Escolar Documentos

Profissional Documentos

Cultura Documentos

Cryogenic ProcessingA Study of Materials at Low Temp

Enviado por

Chinmay DalviDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cryogenic ProcessingA Study of Materials at Low Temp

Enviado por

Chinmay DalviDireitos autorais:

Formatos disponíveis

J Low Temp Phys (2010) 158: 934945 DOI 10.

1007/s10909-009-0058-x

Cryogenic Processing: A Study of Materials at Low Temperatures

Susheel Kalia

Received: 24 August 2009 / Accepted: 17 November 2009 / Published online: 26 November 2009 Springer Science+Business Media, LLC 2009

Abstract Cryogenics is an exciting, important and inexpensive technique that already has led to main discoveries and holds much future assurance. Cryogenic processing is the treatment of the materials at very low temperature around 77 K. This technique has been proven to be efcient in improving the physical and mechanical properties of the materials such as metals, alloys, plastics and composites. It improves the wear, abrasion, erosion and corrosion resistivity, durability and stabilizes the strength characteristics of various materials. Cryogenic renes and stabilizes the crystal lattice structure and distribute carbon particles throughout the material resulting a stronger and hence more durable material. In present paper, we have reviewed the effect of cryogenic treatment on some metals, alloys, plastics and composites. Keywords Cryogenic processing Metals Alloys Plastics Composites

1 Introduction Cryogenic and refrigeration technology share a common history. The most obvious difference between two is the temperature range. Cryogenics had its beginning in the mid of 19th century when for the rst time man learned to cool objects to a temperature lower than had ever existed naturally on the surface of earth. First practical vapor compression refrigerator was invented by James Harrison in 1855. In 1872, Sir James Dewar invented the vacuum ask. The air rst liqueed in 1883 by Polish scientist

S. Kalia ( ) Material Science Laboratory, Singhania University, Pacheri Bari, Dist. Jhunjhunu, 333 515 Rajasthan, India e-mail: susheel_kalia@yahoo.com S. Kalia e-mail: susheel.kalia@gmail.com

J Low Temp Phys (2010) 158: 934945

935

named Olszewski. Ten years later Olszewski and a British scientist Sir James Dewar liqueed hydrogen. In 1902, Georges Claude improved the efciency of air liquefaction by including reciprocating expansion engine. The Dutch Physicist Kamerlingh Onnes nally liqueed helium in 1908. Thus, by the beginning of twentieth century the door had been opened to a strange new world of experimentation [15]. The word cryogenics comes from the Greek word kryos, which means cold. Cryogenics is simply the science of study of materials at low temperatures at which the properties of materials signicantly change. Cold treatments were reported to have benecial effects on tool performance as far back as 1937. Both in the United States and Europe, several reports have appeared of substantial benets which can be realized by treating steel tools at a low temperature, around 77 K. Within the United States, claims for improvements have been expanded to include copper (Cu), carbides, nylon and some high temperature alloys [6]. It has been found that a cryogenic treatment of high speed steel (HSS) allowed the use of higher cutting speed in certain instances [7]. Gordon and Cohen [8] found that only by including a cold treatment in the processing cycle of tool steel, a certain favorable combination of properties could be achieved. Moderate to large improvements in tool steel performance because of cold treatments were reported after several years later [9]. Transformation of retained austenite at low temperatures in tool steels is expected to be dependent only on temperature and not on time. But Barron [10] found that holding at for longer times produced greater improvement in wear resistance. On the basis of a survey of 47 companies, Smolnikov and Kossovich [11] observed that tool life was increased only about 1040% by cryogenic treatment. Those improvements occurred only when the tools were improperly heat treated initially. Cryogenic technology has experienced fast development within the last few years. The science of heat treatment is well known to each one while the principle of cryogenics is still a mystery to most of the people in industry. Cryogenic technique is the treatment of the materials at very low temperature. It uses temperature around 77 K because this temperature is easily obtainable with liquid nitrogen. Among different means of cooling liquid nitrogen is relatively inexpensive. There is some evidence to indicate that some of the desirable changes happen very near to this temperature, as these changes do not happen at higher temperature. There is also some evidence to indicate that some of changes happen as the component is within certain temperature ranges on the way down to low temperature and some on the way back to room temperature. This makes the ramp up and ramp down parts of cryogenic process important [12]. An experimental measurement of on-resistances and switching characteristics of the Metal Oxide Semiconductor Field-Effect Transistors (MOSFET) at 77 K, 173 K, 243 K and 295 K was carried out by applying cryogenic cooling techniques. The decrease in on-resistance and capacitance associated with the temperature led to an enhancement of overall time response of the MOSFET. Decrease of the internal thermal resistance is another advantage associated with operating MOSFET under cryogenic temperature [13]. Tungsten carbide cutting tools are now in common use in industry. The differences in tool performance between cryogenically treated and untreated tungsten carbide tool inserts during the high-speed milling of medium carbon steel were analyzed. It has been found that cryogenically treated tools exhibit better tool wear resistance than untreated ones. It is also evident that the

936

J Low Temp Phys (2010) 158: 934945

application of coolant during cutting helps to reduce tool wear experienced by the cryogenically treated tools even further [14]. Very few papers have been published about the benecial uses of a deep cryogenic treatment at 77 K on the properties of high speed steel [15]. The effects of thermal shocks on exural modulus of thermally and cryogenically conditioned Kevlar/epoxy composites have been studied. Thermal and cryogenic conditions were concurrently followed by down-thermal shock (positive to negative temperature excursion) and up-thermal shock (negative to positive temperature excursion) treatments respectively on the composite laminates [16]. The effects of thermal and cryogenic conditionings on mechanical behavior of thermally shocked glass ber-epoxy composites were studied by Ray [17]. The de-bonding effect of different natures of thermal shock (up and down-cycles) and strengthening phenomena of thermal conditionings (above and subzero temperature conditionings) were assessed for the different durations of conditioning and different states of thermal conditionings (thermal and cryogenic). The state of the interactions between ber and polymer matrix by the treatment was reected in the shear values of the composites. Cryogenic processing of semiconductor material has been used for enhancing the Schottky contact performance for metal/InP, InGaAs contacts [1820]. Three methods were performed to achieve uniform tensile deformation in a nanostructured metal. In second method, deformation is conducted at cryogenic temperature. Due to suppressed dynamic recovery, the material regains the ability to work hardened. As a result, uniform elongation is achieved together with an elevated strength at 77 K [21]. There are few reports on the fatigue properties of A5083 welds at cryogenic temperature [2224]. AlSi alloys are widely used for applications in the tribological components of I.C. engines due to their high corrosion resistance, low density and good castability. The wear resistance of such alloys depends upon the alloy composition, applied load and sliding speed [25]. Poor seizure resistance of AlSi alloys tends to restrict their uses in such tribological environments [26]. The effect of deep cryogenic treatment (DCT) on mechanical properties of tool steels through eld test and lab test on AISI M2 and AISI H13 was studied by Molinary [27]. Cold treatment was done at 213 K to 193 K to improve surface hardness and thermal stability and DCT was done at 148 K to 77 K, which improves properties beyond the improvement obtained by normal cold treatment. Cryogenic treatment is an extension of conventional heat treatment, which converts retained austenite to martensite. Due to this, durability of the component was increased [28]. Collins and Dormer studied the effect of DCT on D2 cold work tool steel. Cryogenically treated samples give lowest wear rate compared to conventional heat treated steels [2931]. However, there were reports from metallurgists who were doubter about cryogenic treatment [32, 33]. Reitz and Pendray [34] have reviewed the effects of cryoprocessing on steel and some copper alloys. An improvement in wear resistance, electrical and thermal conductivity, dimensional stability and hardness has been resulted. In cryogenic treatment, vapors from liquid nitrogen can be used to strengthening wear parts, band saw blades, brake rotors and pads and shear blades has been successfully cryogenically treated by Reid [35]. Various workers have done research in the eld of grinding with cryogenic coolant. Chattopadhyay et al. [36] observed some benets of cryogenic process with respect to grinding forces and surface quality. The work done by Evans [37] and Bhattacharya

J Low Temp Phys (2010) 158: 934945

937

[38] also indicates successful applications of cryogenic cooling in other machining operation. Paul et al. [39] studied the effects of cryogenic process in grinding steel, grinding forces and surface quality. Another publication of Paul [40] indicate the effectiveness of cryogenic cooling in controlling both the grinding zone temperature and residual stress with respect to dry and wet grinding. The magnitude of residual strain existing at the ber matrix interface is the major factor controlling the cryogenic mechanical performance of ber reinforced composites. A high residual strain can reduced the ultimate tensile strength. Cryogenic properties of polymers are recently drawing attention with new developments in space, superconducting magnet and electronic techniques [41]. Woodward et al. [42] provided data on the dynamic mechanical behavior of several polyolens and vinyl polymers at cryogenic temperatures [43]. Mechanical strength of most polymers increase or remains constant as the temperature is decreased, the elongation to failure decreases to extremely low values at cryogenic temperature [44]. Polyethylene terephthalate (PET) exhibits good mechanical properties at cryogenic temperatures. The mechanical and relaxation behavior of PET at cryogenic temperature has been extensively studied with dynamic mechanical and stress strain measurements [4547].

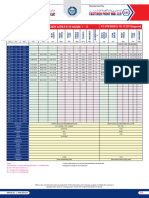

2 Cryogenic Processing Cryogenic processing is capable of treating a wide variety of materials such as metals, alloys, polymers, carbides, ceramics and composites. Deep cryogenic is the ultra low temperature processing of materials to enhance their desired metallurgical and structural properties. This is a temperature about 77 K. Cryogenic processing uses temperature around 77 K because this temperature is easily achieved using computer controls, a well insulated treatment chamber and liquid nitrogen (Fig. 1). Cryogenic is a dry process in which liquid nitrogen is converted to a gas before it enters the chamber so that it does not came into contact with the parts assuring that the dangers of cracking from too fast cooling are eliminated. The risk of thermal shock is eliminated as there is no exposure to cryogenic liquids. The whole process takes between 36 to

Fig. 1 Deep cryogenic tempering processor

938 Fig. 2 Increase in bonding energy at atomic levels with decrease in temperature

J Low Temp Phys (2010) 158: 934945

Fig. 3 Micrographs of steel samples before and after cryotreatment

74 hours depending upon the type and weight of material under treatment. Cryogenics involves slow cooling of the material from room temperature to 77 K and ramp down times are in the 4 to 10 hours range. Thereafter the material is soaked or holded at 77 K for 20 to 30 hours which depends upon the volume of the part. Finally the material is brought back to room temperature [7]. The ramp up times can be from 10 to 20 hours range. Cryogenic is the treatment of materials at extremely low temperatures and considered to be environment friendly. Sub-zero treatments for ferrite steels at temperature of approximately 193 K transforms retained austenite left by the heat treatments process to martensite [48] enhance the material properties. Cryogenic renes and stabilizes the crystal lattice structure and distribute carbon particles throughout the material resulting a stronger and hence more durable material. All of the individual constituents that make up an alloy are placed into their most stable state. These constituents then are aligned optimally with surroundings. Also, molecular bonds are strengthened by the process. Particle alignment and grain renement combine to relieve internal stresses, which can contribute to part failure. This results in material that is optimized for durability. The extremely low temperature during cryogenic processing also slows the movement at atomic levels and increases the internal molecular bonding energy and hence promotes a pure structural balance throughout the material (Fig. 2). As a result the material is obtained with an extremely uniform, rened and dense microstructure which ultimately leads to improvement in physical and mechanical properties. Comparative microphotographs of steel samples (Fig. 3) show the change in microstructure produced by the cryogenic treatment [49]. Smith [50] has disclosed the apparatus and method for the deep cryogenic treatment of materials such as metallic carbides, ceramics and plastics parts to materially increase their wear, abrasion, erosion and corrosion resistivity, stabilize their strength characteristics, improve their machinability and provide stress relief. 3 Effect of Cryogenic Processing on Metals and Alloys Cryogenic treatment enhances metallurgical properties of most of the metals, which in turn improve various strengths of the treated parts. Cryogenic treatment creates

J Low Temp Phys (2010) 158: 934945

939

denser molecular structure of the metals and alloys resulting in a larger contact surface area that reduces friction, heat and wear. It improves the entire structure of metals and alloys, not just the surface. Cryo-processing is the expensive so it is employed for the expensive machine parts and in case where the reliability of whole machine is crucial [30]. Cryogenically treated nonferrous metals will exhibit longer wear and more durability. This growing eld of engineering is an excellent technique to improve the mechanical properties of metals. Leskovsek et al. [51] has studied the effect of deep cryogenic processing at 77 K on wear resistance of vacuum heat treated high speed steel (HSS). They have compared the wear resistance behavior of a vacuum heat treated ESR AISI M2 HSS and the same vacuum heat treated steel in conjugation with deep cryogenic processing. Deep cryogenic treated samples have a better wear resistance than the vacuum heat treated samples, which is a result of their fracture toughness and hardness. With increase in tempering temperature, there is increase in wear resistance. Scanning electron microscopy (SEM) analysis of deep cryogenic treated samples shows that their worn surfaces are less damaged in comparison to vacuum heat treated samples. By changing the heat-treatment conditions, it is possible to improve the strength and resistant to creep of nickel-based alloys. The effect of heat treatment is a very useful tool to investigate the measurement of the specic heat capacity of nickelbased alloys. The specic heat capacity of nickel-based alloys were measured using a differential scanning calorimetry (DSC) in the temperature range of 1001000 K and it increases monotonically with temperature; however, above 800 K, it is strongly dependent on the heat treatment conditions [52]. Sorokina et al. [53] have studied the structure and properties of nickel alloys for cryogenic applications. It is necessary to have high plasticity at aging temperatures to ensure fairly high resistance of weldments to cracking during heating of precipitation-hardening alloys. At room and cryogenic temperatures, the toughness of nickel, stainless, and complex alloyed martensitic steels can be increased by stabilizing austenite in a dispersed state [54]. Fatigue properties are considered to be more readily affected by the blowholes at cryogenic temperature. Welds in Al alloys are more likely to produce blowholes and this is one of the defects as compared with other metals. The effect of blowholes on the mechanical properties depends upon the size, number, shape and distribution of blowholes, as reported by Yuri et al. [55] that blowholes decreased the high cycle fatigue properties of SUS304L weld metals particularly below 77 K. Yuri et al. [56] have studied the effect of welding structure on high cycle and low cycle fatigue properties for metal inert gas welded A5083 Al alloys at cryogenic temperatures. They have reported that fatigue lives of A5183 weld metals were slightly shorter than those of A5083 base metals at cryogenic temperature, in case of low cycle fatigue tests. Whereas, the effect of blowholes on high cycle fatigue properties are not clear. In the low cycle fatigue tests, the fatigue lives of A5183 weld metals at 4 K were superior to those of conventional A5083 weld metals. Cryogenic processing is efcient in increasing the Schottky barrier height and signicantly reducing device reverse leakage current [14, 57, 58]. He and Siewenie [59] have studied the cryogenic processing of thin metal lms. Schottky barrier height was found to be high as 0.64 eV in case of Ag/InGaAs/InP contacts fabricated by a low

940

J Low Temp Phys (2010) 158: 934945

temperature processing. Whereas, half of this value of the same contact is obtained in case of room temperature processing. The effect of deep cryogenic processing on microstructure, hardening behavior and abrasion resistance for high chromium cast iron subjected to sub-critical treatments by X-ray diffraction, hardness tests and abrasion tests were investigated by Liu et al. [60]. The results show that cryogenic processing effectively reduces the austenite content after sub-critical treatments but cant make retained austenite transforms to martensite completely. Deep cryogenic processing after sub-critical treatments can effectively boost hardness and abrasion resistance of high chromium. The amount of precipitated secondary carbides was more than that in air cooling and the secondary hardening peak advanced at lower temperature in case of cryogenic processing after sub-critical treatments. Abrasion resistance reaches the maximal when there was about 20% retained austenite in microstructures. Cryogenic processing of surface channel diamond eld-effect transistors was investigated. The metal-insulator-semiconductor operates effectively at 4.4 K. The eld effect can develop the carrier concentration in less activated diamond surface channel at 4.4 K [61]. Cryogenic processing increases the abrasion resistance to a great extent and contact fatigue resistance of some metals and alloys. Singh et al. [7] have investigated the effect of cryogenic treatment on the axial fatigue performance of llet welded cruciform joints of AISI 304L stainless steel, which failed in weld metals. Cryogenic treated samples showed the improvement in fatigue properties. Results showed a marked increase between treated and non-treated welds and support the observation of a change in microstructure is due to cryogenic treatment. The formation of strain-induced martensite after cryogenic treatment was conrmed by the increase in magnetic readings in the treated samples. The yield strength, ultimate tensile strength and elongation values for both treated and untreated cases are reported and it is clear that tensile properties do not change due to cryogenic treatment. The effect of cryogenic cooling by liquid nitrogen jet on forces, temperature and surface residual stresses in grinding steels have been reviewed by Paul and Chattopadhyay [62]. Cryogenic cooling provide signicant improvement to grinding forces, specic gravity requirements and surface residual stresses mainly due to substantial reduction in grinding zone temperature. It has substantially reduced the grinding zone temperature and kept the temperature well below the critical temperature range for steels and also reduces the magnitude of the tensile residual stress for all the materials. Cryogenic cooling has substantially more benecial for those steels which are quite soft, ductile and sticky. The effects of cryogenic treatment on the H solubility and the Curie temperature of Fe-B based glasses have been obtained. After holding the samples at cryogenic temperature, the decrease in H solubility was noticed by measuring the time dependence of pressure change in a hermetically closed chamber. This treatment also caused a systematic lowering of temperature of the amorphous phase [63]. The Curie temperature can be altered by holding the samples at cryogenic temperature and sign and magnitude depends upon the alloy composition. The sign and magnitude can also be inuenced by the rate of liquid quench applied during the ribbon formation. Curie temperature is lowered during cryogenic treatment for the binary Fe-B glass. The same effect is obtained when small amount of Si is added to Fe-B glass [64]. Kim

J Low Temp Phys (2010) 158: 934945

941

et al. [65] investigate the effects of cryogenic treatment on nickel-titanium endodontic instruments. The null hypothesis was that cryogenic treatment would result in no changes in composition, micro-hardness or cutting efciency of nickel-titanium endodontic instruments, whereas cryogenic treatment resulted in increased microhardness, but this increase was not detected clinically. No measurable change in elemental or crystalline phase composition was found. Thermal control of interphase micro-stresses and properties of AlSi alloys were studied by Samoilov et al. [66]. It has been reported that thermal cycling (77 to 373 K) reduces the interphase microstresses by 50%. After the rst few cycles, the effect of lowering the stress attenuates rapidly. Complete stress relaxation was not obtained even after treatment in liquid helium (4 K). In material manufactured from powder of lower dispersity, stress relaxation was found more completed. In the process of cryogenic treatment, relaxation of interphase stresses was accompanied by a 40% drop of the toughness and reduction of the low-cycle fatigue strength by more than 50%. Brittle fracture of phases and the development of microcracks at interphase boundaries were responsible for the lower properties of the material after cryogenic treatment as is conrmed by fractographic analysis of the material before and after cryogenic treatment.

4 Effect of Cryogenic Processing on Plastics The development of polymeric materials for cryogenic applications has received much interest in recent years. Most of the polymers lose their ductile properties below their glass transition temperature. Here co-operative chain motion involving main chain bond rotation becomes extremely restricted. There are several possible types of local molecular motions such as uncoordinated torsional oscillations of main chain segments, crankshaft and kink motion accompanied by coordinated movements of few chain bonds and rotations of terminal groups or side groups around a bond linking them to the main chain. Local intermolecular rearrangements result in relaxation within the low temperature region. The relaxation phenomena are more complex in crystalline and oriented polymers, indicating a considerable dependence on the morphology of polymers [41]. Cryogenically treated polymers have numerous desirable attributes. Plastics themselves will become stronger and more durable. During the solidication stage of plastic manufacturing, some of the molecules get caught in a random pattern. But molecules move at subzero and deep cryogenic temperatures, albeit slowly. The molecules do move and form into a tighter denser, realigned pattern. When ramp up to room temperature, the molecules stay in the new relationship, producing less random and more even spacing, which in turn reduces the open areas between the grid matrixes to one another. The resulting product possesses an improved bonding of molecules to each other and a better wear pattern. Cryogenic processing is a one-time process that treats the part all the way through. The immiscibility of different polymers present in beverages bottles makes the recycling process very difcult that has been a main problem in polymer recycling industry over the last few decades. In case of polymers with same density, the oatables are tough to separate and being irreconcilable by nature, normally end up in the

942

J Low Temp Phys (2010) 158: 934945

landll. Cryogenic milling has a signicant role in producing useful polymers from the oatables. Srinivas and Jed [67] have studied the processing and properties of cryogenically milled post-consumer mixed plastic waste stream consisting primarily of polypropylene and polythene. Tensile properties of milled powder samples were found to be higher in spite the presence of porosity than those of un-milled polymers. Cryogenic mechanical alloying is an alternative strategy for the recycling of plastics. A number of methods have been used by workers to pulverize the mixed polymer. High energy impact conditions in a cryogenic ball milling pulverize the mixed plastics into a powder. Ball milling was carried out at cryogenic temperatures by using liquid nitrogen [68]. The cryogenic liquid gas cooled the reactant plastic mixture in the liquid state and provides granulation or pulverization by cold shock. The problem of multiple surface cracking in glass ber reinforced plastics as a result of thermal shock at a low temperature was studied by Sei [69]. The order of stress singularity around the tip of the crack has been obtained in the case of crack that ends at the interface between orthotropic elastic materials. Takeda et al. [70] have studied the stress intensity factors for woven glass/epoxy laminates with cracks at cryogenic temperature. For the case where crack is normal to and ends at an interface between two ber bundles, the order of stress singularities at the tip of a crack is obtained. To determine the stress intensity factors at crack tip of two layered woven laminates, they used nite element methods and presented the results in graphical form. Yamanaka et al. [71] have developed the ber reinforced plastics expanding by cooling down to low temperature. High strength polyethylene is used as strengthening ber. They explained the applications of ber reinforced plastics to winding frames and spacers of a super conducting coil. It has been resulted that ber reinforced plastics with negative expansion property, high thermal conductivity and low friction co-efcient is useful in the super conducting eld. The X-ray scattering, DSC and transmission electron microscopy (TEM) techniques were used to study the effect of cryogenic mechanical milling on the structure and the thermal behavior of isotactic polypropylene. The structural changes by mechanically milling are only partly reversible. DSC results showed the decrease in degree of crystallinity with increase in milling time which is attributed to a reversible transformation of the initial morphology in to nanostructured morphology [72]. Fritz et al. [73] has studied the effect of cryogenics on rapid prototyping materials. They apply cryogenics processing to photopolymer epoxy resins as well as to stratasys acrylonitrile butadiene styrene (ABS) thermoplastic material. They hope an improvement in wear resistance, abrasive resistance, fatigue resistance and reduction in internal stresses. Cryogenic processing may make the materials less brittle without affecting the hardness.

5 Effect of Cryogenic Processing on Composites The effect of cryogenic cooling on the tensile properties of metal-matrix composites has been studied by Gayda and Ebert [74]. Cryogenic welding extends the rst stage totally elastic behavior of the composites. The benecial effects of the cryogenic cooling resulted from an alteration of the residual stress state

J Low Temp Phys (2010) 158: 934945

943

brought about by plastic ow of the matrix. Levi and Papazian [75] used the thermo-elastoplastic nite element methods to investigate the thermal cycling of silicon carbide whisker reinforced Al-matrix composites (SiC/5456). They obtained the changes in residual quantities during thermal cycling including cycling to cryogenic temperatures and the effect of these changes on subsequent mechanical behavior. Mao et al. [76] produce TiAl/NiAl intermetallic composites by using cryogenic mechanical alloying products. They evaluate the mechanical properties by small punch testing and through micro-indentation measurement. Consolidated composites showed exceptionally high hardness values, which are attributed to the formation of ternary phases at the temperatures of consolidation. The samples consolidated at high temperature possessed low fracture toughness which is also attributed to the formation of ternary phases during consolidation. Hemanth [77] prepared B4 Cp/Al-12%Si composites in which Al-12% Si alloy was the matrix and boron carbide particles (B4 Cp) were the reinforcing material. The characterization of tribological behavior of cryo-chilled Al-B4 C composites cast using high rate heat transfer during solidication was studied. He observed that microstructures of the chilled composites are ner than that of the un-chilled matrix alloy with uniform distribution of B4 C particles. Strength, hardness and wear resistance of the chilled metal matrix composites (MMC) also found better to those of the matrix alloy. Chilled MMC showed mild wear regime with high coefcient of friction at lower load but at higher loads MMC showed severe wear with better wear resistance than the matrix alloy. Because of high specic strength and stiffness and low electrical and thermal conductivity of glass ber reinforced composites, these are attractive alternatives to metals for cryogenic applications. Disdier et al. [78] found that glass ber reinforced epoxy composites can be used effectively for cryogenic applications using a vacuum as thermal insulation. Glass ber reinforced composites were subjected to various cure cycles and subsequently cryogenically cooled and inuence of polymer chemical composition and processing parameters on the magnitude of residual stress developed in these composites has been reported. Signicant differences in residual interfacial strain were produced by different resin systems. The polyester resin developed a very low residual interfacial strain which suggest that this type of material should perform well in cryogenic applications [79].

6 Conclusion Cryogenic processing is the treatment of the materials at very low temperature around 77 K. This technique improves the physical and mechanical properties of the materials. Cryogenic renes and stabilizes crystal lattice structure and distribute carbon particles throughout the material resulting a stronger and hence more durable material. Cryogenic treated metals and alloys will exhibit more wear resistance and more durability. Plastics become stronger and durable and composites showed better strength, hardness and wear resistance than the pure matrix alloy.

944

J Low Temp Phys (2010) 158: 934945

References

1. W. Foerg, Int. J. Refrig. 25, 283292 (2002) 2. G. Scurlock, Cryogenics 30, 483500 (1990) 3. W. Steckelmacher, in Monographs on Cryogenics, vol. 8, ed. by R.G. Scurlock (Oxford University Press, Oxford, 1992), p. 653 4. R.N. Richardson, The cooling potential of cryogens, Part 1: The early development of refrigeration and cryogenic cooling technology. Ecolibrium 2, 1014 (2003) 5. K.D. Timmerhaus, The Cryogenic Engineering ConferenceA Record of Twenty Five Years of Low Temperature Progress. Advances in Cryogenic Engineering, vol. 27 (Plenum Press, New York, 1982), p. 1 6. E.R. Busch, President, Materials Improvement, Inc., Detroit, MI. Private communication. December 1986 7. A. Gulyaev, Metallurg 12, 6570 (1937) 8. P. Gordon, M. Cohen, Trans. ASM 30, 569588 (1942) 9. S.W. DePoy, Subzero treatment of high speed steel, in The Iron Age (1994), p. 52 10. R.F. Barron, A study of the effects of cryogenic treatment on tool steel properties, Louisiana Technical University Report (1973) 11. E.A. Smolnikov, G.A. Kossovich, Cold treatments of cutting tools. Met. Sci. Heat Treat. 22, 704705 (1980), English translation of a Russian journal 12. P.J. Singh, B. Guha, D.R.G. Achar, Eng. Fail. Anal. 10, 112 (2003) 13. R.J. Mauriello, K.B. Sundaram, L.C. Chow, Int. J. Electron. 87, 99106 (2000) 14. A.Y.L. Yong, K.H.W. Seah, M. Rahman, Int. J. Adv. Manuf. Technol. 32, 638643 (2007) 15. M. Pellizzari, A. Molinari, in Proceedings of the Sixth International Tooling Conference, Karlstad University, 2002, p. 547, ed. by J. Bergstrom, G. Fredriksson, M. Johansson, O. Kotik, F. Thuvander, 16. B.C. Ray, Adv. Compos. Lett. 14, 5761 (2005) 17. B.C. Ray, J. Reinf. Plast. Compos. 24, 713717 (2005) 18. L. He, Z.Q. Shi, J. Vac. Sci. Technol. A 14, 704708 (1996) 19. L. He, J.E. Siewenie, J. Vac. Sci. Technol. A 17, 17991804 (1999) 20. Z.Q. Shi, W.A. Anderson, J. Vac. Sci. Technol. A 11, 985989 (1993) 21. Y.M. Wang, E. Ma, Acta Mater. 52, 16991709 (2004) 22. A.Y. Ishchenco, N.V. Novikov, Adv. Cryog. Eng. 24, 491504 (1978) 23. R.A. Kelsey, F.G. Nelson, Adv. Cryog. Eng. 24, 505518 (1978) 24. L.P. Rice, J.E. Campbell, W.F. Simmons, Adv. Cryog. Eng. 7, 478489 (1962) 25. K. Kato, Wear 241, 151 (2000) 26. A.S. Reddy, S.K. Biswas, K.S. Murthy, Wear 71, 115123 (1994) 27. A. Molinari, A. Pellizari, Mater. Process. Technol. 118, 350355 (2001) 28. P. Paulin, Frozen gears, Gear Technol. 10, 2629 (1993) 29. D.N. Collins, J. Dormer, Heat Treat. Met. 3, 7174 (1997) 30. R. Chillar, S.C. Agrawal, AIP Conf. Proc. 824, 7782 (2006) 31. F. Meng, K. Tagashira, Scr. Metall. Mater. 31, 865868 (1994) 32. E.A. Smoloikov, V.I. Tkachenko, Mach. Tool. 51, 2224 (1980) 33. G.R. Speich, in ASM Handbook, vol. 9 (ASM International, Materials Park, 1985), pp. 668672 34. W. Reitz, J. Pendray, Mater. Manuf. Process. 16, 829840 (2001) 35. R.L. Reid, Scrap (USA) 59, 3236 (2002) 36. A.B. Chattopadhyay, A. Bose, A.K. Chattopadhyay, Precis. Eng. 7, 9398 (1985) 37. C. Evans, CIRP Ann. 40, 571 (1991) 38. D. Bhattacharya, M.N. Allen, S.J. Mander, Mater. Manuf. Process. 8, 631 (1993) 39. S. Paul, P.P. Bandyopadbyay, A.B. Chattopadhyay, J. Mat. Proc. 37, 791 (1993) 40. S. Paul, A.B. Chattopadhyay, Int. J. MTM 35, 109 (1995) 41. O. Yano, H. Yamaoka, Prog. Polym. Sci. 20, 585613 (1995) 42. J.M. Crissman, A.E. Woodward, J.A. Sauer, J. Polym. Sci. A 2, 50755091 (1964) 43. J.M. Crissman, A.E. Woodward, J.A. Sauer, J. Polym. Sci. A 3, 26932697 (1965) 44. L.E. Nielsen, Mechanical Properties of Polymers and Composities (Dekker, New York, 1975) 45. C.D. Armeniades, B. Eric, J. Polym. Sci. A 9, 13451369 (1971) 46. C.D. Armeniades, I. Kuriyama, J.M. Roe, E. Baer, J. Macromol. Sci. Phys. B 1, 777791 (1967) 47. V. Frosini, A.E. Woodward, J. Macromol. Sci. Phys. B 3, 91100 (1969) 48. R. Diekman, J. Thermosetting. Thermoset Div. 29, 514 (2001)

J Low Temp Phys (2010) 158: 934945

945

49. R. Singh, S. Gupta, in National Seminar on Nonferrous MetalsImperative Need for Sustainable Development. Indian Institute of Metals, Khetari Nagar Chapter, Rajasthan, India, pp. 4548 (2006) 50. J.A. Smith, Ausz. Eur. Patentanmeld. 5, 509510 (1989) 51. V. Leskovsek, M. Kalin, J. Vizintin, Vacuum 80, 507518 (2006) 52. S.H. Lee, S.W. Kim, K.H. Kang, Int. J. Thermophys. 27, 282292 (2006) 53. N.A. Sorokina, E.A. Ulyanin, V.S. Tashchilov, I.A. Rastorgueva, B.N. Kuborskii, Met. Sci. Heat Treat. 13, 823826 (1971) 54. V.I. Kozlovskaya, Y.M. Potak, Y.F. Orzhekhovskii, Met. Sci. Heat Treat. 11, 400405 (1969) 55. T. Yuri, T. Ogata, M. Saito, Y. Hirayama, Cryogenics 40, 251259 (2000) 56. T. Yuri, T. Ogata, M. Saito, Y. Hirayama, Cryogenics 41, 475483 (2001) 57. L. He, Z.Q. Shi, Solid-State Electron. 39, 18111815 (1996) 58. Z.Q. Shi, R.L. Wallace, W.A. Anderson, Appl. Phys. Lett. 66, 446448 (1991) 59. L. He, J.E. Siewenie, Surf. Coat. Technol. 150, 7679 (2002) 60. H. Liu, J. Wang, B. Shen, H. YangH, S. Gao, S. Huang, Mater. Design 28, 10591064 (2007) 61. I. Hiroaki, T. Minoru, S. Kwang-Soup, U. Hitoshi, K. Hiroshi, Diam. Relat. Mater. 12, 18001803 (2003) 62. S. Paul, A.B. Chattopadhyay, Cryogenics 35, 515523 (1995) 63. K. Ban, A. Lovas, K. Csach, Czechoslov. J. Phys. 54, 137140 (2004) 64. K. Ban, A. Lovas, J. Kovc, Czechoslov. J. Phys. 54, 141144 (2004) 65. J.W. Kim, J.A. Griggs, J.D. Regan, R.A. Ellis, Z. Cai, Int. Endod. J. 38, 364371 (2005) 66. A.I. Samoilov, A.I. Krivko, V.S. Kozlova, I.P. Zhegina, Met. Sci. Heat Treat. 18, 157160 (1976) 67. J. Srinivas, L. Jed, Polym. Test. 24, 428434 (2005) 68. A.P. Smith, H. Ade, C.C. Koch, R.J. Spontak, Polymer 42, 44534457 (2000) 69. U. Sei, J. Therm. Stress. 24, 695707 (2001) 70. T. Takeda, Y. Shindo, F. Narita, K. Sanada, Mech. Adv. Mater. Struct. 11, 109132 (2004) 71. A. Yamanaka, T. Kashima, Zairyo (Function and Materials, Japan) 20, 4046 (2004) 72. S. Michael, K. Uwe, Colloid Polym. Sci. 282, 381386 (2004) 73. B. Fritz, W. Guan, A. Morrow, D. Truong, I. Wong, K. Golda, J. Foyos, R. Noorani, in Rapid Prototyping and Manufacturing Conference, Rosemont, IL, USA, 2000, p. 23 74. J. Gayda, L.J. Ebert, Metall. Trans. A., Phys. Metall. Mater. Sci. 10, 349353 (1979) 75. A. Levy, J.M. Papazian, J. Eng. Mater. Technol. 115, 129133 (1993) 76. S.X. Mao, N.A. McMinn, N.Q. Wu, Mater. Sci. Eng. A 363, 275289 (2003) 77. J. Hemanth, Wear 258, 17321744 (2005) 78. S. Disdier, J.M. Rey, P. Pailler, A.R. Bunssel, Cryogenics 38, 135142 (1998) 79. M. Kasen, R. Santoyo, Cryogenics 35, 731733 (1995)

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Tata Steel CultureDocumento18 páginasTata Steel CulturePriyaBhargavaAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- IEEMA Formula MotorDocumento4 páginasIEEMA Formula Motorfixer_007722Ainda não há avaliações

- Spirol Pins Bissel Pins Tension Pins SLTP - UsDocumento8 páginasSpirol Pins Bissel Pins Tension Pins SLTP - Usstuartj01Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Tool Bodies (Jigs & Fixtures)Documento8 páginasTool Bodies (Jigs & Fixtures)nilam0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Element Is: The MissingDocumento12 páginasElement Is: The MissingDaniel MoralesAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- India Nippon Electricals LimitedDocumento26 páginasIndia Nippon Electricals Limitedsumit kumarAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairDocumento15 páginask2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Characteristics Properties and Uses in MetalDocumento13 páginasCharacteristics Properties and Uses in MetalIvy DillaAinda não há avaliações

- Manganese-It Turns Iron Into Steel (And Does So Much More) : How Do We Use Manganese?Documento2 páginasManganese-It Turns Iron Into Steel (And Does So Much More) : How Do We Use Manganese?Nia AzZuhra AngelicaAinda não há avaliações

- List of Top 10 Steel Companies in IndiaDocumento7 páginasList of Top 10 Steel Companies in IndiaRahul SrivastavaAinda não há avaliações

- Echivalenta Internationala MaterialeDocumento2 páginasEchivalenta Internationala Materialenelu dicanAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Valbruna Grade Steel TypeDocumento3 páginasValbruna Grade Steel TypeLebasAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- VictaulicDocumento6 páginasVictaulicdeep manAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Smaw Midterm Laboratory Exercises 1 4Documento11 páginasSmaw Midterm Laboratory Exercises 1 4IBONIA, Kendrix N.Ainda não há avaliações

- Steel Casting Handbook - Supplement 2Documento58 páginasSteel Casting Handbook - Supplement 2RicardoAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- HEKO Products and Services: Elements For Bucket ElevatorsDocumento36 páginasHEKO Products and Services: Elements For Bucket ElevatorsShariq KhanAinda não há avaliações

- 03 Bolt Astm A325mDocumento1 página03 Bolt Astm A325mMUSTAFA TEMEMIAinda não há avaliações

- Induction FurnaceDocumento0 páginaInduction Furnaceshaishav upadhyayAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Podem - Electric Chain Hoists - CLF & CLW (En)Documento8 páginasPodem - Electric Chain Hoists - CLF & CLW (En)GogyAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Shielded Metal WeldingDocumento74 páginasShielded Metal WeldingwernhowAinda não há avaliações

- Structural FRP Applications On Topside Projects - How Do CAPEX and OPEX Costs Really Compare To Conventional Carbon SteelDocumento7 páginasStructural FRP Applications On Topside Projects - How Do CAPEX and OPEX Costs Really Compare To Conventional Carbon SteelMubeenAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- CSC SteelDocumento28 páginasCSC Steelmukul.ranjan3851Ainda não há avaliações

- Mac AlloyDocumento16 páginasMac AlloyAnonymous u7YkrCwCAinda não há avaliações

- Hughes Brothers PDFDocumento52 páginasHughes Brothers PDFJavier MaldonadoAinda não há avaliações

- Corrosion of Reactor Effluent Air Coolers-20180315Documento47 páginasCorrosion of Reactor Effluent Air Coolers-20180315庄查理100% (1)

- Tunnel and Metro VentilationDocumento16 páginasTunnel and Metro VentilationIrinaAinda não há avaliações

- BUILDING MATERIALS AND ASSEMBLIES (Handout) - BSCE-3BDocumento24 páginasBUILDING MATERIALS AND ASSEMBLIES (Handout) - BSCE-3BArianne Mae De Vera GallonAinda não há avaliações

- A Practical Treatise of Foundry Irons 1911 PDFDocumento340 páginasA Practical Treatise of Foundry Irons 1911 PDFAngel AlvaroAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Atlas Product ManualDocumento165 páginasAtlas Product ManualAndrew WallworkAinda não há avaliações

- IAB-041-02 (IW Inspection Personnel)Documento43 páginasIAB-041-02 (IW Inspection Personnel)Teddy TP100% (1)