Escolar Documentos

Profissional Documentos

Cultura Documentos

Gunstone 61 e

Enviado por

susu222000Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gunstone 61 e

Enviado por

susu222000Direitos autorais:

Formatos disponíveis

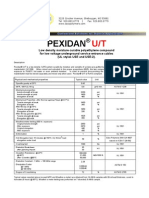

EREDI SCABINI S.r.l .

Via Brallo, 2 27010 Siziano (PV) Italia

Tel. +39 0382 66711 fax +39 0382 6671492

C.F./P.I. 00950920157 C.C.I.A.A. 341417

Trib. Milano n. 230707 Cap. Soc. I.V. 119.000

Riserve 2.161.000

Sito internet: www.erediscabini.com

R E F R A T T A R I E D I S O L A N T I A D A L T O C O N T E N U T O T E C N O L O GI C O

Bollettino

Prodotto

GUNSTONE

61

1F.ES.07.061E

Pag.1 di 1

Rev. 01/08/06

G61_E

LE SUDDETTE INFORMAZIONI SONO GENERICHE E NON RIFERITE AD APPLICAZIONI SPECIFICHE. CONTATTATECI PER ISTRUZIONI DETTAGLIATE.

THE INFORMATION STATED IS FOR GENERAL PURPOSES ONLY AND NOT FOR SPECIFIC APPLICATION. PLEASED CONTACT US FOR DETAILED INSTRUCTION.

LES RENSEIGNEMENTS CI-DESSUS ONT CARACTERE GENERAL ET NON SPECIFIQUE. VEUILLEZ NOUS CONTACTER POUR INSTRUCTIONS DETAILLEES.

TECHNICAL CONSIDERATIONS

GUNSTONE

61 belongs to our most recent and advanced range of ecological refractory castables, unique in

their kind, having Microionic set with controlled porosity and relative diameter of the pores. Its other exclusive

characteristics are:

High density, low apparent porosity and good dielectric value.

Excellent mechanical strength in hot conditions, thermal shock, spalling and oxidising atmospheres

resistance.

Chemical inertia to ferrous and non ferrous metals and their slags.

Excellent sticking capability.

It belongs to the self-bonding range and it can be relined both in hot and cold conditions.

It can be rammed, trowelled and, especially, spayed even on hot support with min. rebound.

CHEMICAL-PHYSICAL CHARACTERISTICS

RAW MATERIAL: Mullite Extra REFRACTORINESS: 1.805C

TYPE OF SET: Microionic MAX. OPERATING T. 1.680C

APPARENT POROSITY: @ 1.315 C: 14% GRAIN SIZE: 0-5 mm

Al

2

O

3

+TiO

2

: 61,23% SiO

2 (NOT FREE)

: 35,27%

Fe

2

O

3

: 0,30% CaO+MgO: 1,80% CHEMICAL ANALYSIS:

SiC + C: - OTHERS: 1,40%

@ C 110 1.000 1.400 1.600

CRUSHING STRENGTH:

kg/cm

2

405 1.316 1.563 1.684

@ C 500 800 1.000

THERMAL CONDUCTIVITY:

kcal/m h C 0,75 0,80 0,90

@ C 110 1.000 1.400 1.600

THERMAL EXPANSION:

%

0,00 0,10 0,20 0,20

INFORMATION FOR INSTALLATION

P PR RO OC CE ED DU UR RE E B BU UL LL LE ET TI IN N: :

being prepared

INSTALLATION METHOD:

Gunning - Trowelling Casting / Vibration

MIXING WATER:

N/A

MIXING AFTER WETTING:

N/A

MATERIAL REQUIRED:

2,16-2,45 kg/dm

3

depending on the installation method

INITIAL SET*:

1,0 2,0 h

FINAL SET *:

2,0 6,0 h

FORM REMOVAL*: 18h from casting WORKABILITY *:

30-60 minutes

* with ambient and dry mix

temperature of 21 C

STORAGE :

12 months in cool and dry location in the original packing

PACKING:

Material supplied in one component ready to be wetted

This heat-up schedule is to

be considered typical for

100 mm. thickness linings

and therefore it could not

be suitable for all

applications. Pls contact

our technical office or our

representative for further

details.

0

200

400

600

800

0 10 20 30 40 50 60

Time [h]

T

e

m

p

e

r

a

t

u

r

e

[

C

]

30C/h

20C/h

30C/h

50C/h

150Cx6h

250Cx6h

430Cx6h

Você também pode gostar

- Erico - Ceramic ComponentsDocumento4 páginasErico - Ceramic Componentsjaredf@jfelectric.comAinda não há avaliações

- Colpoly 783 02 TDSDocumento2 páginasColpoly 783 02 TDSKristjan PosavecAinda não há avaliações

- Colpoly 768 TDSDocumento2 páginasColpoly 768 TDSKristjan PosavecAinda não há avaliações

- Technical InformationDocumento1 páginaTechnical Informationbuji1212Ainda não há avaliações

- Colpoly 739 S TDSDocumento2 páginasColpoly 739 S TDSKristjan PosavecAinda não há avaliações

- Description Applications: Tipplen K 850 Impact Copolymer For Extrusion ApplicationsDocumento4 páginasDescription Applications: Tipplen K 850 Impact Copolymer For Extrusion ApplicationsRuberlei FerrerAinda não há avaliações

- It - 100 20c TdsDocumento2 páginasIt - 100 20c TdsNagaraju PanguluriAinda não há avaliações

- Bergolin LEP 6D1100 RAL7035 TDSDocumento3 páginasBergolin LEP 6D1100 RAL7035 TDSAdeel KhanAinda não há avaliações

- WF Ae390Documento6 páginasWF Ae390dadang2121Ainda não há avaliações

- Sensirion Humidity SHTC1 Application GuideDocumento4 páginasSensirion Humidity SHTC1 Application GuidesugneshhirparaAinda não há avaliações

- Tds Tasnee LD 0222nDocumento2 páginasTds Tasnee LD 0222nNoman Abu-FarhaAinda não há avaliações

- Briliant Green Bile Broth 2%-LiofilchemDocumento5 páginasBriliant Green Bile Broth 2%-LiofilchemMitha AriantiAinda não há avaliações

- Manual BF Machines Inpsection&Calibration Rev00Documento11 páginasManual BF Machines Inpsection&Calibration Rev00iqbal alfurqonAinda não há avaliações

- Tds Tasnee HD Im2050 Revised in 2022Documento2 páginasTds Tasnee HD Im2050 Revised in 2022Amir NawazAinda não há avaliações

- Tefabloc Tosi 431 65a PDFDocumento5 páginasTefabloc Tosi 431 65a PDFAdriana UceanuAinda não há avaliações

- HGKA 85-2-UV Rev1Documento1 páginaHGKA 85-2-UV Rev1buji1212Ainda não há avaliações

- CELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionDocumento3 páginasCELSTRAN® PP-GF50-02 - PP - Glass Reinforced: DescriptionabirAinda não há avaliações

- Battery Information Sheet: Rechargeable Lithium-Ion Cells, Modules and Battery SystemsDocumento6 páginasBattery Information Sheet: Rechargeable Lithium-Ion Cells, Modules and Battery SystemsRafaella Brandão PradoAinda não há avaliações

- j1400 Eng 1874Documento2 páginasj1400 Eng 1874ervin87Ainda não há avaliações

- Colpoly 736 WAT TDSDocumento2 páginasColpoly 736 WAT TDSKristjan PosavecAinda não há avaliações

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Documento4 páginasTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316Ainda não há avaliações

- HFX 500P Rev 6 - 2018 PDFDocumento2 páginasHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanAinda não há avaliações

- Tds Tasnee 100 Black Revised in 2022Documento2 páginasTds Tasnee 100 Black Revised in 2022Amir NawazAinda não há avaliações

- Polietilena Joasa Dens Bralen VA 20 60 Fisa THDocumento4 páginasPolietilena Joasa Dens Bralen VA 20 60 Fisa THCornel CarabusAinda não há avaliações

- 751 Epoxy Zinc Primer TDS enDocumento2 páginas751 Epoxy Zinc Primer TDS enAgoritsaAinda não há avaliações

- PP h4120 TdsDocumento2 páginasPP h4120 TdsengrmfawadazharAinda não há avaliações

- TDS - HZ 01CPR - V02 - enDocumento2 páginasTDS - HZ 01CPR - V02 - enFakhreddine BousninaAinda não há avaliações

- COLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsDocumento19 páginasCOLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsCiprian BalcanAinda não há avaliações

- Material Safety Data Sheet - MSDS1Documento5 páginasMaterial Safety Data Sheet - MSDS1Daniel UmañaAinda não há avaliações

- TS8833 (Electronic Thermal Silicone Potting) - 2Documento6 páginasTS8833 (Electronic Thermal Silicone Potting) - 2ana.luiza.nanyAinda não há avaliações

- 3406-00 Simacover EP GlassflakeDocumento3 páginas3406-00 Simacover EP GlassflakeAnonymous YN4aNlAinda não há avaliações

- Colpoly 7160 TDSDocumento2 páginasColpoly 7160 TDSKristjan PosavecAinda não há avaliações

- Tar ProductsDocumento14 páginasTar ProductsShaival JhaAinda não há avaliações

- Tds-Tasnee PP h1030Documento2 páginasTds-Tasnee PP h1030أبو أميرAinda não há avaliações

- Battery Size Calculator 22-8-12Documento2 páginasBattery Size Calculator 22-8-12hintesarAinda não há avaliações

- Syh 2RDocumento9 páginasSyh 2RBogdan GrigoreAinda não há avaliações

- Elan-Tron MC4260 W4260 IngDocumento4 páginasElan-Tron MC4260 W4260 IngZdzisław LatoAinda não há avaliações

- Material Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00Documento5 páginasMaterial Safety Data Sheets: Rev.: 00 TSD/F/020 REV. 00martinacaisarferanandaAinda não há avaliações

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocumento3 páginasXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhAinda não há avaliações

- Natech Kolseal MO2Documento8 páginasNatech Kolseal MO2marlon_3gsAinda não há avaliações

- TDS - Adingpoks 1 - ENDocumento4 páginasTDS - Adingpoks 1 - ENMickijevicAinda não há avaliações

- Updated TDS-TASNEE 100 OrangeDocumento2 páginasUpdated TDS-TASNEE 100 Orangelamia.elgammalAinda não há avaliações

- TDS N120.GbDocumento2 páginasTDS N120.GbleimagnoudAinda não há avaliações

- Build: Builders Silicone SealantsDocumento3 páginasBuild: Builders Silicone SealantsAhmed KhameisAinda não há avaliações

- Tipplen R959A - Random CopolymerDocumento4 páginasTipplen R959A - Random CopolymerCarol JacksonAinda não há avaliações

- Pexidan Ut Saco 0510Documento2 páginasPexidan Ut Saco 0510Eddy BrentonAinda não há avaliações

- JotunBitum Ballastic BlackDocumento3 páginasJotunBitum Ballastic BlackMekhmanAinda não há avaliações

- Colpoly 7331 LV TDSDocumento2 páginasColpoly 7331 LV TDSKristjan PosavecAinda não há avaliações

- Tasnee LD 1925as: Low Density PolyethyleneDocumento2 páginasTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaAinda não há avaliações

- Especificacion Tecnica LEDDocumento10 páginasEspecificacion Tecnica LEDJorge Herrero GarcíaAinda não há avaliações

- O F F E R No. 313232 /32: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/BremenDocumento15 páginasO F F E R No. 313232 /32: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/BremenRidouane EL HAJJIAinda não há avaliações

- MSDS FIBER (Woven Roving & Chopped Strand Mat) PDFDocumento8 páginasMSDS FIBER (Woven Roving & Chopped Strand Mat) PDFbenAinda não há avaliações

- Adingpoks 1: Filed of AplicationDocumento3 páginasAdingpoks 1: Filed of AplicationFilip PopordanoskiAinda não há avaliações

- Epoxy Component Prepreg: Typical Applications: General Purpose - VisualDocumento3 páginasEpoxy Component Prepreg: Typical Applications: General Purpose - VisualJohnnyAinda não há avaliações

- TDS 01ofg V08 enDocumento2 páginasTDS 01ofg V08 enDenisTarasAinda não há avaliações

- Sikagard 62 PDSDocumento3 páginasSikagard 62 PDSMattAinda não há avaliações

- Product Data Sheet - High Density Polyethylene HCH 5110A: TEC-PRO-PDS-024Documento3 páginasProduct Data Sheet - High Density Polyethylene HCH 5110A: TEC-PRO-PDS-024MohamadMostafaviAinda não há avaliações

- Registratore IN CASSETTA Serie APT - EngDocumento6 páginasRegistratore IN CASSETTA Serie APT - EngshahiffudinAinda não há avaliações

- Product Data Energol THB: DescriptionDocumento2 páginasProduct Data Energol THB: Descriptionkarim karimAinda não há avaliações

- Non-Ferrous Molten Metal Handling Applications: Advanced Silicon Nitride & Sialon CeramicsDocumento2 páginasNon-Ferrous Molten Metal Handling Applications: Advanced Silicon Nitride & Sialon Ceramicssusu222000Ainda não há avaliações

- Ergi̇tme Ocaği HesaplamalariDocumento6 páginasErgi̇tme Ocaği Hesaplamalarisusu222000Ainda não há avaliações

- User Guide 001Documento2 páginasUser Guide 001susu222000Ainda não há avaliações

- Sialon ENDocumento2 páginasSialon ENsusu222000Ainda não há avaliações

- Jet Cooling English Presentationv2Documento21 páginasJet Cooling English Presentationv2susu22200050% (2)

- Chromalox Immersion Heater Ceramic Sheathed Immersion Heater (SiAlON) CsDocumento2 páginasChromalox Immersion Heater Ceramic Sheathed Immersion Heater (SiAlON) Cssusu222000Ainda não há avaliações

- Runner Design Guide Lines-Issue 5Documento15 páginasRunner Design Guide Lines-Issue 5sivanandp100% (1)

- Aluminium Insight 2009-05 ACT Immersion HeatersDocumento2 páginasAluminium Insight 2009-05 ACT Immersion Heaterssusu222000Ainda não há avaliações

- Aluminium Insight 2009-05 ACT Immersion HeatersDocumento2 páginasAluminium Insight 2009-05 ACT Immersion Heaterssusu222000Ainda não há avaliações

- Tooling Standard (Die Casting)Documento39 páginasTooling Standard (Die Casting)Kmilo GiraldoAinda não há avaliações

- Kastas Agricultural Machinery - LowDocumento5 páginasKastas Agricultural Machinery - Lowsusu222000Ainda não há avaliações

- TALAT Lecture 3201: Introduction To Casting TechnologyDocumento29 páginasTALAT Lecture 3201: Introduction To Casting TechnologyCORE MaterialsAinda não há avaliações

- Product CatalogueDocumento12 páginasProduct Cataloguesusu222000Ainda não há avaliações

- Product CatalogueDocumento12 páginasProduct Cataloguesusu222000Ainda não há avaliações

- 06 TD Liquidmetals GBDocumento1 página06 TD Liquidmetals GBsusu222000Ainda não há avaliações

- Diamant Metal FillerDocumento16 páginasDiamant Metal Fillersusu222000Ainda não há avaliações

- 11 TD Ultrametal GBDocumento2 páginas11 TD Ultrametal GBsusu222000Ainda não há avaliações

- 04 TD Dichtol GBDocumento2 páginas04 TD Dichtol GBsusu222000Ainda não há avaliações

- 06 TD Ironcement GBDocumento1 página06 TD Ironcement GBsusu222000Ainda não há avaliações

- 02 TD PM GBDocumento2 páginas02 TD PM GBsusu222000Ainda não há avaliações

- IRC5 Additional Options 3HAC023668 001 - RevDocumento66 páginasIRC5 Additional Options 3HAC023668 001 - RevyangardaixAinda não há avaliações

- Method Statement For Plastering WorkDocumento15 páginasMethod Statement For Plastering Workstrikersam100% (9)

- Food Industry in LatviaDocumento87 páginasFood Industry in Latviafdsfsdf dfdss0% (1)

- Finals Exam Part 1 (Theories)Documento7 páginasFinals Exam Part 1 (Theories)Zee De Vera LaderasAinda não há avaliações

- Reinforcement: Industrial Training Report Tudawe Brothers LimitedDocumento8 páginasReinforcement: Industrial Training Report Tudawe Brothers Limitedymanfas100% (1)

- NOBLE Bahrain For GRP SiteDocumento40 páginasNOBLE Bahrain For GRP SiteAntony PiousAinda não há avaliações

- Asian Paints RuralDocumento17 páginasAsian Paints RuralAjith RavindranAinda não há avaliações

- (RMD™) MIG Welding ProcessDocumento5 páginas(RMD™) MIG Welding ProcessPradip GoswamiAinda não há avaliações

- Asme Sec Ix PT QB Article Xiv - Brazing DataDocumento24 páginasAsme Sec Ix PT QB Article Xiv - Brazing Datasamitha505Ainda não há avaliações

- Purchasing Documents TypesDocumento8 páginasPurchasing Documents TypesMohamed Awad100% (1)

- Principal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordDocumento2 páginasPrincipal Defense Mechanical Engineer in Huntsville AL Resume Jeffery WhitfordJeffreyWhitfordAinda não há avaliações

- IoclDocumento25 páginasIoclShubham JainAinda não há avaliações

- VCM PVC AN RevADocumento4 páginasVCM PVC AN RevAHamdySharafAinda não há avaliações

- Click On The Image To View DimenDocumento2 páginasClick On The Image To View DimenPradip RauljiAinda não há avaliações

- Welded Steel Pipe American Iron and Steel InstituteDocumento80 páginasWelded Steel Pipe American Iron and Steel Institutemaminu1100% (1)

- Hamid Construction Limited ProfileDocumento17 páginasHamid Construction Limited ProfileAqib RafiAinda não há avaliações

- Plasma Vrs PermanganateDocumento11 páginasPlasma Vrs PermanganatearinramAinda não há avaliações

- Cavi FlexDocumento11 páginasCavi FlexCandace BlackburnAinda não há avaliações

- Homeless Serving Land Use Overnight Shelter Parcel DataDocumento14 páginasHomeless Serving Land Use Overnight Shelter Parcel DataAbhishekh GuptaAinda não há avaliações

- Acc320ptiipii SP12Documento3 páginasAcc320ptiipii SP12Melanie KilpatrickAinda não há avaliações

- Grid-Lign Fl4011 1209 WebDocumento2 páginasGrid-Lign Fl4011 1209 WebRenzo Jo LaurentAinda não há avaliações

- The Next Generation Melting SystemDocumento19 páginasThe Next Generation Melting SystemkhladunAinda não há avaliações

- 6.1 The Industrial Revolution SpreadsDocumento15 páginas6.1 The Industrial Revolution SpreadsMissDangAinda não há avaliações

- Solution 2Documento5 páginasSolution 2Alexandria SomethingAinda não há avaliações

- SIBOR Oxidation ProtectionDocumento5 páginasSIBOR Oxidation ProtectionMohammed Abdul NaseerAinda não há avaliações

- Improvement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesDocumento9 páginasImprovement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesTavo MuñizAinda não há avaliações

- Underground MiningDocumento191 páginasUnderground MiningrockyminAinda não há avaliações

- Ryson BucketDocumento4 páginasRyson Bucketaani1984Ainda não há avaliações

- Problems & Homework Assignment-2013Documento5 páginasProblems & Homework Assignment-2013mickey_disney93Ainda não há avaliações

- Ointment Process ValidationDocumento25 páginasOintment Process ValidationTrinh Huy CongAinda não há avaliações

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincNo EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincNota: 3.5 de 5 estrelas3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNo EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNota: 4 de 5 estrelas4/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNo EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNota: 5 de 5 estrelas5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNo EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNota: 4 de 5 estrelas4/5 (146)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNo EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNota: 5 de 5 estrelas5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (90)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolNo EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolAinda não há avaliações

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNo EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNota: 3.5 de 5 estrelas3.5/5 (22)

- Transformer: The Deep Chemistry of Life and DeathNo EverandTransformer: The Deep Chemistry of Life and DeathNota: 4.5 de 5 estrelas4.5/5 (13)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilNo EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilNota: 5 de 5 estrelas5/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsNo EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsAinda não há avaliações

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookAinda não há avaliações

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideNo EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideAinda não há avaliações

- Taste: Surprising Stories and Science About Why Food Tastes GoodNo EverandTaste: Surprising Stories and Science About Why Food Tastes GoodNota: 3 de 5 estrelas3/5 (20)

- Chemistry: a QuickStudy Laminated Reference GuideNo EverandChemistry: a QuickStudy Laminated Reference GuideNota: 5 de 5 estrelas5/5 (1)

- Tribology: Friction and Wear of Engineering MaterialsNo EverandTribology: Friction and Wear of Engineering MaterialsNota: 5 de 5 estrelas5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeNo EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeNota: 5 de 5 estrelas5/5 (1)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireNo EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireNota: 4 de 5 estrelas4/5 (129)