Escolar Documentos

Profissional Documentos

Cultura Documentos

110PAX4 Maint Manual

Enviado por

metrobsDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

110PAX4 Maint Manual

Enviado por

metrobsDireitos autorais:

Formatos disponíveis

Zebra

110PAX4

Print Engine

Maintenance Manual

Customer Order # 57515L-001

Manufacturer Part # 57515L-001 Rev. 1

2005 ZIH Corp.

The copyrights in this manual and the label print engine described therein are

owned by Zebra Technologies Corporation. Unauthorized reproduction of this

manual or the software in the label print engine may result in imprisonment of up

to one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be

subject to civil liability.

This product may contain ZPL

, ZPL II

, and ZebraLink programs; Element

Energy Equalizer

Circuit; E3

; and AGFA fonts.

Software ZIH Corp. All rights reserved worldwide.

ZebraLink and all product names and numbers are trademarks, and Zebra, the

Zebra logo, ZPL, ZPL II, Element Energy Equalizer Circuit, and E3 Circuit are

registered trademarks of ZIH Corp. All rights reserved worldwide.

CG Triumvirate is a trademark of AGFA Monotype Corporation. All rights

reserved worldwide. CG Triumvirate(tm) font AGFA Monotype Corporation.

Intellifont

portion AGFA Monotype Corporation. All rights reserved

worldwide. UFST is a registered trademark of AGFA Monotype Corporation. All

rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective

holders.

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual iii

Cont ent s

About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Who Should Use This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Document Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Print Engine Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel Indicator Lights (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Agency Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Zebra Programming Language (ZPL II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

iv 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Cont ents

Standard Print Engine Font Matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Applicator Pin Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Print Engine Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Print Engine Assembly Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Platen Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Peel Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ribbon Tension Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DC Power Supply Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Power Supply Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Media Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Peel Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Applicator Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unpack and Inspect the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Report Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Store the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Print Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install the Print Engine in an Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connect the Print Engine to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Select a Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Standard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Optional Print Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DB-15 Applicator Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Interface Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Data Cable Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Media and Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Types of Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Load Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Load Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Remove Used Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Parameters Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Enter Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Exit Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Contents

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual v

Changing Password-Protected Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Default Password Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Disable the Password Protection Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Front Panel LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ZebraNet

Print Server LCD Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Calibrate the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Toggle Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Printhead Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Power Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Troubleshooting Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

LCD Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Memory Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Communications Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Miscellaneous Print Engine Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Print Engine Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Power-On Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Additional Print Engine Self Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Communications Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

4 Preventive and Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Equipment Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Personal Safety Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Tools Required for Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Recommended Preventive Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Cleaning the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Cleaning the Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Cleaning the Printhead and Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Cleaning the Peel Bar and Media Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

vi 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Cont ents

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Print Quality Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Prepare for Making Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Printhead Parallelism Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Printhead Balance Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Printhead Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Printhead Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Strip Plate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Ribbon Sensor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Reflective Media Sensor Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Upper Pinch Roller Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Adjusting the Elastomer Pinch Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Media Tracking Cam Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Routine Referral Procedures (RRPs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Print System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Printhead Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Printhead Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Toggle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Compound Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Stepper Motor Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Stepper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Ribbon Take-Up Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Ribbon Supply Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Roller System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Pinch Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Peel Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Auxiliary Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

PCMCIA Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Wireless PCMCIA Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Compact Flash and PCMCIA Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Print Server Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Main Logic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Applicator Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

AC Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Exterior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Door-Open Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Contents

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual vii

5 Maintenance and Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

A Data Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Serial Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

RS-232 Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Applicator Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Applicator Interface Connector Pin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 318

J umper Configurations for +5 V I/O Applicator Interface Board . . . . . . . . . . . . . . . . 320

Proprietary Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Printer Software and Firmware License Agreement . . . . . . . . . . . . . . . . . . . . 329

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

viii 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Cont ents

Notes ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual ix

About Thi s Doc ument

This section provides you with contact information, document structure and organization, and

additional reference documents.

Contents

Who Should Use This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

How This Document Is Organized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

x 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

About Thi s Document

Who Should Use This Document

Who Should Use This Document

This Maintenance Manual is intended for use by any person who needs to perform routine

maintenance, upgrade, or troubleshoot problems with the print engine.

How This Document Is Organized

The Maintenance Manual is set up as follows:

Section Description

About This Document onpageix This section provides you with contact

information, document structure and organization,

and additional reference documents.

System Description onpage1 This chapter provides an overview of the print

engine and its components. Specifications of the

print engine and a brief explanation of each main

component and its function are included.

Operations onpage27 This chapter provides the tasks that you must

complete and the issues that you must consider

before you load and configure your print engine.

Troubleshooting onpage89 This section contains tables showing symptom,

diagnosis, and action columns. These tables help

the technician to diagnose print engine faults and

determine the repair needed.

Preventive and Corrective

Maintenance onpage107

This section provides various levels of print

engine maintenance required for optimum

performance. This section also provides

information on cleaning and general maintenance,

replacement of major assemblies, and mechanical

adjustments.

Maintenance and Assembly Drawings

onpage267

This section contains mechanical assembly

drawings and parts lists. Included are illustrations

of parts and assemblies common to all 110PAX4

models, as well as their part numbers.

Maintenance kits and their contents are also listed.

Data Ports onpage313 This appendix describes the standard

communication ports available to connect the print

engine to your computer or network.

Glossary onpage335 The glossary provides a list of common terms.

About This Document

Contacts

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual xi

Contacts

You can contact Zebra Technologies at any of the following:

Visit us at: http://www.zebra.com

Our Mailing Addresses:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061.3109 U.S.A

Telephone: +1 847.634.6700

Fax: +1 847.913.8766

Zebra Technologies Europe Limited

Zebra House

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, UK

Telephone: +44 (0)1494 472872

Fax: +44 (0)1494 450103

Support

You can contact Zebra support at:

Web Address: www.zebra.com/SS/service_support.htm

US Phone Number +1 847.913.2259

UK/International Phone Number +44 (0) 1494 768289

Note The web address is case-sensitive.

xii 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

About Thi s Document

Document Conventions

Document Conventions

The following conventions are used throughout this document to convey certain information:

Alternate Color (online only) Cross-references contain hot links to other sections in this

guide. If you are viewing this guide online in .pdf format, you can click the cross-reference

(blue text) to jump directly to its location.

Command Line Examples All command line examples appear in Cour i er New font.

For example, type the following to get to the Post-Install scripts in the bi n directory:

Zt ool s

Files and Directories All file names and directories appear in Cour i er New font. For

example, the Zebr a<ver si on number >. t ar file and the / r oot directory.

Cautions, Important, Note, and Example

Caution Warns you of the potential for electrostatic discharge.

Caution Warns you of a potential electric shock situation.

Caution Warns you of a situation where excessive heat could cause a burn.

Caution Advises you that failure to take or avoid a specific action could result in physical

harm to you.

Caution Advises you that failure to take or avoid a specific action could result in physical

harm to the hardware.

Important Advises you of information that is essential to complete a task.

Note Indicates neutral or positive information that emphasizes or supplements important

points of the main text.

Example Provides an example, often a scenario, to better clarify a section of text.

About This Document

Related Documents

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual xiii

Illustration Callouts Callouts are used when an illustration contains information that needs

to be labeled and described. A table that contains the labels and descriptions follows the

graphic. Figure1 provides an example.

Figure 1 Sample Figure with Callouts

Related Documents

The following documents and CDs might be helpful references:

Tools Tells you what tools you need to complete a given task.

1 SETUP/EXIT button

2 CALIBRATE button

2 1

57512L-001 110PAX4 User Guide

57511-001 PAX4 Series User CD

57515L-001 110PAX4 Print Engine Maintenance Manual

57513L-001 110PAX4 Quick Reference Guide

49560 PAX4 Maintenance Manual CD

45541L ZPLProgramming Guide Vol. 1

45542L ZPLProgramming Guide Vol. 2

45631 ZPL IIProgramming Guide CD

45537L ZebraNetPrintServer IIUser and Reference Guide

45630 ZebraNetPrintServer II CD

47619L ZebraNet10/100 Print Server User Guide

45638 ZebraNet10/100 Print Server CD

13422L ZebraNetWireless Print Server User Guide

xiv 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

About Thi s Document

Related Documents

Notes ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 1

1

Syst em Desc r i pt i on

This chapter provides an overview of the print engine and its components. Specifications of

the print engine and a brief explanation of each main component and its function are included.

Contents

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel Indicator Lights (LEDs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Zebra Programming Language (ZPL II). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ribbon Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standard Print Engine Font Matrices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Applicator Pin Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Print Engine Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Print Engine Assembly Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Peel Roller Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ribbon Tension Control Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DC Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Contents (Continued)

2 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

AC Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Media Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Peel Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Applicator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Description

General

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 3

General

This technical service guide contains information about service and maintenance of Zebras

110PAX4 print engine. The 110PAX4 thermal transfer print engine consists of the 203 dot/inch

and the 300 dot/inch models.

All models are available in right-hand and left-hand configurations. They are versatile,

pressure-sensitive label print engines designed to print high-quality bar codes, various sizes

and styles of alphanumeric characters, and graphics in thermal transfer mode.

All print engines have the flexibility to meet a variety of applications. The Zebra Programming

Language (ZPL II) allows the programmer to format the printed material. ZPL II is transparent

to protocol converters and allows for easy integration of the 110PAX4 print engines into most

systems and host main frames.

4 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Print Engine Exterior View

Print Engine Exterior View

Print engines are available in a right-hand configuration (media moves from left to right,

Figure1) and a left-hand configuration (media moves from right to left, Figure2).

Figure 1 Right-Hand (RH) Print Engine

Figure 2 Left-Hand (LH) Print Engine

1 Media Door

2 Front Panel

3 Power Switch

2

3

1

2

3

1

System Description

Front Panel

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 5

Front Panel

All controls and indicators for the print engine are located on the front of the print engine on

the front panel (Figure3). The Liquid Crystal Display (LCD) shows operating status and

feature parameters. The front panel buttons are used to control the print engine operations and

to set parameters. The front panel lights (LEDs) indicate the print engines status.

Figure 3 Front Panel

Front Panel Buttons

The front panel buttons are shown in Table1.

1 Buttons

2 LCD

3 Lights/LEDs

2 1 3 1

Table 1 Front Panel Buttons

Button Description/Function

BLACK OVALS The two black ovals are used to change values for the parameter displayed on the

LCD. Common uses include increasing or decreasing a value, answering yes or no,

indicating ON or OFF, and scrolling through choices.

PREVIOUS Scrolls the LCD to the previous parameter.

NEXT Scrolls the LCD to the next parameter.

SETUP/EXIT Enters and exits Setup mode.

PAUSE Stops and restarts the printing process or removes error messages and clears the LCD.

When the print engine is paused, the PAUSE light is on.

If the print engine is idle, it enters Pause mode immediately.

If the print engine is printing, the label is completed before the printing process

stops.

6 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Front Panel

Front Panel Indicator Lights (LEDs)

The front panel lights are described in Table2.

CANCEL CANCEL functions only in PAUSE mode. Pressing CANCEL has these effects:

Cancels the label format that is currently printing.

If no label format is printing, the next one to be printed is canceled.

If no label formats are waiting to be printed, CANCEL is ignored.

To clear the print engines entire label format memory, press and hold CANCEL until

the DATA light turns off.

FEED Feeds a blank label.

If the print engine is idle or paused, the label is fed immediately.

If the print engine is printing, the label is fed after the current batch finishes

printing.

CALIBRATE CALIBRATE functions only in PAUSE mode. Press CALIBRATE to recalibrate for

proper media length, to set media type (continuous/noncontinuous), and to set print

method (direct thermal/thermal transfer).

Table 1 Front Panel Buttons (Continued)

Button Description/Function

Table 2 Front Panel Lights

LED OFF Indicates ON Indicates FLASHING Indicates

POWER

(Green)

Print engine is

OFF, or no power

to print engine.

Power switch is ON, and power is

being supplied to print engine.

PAUSE

(Yellow)

Normal operation. One of the following:

Print engine is paused because of

an error condition (printhead,

ribbon, or paper error). Usually

occurs in conjunction with

another LED.

PAUSE was pressed.

A pause was requested from the

Applicator Port.

A pause was received as part of

the label format.

DATA

(Green)

No data being

received or

processed.

Data is processing or printing is

taking place. No data is being

received.

Print engine is receiving data

from or sending status

information to the host computer.

System Description

Front Panel

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 7

MEDIA

(Yellow)

Normal operation.

Media properly

loaded.

Out of media. (Print engine is

paused, LCD displays error

message, and PAUSE light is ON).

RIBBON

(Yellow)

Normal operation.

Ribbon properly

loaded.

Ribbon in while print engine is in

direct thermal mode, or no ribbon

loaded while print engine is in

thermal transfer mode. Print engine

is paused, LCD displays error

message, and PAUSE light is ON.

ERROR

(Orange)

No print engine

errors.

Print engine error exists. Check

the LCD for status.

Table 2 Front Panel Lights (Continued)

LED OFF Indicates ON Indicates FLASHING Indicates

8 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Power On/Off Switch

Power On/Off Switch

The power on/off switch is located on the top of the print engine housing, as shown in

Figure4. When this switch is placed in the ON (I) position, the POWER light turns on, and the

print engine automatically performs a Power-On Self Test (POST). For more information, see

Power-On Self Test onpage100.

Figure 4 Print Engine Power Switch

System Description

General Specifications

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 9

General Specifications

Physical

For installation information, refer to the User Guide.

Environmental Conditions

Agency Approvals

.

Height 11.8 in. (300mm)

Width 9.6 in. (245mm)

Depth 18.831 in. (478.31mm)

Weight 36 lb. (16.3 kg)

Operating Temperature

Thermal Transfer

Direct Thermal

41F to 104F (5C to 40C)

32F to 104F (0C to 40C)

Non-condensing relative humidity

Operation

Storage

20% to 95%

5% to 95%

Storage temperature 40 F to 160 F (40 C to 71 C)

Agency Approvals IEC 60950-1

EN55022, Class A

EN61000-6-2

Product Markings cULus

CE Mark

FCC-A

ICES-003

VCCI

C-Tick

CCC

Gost-R

10 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

General Specifications

Electrical Specifications

Communications Specifications

Memory

Power Supply Universal Power Supply with power-factor correcting 90264

VAC, 4763 Hz

Power Consumption

Idle

Printing

19 W

375 W (maximum)

Fuses 5 Amp, 250 VAC, 5 20mm IEC style, as supplied with the

print engine

Parallel Interface Bidirectional high-speed Centronics Parallel (36-pin

connector)

IEEE 1284-compliant software protocol (standard)

Serial Interfaces Serial RS-232C w/DTR hardware handshake via DB-9

connector (standard)

Serial RS-422/485 via 2- or 4-wire w/XON/XOFF

handshake on alternate pins of DB-9 connector (standard)

Configurable baud rates between 110 and 57.6K baud with

7 or 8data bits, standard parity, 1 or 2 stop bits

Fused +5V @ 750 mA supplied at pin 9 of the DB-9

connector

Network Connections ZebraNet 10/100PrintServer

Applicator Interface with

DC15F Connector

North America

Europe

5V I/O port

24-28V I/O port

Standard 10.0 MB RAM

2.0 MB Flash

Flash Options Up to 256 MB Compact Flash

32 MB PC memory card

System Description

General Specifications

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 11

Zebra Programming Language (ZPL II)

Bar Codes

Communicates in printable ASCII

characters

Controlled via mainframe, mini, or PC

Downloadable graphics, scalable and

bitmap fonts, label templates and formats

Object copying between memory areas

(RAM and PC memory card)

Adjustable print cache

Data compression

Automatic memory allocation for

format while printing

Bit image data transfer and printing,

mixed text/graphics

Status messages to host upon request

Format inversion (white on black)

Mirror image printing

Four-position field rotation

(normal/0, 90, 180, and 270)

Slew command

Programmable label quantities with print

and pause control

Automatic serialization of fields

User-programmable password

Portable Data Terminal

In-Spec OCR-A and OCR-B

Bar code modulus X dimensions

Picket fence (non-rotated) orientation:

203 dpi =0.0049 in. mil to 0.049 in.

300 dpi =0.0033 in. mil to 0.033 in.

Ladder (rotated) orientation:

203 dpi =0.0049 in. mil to 0.049 in.

300 dpi =0.0039 in. mil to 0.039 in.

Linear bar codes

Code 11

Code 39

Code 93

Code 128 with subsets A/B C and

UCC Case Codes

ISBT-128

UPC-A

UPC-E

EAN-8

EAN-13

UPC and EAN 2 or 5 digit extensions

Plessey

Postnet

Standard 2of 5

Industrial 2 of 5

Interleaved 2 of 5

LOGMARS

MSI

Codabar

RSS-14

Two-dimensional bar codes

Code 49

Maxi Code

PDF-417

QR Code

Codablock

DataMatrix

Micro-PDF417

Bar code ratios

2:1

7:3

5:2

3:1

12 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Printing Specifications

Printing Specifications

Specification 112PAX4 113PAX4

Resolution 203 dots per inch

(8 dots per mm)

300 dots per inch

(12 dots per mm)

Dot size 0.0049 in. x 0.0049 in.

(0.125mm x 0.125mm)

0.0033 in. x 0.0039 in.

(0.084mm x 0.100mm)

First dot location (from inside media edge) 0.093 in. (2.4mm)

0.035 in. (0.89mm)

0.093 in. (2.4mm)

0.035 in. (0.89mm)

Maximum print width 4.1 in. (104mm) 4.2 in. (106mm)

Maximum print length (with full width media)

Non-continuous

Continuous

39 in. (990mm)

150 in. (3.810mm)

39 in. (990mm)

100 in. (2,540mm)

Programmable constant printing speeds

(per second)

2.4 in. (61mm)

3 in. (76mm)

4 in. (102mm)

5 in. (127mm)

6 in. (152mm)

7 in. (178mm)

8 in. (203mm)

9 in. (229mm)

10 in. (254mm)

11 in. (279mm)

12 in. (305mm)

2.9 in. (74mm)

3 in. (76mm)

4 in. (102mm)

5 in. (127mm)

6 in. (152mm)

7 in. (178mm)

8in. (203mm)

System Description

Media Specifications

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 13

Media Specifications

Media width

(label and

liner)

Minimum 0.625 in (16mm)

Maximum 4.5 in. (114mm)

Label length Minimum Applicator mode 0.5 in. (12.7mm) with backfeed on

0.25 in. (6mm) with backfeed off

Tear-off mode 0.5 in. (12.7mm) with backfeed on

0.25 in. (6mm) with backfeed off

Registration tolerance

(not including label/liner

position tolerances)

Vertical

(concurrent labels)

0.040 in. (1.0mm)

(in Applicator mode)

Horizontal 0.040 in. (1.0mm)

Total thickness (including liner) 0.0058 in. to 0.010 in. (0.148mm to 0.256mm)

Interlabel Gap

(TransmissiveSensor)

Minimum 0.079 in. (2mm)

Preferred 0.118 in. (3mm)

Maximum 0.157 in. (4mm)

Notch Size (W x L) 0.25 in. x 0.12 in. (6mm x 3mm)

Position On inside edge, <0.8 in (<20mm) from leading

edge of media

Hole Minimum 0.125 in. (3.2mm)

Position 0.25 to 3.0 in. (6.3 to 76.2mm) from inside edge

<0.8 in. (<20mm) from leading edge of media

Black Mark

(Reflective Sensor)

Vertical length (parallel

to inside media edge)

0.12 in. to 0.43 in. (3mm to 11mm)

Horizontal width

(perpendicular to inside

media edge)

0.43 in. (11mm)

Position Within 0.04 in. (1mm) of the inside edge and

<0.8 in (20mm) from leading edge of media

Print Line to Peel Bar Distance 0.464 in. (11.8mm)

Media Unwind Force Steady State Must be uniform and must not exceed

2lb. (907g)

Transient (Start/Stop) Must not exceed 4lb. (1814 g)

Media Rewind Force Applicator take-up pull tension must be uniform

from 1 to 4 lb. (454 to 1818 g) and must not vary

more than 20% during operation.

14 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Ribbon Specifications

Ribbon Specifications

Standard Print Engine Font Matrices

Bit mapped fonts A, B, D, E, F, G, H, and GS are expandable up to 10 times, height and width

independent. However, fonts E and H (OCR-B and OCR-A) are not in spec when expanded.

The Scalable Smooth Font (CG Triumvirate Bold Condensed) is expandable on a dot-by-dot

basis, height and width independent, while maintaining smooth edges, to a maximum of 1500

1500 dots.

IBM Code Page 850 International characters are available in fonts A, B, D, E, F, G, and

through software control.

Thickness 4.5 microns

Width (wound coated side out) 1.0 in. to 4.2 in. (25.4mm to 107mm)

Maximum length 2955 ft. (900 m)

Roll size

Inner core diameter

Maximum roll size

1.0 in. (25.4mm)

4.2 in. (107mm)

System Description

Standard Print Engine Font Matrices

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 15

Table 3 Font Matrix for 8 dot/mm (203 dpi) Printheads

Font

Matrix Type* Character Size

Height Width

Baseline

Dots

Inter-

Character

Gap

Cell

Width

Font

Matrix

Inches Millimeters

Height Width

Char/

Inch

Height Width

Char/

mm

A 9 5 7 1 6 U-L-D 0.044 0.030 33.87 1.13 0.75 1.33

B 11 7 11 2 9 U 0.054 0.044 22.58 1.38 1.13 0.89

C,D 18 10 14 2 12 U-L-D 0.089 0.059 16.93 2.25 1.50 0.67

E 28 15 23 5 20 OCR-B 0.138 0.098 10.16 3.50 2.50 0.40

F 26 13 21 3 16 U-L-D 0.128 0.079 12.70 3.25 2.00 0.50

G 60 40 48 8 48 U-L-D 0.295 0.236 4.23 7.50 6.00 0.17

H 21 13 21 6 19 OCR-A 0.103 0.094 10.69 2.63 2.38 0.42

GS 24 24 24 2 26 SYMBOL 0.118 0.128 7.82 3.00 3.25 0.31

P 20 18 N/A N/A N/A U-L-D 0.098 0.089 N/A 2.50 2.25 N/A

Q 28 24 N/A N/A N/A U-L-D 0.138 0.118 N/A 3.50 3.00 N/A

R 35 31 N/A N/A N/A U-L-D 0.172 0.153 N/A 4.38 3.88 N/A

S 40 35 N/A N/A N/A U-L-D 0.197 0.172 N/A 5.00 4.38 N/A

T 48 42 N/A N/A N/A U-L-D 0.236 0.207 N/A 6.00 5.25 N/A

U 59 53 N/A N/A N/A U-L-D 0.290 0.261 N/A 7.38 6.63 N/A

V 80 71 N/A N/A N/A U-L-D 0.394 0.349 N/A 10.00 8.88 N/A

0 Default: 15 x 12 U-L-D Scalable

*U =Uppercase, L =Lowercase, D =Descenders

Table 4 Font Matrix for 12 dot/mm (300 dpi) Printheads

Font

Matrix Type* Character Size

Height Width

Baseline

Dots

Inter-

Character

Gap

Cell

Width

Font

Matrix

Inches Millimeters

Height Width

Char/

Inch

Height Width

Char/

mm

A 9 5 7 1 6 U-L-D 0.030 0.020 50.00 0.76 0.51 1.97

B 11 7 11 2 9 U 0.037 0.030 33.33 0.93 0.76 1.31

C, D 18 10 14 2 12 U-L-D 0.060 0.040 25.00 1.52 1.02 0.98

E 41 20 32 6 26 OCR-B 0.137 0.087 11.54 3.47 2.20 0.45

F 26 13 21 3 16 U-L-D 0.087 0.053 18.75 2.20 1.35 0.74

G 60 40 48 8 48 U-L-D 0.200 0.160 6.25 5.08 4.06 0.25

H 30 19 30 9 28 OCR-A 0.100 0.093 10.71 2.54 2.37 0.42

GS 24 24 24 2 26 Symbol 0.080 0.087 11.54 2.03 2.20 0.45

P 20 18 N/A N/A N/A U-L-D 0.067 0.060 N/A 1.69 1.52 N/A

Q 28 24 N/A N/A N/A U-L-D 0.093 0.080 N/A 2.37 2.03 N/A

R 35 31 N/A N/A N/A U-L-D 0.117 0.103 N/A 2.96 2.62 N/A

S 40 35 N/A N/A N/A U-L-D 0.133 0.117 N/A 3.39 2.96 N/A

T 48 42 N/A N/A N/A U-L-D 0.160 0.140 N/A 4.06 3.56 N/A

U 59 53 N/A N/A N/A U-L-D 0.197 0.177 N/A 5.00 4.49 N/A

V 80 71 N/A N/A N/A U-L-D 0.267 0.237 N/A 6.77 6.01 N/A

*U =Uppercase, L =Lowercase, D =Descenders

16 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Applicator Pin Interface

Applicator Pin Interface

Table 5 110PAX4 Applicator Pin Interface

Pin

#

Signal

Name

Signal

Type

Functional Description

1* SIGNAL GROUND

(+5V Return)

Ground JP1 IN Ground return for Internal +5 power source and is

available here for remote opto-isolators, if required.

(J P2 IN)

JP1 OUT Ground return for External +5V power source.

(J P2 OUT)

1* SIGNAL GROUND

(+24-28V Return)

Ground Customer must provide this external power.

2* +5V

(Fused at 750mA)

Power JP2 IN Internal +5V power source supplies power to

internal opto-isolators and is available here for remote opto-

isolators, if required. (J P1 IN)

JP2 OUT External +5V power source must be connected

here to supply power to internal opto-isolators.

2* +24-28V

(Fused at 750mA)

Power Customer must provide this external power.

3 START PRINT Input PULSE MODE The label printing process begins on the

HIGH to LOW transition of this signal, if a format is ready.

Deassert this signal HIGH to inhibit printing a new label.

LEVEL MODE Assert LOW to enable print engine to

begin printing if a format is ready. The print engine prints a

new label as long as the signal is asserted. When deasserted,

the currently printing label is completed and the print engine

stops and waits for this input to be reasserted LOW.

4 FEED Input When the print engine is in an Idle state or in Pause, assert

this input LOW to trigger repeated feeding of blank labels.

Deassert HIGH to stop feeding blank labels and to register to

the top of the next label.

5 PAUSE Input To toggle the current Pause state, this input must be asserted

LOW for 200milliseconds or until the SERVICE

REQUIRED output (pin 10) changes state.

6 REPRINT Input If the REPRINT feature is enabled, this input must be

asserted LOW to cause the print engine to reprint the last

label. (See the Configuration and Calibration Section.)

If the REPRINT feature is disabled, this input is ignored.

7 +28VDC

(Fused at 500mA)

Power Interface Power Supply supplies power to external sensors

as required.

* Applicator Boards are provided with separate part numbers for the +5V version and the +24-28V version.

System Description

Applicator Pin Interface

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 17

8 POWER GROUND

(+28VDC return)

Ground Interface Power Ground

9 RIBBON LOW Output If the RIBBON LOW feature is enabled and the amount

of ribbon remaining on the supply spool is below a

specific threshold level, this output is asserted HIGH.

If the RIBBON LOW feature is disabled, this output lead

is disabled.

(See the Configure and Calibration Section.)

10 SERVICE

REQUIRED

Output If the media cover or printhead is open, the ribbon or

media is out, the print engine is paused, or an operational

fault has occurred, this output is asserted LOW.

If the applicator RESYNCH mode is set to Error Mode,

this signal also asserts low for a resynch error.

11 END PRINT Output OFF: Applicator Port is Off.

MODE 1: Asserted LOW only while the print engine is

moving the label forward; otherwise deasserted HIGH.

MODE 2: Asserted HIGH only while the print engine is

moving the label forward; otherwise deasserted LOW.

MODE 3: (Default) Asserted LOW for 20milliseconds

when a label has been completed and positioned. Not

asserted during continuous printing.

MODE 4: Asserted HIGH for 20milliseconds when a label

has been completed and positioned. Not asserted during

continuous printing.

12 MEDIA OUT Output Asserted LOW when media is out.

13 RIBBON OUT Output Asserted LOW when ribbon is out.

14 DATA READY Output Asserted LOW when sufficient data has been received to

begin printing the next label.

Deasserted HIGH whenever printing stops after the

current label due to either a PAUSE condition or the

absence of a label format.

15 SPARE Output To be determined

Table 5 110PAX4 Applicator Pin Interface (Continued)

Pin

#

Signal

Name

Signal

Type

Functional Description

* Applicator Boards are provided with separate part numbers for the +5V version and the +24-28V version.

18 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Print Engine Options

Print Engine Options

Internal and External ZebraNet 10/100 Print Server

Advanced counter

8 MB, 32 MB PCMCIA Flash Card

Additional fonts available on PCMCIA Flash Cards

32 MB, 64 MB, 128 MB, 256 MB Compact Flash Memory Card

Wireless option (provides socket for PCMCIA Radio Card)

Firmware support for downloadable TrueType fonts

System Description

Main Print Engine Assembly Locations

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 19

Main Print Engine Assembly Locations

Platen Roller

See Figure5. The platen roller provides the frictional force to drive media under the printhead.

It also provides the compliant surface that resists the printhead pressure necessary for

conventional thermal transfer printing. It is driven by the print engines stepper motor through

two drive belt stages.

Figure 5 Platen Roller

Platen Roller

20 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Main Print Engine Assembly Locations

Peel Roller Assembly

See Figure6. The 110PAX4 Series peel roller assembly is located farther away from previous

assemblies, allowing the label sensors to be located closer to the print line. The assembly

consists of a spring-loaded knurled roller in a pivoting frame that can be unlatched to allow

media liner loading.

The supported pivoting frame is around inboard and outboard pins. In the latched position, the

knurled roller is in position for the media liner to achieve a wrap angle around the elastomer

peel roller. This increases the driving force on the liner that assists in reducing liner slack and

improves label peeling.

Figure 6 Peel Roller Assembly

Peel

Roller

Latch

Peel Roller

Bracket Assembly

Mounting Screw

Peel Roller

Bracket Assembly

Open/Close

System Description

Main Print Engine Assembly Locations

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 21

Ribbon Tension Control Assembly

See Figure7. The ribbon tension control assemblys main function is to provide appropriate

output to the DC motors on the ribbons supply and take-up spindles in response to ribbon

dancer arm movement to control the ribbons tension.

Figure 7 Ribbon Tension Control Assembly

A magnet is attached to each dancer arm. In the center of each magnets path is a fixed location

Hall effect sensor mounted on the main frame. As the dancer arm moves in response to

changes in the ribbons tension, the magnetic flux varies, causing the output voltage to vary

accordingly. The voltage is processed by the ribbon/tension control subsystems electronics

and provides the appropriate signals to the motor control board for the DC motors and thereby

the ribbons tension.

Ribbon Supply

Spindle Assembly

Ribbon Take-Up

Spindle Assembly

Lower Dancer

Assembly

Upper Dancer

Assembly

22 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Main Print Engine Assembly Locations

DC Power Supply Assembly

See Figure8. The DC power supply provides power for the printhead, the +5V system power,

and the stepper motor drive circuit.

Figure 8 DC Power Supply Assembly (RH Shown)

AC Power Supply Assembly

See Figure9. This modified board contains a transformer and choke to allow +32 VDC to be

generated for use by the printhead

Figure 9 AC Power Supply Board

System Description

Main Print Engine Assembly Locations

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 23

Drive System

See Figure10. The 110PAX4 drive system uses a series of pitch timing belts and pulleys. The

staged belt drive systems consist of one stage from stepper motor to a compound pulley and

another serpentine stage from the compound pulley to the pinch and peel rollers. The final

stage is from the compound pulley to the platen shaft.

The serpentine belt uses a stationary backside idler pulley to maximize timing belt wrap angle

around the pinch and peel roller pulleys. The serpentine belt also uses a spring-loaded

backside idler pulley to maintain belt tension during backfeed. Both serpentine and platen

shaft belts are constantly pretensioned by means of an extension spring.

Figure 10 Drive System

Auxiliary Pulley

Platen Pulley

Compound

Pulley

Stepper Motor

Pulley

Stepper Belt

Tensioner

Idler

Pulley

Slack Side

Idler Pulley

Peel Roller Pulley

Pinch Roller Pulley

Auxiliary Pulley

Stepper Belt

Tensioner

Stepper Motor

Pulley

Idler

Pulley

Pinch Roller Pulley Platen Pulley

Slack Side

Idler Pulley

Peel Roller Pulley

Right-Hand

Print Engine

Left-Hand

Print Engine

Compound

Pulley

24 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Main Print Engine Assembly Locations

Media Sensor

See Figure11. The media sensor uses an LED array in a fixed location under the media with a

moveable photo transistor above the media in line with the LED array. The black mark sensor

is on the same board as the LED array.

Figure 11 Media Sensor

There are seven LEDs in the array and one black mark sensor on the lower media sensor board

inside the pinch roller assembly. The LED array and black mark sensor are pointed upward at

the back of the media. In operating position, the photo transistor is on the upper media sensor

board inside the channel pinch roller assembly. The photo transistor is pointing downward

toward the top of the media.

Reflective

Media Sensor

Transmissive

Media Sensor

Transmissive

Media Sensor

System Description

Main Print Engine Assembly Locations

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 25

Peel Bar

See Figure12. The peel bar creates a sharp edge over which the media liner is tensioned to

separate and present the label to the applicators label transport mechanism.

Figure 12 Peel Bar

Applicator Interface

See Figure13. The applicator interface allows the print engine to be controlled by and its

status monitored from an external program logic controller (PLC).

Figure 13 Applicator Interface

Peel Bar

Applicator

Interface

26 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Syst em Descri pt i on

Main Print Engine Assembly Locations

Notes ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 27

2

Oper at i ons

This chapter provides the tasks that you must complete and the issues that you must consider

before you load and configure your print engine.

If you have completed the tasks and resolved issues in the checklist in Before You Begin

onpage29, use this chapter to load the print engine, to calibrate the print engine, and to print

configuration labels.

Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unpack and Inspect the Print Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Report Shipping Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Store the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Shipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Print Engine Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install the Print Engine in an Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connect the Print Engine to a Power Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Cord Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Select a Communication Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Standard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Optional Print Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DB-15 Applicator Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Interface Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Data Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Media and Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Types of Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Load Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Load Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Remove Used Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Parameters Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Enter Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Contents (Continued)

28 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Exit Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Changing Password-Protected Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Default Password Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Disable the Password Protection Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Front Panel LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ZebraNet

Print Server LCD Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Calibrate the Print Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Toggle Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Printhead Pressure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Power Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Operations

Installation

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 29

Installation

Before You Begin

Review this checklist, and resolve any issues before you begin setting up your print engine.

Unpack and Inspect the Print Engine Have you unpacked the print engine and

inspected it for damage? If you have not, see Unpack and Inspect the Print Engine

onpage30.

Install the Print Engine Have you considered what factors will affect how the print

engine is installed into an applicator? Is the print engine mounted in an applicator? For

information, see Print Engine Installation onpage31.

Attach a Power Cord Do you have the correct power cord for your print engine? If

you are unsure, see Power Cord Specifications onpage38. To attach the power cord and

connect the print engine to a power source, see Connect the Print Engine to a Power

Source onpage37.

Connect to a Data Source Have you determined how the print engine will connect to

a data source (usually a computer)? For more information, see Select a Communication

Interface onpage39.

Select Media Do you have the correct media for your application? If you are unsure,

see Types of Media onpage42.

Select Ribbon Do you need to use ribbon, and is the appropriate ribbon available, if

needed? If you are unsure, see Ribbon onpage50.

30 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Unpack and Inspect the Print Engine

Unpack and Inspect the Print Engine

When you unpack the print engine, save all packing materials and boxes. Inspect the print

engine for possible damage incurred during shipment.

Inspect the print engine for possible damage incurred during shipment.

Check all exterior surfaces for damage.

Raise the media door, and inspect the media compartment for damage to components.

Report Shipping Damage

If you discover shipping damage upon inspection:

Immediately notify the shipping company of the damage, and file a damage report with

them. Zebra is not responsible for any damage incurred during shipment of the equipment

and does not repair this damage under warranty.

Keep all packaging material for shipping company inspection.

Notify your authorized Zebra reseller.

Store the Print Engine

If you are not placing the print engine into immediate operation, repackage it using the original

packing materials. You may store the print engine under the following conditions:

Temperature: 40 to 160F (40 to 71C)

Relative humidity: 5% to 95% non-condensing

Shipping

If you must ship the print engine, remove any ribbon from the spindles to avoid damaging the

print engine. Carefully pack the print engine into the original container or a suitable alternate

container to avoid damage during transit. A shipping container can be purchased from Zebra if

the original packaging has been lost or destroyed.

Operations

Print Engine Installation

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 31

Print Engine Installation

This section provides basic information for mounting the print engine into an applicator. The

illustrations in this section show the print engine from different angles and include

measurements and clearance needs.

Requirements

Stability When the print engine is mounted, the complete assembly must be physically

stable. When the print engine is loaded with ribbon and media, the equipment must not

become physically unstable.

Ventilation and Temperature Provide ventilation for the print engine mounting enclosure

to remove heat and ensure uninterrupted, trouble-free operation of the print engine. Ambient

air temperature surrounding the print engine must not exceed the following:

Temperature: 32 to 105F (0 to 41C)

Relative humidity: 20% to 95% non-condensing

Power Requirements Consider the current rating of the print engine during installation.

When power is applied to the print engine and the enclosing equipment, an overload condition

must not be created.

Grounding Requirements Maintain reliable grounding of the print engine. Pay particular

attention to the AC power supply connections so that earth ground is maintained through the

AC power input connector.

Clearance for Cables and Connectors Allow ample space at the rear of the print engine

for electronic connectors and dressing of the following cables: IEC power cord, serial and/or

parallel host communication cable, optional host communication cable (Ethernet), and the

discrete signal (applicator) interface cable.

Power Cord Requirements The IEC power cord does not have a strain relief on the print

engine. If the operating characteristics of the applicator include vibration or strain on the

power cord, provide an appropriate clamping mechanism to avoid unintentional disconnection

of the power cord from the print engine.

32 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Print Engine Installation

Figure 14 Front View of Right-Hand Print Engine

Operations

Print Engine Installation

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 33

Figure 15 Right Side View of Right-Hand Print Engine

34 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Print Engine Installation

Figure 16 Rear View of Right-Hand Print Engine

Operations

Print Engine Installation

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 35

Figure 17 Top View of Right-Hand Print Engine

36 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Print Engine Installation

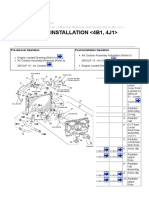

Install the Print Engine in an Applicator

This section provides the basic instructions for installing the print engine into an applicator.

To install the print engine into an applicator, complete these steps:

1. See Figure18. Install the center mounting bolt into the center hole on the applicator.

2. Carefully place the keyhole on the center mounting bolt.

3. Install the four corner mounting screws to secure the print engine to the applicator.

Figure 18 Front View of 110PAX4 Print Engine in Applicator

Caution If the print engine is installed improperly, it could fall out of the applicator and

cause injury. The center mounting bolt and four mounting screws must be installed and

secured. See Figure 18 for the location of the bolt and screws.

Note The keyhole and the center mounting bolt are designed to support the print engine

and assist in installing and removing the four mounting screws.

1 Mounting screws (four total)

2 Keyhole

3 Center mounting bolt (shown inside hole on applicator)

2 1

1

1

3

1

Operations

Connect the Print Engine to a Power Source

57515L-001 Rev. 1 2/2/05 110PAX4 Maintenance Manual 37

Connect the Print Engine to a Power Source

The power supply in the print engine automatically detects the applied line voltage and works

in the 90 to 264 VAC, 47 to 63 Hz range.

Refer to Figure19. The AC power cord must have a three-prong female connector on one end

that plugs into the mating AC power connector at the rear of the print engine. If a power cable

was not included with your print engine, refer to Power Cord Specifications onpage38.

To connect the print engine to a power source, complete these steps:

1. Turn Off (O) the print engine power switch (located on the top of the print engine

housing).

2. Plug the power cord into the AC power connector on the rear of the print engine.

Figure 19 Power Connection

3. Plug the other end of the power cord into the power source.

Caution For personnel and equipment safety, always use an approved three-conductor

power cord specific to the region or country intended for installation. This cord must use

an IEC 320 female connector and the appropriate region-specific three-conductor

grounded plug configuration.

1 AC power connector

Left-Hand Right-Hand

1 1

38 110PAX4 Maintenance Manual 57515L-001 Rev. 1 2/2/05

Operat i ons

Connect the Print Engine to a Power Source

Power Cord Specifications

Depending on how your print engine was ordered, a power cord may or may not be included.

If one is not included or if the one included is not suitable for your requirements, refer to the

following guidelines:

The overall cord length must be less than 9.8ft. (3.0 m).

The cord must be rated for at least 5 A, 250 V.

The chassis ground (earth) must be connected to ensure safety and reduce electromagnetic

interference. The third wire in the power cord grounds the connection (Figure20).

Figure 20 Power Cord Specifications

The AC power plug and the IEC 320 connector must bear the certification mark of at least

one of the known international safety organizations shown in Figure21.

Figure 21 International Safety Organization Marks

1 AC power plug for your country

2 3-conductor HAR cable

3 IEC 320 connector