N

'-

. Reference

Description

Output

AP = 547,823 N

e = 664 mm

zpl,

= 1.41E+09 mm

3

zpb '

mm

3

= 1.02E+09

loss of stress due to loss of moment at the top fiber= -0.26 N/mm

2

-0.05

Loss of stress due to loss of moment at the bottom fiber =

0

M x e

zpb '

= 0.36 N/mm

2

0.56

Stresses after stage 1 stressing -Mid span,

Stress at the top most fibre/(N/mm2) = 3.08

Stress at bottom most fiber/(N/mm2) = 11.25

Stress at tendon leveii(N/mm2) = 9. 77

Stresses after the losses,

Resultant stresses at top fiber = 2.62 N/mm

2

Resultant stresses at botttom fiber = 1 0.69 N/mm

2

Similarly,

Mid Span

Average

Loss of stress

Loss of stress

Loss of stress due

Cables stress along

M

due to direct

due to loss of

to loss of moment

considered the

A. moment at the

cable/N/mm

2

mm

2

N

force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 11.11 14700 547823 0.20 -0.26 0.36

St2 cbls 5.76 6300 121668 0.04 -0.06 0.08

Stage 2

St1 cbls 5.76 14700 283968 0.10 -0.13 0.18

Total prestress loss 953458

Quarter Span

Average

Loss of stress

Loss of stress

Loss of stress due

Cables

stress along

As

M due to direct

due to loss of

to loss of moment

considered the moment at the

cable/N/mm

2

mm

2

N

force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 11.11 14700 547823 0.20 -0.26 0.35

St2 cbls 5.76 6300 121668 0.04 -0.06 0.08

Stage 2

283968 St1 cbls 5.76 14700 0.10 -0.13 0.18

Total prestress loss 953458

--

.---

.Reference I

Description

I

Output

BS 5400-4

1990

Cl6 7.2.6

Beam Edse

Average

Loss of stress

Loss of stress

Cables I stress along

A.

I1P

due to direct

due to loss of I Loss of stress due

to loss of moment

considered the

moment at the t th b

11

fibe

cable/N/mm

2

, mm

2

force loss

topfiber a e o om r

N

Stage 1 St1 cbls 11.11 14700 547823 0.20 -0.21

St2 cbls 5.76 6300 121668 0.04 -0.05

Stage 2

St1 cbls 5.76 14700 283968

I 0.10 I -0.11

Total prestress loss 953458

B. loss of prestress due to slip during anchorage

Stage 1

At mid span

if,Anchorage slip = 8

loss of prestressing force = x E x A

I s s

Modulus of Elasticity of steel

E.

A.

I

= 200,000

= 14700

= 30

Assume Slip of the cable = 6

8

= 12

N/mm

2

mm

2

m

mm per 15m

mm

loss of prestressing force = 1, 176,000 N

loss of direct stress = M

A'

p

A' = 2.68E+06 mm

2

p

loss of direct stress = 0.44

loss of stress at the top most fiber = M x e

zpt,

N/mm

2

e = 664 mm

zpt'

Mxe

zpt,

= 1.41E+09

= -0.55

Mxe

loss of stress at the bottom most fiber = ---

Zph'

mm

3

N/mm

2

I

I

I

0.29

0.06

0.15

1,176,000

N

Reference

Description Output

..

z pb ' = 1.02E+09

mm

3

Mxe

= 0.76 N/mm

2

zph,

Stresses after the elastic deformation,

Stress at top most fibre = 2.62 N/mm

2

Stress at bottom most fibre = 10.69 N/mm

2

.

Stresses after the losses,

Resultant stresses at top fiber = 1.62 N/mm

2

Resultant stresses at botttom fiber = 9.48 N/mm

2

Mid Span

Loss of stress

Loss or stress

Loss of stress due

Cables due to loss of

considered A

llP

due to direct

moment at the

to loss of moment

mms:z

N

force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 14700 1176000 0.44 -0.55 0.76

St2 cbls 6300 504000 0.19 -0.23 0.31

Stage 2

St1 cbls 14700 0 0.00 0.00 0.00

Total prestress loss 1680000

Quarter Span

Loss of stress

LOSS 01 Suess

Loss of stress due

Cables due to loss of

considered

A M

due to direct

moment at the

to loss of moment

(Jr mmi

N

force loss

too fiber

at the bottom fiber

Stage 1 St1 cbls 14700 1176000 0.44 -0.55 0.76

St2 cbls 6300 504000 0.19 -0.23 0.31

Stage 2

St1 cbls 14700 0 0.00 0.00 0.00

Total prestress loss 1680000

Beam Ed e

Loss of stress

Loss of stress

Loss of stress due

Cables

As

due to direct

due to loss of

to loss of moment

considered

M

moment at the

a mm

2

N

force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 14700 1176000 0.44 -0.46 0.63

St2 cbls 6300 504000 0.19 -0.19 0.26

Stage2

0 St1 cbls 14700 0.00 0.00 0.00

Total prestress loss 1680000

--

.

.

.--

.. Reference

BS 5400-4

1990

cl.6.7.2.5 1

BS 5400-4!1

1990

T.able 20

Description

C.Loss of prestress due to creep of concrete

Stage 1 at mid span

Loss of prestress of the tendon = Creep coefficient X Modulus of elasticity

of the tendon X stress at the tendon level

After 14 days of concreting,

Stress at tendon level = 9. 77

Strength of concrete =. 36

N/mm

2

N/mm

2

After 14 days of concreting, Creep coefficient = 0.000036 X 40/fci

Es

= 0.00004

= 200,000 N/mm

2

<40

N/mm

2

perN/mm

2

After 14 days of concreting,Loss of prestress of the tendon = 0.5X(Creep coefficient X Modulus of elasticity of the

tendon X stress at the tendon level)

Maximum stress in the section = 11.25

<fa/3

ok

Stress at tendon level = 9. 77

Loss of prestress of the tendon = 39

N/mm

2

A, = 14700

Loss of prestressing force/(N) = 574343 N

Loss of stress

Direct loss = M

A'

p

= 574.343

2.68E+06

= 0.21

Loss of stress due to loss of moment at the top fiber = AP x e

z p ~

N/mm

2

AP = 574,343 N

e=664 mm

z I 3

pr = 1.41E+09 mm

Z ph

1

= 1.02E+09 mm

3

Loss of stress due to loss of moment at the top fiber = -0.27 N/mm

2

Output

574,343

N

Reference Description

Output

Loss of stress due to Joss of moment at the bottom fiber =

Mxe

zpb

'

= 0.37 N/mm

2

Stresses after the elastic deformation and anchorage slip mid span after 14 days,

Stress at top most fibre = 1.62 N/mm

2

Stress at bottom most fibre := 9.48 N/mm

2

Resultant stresses after 14 days creep of concrete

Resultant stresses at top fiber = 1.14 N/mm

2

I

Resultant stresses at botttom fiber = 8.90 Nlmm

2

Similarly,

Mid Span

Stress at

M

Loss of stress

Loss of stress

Loss of stress due

Cables

cable A,

N due to direct

due to loss of

to loss of moment

considered moment at the

levei/N/mm

2

mm

2 force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 9.768 14700 574343 0.21 -0.27 0.37

St2 cbls 5.983 6300 135685 0.05 -0.06 0.08

Stage 2

St1 cbls 5.985 14700 316736 0.12 -0.15 0.20

Total prestress loss 1026763

Quarter Span

Stress at Loss of stress

Loss of stress

Loss of stress due

Cables

cable A,

N due to direct

due to loss of

to loss of moment

considered moment at the

leveVN/mm

2

mm

2 force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 11.164 14700 656426 0.24 -0.31 0.42

St2 cbls 6.086 6300 138036 0.05 -0.06 0.09

Stage 2

St1 cbls 6.088 14700 322192 0.12 -0.15 0.20

Total prestress Joss

1116654

Beam Ed! e

Stress at Loss of stress

Loss ot stress

Loss of stress due

Cables

cable A,

N due to direct

due to loss of

to loss of moment

considered moment at the

leveVN/mm

2

mm

2 force loss

top fiber

at the bottom fiber

Stage 1 St1 cbls 12.385 14700 728247 0.27 -0.28 0.39

St2 cbls 5.196 6300 117854 0.04 -0.05 0.06

Stage 2

274993 St1 cbls 5.196 14700 0.10 -0.11 0.14

Total prestress loss 1121095

~ ~

r - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ~ - - - - - - - - -

.Reference Description

D.Loss of prestress due to shrinkage of the concrete

Shrinkage per unit length, = c_,h

BS 5400

Part4

ci.6.7.2.4,After 14 days

Table29

Prestress loss due to shrinkage= &sh x E, x A.

Prestress loss due to shrinkage = 0.5 x & sh x E s x As

Total area of steel A.

E.

= 21000

= 200000

= 0.0002

mm

2

kN/mm

2

For normal exposure,

Esh

Prestress loss due to shrinkage = 420000 N

Loss of stress Direct force =

~ p

A

p

= 420000

2.74E+06

= 0.15

Loss of stress due to loss of moment at the top fiber = .6. P x e

zpl

N/mm

2

e = 652 mm

zp,

= 1.42E+09

Loss of stress due to loss of moment at the top fiber = -0.19

Loss of stress due to loss of moment at the bottom fiber = Ll P X e

z ph

mm

3

N/mm

2

Z ph = 1.07E+09 mm

3

Loss of stress due to loss of moment at the bottom fiber = 0.26 N/mm

2

Resultant stresses after 14 days of creep of concrete

Resultant stresses at top fiber = 1.14

Resultant stresses at bottom fiber = 8.90

N/mm

2

N/mm

2

Resultant stresses after 14 days of the cable set one before stressing cable set 2

Resultant stresses at top fiber = 0. 79

Resultant stresses at bottom fiber = 8.49

N/mm

2

N/mm

2

Output

420000

N

Reference I

Description

Loss of stress

Prestress loss due I d t d" ct

~ ~ : s t ~ ~ ~ : : ~ ; Loss of stress due

Age

I A.,

. ue o 1re

to shnnkage/(N) ~

1

/(mm

2

)

Mid Span 1 month 21000 420,000

Quarter Span 1month 21000 420,000

Beam Edge 1 month 21000 420,000

After stressing cable set 2 at stage 2 after one month

At mid span

Stress at top fiber due to stresses in cable set 2

Stress at bottom fiber due to stresses in cable set 2

Loss due to elastic deformation

Cable set 1

Loss of direct stress in cable set 1

Loss of stress in cable set 1 due to moment loss at the

top fibre

Loss of stress in cable set 1 due to moment loss at the

bottom fibre

Cable set 2 loss due to elastic deformation

Loss of direct stress in cable set 2

Loss of stress in cable set 2 due to moment loss at the

top fibre

Loss of stress in cable set 2 due to moment loss at the

bottom fibre

Anchorage loss

Cable set 1 anchorage loss

Loss of direct loss in cable set 1

Loss of stress in cable set 1 due to moment loss at the

top fibre

Loss of stress in cable set 1 due to moment loss at the

bottom fibre

orce oss

I 0.15

I 0.15

I

0.15

= -0.70

= 7.38

= 0.10

= -0.131

= 0.176

= 0.04

= -0.06

= 0.08

= 0.00

= 0.00

= 0.00

t t th to loss of moment

momen a e t the bott fibe

top fiber a om r

I -0.19

I -0.19

I -0.16

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

I 0.26

I 0.25

I 0.21

Output

~ ~ ~

Reference

Description

Output

Cable set 2 anchorage loss

Loss of direct stress in cable set 2 = 0.19 N/mm

2

Loss of stress in cable set 2 due to moment loss at the = -0.23

N/mm

2

top fibre

Loss of stress in cable set 2 due to moment loss at the = 0.31

N/mm

2

bottom fibre

0

Total losses

Loss of direct stress = 0.33 N/mm

2

Loss of stress at top most fibre = -0.420 N/mm

2

Loss of stres at bottom most fibre = 0.565 N/mm

2

Resultant stresses at top fiber = -0.67 N/mm

2

I

Resultant stresses at botttom fiber = 14.97 N/mm

2

Loss of prestress due to creep of concrete after 30 days

"

Cable set 1

Loss of direct stress in cable set 1 = 0.12 N/mm

2

Loss of stress in cable set 1 due to moment loss at the = -0.15

N/mm

2

top fibre

Loss of stress in cable set 1 due to moment loss at the = 0.20

N/mm

2

bottom fibre

Resultant stresses at top fiber = -0.40 N/mm

2

Resultant stresses at botttom fiber = 14.66 N/mm

2

Cable set 2 loss due to elastic deformation

Loss of direct stress in cable set 2 = 0.05 N/mm

2

Loss of stress in cable set 2 due to moment loss at the

top fibre = -0.06 N/mm

2

Loss of stress in cable set 2 due to moment loss at the

bottom fibre = 0.08 N/mm

2

I_

Resultant stresses at top fiber = -0.29 N/mm

2

Resultant stresses at botttom fiber = 14.52 N/mm

2

i!.

Reference

Description

E. loss of prestress due to relaxation of steel

BS 5400-41 For relaxation class 1, Maximum relaxation after 1000 h for an initial load of 70% of the breaking load,

is 8 % of prestressing force

1990

cl.6.7.2.2 Type of strand = BS 5896-3 super strand-1770-15.7-relax 1

BS 5896

1980

~ _ h - a

In all cables

At mid span

Loss of stress

Relaxation class = class 1

Prestresing force at the jacking end = 26,019,000 N

Percentage prestress loss = 8

%

Loss of Prestressing force = 2081520 N

As = 21000 mm

2

Loss of stress in cable = 99.12

Direct force = ~

A

p

= 2081520

2.74E+06

= 0.76

N/mm

2

N/mm

2

!l.P x e

Loss of stress due to Joss of moment at the top fiber =

z pt

e = 652 mm

Z P

1

= 1.42E+09 mm

3

Loss of stress due to Joss of moment at the top fiber = -0.96 N/mm

2

Loss of stress due to Joss of moment at the bottom fiber

_ !l.P x e

zph

Z ph = 1.07E+09 mm

3

Loss of stress due to Joss of moment at the bottom fiber = 1.27

Resultant stresses after 30 days

Resultant stresses at top fiber

Resultant stresses at botttom fiber

= -0.29

= 14.52

N/mm

2

N/mm

2

N/mm

2

After 2 months

Output

---

Reference

Description Output

Resultant stresses after 1 month

Resultant stresses at top fiber = 1.42 N/mm

2

Resultant stresses at botttom fiber = 12.49 N/mm

2

Similarly,

"

'

Loss of stress

Loss of stress Loss of stress

M due to direct

due to toss of due to loss of

/(N) force loss

moment at the moment at the

top fiber bottom fiber

I

Mid Span 2081520

0.76 -0.96 1.27

Quarter Span 2081520

0.76 -0.95 1.26

Beam Edge 2081520

0.76 -0.79 1.08

Total prestress force loss = 4411399 N

Total prestressing force = 24956816 N

Percentage prestress loss = 17.68 %

Smilarly,After stressing cable set 2 at stage 2 after one month streesses at quarter and mid

span can be summarised as follows,

MidSpan Quarter span Beam edge

Stresses after stage 1 stressing

3.08 1.88 -0.33

11.25 13.25 16.53

Loss due to elastic defonnation after stage 1 stressing

Top fibre

-0.26 -0.26 -0.21

Bottom fibre

0.36 0.35 0.29

Direct

0.20 0.20 0.20

Resultant

Top

2.62 1.42 0.09

Bottom

10.69 12.69 16.04

Loss of slip stage 1

Top

-0.55 -0.55 -0.46

Bottom

0.76 0.76 0.63

Direct

0.44 0.44 0.44

--

---

---

Reference

Description Output

Resultant

Top

1.62 0.43 -0.81

I

Bottom

9.48 11.49 14.97

I

I

Creep loss after stage 1stressing

-0.27 -0.31 -0.28

I

Top

I

I

Bottom

0.37 0.42 0.39

I

!

Direct

0.21 0.24 0.27

Resultant

Top

1.14 -0.12 -0.25

Bottom

8.90 10.82 14.31

Loss of prestress due to shrinkage of the concrete

Top

-0.19 -0.19 -0.16

Bottom

0.26 0.25 0.21

Direct

0.15 0.15 0.15

Resultant

Top

I

0.79

I

0.23

I

0.06

I

Bottom

8.49 10.41 13.94

After stressing cable set 2 at stage 2 after one month

Top -0.70 -0.70 -0.14

Bottom 7.38 7.53 6.90

Resultant stresses after stressing cable set 2

Top

0.09 -0.47 -0.08

Bottom

15.87 17.95 20.84

-- -- --- - ~

nee Description

Output

Loss due to elastic deformation

Cable set 1

Top

-0.13 -0.13 -0.11

Bottom

0.18 0.18 0.15

Direct

0.10 0.10 0.15

Resultant

Top

-0.15 -0.24 0.18

Bottom

15.59 17.67 20.55

Cable set2

Top

-0.06 -0.06 -0.05

Bottom

0.08 0.08 0.06

Direct

0.04 0.04 0.04

Resultant

Top

-0.05 -0.14 0.09

Bottom

15.47 17.55 20.44

Anchorage loss

Cable set 1 anchorage loss

Top

0.00. 0.00 0.00

Bottom

0.00 0.00 0.00

Direct

0.00 0.00 0.00

Top

-0.05 -0.14 0.09

Bottom

15.47 17.55 20.44

Resultant

Cable set 2 anchorage loss

Top

-0.23 -0.23 -0.19

Bottom

0.31 0.31 0.26

Direct

0.19 0.19 0.19

r-

.. Reference

Resultant

Top

Bottom

0.37

14.97

Description

0.28

17.05

Loss of prestress due to creep of concrete after 30 days

cable set 1

Top

Bottom

Direct

Resultant

Top

Bottom

cable set 2

Top

Bottom

Direct

Resultant

Top

Bottom

-0.15

0.20

0.12

0.11

14.66

-0.06

0.08

0.05

0.00

14.53

Loss of prestress due to relaxation of steel

Top

Bottom

Direct

Resultant

Top

Bottom

-0.96

1.27

0.76

1.71

12.49

-0.15

0.20

0.12

0.01

16.73

-0.06

0.09

0.05

-0.10

16.60

-0.95

1.26

0.76

1.61

14.57

Output

-0.29

20.00

-0.11

0.14

0.10

-0.09

19.75

-0.05

0.06

0.04

0.00

19.65

-0.79

1.08

0.76

-1.55

17.81

r-------,-------------------------------------------------------------------------.-------,

Reference

Description

Immediately after placing the concrete

Mid span

Prestressing force after initial losses, P = 20,545,417 N

Moment at mid span due to self weight of the beam, Mgt = 6913 kNm

Moment at mid span due to screed concrete, Mg2 = 1804 kNm

Sectional Modulus of the top fiber,

Sectional Modulus of the bottom fiber,

Cross sectional Area,

Resultant Eccenticity of cables,

PIA Pxe/Zpt

8

c>

Neutral

Axis

c>

CB

PIA

Pxe/Zpb

Z pi = 1.42E+09 mm

3

zpb = 1.07E+09 mm

3

AP = 2. 7 4E+06 mm

2

e = 652 mm

Mgl/Zpt Mg2/Zpt

()

[r

8

~

Mgl!Zpb

Mg2/Zpb

P Pxe Mg, Mg2

----+--+--

Stress at top most fibre = A z z z

pi pi pi

= 2.98 N/mm

2

p Pxe Mg, Mg2

stress at bottom most fibre = A + -

2

- z-z

ph ph ph

= 10.80 N/mm

2

Output

2.98

N/mm

2

10.80

N/mm

2

L L ~

,.-----

Reference

Description

Output

Similarly,

Quarter

Beam Edge

Span

Initial prestressing force

25,537,504 26,019,000

!

Total pre stress losses

4419206 4351826

Prestressing force after initiallosses,P/N 21,118,298 21,667,174

Moment due to self weight of the

Mg,

5184.77 0

beam/(N/mm)

.

Moment due to screed concrete/(N/mm)

Mgz

1352.96 0

Sectional Modulus of the top fiber,

zp,

mm

3

1.42E+09 1.42E+09

Sectional Modulus of the bottom fiber,

zpb

mm

3

1.07E+09 1.07E+09

Cross sectional Area,

AP

mm

2

2.74E+06 2.74E+06

Resultant Eccentricity of all tendons, e mm 648 542

Stress at top most fibre N/mm

2

-0.67 1.54

Allowable stress at bottom most fibre N/mm

2

12.16 16.77

I

loss of prestress due to differential shrinkage

After placing screed on the beam,

__[_ t.Q6QM

5.200M

__[_Q.132M

Prestress

l rm

A

~ w -r250M

0

Designers

p.290M .J

cr.1isr1

a

..........

- -

7

Handbook

0.400rv

P.W.Ables

eP

1.667M

Q 952M

To find the neutral axis of added concrete,

Taking moments along the axis through point A

-

(60x5200x30+0.5x72x5200x84-

X

=

2x400x250x125-2x0.5x400x40x263)

(60x5200+0.5x72x5200+2x400x250+2x0.

5x400x40)

= -5.77 mm

ea +ep = 1670-5.77-ypb

......... (1)

= 712

mm

e a I a

--= m --

.......... (2)

eP

Ixp

.

ence

'

400-4

90

t3.4

At mid span

(1) And (2)

Description l I Output

I ' _ 9.40E+09 mm

4

ar -

IxJ = 1.02E+12 mm

4

I

nil - Modular ratio=1

I

I) _ Moment of Inertia of added concrete

I ~ _ Moment of inertia of precast concrete

e /

~

e ;

I

m __ a

P:

I

xp

i

j

i = 0.01

eP = 706

ea = 7

AP = 2.74E+06

lxp = 1.02E+12

Au = 7.15E+05

Ia = 9.40E+09

Ea,Ep = 34000

mm

mm

mm

2

mm

4

mm

2

mm

4

N/mm

2

F - Force exerted by differential Shrinkage

F

2 . 2

' F F xeP Fxe

11& = + ++ a

APxEP AaxEa lxpxEP /axEa

11& = 0.43x200x1 0-6

F= 11&

2 2

e e

---+ ++ p __ a_

1 1

AP xEP Aa xEa lxp xEP Ia xE,

= 1.30E+06 N

Bending moment due to this force= 917586487 Nmm

Loss of direct stress = 0.47

Bending stress at the top fibre = 0.65

Bending stress at the bottom fibre= -0.86

N/mm

2

N/mm

2

N/mm

2

. jstresses at mid span after placing screed

N/mm

2

N/mm

2

l

Stress at the top fiber = 2.98

. Stress at the bottom fiber= 10.80

-

renee Description

Output

- M

Stress at the top fibre of the composite section due to Mq - z q

ct

r.fu

= 3.14 N/mm

2

Stress at the top level of the pre cast section = 2.70 N/mm

2

Stress at the bottom fibre of the composite section due to

=

Mq

Mq

zch

= -5.19 N/mm

2

Stress at the top most fiber of composite section = 1.86 N/mm

2

Resultant stress on the precast section top fibre = 4.56 N/mm

2

Stress at the bottom most fiber of pre cast section = 9.47 N/mm

2

Resultant stress on the precast section bottom fibre = 4.28 N/mm

2

Similarly

Quarter span Beam Edge

Moment due to live loads 4.64E+09 O.OOE+OO

Stress at the top fibre of the composite section due to Mq 2.36 0.00

Mq

zct

Stress at the top level of the pre cast section 2.02 0.00

Stress at the bottom fibre of the composite section due to

-3.89 0.00

Mq

Mq

zcb

Resultant stress on the precast section top fibre 1.35 1.54

Resultant stress on the precast section bottom fibre 8.27 16.77

------ - - -- -

r

Reference Description

Claculation of the balance losses after 2nd month-

Loss of prestress due to shrinkage of the concrete

Loss of prestress due to shrinkage of the concrete = Rest 50% of the shrinkage loss

BS 5400 I Loss of stress Direct force =

I!J>

Part4

cl6.7.2.4

Table29

Ac

="420000

3.45E+06

= 0.12

tiP x e

Loss of stress due to loss of moment at the top fiber =

zclt

N/mm

2

e = 799 mm

zc!, = 1.97E+09 mm

3

Loss of stress due to loss of moment at the top fiber = ..0.17

Stress at top of precast section = ..0.15

tiP x e

Loss of stress due to loss of moment at the bottom fiber = ----

Z clb

N/mm

2

N/mm

2

Zc!b = 1.19E+09 mm

3

Loss of stress due to loss of moment at the bottom fiber = 0.28

Resultant stresses after live loading

Loss due to creep

Resultant stresses at top fiber= 9.47

Resultant stresses at botttom fiber = 4.28

Resultant stresses at top fiber = 9.20

Resultant stresses at botttom fiber = 3.87

In cabe set one at mid span

N/mm

2

N/mm

2

N/mm

2

N/mm

2

N/mm

2

Loss of pre stress = Rest 50% of the initial loss

N

N/mm

2

N/mm

2

Loss of prestress = 1026763

Loss of direct stress at the top fibre = 0.30

Loss of strees at the top fiber due to moment = -0.42

Loss of strees at the bottom fiber due to moment = 0.69

-- N/mm

2

Output

r---

Reference Description

Output

Resultant stresses

Resultant stresses at top fiber = 9.20 N/mm

2

Resultant stresses at botttom fiber = 3.87 N/mm

2

Resultant stresses after creep loss

Resultant stresses at top fiber after all the losses = 8.49

N/mm

2

-

Resultant stresses at botttom fiber after all the losses = 4.26

N/mm

2

Mid Span

Stress resultants after rest of the losses for the quarter span and beam edge

Resultant streses after placing the screed

Quarter span Beam edge

Resultant stresses at top fiber 1.35 1.54

Resultant stresses at botttom fiber 8.27 16.77

Quarter span Beam edge

Losses due to diferential shrinkage

Loss of prestress 1300240 1300240' N

I

Loss of direct stress at the top fibre 0.47 0.47

N/mm

2

Loss of strees at the top fiber de to moment 0.65 0.65

N/mm

2

Loss of strees at the bottom fiber de to moment -0.86 -0.86

N/mm

2

Resultant stresses at top fiber 0.23 0.42 N/mm

2

Resultant stresses at botttom fiber 6.93 15.44 N/mm

2

Quarter span Beam edge

Losses due to shrinkage

Loss of prestress 420000 420000 N

Loss of direct stress at the top fibre 0.12 0.12

N/mm

2

Loss of strees at the top fiber due to moment -0.17 -0.17

N/mm

2

Loss of strees at the top fiber of the pre cast section due

-0.15 -0.15

to moment

N/mm

2

Loss of strees at the bottom fiber due to moment 0.28 0.28

N/mm

2

Resultant stresses at top fiber after final shrinka_g_e losses -0.04 0.15 N/mm

2

Resultant stresses at botttom fiber after final shrinkage

6.53 15.03.

-

losses N/mm

2

,----

Reference Description

Output

Losses due to creep

Loss of p_!estress 1116654 1121095 N

Loss of direct stress at the top fibre 0.32 0.32

N/mm

2

Loss of strees at the top fiber due to moment -0.45 -0.46

N/mm

2

Loss of strees at the top fiber of the pre cast section due

to moment

-0.39 -0.39

Loss of strees at the bottom fiber due to moment

0.75 0.75

N/mm

2

Resultant stresses at top fiber -0.04 0.15 N/mm

2

Resultant stresses at botttom fiber 6.53 15.03 N/mm

2

Resultant stresses at top fiber after all the losses 0.74 -0.63 N/mm

2

Resultant stresses at botttom fiber after all the losses 5.46 13.96 N/mm

2

I

Allowable tensile stress at service,

famn

= -2.55 N/mm

2

;

Allowable compressive stress at service, farrax

= 20 N/mm

2

Resultant prestress force after all the losses

Initial prestressing Prestress

Final Percentage

force/(N) Loss/(N)

prestressing prestress

force/(N) Loss/(%)

Mid Span 24,956,816 8,908,745 16,048,072 36

Quarter span 25,537,504 9,088,525 16,448,979 36

Beam edge 26,019,000 9,097,408 16,921,592 35

--

--

.Reference

Description

Output

Check for ultimate limit state

BS 5400-4

-

"'

E

Cl.6.3.3.

.

-...

rJ)

rJ)

-

"

1pu

Ym

___ /!

0.8fpu

Ym

I I

I

I

I

I

I

I

I

I

200kNif

2