Escolar Documentos

Profissional Documentos

Cultura Documentos

Fuji MC Selection

Enviado por

masakpDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fuji MC Selection

Enviado por

masakpDireitos autorais:

Formatos disponíveis

There are four basic motor control options available: Basic contactors, traditional starters, manual motor starters,

or combination starters. Follow these 3 steps to choose the best fit.

What Fuji Motor Control Do I Need?

What does the application require?

Traditional Starters Manual Motor Starters Combination Starters

Basic Contactors Only

Contactor

Typical applications: Electronic switching Lighting Resistive loads Non-motor-related inductive loads Disconnect switches VFD bypass/isolation

relay

Contactor and overload

Manual motor starter (MMS) Typical applications: Inductive motor starting and manual control NEC 430 fulfillment Lockout/tagout UL 508, type E Not AC-4 rated

Typical applications: Inductive motor starting and control NEC 430 and 409 fulfillment Nm starter replacement/retrofit

Manual motor starter, contactor, link module, and base plate Typical applications: Inductive motor starting and control NEC 430 and 409 fulfillment Lockout/tagout UL 508, type F

2 3

Duo Series

Horsepower (HP) and full load amperage (FLA); Refer to motor data plate information.

Load type: Resistive (AC-1) or inductive (AC-3) Duty cycle: One direction, reversing, plugging (AC-4); Refer to IEC Utilization Chart on page 17-78

Consider these factors when selecting components:

Select your components.

SC-E Contactor See page 17-5 1/2 to 100 hp @ 480 V 9-150 A (AC3) Odyssey Series

SC-E Contactor

Duo Series

See page 17-52 3N Contactor 60 to 300 hp 180-361 A (AC3)

Volume 14

TK-E Overload relay 1/2 to 100 hp @ 480 V 3N Contactor Odyssey Series 3N Overload relay

See page 17-5 See page 17-21

BM3 Manual motor starter 1/2 to 40 hp @ 480 V See page 17-28

Duo Series

BM3 Manual motor starter SC-EContactor BZ0L link module

See page 17-28 See page 17-5 See page 17-43

Duo Series

See page 17-52 See page 17-55

BZ0BP base plate 1/2 to 40 hp @ 480 V

e17-4

Motor Controls

1 - 80 0 - 633 - 0405

Features

Fuji Duo Series SC-E Contactors

5 to 100 hp at 480 VAC cULus and CSA approval, CE mark, meets JIS and IEC standards. Models SC-E02-xxx to SC-E4-xxx have 3-pole main circuits and come in three sizes with widths of 43 mm, 54 mm, and 67 mm. Models SC-E1-xxx to SC-E7-xxx employ a box terminal structure; allowing wires to be connected directly to the main circuit. Has a finger-protection terminal structure that prevents the exposure of live parts. Models SC-E5-xxx to SC-E7-xxx use a SUPERMAGNETTM (AC-input/DC-output operation) for high operating reliability and requires no surge suppressor. SC-E02-xxx to E05-xxx: 43mm wide SC-E1-xxx to E2S-xxx: 54mm wide SC-E3-xxx, E4-xxx: 67mm wide SC-E5-xxx: 88mm wide

Company Information Systems Overview Programmable Controllers Field I/O

Safety Utility

SC-E2S Terminals with finger-touch protection (DIN 57106/VDE 0106 Teil100)

Software

Standards & Approvals

UL listed , file E42419, Standard UL 508 cUL listed, file E42419, Standard CSA C 22.2 No.14 VDE 0660 JIS C 8201-4-1 IEC 60947-4-1 / EN 60947-4-1 CE compliant Auxiliary contact blocks Coil surge suppression units Replacement coils for contactor sizes SC-E5 and larger

SC-E7

C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches

Small Size

Environmental

Box lug terminal construction Long electrical life Easy to wire Low power consumption Recycled thermoplastic resin used for plastic parts. The names of materials are indicated on all major parts to facilitate recycling

Optional accessories

SC-E Series Contactors Specifications - UL and CSA

Rated Insulation Voltage (V) Rated AC-1 Thermal Current (A) [note 2] Rated Capacity (HP) Nominal Coil Voltage Model Price 3-Phase Motor 1-Phase Motor Rated AC-3 Current (A) [note 1] SCCR Ratings (KA) Frame Width (mm)

Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights Process Relays/ Timers

440 550 100 220 200V 220 240V 480V 600V 120V 240V

SC-E02-24VAC SC-E02-110VAC SC-E02-220VAC SC-E02-440VAC SC-E02-500VAC SC-E02G-24VDC SC-E03-24VAC SC-E03-110VAC SC-E03-220VAC SC-E03-440VAC SC-E03-500VAC SC-E03G-24VDC SC-E04-24VAC SC-E04-110VAC SC-E04-220VAC SC-E04-440VAC SC-E04-500VAC SC-E04G-24VDC SC-E05-24VAC SC-E05-110VAC SC-E05-220VAC SC-E05-440VAC SC-E05-500VAC SC-E05G-24VDC

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <--->

24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 5 7.5 15 15 2 3 25 32 5 5 10 10 1 3 18 25 5 690 43 3 3 7.5 7.5 1/2 2 12 20 2 2 5 5 1/3 1 9 20

Comm. Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

TABLE CONTINUED NEXT PAGE Notes: 1. AC3 type loads consist of squirrel cage three-phase motors; occasional, limited jogging duty. 2. AC1 non-inductive or slightly inductive loads. Typically resistive loads (i.e. furnaces, ovens, etc.)

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-5

Fuji Duo Series SC-E Contactors

SC-E Series Contactors Specifications - UL and CSA

Rated AC-1 Thermal Current (A) [note 2] Rated Insulation Voltage (V)

690 67

Rated Capacity (HP) Nominal Coil Voltage Model Price 3-Phase Motor 1-Phase Motor

Rated AC-3 Current (A) [note 1]

SCCR Ratings (KA)

440 550 100 220 200V 220 240V 480V 600V 120V 240V

SC-E1-24VAC SC-E1-110VAC SC-E1-220VAC SC-E1-440VAC SC-E1-500VAC SC-E1G-24VDC SC-E2-24VAC SC-E2-110VAC SC-E2-220VAC SC-E2-440VAC SC-E2-500VAC SC-E2G-24VDC SC-E2S-24VAC SC-E2S-110VAC SC-E2S-220VAC SC-E2S-440VAC SC-E2S-500VAC SC-E2SG-24VDC SC-E3-24VAC SC-E3-110VAC SC-E3-220VAC SC-E3-440VAC SC-E3-500VAC SC-E3G-24VDC SC-E4-24VAC SC-E4-110VAC SC-E4-220VAC SC-E4-440VAC SC-E4-500VAC SC-E4G-24VDC SC-E5-24V SC-E5-100V SC-E5-200V SC-E5-400V SC-E5-500V SC-E6-24V SC-E6-100V SC-E6-200V SC-E6-400V SC-E6-500V SC-E7-24V SC-E7-100V SC-E7-200V SC-E7-400V SC-E7-500V

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <--->

24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC 110VAC 220VAC 440-480VAC 500-550VAC 24VDC 24VAC/VDC 110VAC/VDC 220VAC/VDC 380-450VAC 460-575VAC 24VAC/VDC 110VAC/VDC 220VAC/VDC 380-450VAC 460-575VAC 24VAC/VDC 110VAC/VDC 220VAC/VDC 380-450VAC 460-575VAC 50 50 100 125 15 25 150 200 115 40 40 75 100 10 20 125 150 10 100 30 30 60 75 7.5 15 105 150 88 25 30 50 50 5 15 80 105 20 25 50 50 5 15 65 100 15 20 30 30 3 10 50 65 5 10 15 30 30 3 5 40 60 54 7.5 10 25 25 2 3 32 50

Notes: 1. AC3 type loads consist of squirrel cage three-phase motors; occasional, limited jogging duty. 2. AC1 non-inductive or slightly inductive loads. Typically resistive loads (i.e. furnaces, ovens, etc.)

Volume 14

e17-6

Motor Controls

1 - 80 0 - 633 - 0405

Frame Width (mm)

Fuji Duo Series SC-E Contactors

SC-E Series Contactors Specifications - IEC

Rated Capacity (kW) Contactor Type 3-Phase Motor AC-3 / AC-4 200240V SC-E02(G)-xxx SC-E03(G)-xxx SC-E04(G)-xxx SC-E05(G)-xxx SC-E1(G)-xxx SC-E2(G)-xxx SC-E2S(G)-xxx SC-E3(G)-xxx SC-E4(G)-xxx SC-E5-xxx SC-E6-xxx SC-E7-xxx

2.2 / 2.2 3/3 4/4 5.5 / 4 7.5 / 7.5 11 / 11 15 / 11 18.5 / 18.5 22 / 18.5 30 / 30 37 / 37 45 / 45

Company Information Systems Overview Programmable Controllers

Rated Operating Current (A) 3-Phase Motor AC-3 / AC-4 600690V

4 / NA 5.5 / NA 7.5 / NA 7.5 / NA 11 / NA 15 / NA 22 / NA 30 / NA 37 / NA 55 / NA 60 / NA 90 / NA

380440V

4/4 5.5 / 5.5 7.5 / 7.5 11 / 7.5 15 / 15 18.5 / 18.5 22 / 18.5 30 / 30 40 / 30 55 / 55 60 / 60 75 / 75

500550V

4 / NA 5.5 / NA 7.5 / NA 11 / NA 15 / NA 18.5 / NA 25 / NA 37 / NA 37 / NA 5 5/ NA 6 0 / NA 75 / NA

200240V

9/9 12 / 12 18 / 18 25 / 18 32 / 32 40 / 40 50 / 40 68 / 68 80 / 68 105 / 105 125 / 125 150 / 150

380440V

9/9 12 / 12 18 / 18 25 / 18 32 / 32 40 / 40 50 / 40 65 / 65 80 / 65 105 / 105 125 / 125 150 / 150

500550V

7 / NA 9 / NA 13 / NA 17 / NA 24 / NA 29 / NA 38 / NA 60 / NA 60 / NA 85 / NA 90 / NA 120 / NA

600690V

5 / NA 7 / NA 9 / NA 9 / NA 15 / NA 19 / NA 26 / NA 38 / NA 44 / NA 64 / NA 72 / NA 103 / NA

Resistive Load AC-1 200380240V 440V

20 20 25 32 50 60 65 100 105 150 150 200 20 20 25 32 50 60 65 100 105 150 150 200

Rated Thermal Current (A)

20 20 25 32 50 60 65 100 105 150 150 200

Internal Auxilliary Contact Arrangement

2NO+2NC 2NO+2NC 2NO+2NC

Field I/O Software C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors

Internal Auxiliary Contact Ratings

Internal Auxiliary Contact Ratings - UL and CSA

Frame Size

( note 1 )

Rated Insulation Voltage (V)

690

NEMA ICS 5-2000 Ratings ( note 2 ) AC Ratings Designation

A600

DC Ratings Making VA

7200

Breaking VA

720

Designation

Q300

Making/Breaking VA

69

E5 to E7-xxx

Temperature Sensors Pushbuttons/ Lights Process Relays/ Timers Comm.

Notes: 1. E02(G) to E4(G) do not have internal auxiliary contact. 2. NEMA ICS 5-2000. For more information, refer to Control Circuit Contact Electrical Ratings, see page 17-77.

Internal Auxiliary Contact Ratings - IEC, JIS

Based on IEC 60974-4-1, EN 60947-4-1, JIS C 8201-4-1 Frame Size

( note 1 )

Rated Insulation Voltage (V)

Rated Thermal Current (A)

Making and Breaking Capacity (A) AC Voltage

120V

Amps

60 30 15 12

Minimum Operating Voltage and AC-15 DC-13 AC Voltage (Ind. load) DC Voltage (Ind. load) Current Rated Operational Current (A)

120V 220V 440V 600V 6 3 1.5 1.2 24V 48V 110V 220V 3 1.5 0.55 0.27 5VDC, 3mA

Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

E5 to E7-xxx

690

10

220V 440V 600V

Note 1: E02(G) to E4(G) do not have internal auxiliary contact.

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-7

Description

Fuji Odyssey Series 3N Contactors

Features

Equipped with 2 N.O. and 2 N.C. auxiliary contacts Chatter-free operation eliminates contact welding and coil burning SUPERMAGNET coil operates on either AC or DC voltage Wire Terminal Connection Type: Crimp ring Terminal (See page 17-55 for specs)

- 180 - 361A rating (AC3)

- Provides higher current and horsepower capabilities than SC-E series. Designed for reliable use in applications requiring constant switching, reduced coil energyconsumption, and increased horsepower capabilities. - Available in 154 mm and 169 mm frame widths - Use with Odyssey 3N series overload relays. - SUPERMAGNET for high operating reliability.

Agency approvals

Optional accessories

Replacement coils Terminal covers

UL listed file E42419, Standard UL508 cUL listed file E42419, Standard CSA C22.2 No. 14 CE: Meets LVD EN60947-4-1 SEMI F47-0200

Ecology

3NC4H0122

Low power consumption Recycled thermoplastic resin used for plastic parts. The names of materials are indicated on all major parts to facilitate recycling.

Odyssey 3N Series Contactors 180361 Amps

Rated AC-1 Thermal Current (A) [note 2] Rated Motor Capacity (HP) Part Number Fuji Type Price Coil Voltage 3-Phase 1-Phase Rated AC-3 Current (A) [note 1] SCCR Ratings (KA)

10 18

200 220 440 550 100 220 208V 240V 480V 600V 120V 240V 3NC4Q0E22 3NC4Q0122 3NC4Q0222 3NC4Q0Q22 3NC4Q0422 3NC4H0E22 3NC4H0122 3NC4H0222 3NC4H0Q22 3NC4H0422 3NC5F0E22 3NC5F0122 3NC5F0222 3NC5F0Q22 3NC5F0422 3NC5H0E22 3NC5H0122 3NC5H0222 3NC5H0Q22 3NC5H0422

<---> <---> 2425VAC / 24VDC 100127VAC / 100120VDC 200250VAC / 200240VDC 380450VAC 460575VAC 2425VAC / 24VDC 100127VAC / 100120VDC 200250VAC / 200240VDC 380450VAC 460575VAC 2425VAC / 24VDC 100127VAC / 100120VDC 200250VAC / 200240VDC 380450VAC 460575VAC 2425VAC / 24VDC 100127VAC / 100120VDC 200250VAC / 200240VDC 380450VAC 460575VAC 125 150 300 350 100 100 200 250 N/A 75 75 150 200 60 60 150 150

NO NC

SC-N8

<---> <---> <---> <---> <--->

180

260

SC-N10

<---> <---> <---> <---> <--->

221

260

SC-N11

<---> <---> <---> <---> <--->

285

350

SC-N12

<---> <---> <--->

361

450

Notes: 1. AC3 type loads consist of squirrel cage three-phase motors; occasional, limited jogging duty. 2. AC1 non-inductive or slightly inductive loads. Typically resistive loads (i.e. furnaces, ovens, etc.)

Contactor Coil Characteristics - AC Input

Power Consumption (VA) Part Number 3NC4Qxxxx, 3NC4Hxxxx 3NC5Fxxxx, 3NC5Hxxxx

Volume 14

Inrush

277 265

Sealed

5.4 5.9

Pick-up Voltage (V)

70-80 70-80

Operating Time (ms) Drop-out Voltage Coil ON to Coil OFF to (V) Contact ON Contact OFF

35-50 35-50 35-41 40-47 37-45 36-43

NOTE: This data is based on 100-120V SUPERMAGNET coil, tested at 120VAC, 60Hz.

e17-52

Motor Controls

1 - 80 0 - 633 - 0405

Frame Width (mm)

138 148

Quantity of Auxiliary Contacts

Fuji Odyssey Series 3N Contactors

Contactor Coil Characteristics - DC Input - 110VDC

Power Consumption (watts) Part Number 3NC4Qxxxx, 3NC4Hxxxx 3NC5Fxxxx, 3NC5Hxxxx Inrush

324 340

Company Information Systems Overview Programmable Controllers Field I/O Software C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights Process

COIL

Sealed

4.1 4.5

Pick-up Voltage (V)

77-88 77-88

Operating Time (ms) Drop-out Voltage Coil ON to Coil OFF to (V) Contact ON Contact OFF

28-44 28-44 35-41 40-47 37-45 36-43

NOTE: This data is based on 100-120V SUPERMAGNET coil, tested at 110VDC.

Contactor Coil Characteristics - DC Input - 24VDC

Power Consumption (watts) Part Number 3NC4Qxxxx, 3NC4Hxxxx Inrush

250

Sealed

5.9

Pick-up Voltage (V)

17-19.2

Operating Time (ms) Drop-out Voltage Coil ON to Coil OFF to (V) Contact ON Contact OFF

6-12 35-41 37-45

NOTE: This data is based on 100-120V SUPERMAGNET coil, tested at 110VDC.

Contactor Auxiliary Contact Ratings

NEMA ICS 5-2000 Ratings ( note 1 ) AC Ratings Designation

A600

DC Ratings Making VA

7200

Breaking VA

720

Designation

Q300

Making/Breaking VA

69

Note 1: NEMA ICS 5-2000. For more information, refer to Control Circuit Contact Electrical Ratings, page 16-75.

Contactor Terminal Tightening Torque Chart

Max. Cable Size Applicable Part Number Terminal for Ring Tightening Size Maximum Width Torque Terminal 3NC4Q0XXX M10 3NC4H0XXX M10 3NC5F0XXX M12 3NC5H0XXX

300MCM (152mm2) 300MCM (152mm2) 400MCM (203mm2) 36.5mm 36.5mm 44.5mm 133-177 in.lbs. 15-20 Nm 133-177 in.lbs. 15-20 Nm 310-399 in.lbs. 35-45 Nm

Contactor Life Expectancy Performance Data

Model 3NC4Qxxxx through 3NC5Fxxxx 3NC5Hxxxx Current Operating Life Expectancy (million operations) Capacity Cycles Make/Break per Hour Electrical Mechanical

12xle/10xle 12xle/10xle 1200 1200 1 0.5 5 5

Note: Rated operational current. Electrical life test: Conforming to IEC947-4-1, AC3. The endurance test complies with the requirements of international standard IEC, JIS and JEM.

IC-circuit

Note: Super Magnet Coils on 3NC4 and 3NC5 series contactors have internal surge suppression. See diagram below.

Optional accessories

Terminal covers

Prevent contact with electrified terminals.

Power supply AC or DC INPUT

Surge suppression circuit Voltage detector Rectier circuit

Closing signal circuit

Power switching circuit

Sealing signal circuit

Relays/ Timers Comm. Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

Odyssey Series Contactor Terminal Covers

Part Number SZ-N8T SZ-N8T SZ-N11T SZ-N11T Price

<---> <--->

Description

Applicable Contactors

Terminal cover for line or load 3NC4Qxxxx, 3NC4Hxxxx contactors side. Prevents contact with electrified contactor terminals. 3NC5Fxxxx, 3NC5Hxxxx contactors

Replacement contactor coils

Odyssey Series Replacement Contactor Coils

Part Number SZ-GSN8-100 SZ-GSN11-100 SZ-GSN8-24 SZ-GSN11-24 Price

<---> <---> <---> <--->

Applicable Contactors

3NC4Q0122, 3NC4H0122 3NC5F0122, 3NC5H0122 3NC4Q0E22, 3NC4H0E22 3NC5F0E22, 3NC5H0E22

Coil Voltage

100-127VAC/100-120VDC 100-127VAC/100-120VDC 24-25VAC/24VDC 24-25VAC/24VDC

Replacement coils are not available for coil codes Q and 4 (380450VAC and 460575VAC).

SZ-GSN11-100

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-53

Fuji Duo Series TK-E Overload Relays

TK-E series thermal overload relays with open-phase protective device

Features

This relay protects motor windings from burning due to overloads, locked rotor current, or open-phases Maintenance and inspection safety has been improved by employing a finger protection mechanism to cover exposed terminals (conforms to DIN 57106, VDE 0106 Teil 100) Isolated NO and NC contacts can be used with different potentials A high-precision scale for the current adjustment dial enables easy and exact current setting The operating status can be visually checked with ease The relays can be manually tripped. A trip-free mechanism is also provided Base unit can be added to enable separate mounting of the TK-E02, E2, and E3-xxx models CE

Company Information Systems Overview Programmable Controllers Field I/O Software C-more & other HMI Drives

TK-E02-900 TK-E3-5000

Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors

Standards

TK-E2-800

TK-E5-3600

Compliant

Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights

UL listed, file E44592, Standard UL 508 cUL listed, file E44592, CSA C22.2 No. 14 IEC 60947-4-1, EN60947-4-1 VDE 0660, JIS C 8201-4-1

TK-E Series Overloads

Amperage Frame Part Number Price Adjustment Width/ Range (A) Contactor TK-E02-15 TK-E02-20 TK-E02-24 TK-E02-30 TK-E02-36 TK-E02-54 TK-E02-72 TK-E02-96 TK-E02-120 TK-E02-145 TK-E02-220 TK-E02-260 TK-E02-340 TK-E02-420 TK-E02-600 TK-E02-800 TK-E02-900 TK-E02-1100 TK-E02-1300 TK-E02-1800 TK-E02-2200 TK-E02-2500

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> 0.1 - 0.15 0.13 - 0.2 0.15 - 0.24 0.2 - 0.3 0.24 - 0.36 0.36 - 0.54 0.48 - 0.72 0.64 - 0.96 0.8 - 1.2 0.95 - 1.45 1.4 - 2.2 1.7 - 2.6 2.2 - 3.4 2.8 - 4.2 4.0 - 6.0 5.0 - 8.0 6.0 - 9.0 7.0 - 11.0 9.0 - 13.0 12 - 18 16 - 22 20 - 25 53mm SC-E02(G) through SC-E05(G) For separate mounting, use with optional base unit SZ-HCE on page 17-26

TK-E Series Overloads (continued)

Amperage Frame Part Number Price Adjustment Width/ Range (A) Contactor TK-E2-600 TK-E2-800 TK-E2-900 TK-E2-1100 TK-E2-1300 TK-E2-1800 TK-E2-2600 TK-E2-3600 TK-E2-4200 TK-E2-5000 TK-E2-5400 TK-E3-1100 TK-E3-1300 TK-E3-1800 TK-E3-2600 TK-E3-3600 TK-E3-4000 TK-E3-5000 TK-E3-6500 TK-E3-6800 TK-E3-8000

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> 4-6 5-8 6-9 7 - 11 9 - 13 12 - 18 18 - 26 24 - 36 32 - 42 40 - 50 44 - 54 7 - 11 9 - 13 12 - 18 18 - 26 24 - 36 28 - 40 34 - 50 45 - 65 48 - 68 64 - 80 For separate mounting, use with optional base unit SZ-HEE on page 17-24 SC-E3(G) through SC-E4(G) 68mm SC-E1(G) through SC-E2S(G) For separate mounting, use with optional base unit SZ-HDE on page 17-26 54mm

TK-E6-6500

Process Relays/ Timers Comm.

TK-E Series Overloads (continued)

Amperage Frame Part Number Price Adjustment Width/ Range (A) Contactor TK-E5-2600 TK-E5-3600 TK-E5-4000 TK-E5-5000 TK-E5-6500 TK-E5-9500 TK-E5-10500 TK-E6-6500 TK-E6-8000 TK-E6-9500 TK-E6-12500 TK-E6-16000

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> 18 - 26 24 - 36 28 - 40 34 - 50 45 - 65 65 - 95 85 - 105 45 - 65 53 - 80 65 - 95 85 - 125 110 - 160

Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety

76.5mm SC-E5

100mm SC-E6 SC-E7

Appendix Product Index Part # Index

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-21

Fuji Duo Series Contactor and Overload Relay Selection Tables

A

SC-E Contactor

TK-E Overload Relay

100-240V Single Phase Motor (1/3 to 25 hp)

Step 2. Select an overload relay from page 17-21 based on motor full load current.

Check the data plate on the motor for the hp, volts and full-rated amps.

Step 1. Select a contactor from page 17-5 based on motor voltage and horsepower.

Motor HP 5 Volts 460 Amps 7.6 AMB 40C Encl TEFC Phase 3 Hz 60 Type P SF F 1.15

RPM 1725 DesignB

Motor horsepower

Insul Class Code K

Duty Cont

Motor voltage

Motor full-load rated amperage (FLA)

Three Phase Motors - Refer to tables on following page

Step 1. Select a SC-E contactor from Column A based on motor voltage, and horsepower.

Step 2. Select a TK-E overload relay from Column B to work with the SC-E contactor selected in Step 1. The motor full load current (FLA) should be within the adjustable current range of the overload relay.

Volume 14

e17-22

Motor Controls

1 - 80 0 - 633 - 0405

Fuji Duo Series Overload Relay Selection Tables

220-240V 3-Phase Motor (0.5 to 50 hp)1

Motor Rating Motor Full Load Motor HP Amperage (FLA) 2

1/2 3/4 1 1-1/2 2 3 5 7-1/2 10 15 20 25 30 40 50 2.2 3.5 4.2 6 6.8 9.6 15.2 22 28 42 54 68 80 104 130 SC-E03-xxxx SC-E04-xxxx SC-E05-xxxx SC-E1-xxxx SC-E2-xxxx SC-E3-xxxx SC-E4-xxxx SC-E5-xxxx SC-E6-xxxx SC-E7-xxxx SC-E02-xxxx

Company Information Systems Overview Programmable Controllers Field I/O Software

Overload Relay Selection for 220240V 3-phase motors

A Contactor B Overload Relay Part Number

TK-E02-260 TK-E02-420 TK-E02-600 TK-E02-800 TK-E02-900 TK-E02-1300 TK-E02-1800 TK-E02-2500 TK-E2-3600 TK-E2-4200 TK-E3-6500 TK-E3-6800 TK-E5-9500 TK-E6-12500 TK-E6-16000

Adjustable Current Range

1.7 to 2.6 Amps 2.8 to 4.2 Amps 4 to 6 Amps 5 to 8 Amps 6 to 9 Amps 9 to 13 Amps 12 to 18 Amps 20 to 25 Amps 24 to 36 Amps 32 to 42 Amps 45 to 65 Amps 48 to 68 Amps 65 to 95 Amps 85 to 125 Amps 110 to 160 Amps

C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights Process Relays/ Timers Comm. Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

Note 1: For 220-240 V three-phase motors up to 150 hp refer to the Fuji Odyssey series. Note 2: Per NEC 2005 table 430.250

440-480V 3-Phase Motor (0.5 to 100 hp)1

Overload Relay Selection for 440480V 3-phase motors

Motor Rating Motor Full Load Motor HP Amperage (FLA) 2

1/2 3/4 1 1-1/2 2 3 5 7 1/2 10 15 20 25 30 40 50 60 75 100 1.1 1.6 2.1 3.0 3.4 4.8 7.6 11 14 21 27 34 40 52 65 77 96 124

A Contactor

SC-E02-xxxx SC-E02-xxxx SC-E02-xxxx SC-E02-xxxx SC-E02-xxxx SC-E02-xxxx SC-E02-xxxx SC-E03-xxxx SC-E04-xxxx SC-E05-xxxx SC-E1-xxxx SC-E1-xxxx SC-E2-xxxx SC-E3-xxxx SC-E4-xxxx SC-E5-xxxx SC-E6-xxxx SC-E7-xxxx

B Overload Relay Part Number

TK-E02-145 TK-E02-220 TK-E02-260 TK-E02-420 TK-E02-420 TK-E02-600 TK-E02-900 TK-E02-1300 TK-E02-1800 TK-E02-2500 TK-E2-3600 TK-E2-4200 TK-E2-4200 TK-E3-6500 TK-E3-6800 TK-E5-9500 TK-E6-12500 TK-E6-16000

Adjustable Current Range

0.95 to 1.45 Amps 1.4 to 2.2 Amps 1.7 to 2.6 Amps 2.8 to 4.2 Amps 2.8 to 4.2 Amps 4 to 6 Amps 6 to 9 Amps 9 to 13 Amps 12 to 18 Amps 20 to 25 Amps 24 to 36 Amps 32 to 42 Amps 32 to 42 Amps 45 to 65 Amps 48 to 68 Amps 65 to 95 Amps 85 to 125 Amps 110 to 160 Amps

Note 1: For 440-480 V three-phase motors up to 300 hp refer to the Fuji Odyssey series. Note 2: Per NEC 2005 table 430.250

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-23

Fuji Duo Series Manual Motor Starters

BM3RHB-xxx Specifications

General Specifications: 45 mm Frame Width - BM3RHB-XXX Series

Adjustable Current Range UL/CSA 3-Phase HP Rating1 Part Number Price le: Min.-Max. (A)

0.1-0.16 0.16-0.25 0.25-0.4 0.4-0.63 0.63-1 1-1.6 1.6-2.5 2.5-4 4-6.3 6.3-10 9-13 11-16 14-20 19-25 24-32 1/2 3/4 1 2 3 3 5 7-1/2 10 1/2 3/4 1-1/2 3 3 5 5 7-1/2 10 3/4 1 2 3 5 7-1/2 10 10 15 20

Instant- UL/CSA Short Circuit aneous Current Rating (kA)2 Trip 200220440550208VAC 240VAC 480VAC 600VAC Current (A) 240VAC 480VAC 600VAC

2.1 In accordance with motor full-load current 5.2 Rated to motor full-load amperage 8.2 1/2 3/4 1-1/2 3 5 7-1/2 10 10 15 20 30 13 20.8 32.5 52 81.9 130 169 208 260 325 416 3.3 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10

Max. Listed Branch Circuit Protection Fuse or MCCB (A)2

500 500 500 500 500 500 500 500 500 500 500 500 500 500 500

BM3RHB-P16 BM3RHB-P25 BM3RHB-P40 BM3RHB-P63 BM3RHB-001 BM3RHB-1P6 BM3RHB-2P5 BM3RHB-004 BM3RHB-6P3 BM3RHB-010 BM3RHB-013 BM3RHB-016 BM3RHB-020 BM3RHB-025 BM3RHB-032

<---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <---> <--->

Note 1: BM3RHB-xxx are cUL listed as HP rated motor controllers.

Note 2: BM3RHB-xxx are cUL listed for group installation per NEC430-53(C).

General Specifications: 45 mm Frame Width - BM3RHB-XXX Series - continued

Features Number of Poles Handle Type Rated Current le (A) Rated Operational Voltage Ue (V) Rated Frequency (Hz) Rated insulation Voltage Ui (V) Rated Impulse Withstand Voltage Uimp (kV) IEC 60947-2 Circuit Breaker Utilization Category IEC 60947-4-1 Motor Starter Trip Class IEC 60947-4-1 Instantaneous Trip Characteristic Power Loss (total of 3-pole) Mechanical Durability (operations) Electrical Durability (operations) Max. Operations per Hour (motor start-up) Phase-loss Protection Trip Indicator Test Trip Function Dimensions (mm) WxHxD Weight (oz/g) Auxiliary Contact Block Alarm Contact Block Auxiliary and Alarm Contact Block Optional Short-Circuit Alarm Contact Block Accessories Shunt Trip Device Undervoltage Trip Device External Operating Handle Standards & Agency Approvals

Volume 14

Adjustable thermal-magnetic trip type 3 Rotary 0.16 to 32 200 to 690 50/60 690 6 Cat. A AC-3 10 13 x le max. 7W: In=0.16 to 25A 8.5W: In=32A 70,000: In=32A 70,000: In=32A 100,000: In=0.16 to 25A 100,000: In=0.16 to 25A 25 Provided Provided Provided 45x90x79 13.05 / 370 Yes Yes Yes Yes Yes Yes Yes IEC 60947-1, 60947-2, 60947-4-1, UL 508 file E163944, CSA C22.2 No.14 file 20479

e17-30

Motor Controls

1 - 80 0 - 633 - 0405

BM3VHB-xxx Specifications

Fuji Duo Series Manual Motor Starters

General Specifications: 55 mm Frame Width - BM3VHB-XXX Series

Adjustable Current Range UL/CSA 3-Phase hp Rating1 Part Number Price le: Min.-Max. (A)

6.3-10 9-13 11-16 14-20 19-25 24-32 28-40 35-50 45-63

Company Information Systems Overview Programmable Controllers

Instant- UL/CSA Short Circuit aneous Current Rating (kA)2 Trip 200220440550208VAC 240VAC 480VAC 600VAC Current (A) 240VAC 480VAC 600VAC

2 3 3 5 7-1/2 10 10 15 20 3 3 5 5 7-1/2 10 10 15 20 5 7-1/2 10 10 15 20 30 30 40 7-1/2 10 10 15 20 30 30 40 60 130 169 208 260 325 416 520 650 819 100 100 100 100 100 100 100 100 100 50 50 50 50 50 50 50 50 50 10 10 10 10 10 10 10 10 10

Max. Listed Branch Circuit Protection Fuse or MCCB (A)2

600 600 600 600 600 600 600 600 600

Field I/O Software C-more & other HMI Drives Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights

BM3VHB-010 BM3VHB-013 BM3VHB-016 BM3VHB-020 BM3VHB-025 BM3VHB-032 BM3VHB-040 BM3VHB-050 BM3VHB-063

<---> <---> <---> <---> <---> <---> <---> <---> <--->

Note 1: BM3VHB-xxx are cUL listed as HP rated motor controllers.

Note 2: BM3VHB-xxx are cUL listed for group installation per NEC430-53(C).

General Specifications: 55 mm Frame Width - BM3VHB-XXX Series - continued

Features Number of Poles Handle Type Rated Current le (A) Rated Operational Voltage Ue (V) Rated Frequency (Hz) Rated Insulation Voltage Ui (V) Rated Impulse Withstand Voltage Uimp (kV) IEC 60947-2 Circuit Breaker Utilization Category IEC 60947-4-1 Motor Starter Trip Class IEC 60947-4-1 Instantaneous Trip Characteristic Power Loss (total of 3-pole) Mechanical Durability (operations) Electrical Durability (operations) Max. Operations per Hour (motor start-up) Phase-Loss Protection Trip Indicator Test Trip Function Dimensions (mm) WxHxD Weight (oz/g) Auxiliary Contact Block Alarm Contact Block Auxiliary and Alarm Contact Block Optional Short-Circuit Alarm Contact Block Accessories Shunt Trip Device Undervoltage Trip Device External Operating Handle Standards & Agency Approvals

Adjustable thermal-magnetic trip type 3 Rotary 10 to 63 200 to 690 50/60 1,000 8 Cat. A AC-3 10 13 x le max. 11W: In = 10 to 32A 50,000 25,000 25 Provided Provided Provided 55x110x96 27.51 / 780 Yes Yes Yes Yes Yes Yes Yes IEC 60947-1, 60947-2, 60947-4-1, UL 508 file E163944, CSA C22.2 No.14 file 20479 15W: In = 40 to 50A 17W: In = 63A

Process Relays/ Timers Comm. Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-31

Fuji Duo Series Manual Motor Starters

The MMS can be mounted to a 35 mm DIN rail. Secure the rail with screws at mounting pitch of less than 400 mm for the BM3R type and less than 300 mm for the BM3V type. Use a 15 mm-high DIN rail, such as our DN-R35HS1, which conforms to EN-50022 and IEC715. Applicable rail:

DIN-rail mounting

Environmental Specifications

Ambient Temperature Humidity Altitude Atmosphere Vibration Shock

Operating: -5 to +55C Storage: -40 to +65C 45 to 85%RH 2000m or lower No excessive dust, smoke, corrosive gases, flammable gases, steam or salt. 10 to 55Hz 15m/s2 50m/s2 No abnormal shock or vibration.

No sudden temperature changes resulting in condensation or icing.

The standard DIN rail mounting direction is horizontal. When using the MMS on vertically mounted DIN rail, use end clamps. The separately sold push-in lug (BZ0SET) is required for screw mounting the BM3R frame. The BM3V frame can be screw mounted directly to the panel.

Mounting

15mm

Wiring Specifications

Wire Size and Tightening Torque

Type Solid Wire (mm) Stranded Wire (mm2) AWG Single-wire 2-wire Single-wire 2-wire BM3RHB-XXX BM3VHB-XXX BZ0 Accessories

1.6 to 2.6 dia. 1 to 10 1 to 6 18 to 8 18 to 10 Approx.10 Pan head screw (PZ2) M4 2 1.6 to 2.6 dia. 1 to 25 1 to 16 18 to 4 18 to 4 Approx.13 Pan head screw (PZ2) M6 4 1 to 1.6 dia. 0.5 to 2.5 0.5 to 2.5 18 to 14 18 to 14 Approx.10 Pan head screw (PZ2) M3.5 0.8

Screw mounting

Removing

Sheath Stripping Length (mm) Terminal Screw Tightening Torque (Nm)

35mm wide rail

Note: There is no need for a crimp terminal or any other terminal on the end of the connection wire.

1

Snap

1

5mm or less dia.

Arc Space Requirements

Arc Space Requirements

Part Number

M4

Push-in lug BZ0SET

BM3RHB-xxx

M4

BM3VHB-xxx

Rated operational voltage Ue (V)

Minimum distance to grounded metal (mm) A,B 15 40 15 40 C,D 30 50 40 50

BM3RHB-XXX BM3VHB-XXX

Up to 500 Up to 690 Up to 500 Up to 690

M4

M4

Mounting angle

180 180

30 90

Wiring

D Grounded metal

When frames are mounted side-by-side, operating conditions such as a high ambient temperature or using the maximum setting for continuous carrying current may cause slight changes in operating characteristics due to temperature rises. Under such conditions, it is recommended that the frames be separated by at least 5mm.

While pressing the wire with a screwdriver, tighten the screw to the specified tightening torque.

Volume 14

e17-32

Motor Controls

1 - 80 0 - 633 - 0405

Fuji Duo Series Combination Starter Selection Table - 45 mm

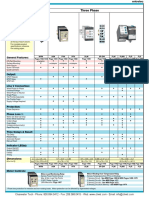

Combination Starter Selection Table - 45 mm Three Phase Motor

220-240 Volt Motor Horsepower (hp) See Note 1 below Motor FullLoad Amperage (FLA) See Note 4 below

2.2 3.2 6 9.6 15.2 15.2 22 28

Company Information Systems Overview Programmable Controllers Field I/O Software C-more & other HMI Drives

Use this selection table to select 45 mm frame width (A) Manual Motor Starter, (B) Contactor, (C) Link Module, and (D) Base Plate for a Combination Starter

A

Manual Motor Starter Adjustable Current Range (A) Manual Motor Starter See Note 2 below for UL Type E applications.

BM3RHB-P16 BM3RHB-P25 BM3RHB-P40 BM3RHB-P63 BM3RHB-001 BM3RHB-1P6 BM3RHB-2P5 BM3RHB-004 BM3RHB-6P3 BM3RHB-010 BM3RHB-013 BM3RHB-016 BM3RHB-020 BM3RHB-025 BM3RHB-032

B

Contactor

440-480 Volt Motor Horsepower (hp) See Note 1 below Motor FullLoad Amperage (FLA) See Note 4 below

1.6 2.1 3.4 4.8 7.6 11 14 14 21 27

The contactor part number Link needs the coil Module voltage suffix. See Note 3 below.

SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E02-110VAC SC-E02G-24VDC SC-E03-110VAC SC-E03G-24VDC SC-E04-110VAC SC-E04G-24VDC SC-E04-110VAC SC-E04G-24VDC SC-E05-110VAC SC-E05G-24VDC SC-E1-110VAC SC-E1G-24VDC BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE22AA BZ0LRE22GA BZ0LRE32AA BZ0LRE32GA

Base Plate

SCCR at 480Y/277 VAC (kA) type F coordination

Soft Starters Motors & Gearbox Steppers/ Servos Motor Controls Proximity Sensors Photo Sensors Limit Switches Encoders Current Sensors Pressure Sensors Temperature Sensors Pushbuttons/ Lights Process Relays/ Timers Comm. Terminal Blocks & Wiring Power Circuit Protection Enclosures Tools Pneumatics Safety Appendix Product Index Part # Index

0.5 0.75 1.5 3 5 5 7.5 10

0.75 1 2 3 5 7.5 10 10 15 20

0.1 to 0.16 0.16 to 0.25 0.25 to 0.4 0.4 to 0.63 0.63 to 1.0 1.0 to 1.6 1.6 to 2.5 2.5 to 4.0 4.0 to 6.3 6.3 to 10 9 to 13 11 to 16 14 to 20 19 to 25 24 to 32

65 65 65 65 65 65 65 BZ0BPRE22A 65 65 65 65 65 65 50 BZ0BPRE32A 50

Note 1: When a horsepower rating is listed on two rows, the motor full-load amperage must be known so you can select the MMS with the best adjustable current range for your application. For example, if you have a 230V, 5 hp, 15.2A motor, you can select a MMS with either a 11-16A range or a 14-20A range. Consult the motor data plate or motor manufacturer. Note 2: When using BM3RHB-xxx MMS in a UL Type E application, you must also use part numbers BZ0TKUAB (short-circuit contact block) and BZ0TCRE (line side terminal cover). Note 3: For AC coil voltages other than 110VAC, substitute the 110VAC in the part number with 220VAC for 220/240VAC coils or 24VAC for 24VAC coils. For example, if the table lists a SC-E02-110VAC contactor for your application and you need a contactor with a 220VAC coil, use contactor SC-E02-220VAC. Note 4: Per NEC 2005 Table 430.250

Volume 14

w w w . a u t o m a t i o n d i r e c t . c o m / m o t o r- c o n t r o l s

Motor Controls

e17-45

Fuji Duo Series Combination Starter Selection Table - 55 mm

Use this selection table to select 55 mm frame width (A) Manual Motor Starter, (B) Contactor, (C) Link Module, and (D) Base Plate for a Combination Starter

Combination Starter Selection Table - 55 mm Three Phase Motor

220-240 Volt Motor FullMotor horsepower Load Amperage (hp) (FLA) See Note 1 See Note 4 below below 440-480 Volt Motor FullMotor Horsepower Load Amperage (hp) (FLA) See Note 1 See Note 4 below below Manual Motor Starter Adjustable Current Range (A)

A

Manual Motor Starter

B

Contactor

The contactor part number Link See Note 2 needs the coil Module below for voltage suffix. UL Type E See Note 3 applicabelow. tions.

BM3VHB-010 SC-E1-110VAC SC-E1G-24VDC SC-E1-110VAC SC-E1G-24VDC SC-E1-110VAC SC-E1G-24VDC SC-E1-110VAC SC-E1G-24VDC SC-E1-110VAC SC-E1G-24VDC SC-E1-110VAC SC-E1G-24VDC SC-E2-110VAC SC-E2G-24VDC SC-E2S-110VAC SC-E2SG-24VDC SC-E3-110VAC SC-E3G-24VDC BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE51AA BZ0LVE51GA BZ0LVE65AA BZ0LVE65GA

SCCR at 480Y/277 VAC (kA) Base Plate type F coordination

9.6

7.6

6.3 to 10

65

9.6

7.5

11

9 to 13

BM3VHB-013

65

15.2

10

14

11 to 16

BM3VHB-016

65

15.2

10

14

14 to 20

BM3VHB-020

65 BZ0BPVE51A 65

7.5

22

15

21

19 to 25

BM3VHB-025

10

28

20

27

24 to 32

BM3VHB-032

65

10

28

30

40

28 to 40

BM3VHB-040

65

15

42

30

40

35 to 50

BM3VHB-050

65

20

54

40

52

45 to 63

BM3VHB-063

BZ0BPVE65A

65

Note 1: When a horsepower rating is listed on two rows, the motor full-load amperage must be known so you can select the MMS with the best adjustable current range for your application. For example, if you have a 230V, 10 hp, 28A motor, you can select a MMS with either a 24-32A range or a 28-40A range. Consult the motor data plate or motor manufacturer. Note 2: When using BM3VHB-xxx MMS in a UL Type E application, you must also use part number BZ0TKUAB (short-circuit contact block). Note 3: For AC coil voltages other than 110VAC, substitute the 110VAC in the part number with 220VAC for 220/240VAC coils or 24VAC for 24VAC coils. For example, if the table lists a SC-E1-110VAC contactor for your application and you need a contactor with a 220VAC coil, use contactor SC-E1-220VAC. Note 4: Per NEC 2005 Table 430.250

Volume 14

e17-46

Motor Controls

1 - 80 0 - 633 - 0405

Você também pode gostar

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Nota: 2.5 de 5 estrelas2.5/5 (3)

- Allen Bradley - PowerFlex 400Documento28 páginasAllen Bradley - PowerFlex 400Marcos José Nuñez YsseleAinda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Ainda não há avaliações

- Sivacon 4RB PowerQualitySolution Pi enDocumento56 páginasSivacon 4RB PowerQualitySolution Pi enkiderilke100% (1)

- Catálogo Técnico Transferencias OTMDocumento116 páginasCatálogo Técnico Transferencias OTMCarolina Alicia Bravo VillegasAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- E Bamocar d3Documento46 páginasE Bamocar d3oscarhereAinda não há avaliações

- MO Contactors and RTO Thermal Overload Relays1Documento28 páginasMO Contactors and RTO Thermal Overload Relays1Ramavtar ChouhanAinda não há avaliações

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsNo EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsNota: 3.5 de 5 estrelas3.5/5 (6)

- Switch On To The Best: Cam Operated Rotary SwitchesDocumento32 páginasSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Bulletin 100S-C/104S-C Safety Contactors Bulletin 700S-CF Safety Control RelaysDocumento20 páginasBulletin 100S-C/104S-C Safety Contactors Bulletin 700S-CF Safety Control RelaysMarco MendozaAinda não há avaliações

- ABB ACS550 Flyer - VariadoresDocumento2 páginasABB ACS550 Flyer - VariadoresirojoshiAinda não há avaliações

- Motor Protection and Control - Catalogue - 2012Documento392 páginasMotor Protection and Control - Catalogue - 2012Jigyesh SharmaAinda não há avaliações

- LVC Pricelist Wef 1st July 2014Documento104 páginasLVC Pricelist Wef 1st July 2014manoj031Ainda não há avaliações

- VFD DocumentsDocumento592 páginasVFD DocumentsLe Anh Dang50% (2)

- 22c Qs001 - en P Power Flex 400Documento28 páginas22c Qs001 - en P Power Flex 400dicicaAinda não há avaliações

- 22b qs001 - Mu PDocumento130 páginas22b qs001 - Mu PJose Butron SalasAinda não há avaliações

- Catalog: General Purpose Plug-In RelaysDocumento12 páginasCatalog: General Purpose Plug-In Relaysmicaziv4786Ainda não há avaliações

- Baldor Section20 StartersDocumento6 páginasBaldor Section20 StartersRichard MorenoAinda não há avaliações

- Advantage NEMADocumento28 páginasAdvantage NEMAJorge Sebastian Cifuentes UnibazoAinda não há avaliações

- Soft Starter Carlo Gavazzi Bse 4012bDocumento4 páginasSoft Starter Carlo Gavazzi Bse 4012bBranko MedanAinda não há avaliações

- Sharp LC 37a37mDocumento38 páginasSharp LC 37a37mnikola1660100% (3)

- MIKI Spring Actuated BrakesDocumento8 páginasMIKI Spring Actuated Brakesaiyubi2Ainda não há avaliações

- C DilmDocumento61 páginasC DilmotavioalcaldeAinda não há avaliações

- STR-K760P v1.1Documento44 páginasSTR-K760P v1.1danielradu27Ainda não há avaliações

- Vacuum ContactorDocumento4 páginasVacuum ContactorArun Kumar0% (1)

- Overload Relay CatalogueDocumento48 páginasOverload Relay Cataloguemech_abhi100% (1)

- Powerflex 70 Quick Start GuideDocumento18 páginasPowerflex 70 Quick Start GuideMichael AlexanderAinda não há avaliações

- Entrelec Voltage Phase Monitors PDFDocumento26 páginasEntrelec Voltage Phase Monitors PDFnew2trackAinda não há avaliações

- Motor Protection DevicesDocumento35 páginasMotor Protection DevicesAli AhmadAinda não há avaliações

- BCM184E - Technical Data SheetDocumento8 páginasBCM184E - Technical Data Sheet3efooAinda não há avaliações

- G 1 MG52A202 PDFDocumento192 páginasG 1 MG52A202 PDFCaspar HeerkensAinda não há avaliações

- Gen 12MW PDFDocumento11 páginasGen 12MW PDFTesta Bonaventura Vincenzo100% (1)

- f3n2c PDFDocumento6 páginasf3n2c PDFEduardo HuaytaAinda não há avaliações

- Coduri de Eroare La VFD-ELDocumento82 páginasCoduri de Eroare La VFD-ELr_corneliu1710Ainda não há avaliações

- JJ.J3C v2Documento2 páginasJJ.J3C v2GOLIANDROAinda não há avaliações

- Ge - Mpact Mpro Acb (400a - 4000a)Documento48 páginasGe - Mpact Mpro Acb (400a - 4000a)Sugumaran100% (1)

- Susol MCCBDocumento18 páginasSusol MCCBMauro VanegasAinda não há avaliações

- Eiki LC-XT3Documento110 páginasEiki LC-XT3Dimas Arenas GonzálezAinda não há avaliações

- METALMECDocumento20 páginasMETALMECClayton PedroAinda não há avaliações

- P1500PB (4012 46tag2a)Documento4 páginasP1500PB (4012 46tag2a)astwan81Ainda não há avaliações

- Retrofit Masterpact M PlugnplayDocumento21 páginasRetrofit Masterpact M Plugnplaynot bookAinda não há avaliações

- ABB Manual Motor ProtectorsDocumento27 páginasABB Manual Motor ProtectorsMaged MounirAinda não há avaliações

- Eaton Series G Circuit BreakerDocumento59 páginasEaton Series G Circuit BreakerWilliam PinzonAinda não há avaliações

- SMD ManualDocumento8 páginasSMD ManualJose K ManadanAinda não há avaliações

- Thiet Bi Bao Ve He Thong DienDocumento215 páginasThiet Bi Bao Ve He Thong Dienngocvqpecc4Ainda não há avaliações

- EOCR EnglishDocumento38 páginasEOCR Englishjb10Ainda não há avaliações

- Automatic Transfer SwitchesDocumento20 páginasAutomatic Transfer SwitchesgianmantAinda não há avaliações

- Price Schedule - Low Voltage ComponentsDocumento104 páginasPrice Schedule - Low Voltage ComponentsLuka YannamAinda não há avaliações

- AB - Contactores NEMA ACDocumento36 páginasAB - Contactores NEMA ACGabriel VerdugoAinda não há avaliações

- Ws5 9eDocumento48 páginasWs5 9ekrukinAinda não há avaliações

- Panel Accessories Catalogue R1Documento184 páginasPanel Accessories Catalogue R1supermannon0% (1)

- BCI164ADocumento8 páginasBCI164A3efooAinda não há avaliações

- HAT Series Air Circuit Breaker Hyundai ElectricDocumento67 páginasHAT Series Air Circuit Breaker Hyundai Electricthanhlangdai67% (6)

- 10 A 8 DDDocumento7 páginas10 A 8 DDElectromateAinda não há avaliações

- BAMOCAR Motor ControllerDocumento46 páginasBAMOCAR Motor ControllerShehzer100% (1)

- Solenoid Valves CETOP 2: The Drive & Control CompanyDocumento44 páginasSolenoid Valves CETOP 2: The Drive & Control CompanymasakpAinda não há avaliações

- Ford Timing Set Installation Instructions: Thrust BearingsDocumento4 páginasFord Timing Set Installation Instructions: Thrust BearingsmasakpAinda não há avaliações

- 4WE10 Series - Tech SpecificationsDocumento6 páginas4WE10 Series - Tech Specificationsargo_arjieantoAinda não há avaliações

- 12 Products Catalogue enDocumento12 páginas12 Products Catalogue enmasakpAinda não há avaliações

- 350z Manual Transmission ProblemsDocumento10 páginas350z Manual Transmission ProblemsmasakpAinda não há avaliações

- Denso PDFDocumento12 páginasDenso PDFbruttus139Ainda não há avaliações

- 2004 PDFDocumento565 páginas2004 PDFNICANOR KANA GAMARRAAinda não há avaliações

- Points Eliminator: Conversion Part No. 2030Documento2 páginasPoints Eliminator: Conversion Part No. 2030masakpAinda não há avaliações

- 4G93 PDFDocumento130 páginas4G93 PDFMarco Diaz100% (2)

- Parts and Service Manual: For KPP15055Documento111 páginasParts and Service Manual: For KPP15055masakpAinda não há avaliações

- 1N60 PDFDocumento8 páginas1N60 PDFmasakpAinda não há avaliações

- 7 - Hydraulic System Troubleshooting PDFDocumento6 páginas7 - Hydraulic System Troubleshooting PDFDIPPOSAinda não há avaliações

- 24 Volt ManualDocumento13 páginas24 Volt ManualCirilo JuniorAinda não há avaliações

- 5a 1Documento55 páginas5a 1Сергей ЕсиповAinda não há avaliações

- LG Flatron CRT TV ManualDocumento3 páginasLG Flatron CRT TV Manualmasakp50% (2)

- 4jj1tybw01 Spec Sheet PDFDocumento10 páginas4jj1tybw01 Spec Sheet PDFcpaolinodAinda não há avaliações

- Ultrahigh-Speed Switching Applications: Package Dimensions FeaturesDocumento4 páginasUltrahigh-Speed Switching Applications: Package Dimensions FeaturesDurah CAinda não há avaliações

- Isahaya Electronics CorporationDocumento5 páginasIsahaya Electronics Corporationaldo_suviAinda não há avaliações

- 7805Documento25 páginas7805DraKo BaracunataAinda não há avaliações

- 2SJ137Documento5 páginas2SJ137masakpAinda não há avaliações

- SMD - Resistors: Pulse Withstanding Thick Film Chip ResistorDocumento9 páginasSMD - Resistors: Pulse Withstanding Thick Film Chip ResistormasakpAinda não há avaliações

- Mazda Bongo Diesel Pump PDF: Download HereDocumento4 páginasMazda Bongo Diesel Pump PDF: Download HeremasakpAinda não há avaliações

- Surface Mount Resistor Marking: VishayDocumento1 páginaSurface Mount Resistor Marking: VishaymasakpAinda não há avaliações

- Relacion TV LG A ChasisDocumento12 páginasRelacion TV LG A ChasisvideosonAinda não há avaliações

- Data Sheets 319 en (A08)Documento2 páginasData Sheets 319 en (A08)masakpAinda não há avaliações

- Mercedes 722.9 TransmissionDocumento56 páginasMercedes 722.9 TransmissionAlex Maceira Graterol100% (13)

- D Regulators enDocumento52 páginasD Regulators enmasakpAinda não há avaliações

- Idle RelearnDocumento2 páginasIdle RelearnSutiknoAinda não há avaliações

- How To Fix A Mazda Bongo Faulty Fuel Gauge PDFDocumento1 páginaHow To Fix A Mazda Bongo Faulty Fuel Gauge PDFmasakpAinda não há avaliações

- Toyota 4EFE - Correa de Distribucion PDFDocumento11 páginasToyota 4EFE - Correa de Distribucion PDFAlvaro Garcia100% (4)

- System Administration ch01Documento15 páginasSystem Administration ch01api-247871582Ainda não há avaliações

- Statistics and Probability Course Syllabus (2023) - SignedDocumento3 páginasStatistics and Probability Course Syllabus (2023) - SignedDarence Fujihoshi De AngelAinda não há avaliações

- Norm ANSI PDFDocumento1 páginaNorm ANSI PDFAbdul Quddus Mat IsaAinda não há avaliações

- Green ChemistryDocumento17 páginasGreen ChemistryAaditya RamanAinda não há avaliações

- Second Language Learning in The Classroom PDFDocumento2 páginasSecond Language Learning in The Classroom PDFThanh Phương VõAinda não há avaliações

- Outbound Idocs Code Error Event Severity Sap MeaningDocumento2 páginasOutbound Idocs Code Error Event Severity Sap MeaningSummit YerawarAinda não há avaliações

- Syllabus: Cambridge IGCSE (9-1) Art & Design 0989Documento27 páginasSyllabus: Cambridge IGCSE (9-1) Art & Design 0989Jashan LoombaAinda não há avaliações

- Lesson Tasks: Lesson Plan: Addition and Subtraction To 20Documento2 páginasLesson Tasks: Lesson Plan: Addition and Subtraction To 20Марина СтанојевићAinda não há avaliações

- Embraer ERJ-170: Power PlantDocumento5 páginasEmbraer ERJ-170: Power Plantபென்ஸிஹர்Ainda não há avaliações

- An Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud ComputingDocumento18 páginasAn Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud Computing0dayAinda não há avaliações

- Couvade SyndromeDocumento5 páginasCouvade SyndromejudssalangsangAinda não há avaliações

- The Hot Aishwarya Rai Wedding and Her Life.20130105.040216Documento2 páginasThe Hot Aishwarya Rai Wedding and Her Life.20130105.040216anon_501746111100% (1)

- Microcontrollers DSPs S10Documento16 páginasMicrocontrollers DSPs S10Suom YnonaAinda não há avaliações

- Math 10 Week 3-4Documento2 páginasMath 10 Week 3-4Rustom Torio QuilloyAinda não há avaliações

- Myth or Fact-Worksheet 1Documento1 páginaMyth or Fact-Worksheet 1Zahraa LotfyAinda não há avaliações

- Kaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeDocumento47 páginasKaibigan, Kabarkada, Kaeskwela: Pinoy Friendships and School LifeGerald M. LlanesAinda não há avaliações

- Revised Exam PEDocumento3 páginasRevised Exam PEJohn Denver De la Cruz0% (1)

- The Politics of GenreDocumento21 páginasThe Politics of GenreArunabha ChaudhuriAinda não há avaliações

- Def - Pemf Chronic Low Back PainDocumento17 páginasDef - Pemf Chronic Low Back PainFisaudeAinda não há avaliações

- Objective-C Succinctly PDFDocumento110 páginasObjective-C Succinctly PDFTKKAinda não há avaliações

- Dadm Assesment #2: Akshat BansalDocumento24 páginasDadm Assesment #2: Akshat BansalAkshatAinda não há avaliações

- Industrial Automation Using PLCDocumento29 páginasIndustrial Automation Using PLCAditya JagannathanAinda não há avaliações

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDocumento27 páginasArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219Ainda não há avaliações

- Paper 11-ICOSubmittedDocumento10 páginasPaper 11-ICOSubmittedNhat Tan MaiAinda não há avaliações

- What Role Does Imagination Play in Producing Knowledge About The WorldDocumento1 páginaWhat Role Does Imagination Play in Producing Knowledge About The WorldNathanael Samuel KuruvillaAinda não há avaliações

- KPR College of Arts Science and Research: Marketing ManagementDocumento127 páginasKPR College of Arts Science and Research: Marketing ManagementSekar M KPRCAS-CommerceAinda não há avaliações

- ShotcreteDocumento7 páginasShotcreteafuhcivAinda não há avaliações

- Notes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFDocumento3 páginasNotes 3 Mineral Dressing Notes by Prof. SBS Tekam PDFNikhil SinghAinda não há avaliações

- JurnalDocumento12 páginasJurnalSandy Ronny PurbaAinda não há avaliações

- The Two Diode Bipolar Junction Transistor ModelDocumento3 páginasThe Two Diode Bipolar Junction Transistor ModelAlbertoAinda não há avaliações