Escolar Documentos

Profissional Documentos

Cultura Documentos

Fisa Tehnica Js 200

Enviado por

MB ViorelDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Fisa Tehnica Js 200

Enviado por

MB ViorelDireitos autorais:

Formatos disponíveis

JCB JS200 EXCAVATOR

F A S T . F A C

Durable build:

X-frame undercarriage with good ground clearance, large diameter swing ring and belly guards as standard.

Computer Aided Power control System (CAPS II):

Constantly monitors control system to maximize productivity, fuel economy and control. Data printouts are available for the service technician.

Boom priority hydraulic system:

Increased operating speed for faster cycle times. Reduced down speed allows greater control.

Superb operator environment:

Features deluxe suspension seat, new shorter control levers, clear all-round visibility, cushion control and Auto Plus one-touch idle controls.

Increased in-system pressure:

Booster provides 10% in-system pressure increase for improved bucket and dipper tearout forces.

Nephron filtration system:

Cleans hydraulic oil down to 1.5 microns for improved system reliability. Extends filter life for 1,000 hour changes and hydraulic oil for 5,000 hour changes.

Powerful swing system:

20 metric ton machine features smoother handling of large loads on steep inclines.

Low emission Isuzu engine:

128 net HP and long-life reliability.

E H

G A B

SPECIFICATION

JCB JS200 TRACKED EXCAVATOR

STATIC DIMENSIONS

E H I

G K A B C D

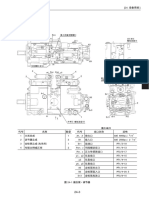

DIMENSIONS

A B C D D D D E F G H I J K L Track length on ground Undercarriage overall length Track gauge Width over tracks (600 shoes) Width over tracks (700 shoes) Width over tracks (800 shoes) Width over tracks (900 shoes) Transport length with Monoboom Transport height with Monoboom Counterweight clearance Tailswing radius Width of superstructure* Height over cab Ground clearance Track height 12ft. 0in. (3660mm) 14ft. 8in. (4460mm) 7ft. 10in. (2390mm) 9ft. 10in. (2990mm) 10ft. 2in. (3090mm) 10ft. 6in. (3190mm) 10ft.10in. (3290mm) 31ft. 0in. (9440mm) 9ft. 5 in. (2860mm) 3ft. 6in. (1066mm) 9ft. 1in. (2770mm) 8ft. 2in. (2500mm) 9ft. 6in. (2886mm) 1ft. 7in. (486mm) 2ft. 11in. (885mm)

OPERATOR STATION

Pressed steel cab frame conforming to ISO dimensional standards, noise and vibration isolated by six hydraulically damped resilient mountings. All safety glass windows with opening front windshield, removable lower shield and opening door windows and roof hatch. Fan forced fresh air ventilation and heater with windshield defogger and wash/wiper. Fully adjustable deluxe suspension seat with headrest, armrests and backrest recline. Seat and servo hand controls are trolley mounted for combined or independent adjustment hand controls are forward and back adjustable. Radio cassette player with digital tuning, cigarette lighter, ashtray, digital clock, cup holder and storage box are standard.

UNDERCARRIAGE

Construction: Fully welded, X frame type with central bellyguarding and sloping sidemembers with dirt relief holes under top rollers. Recovery point: Front and rear. Track shoe options: 24in. (600mm), 28in. (700mm), 31in. (800mm), 35in. (900mm). Upper & lower rollers: Heat treated, sealed and lubricated. Track adjustment: Grease cylinder type. Track idler: Sealed and lubricated, with spring cushioned recoil. Quantity of track guides 1 per side Quantity of lower rollers 8 per side Quantity of upper rollers 2 per side Quantity of track shoes 49 per side

ENGINE

Model: Isuzu A-6BG1TQB-04. Type: Water cooled, 4-stroke, 6-cylinder in-line, direct injection, turbocharged diesel. Net power: (SAE J1349 and 80/1269/EEC) 128hp (95kW) at 1950RPM. Piston Displacement: 396 cu.in. (6.494 liters). Air Filtration: Dry element with secondary safety element and in cab warning indicator. Cooling: Water cooler via large capacity radiator with anti block wavy fins and protected by a separate fine mesh grille. Starting system: 24 volt. Batteries: 2 x 12 volt Heavy Duty. Alternator: 24 volt 40 amp. Refuelling pump: Electric type.

TRACK DRIVE

Type: Fully hydrostatic, three speed with autoshift. Travel motors: Variable swash axial piston type, fully guarded within undercarriage frame. Final drive: Planetary reduction, bolt-on sprockets. Service brake: Hydraulic counter balance valve to prevent overspeeding on gradients. Park brake: Disc type, spring applied, automatic hydraulic release. Gradeability: 70% (35 deg) continuous. Travel speed: High 3.4 mph (5.5 km/h). Mid 2.1 mph (3.3 km/h). Low 1.4 mph (2.3 km/h). Tractive effort: 185.7kN (41234lbf, 18940kgf).

SWING SYSTEM

Swing motor: Axial piston type. Swing brake: Hydraulic braking plus automatic spring applied disc type parking brake. Final drive: Planetary reduction. Swing speed: 11.9RPM. Swing gear: Large diameter, internally toothed fully sealed grease bath lubricated. Swing lock: Multi position switchable brake.

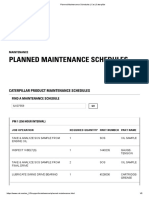

SERVICE CAPACITIES

Fuel tank Engine coolant Engine oil Swing reduction gear Track reduction gear (each side) Hydraulic system Hydraulic tank 81.6 USgal (310.0 l) 6.7 USgal (25.5 l) 5.1 USgal (19.5 l) 1.3 USgal (5.0 l) 1.2 USgal (4.7 l) 52.6 USgal (200.0 l) 31.6 USgal (120.0 l)

* with cab handrail removed

JCB JS200 TRACKED EXCAVATOR

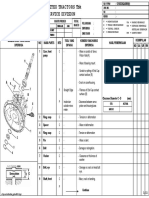

WORKING RANGE

A B G 32-6 29-3 26 22-9 19-6 16-3 13 E 9-9 6-6 3-3 0 ft.-in. C F 35-9 32-6 29-3 26 22-9 19-6 16-3 13 9-9 6-6 3-3 0 ft.-in.

A B C D E F G Boom lenght: 18ft. 7in. Maximum digging reach Maximum digging reach (on ground) Maximum digging depth Maximum digging height Maximum dumping height Maximum vertical wall cut depth Minimum swing radius Bucket rotation Dipper tearout Dipper tearout with boost Bucket tearout Bucket tearout with boost 6ft. 3in. (1.91m) 29ft. 2in. (8.89mm) 28ft. 7in. (8.70mm) 18ft. 2in. (5.53mm) 29ft. 4in. (8.95mm) 20ft. 8in. (6.31mm) 16ft. 1in. (4.90mm) 12ft. 4in. (3.76mm) 183 35948lbs (16340kgf) 38940lbs (17700kgf) 25894lbs (11770kgf) 27962lbs (12710kgf) 7ft. 10in. (2.40m) 30ft. 8in. (9.34mm) 30ft. 1in. (9.16mm) 19ft. 9in. (6.02mm) 30ft. 2in. (9.20mm) 21ft. 5in. (6.53mm) 17ft. 11in. (5.47mm) 12ft. 2in. (3.71mm) 183 28820lbs (13100kgf) 30800lbs (14000kgf) 25894lbs (11770kgf) 27962lbs (12710kgf) 9ft. 9in. (3.00m) 32ft. 5in. (9.87mm) 31ft. 10in. (9.70mm) 21ft. 8in. (6.60mm) 30ft. 10in. (9.40mm) 22ft. 2in. (6.75mm) 19ft. 11in. (6.07mm) 11ft. 10in. (3.60mm) 183 22990lbs (10450kgf) 24794lbs (11270kgf) 25894lbs (11770kgf) 27962lbs (12710kgf)

JCB JS200 TRACKED EXCAVATOR

LIFTING CAPACITIES

Mono Boom: Dipper Length: 6.3 ft. (1.91m), Track Shoe: 27.6 in. (700mm) Triple Grouser. 1.50 cu. Yd. (1.14 cu. M.) Bucket - 1587 lbs. (720 kgs.)

Reach from Swing Center 10 ft. (3m) Load Point Height

lbs. 19.5 ft. (6m) 15 ft. (4.5m) 10 ft. (3m) 5 ft. (1.5m) 0 ft. (0m) - 5 ft. (1.5m) -10 ft. (3m) - 15 ft. (4.5m) 17023 7720 21455 9730 15435 14156 kgs lbs. kgs lbs. kgs lbs. kgs lbs. 10606 7000 13803 6420 14509 5960 13958 5810 13627 5840 13561 5980 13847 kgs 4810 6260 6580 6330 6180 6150 6280 lbs. 9856 9592 9085 8600 8291 8247 8489 kgs 4470 4350 9041 4120 9989 3900 9768 3760 9614 3740 3850 4100 4530 4430 4360 6395 2900 6262 2840 6064 2750 5931 2690 8754 3970 5402 2450 lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs

15 ft. (4.5m)

19.5 ft. (6m)

25 ft. (7.5m)

Capacity at Max. Reach

22447 10180 13142 22072 10010 12811 22050 10000 22050 10000 22138 10040 12877 31355 14220 26967 12230 22381 10150 13186

Mono Boom: Dipper Arm: 8.0 ft. (2.40m), Track Shoe: 27.6 in. (700mm) Triple Grouser. 1.37 cu. Yd. (1.05 cu. M.) Bucket - 1496 lbs. (679 kgs.)

Reach from Swing Center 10 ft. (3m) Load Point Height

lbs. 19.5 ft. (6m) 15 ft. (4.5m) 10 ft. (3m) 5 ft. (1.5m) 0 ft. (0m) - 5 ft. (1.5m) -10 ft. (3m) - 15 ft. (4.5m) 15347 6960 20661 9370 15347 14597 kgs lbs. kgs lbs. kgs lbs. kgs lbs. 11400 6960 12877 6620 14729 6120 14134 5870 13737 5850 13583 5940 13715 6200 kgs lbs. kgs 4570 4450 10297 4670 4210 10121 4590 3970 9856 3810 9658 3750 9614 3800 4470 4380 4360 6593 2990 6395 2900 6152 2790 5976 2710 5931 2690 8070 3660 4983 2260 lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs

15 ft. (4.5m)

19.5 ft. (6m)

25 ft. (7.5m)

Capacity at Max. Reach

5170 10077 5840 6680 6410 6230 6160 6220 9812 9283 8754 8401 8269 8379

22866 10370 13495 22226 10080 12943 23682 10740 23682 10740 22138 10040 12899 34045 15440 26681 12100 22403 10160 13098 27210 12340 27210 12340 19316 8760 13671

Mono Boom: Dipper Arm: 10 ft. (3.00m), Track Shoe: 27.6 in. (700mm) Triple Grouser. .1.34 cu. Yd. (1.03 cu. M.) Bucket - 1554 lbs. (705 kgs.)

Reach from Swing Center 10 ft. (3m) Load Point Height

lbs. 19.5 ft. (6m) 15 ft. (4.5m) 10 ft. (3m) 5 ft. (1.5m) 0 ft. (0m) - 5 ft. (1.5m) -10 ft. (3m) - 15 ft. (4.5m) 27474 12460 27474 12460 18368 8330 13406 6080 14751 6690 15016 11488 6810 13914 6250 14244 5900 13737 5790 13495 5840 13517 3010 13892 5210 6310 6460 6230 6120 6130 6300 9945 9415 8842 8401 8181 8181 8533 4510 10386 4710 4270 10165 4610 4010 9856 3810 9592 3710 9459 3710 3870 4470 4350 4290 6659 3020 6417 2910 6130 2780 5909 2680 5777 2620 5402 2450 4410 2000 kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs lbs. kgs

15 ft. (4.5m)

19.5 ft. (6m)

25 ft. (7.5m)

Capacity at Max. Reach

13406 6080 22800 10340 13781 14751 6690 22337 10130 13010 12767

22469 10190 22469 10190 22028 9990

34288 15550 26173 11870 22138 10040 12877 30958 14040 26901 12200 21565 9780 6637

Lift capacity front and rear. Lift capacity full circle

Notes:

1. Lifting capacities are based on ISO 10567, that is: 75% of minimum tipping load or 87% of hydraulic lift capacity, whichever is the less. Lifting capacities marked* are based on hydraulic capacity. 2. Lift capacities assume that the machine is on firm, level ground and equipped with an approved lifting point and bucket with dozer blade up. 3. Lift capacities may be limited by local regulations. Please refer to your dealer.

JCB JS200 TRACKED EXCAVATOR

WEIGHTS AND GROUND BEARING PRESSURES

Figures include 1.48 cu.yd (1.14cu.m) bucket, operator and full fuel tank.

Undercarriage & shoe width Weight/Ground bearing pressure

GENERAL PURPOSE EXCAVATING BUCKETS

All buckets are JCB Esco fully welded steel, with sealed, hardened steel pivot pins and replaceable wear parts.

Max. Width 24in. (600mm) 36in. (900mm) 39in. (1000mm) 47in. (1200mm) 53in. (1350mm) 57in. (1450mm) 59in. (1500mm) Capacity (SAE heaped) 0.52cu.yd. (0.40cu.m) 0.93cu.yd. (0.71cu.m) 1.06cu.yd. (0.81cu.m) 1.35cu.yd. (1.03cu.m) 1.37cu.yd. (1.05cu.m) 1.49cu.yd. (1.14cu.m) 1.56cu.yd. (1.19cu.m) Weight 1067lb (484kg) 1312lb (595kg) 1382lb (627kg) 1555lb (705kg) 1497lb (679kg) 1588lb (720kg) 1618lb (734kg)

LC 700mm

45621lb (20690kg) 5.25lb/sq.in (0.37kg/sq.cm)

HYDRAULIC SYSTEM

A variable flow load sensing system with flow on demand, variable power output and servo operated, multi-function open center control. Pumps Main pumps: 2 variable displacement axial piston type. Maximum flow: 2 x 51.5 GPM (2 x 196 L/min). Servo pump: Gear type. Maximum flow: 5.32 GPM (20 L/min). Control valve A combined four and five spool control valve with auxiliary service spool as standard. When required twin pump flow is combined to boom, dipper and bucket services for greater speed and efficiency. Relief valve settings Boom/Arm/Bucket 4500psi (320 bar) With power boost 4980psi (350 bar) Swing circuit 4050psi (285 bar) Travel circuit 4980psi (350 bar) Pilot control 569psi (40 bar) A separate Cushion Control valve in the servo system provides cushioning of the boom and dipper spools selection and quick warm-up of the servo system. Hydraulic cylinders Double acting type, with bolt-up end caps and hardened steel bearing bushes. End cushioning is fitted as standard on boom, dipper and bucket rams. Dimensions: Boom Bore 4.9in. (125mm) Rod 3.3in. (85mm) Stroke 49.6in. (1259mm) Dipper Bore 5.3in. (135mm) Rod 3.9in. (100mm) Stroke 62.2in. (1580mm) Bucket Bore 4.7in. (120mm) Rod 3.1in. (80mm) Stroke 39.8in. (1012mm) Filtration The hydraulic components are protected by the highest standard of filtration to ensure long hydraulic fluid and component life. In tank: 150 micron, suction strainer. Main return line: 10 micron, fiberform element. Nephron Bypass line: 1.5 micron, paper element. Pilot line: 10 micron, paper element. Hydraulic hammer return: 10 micron, reinforced microform element. Cooling Worldwide cooling is provided via a full return line air blast cooler with anti-block wavy cooling fins and separate easy clean fine mesh grille.

CONTROLS

Excavator: All servo lever operated, to ISO control pattern, independently adjustable to the seat. Tracks: individually servo operated by foot pedal or hand lever. Speed selection via foot operated switch with autoshift override. Auxiliary: Via servo operated foot pedal. Low flow: via switch in RH servo lever. Controls isolation: Gate lock lever at cab entrance. Engine speed: Dial type throttle control plus servo lever mounted one-touch control and seperate selectable auto-idle. Engine stop: Ignition key operated and separate shut-down button. Power boost: Via servo lever mounted button. Horn: Operated via servo lever mounted button. Instrumentation CAPS II Computer Aided Power control System (2nd generation), with engine speed sensing for 100% engine power usage, controls the power and flow output of the hydraulic system via four operator selectable work modes H (Heavy), S (Standard), L (Light) and F (Fine). Auto engine and hydraulics warm-up is provided on initial start-up together with S (Standard) mode and Cushion Control selection. The computer controller monitors all critical machine functions and operator selections which are displayed via a written LCD message monitor. Bar graph type gauges provide fuel level, water and hydraulic oil temperature readings. A self fault diagnostic system is built-in with a manual override for continuity of operation. Membrane type touch-sensitive switches are sealed against dirt and moisture ingress and are illuminated for night time operation.

EXCAVATOR END

Monoboom is standard on the JS200 along with a choice of dipper lengths to suit the requirements of reach, dig-depth, loadover height, breakouts and site versatility. Reserve strength is built into the fully welded structures for hydraulic hammer and other arduous operations. Fabricated bucket tipping links are provided with a choice of lift points.

THE BEST BACK- UP IN THE BUSINESS.

ALWAYS FINDING A BETTER WAY.

Buy any of the JCB tracked excavator models and youll get a complete deal that extends beyond that of any rival.

FINANCE.

Your JCB dealer can meet your financial needs through a variety of plans for leasing, lease purchases with or without options, installment sales contracts and rental programs.

WARRANTY.

JCB excavators are covered by JCBs one year standard warranty, which is outlined in the JCB Certificate of Warranty. Extended warranty coverage is also available. Contact your JCB dealer for details.

SERVICE.

JCB dealer service people are committed to keeping your JCB up and running. JCB dealer service technicians are enrolled in on-going training programs and supported by experienced JCB service representatives based throughout North America.

PARTS.

JCB dealers convenient locations offer excellent over the counter parts availability. JCB also offers:

48 HOUR PARTS GUARANTEE.

Ask your dealer for details JCB offers its participating dealers a guarantee that breakdown parts will be available at the dealership within 48 hours or the parts and freight will be free.

REGIONAL PARTS DEPOTS.

For the breakdown part your dealer may not have in stock, JCB has SDD Same Day Dispatch, from a parts distribution center in the United States and one in Canada.

See your JCB Dealer Sales Rentals Financing Parts Service

G G G G

JCB Inc, 10939 Philadephia Road, PO Box 209, White Marsh, MD 21162-0209 (410) 335-2800. JCB Excavators Ltd, 3375 North Service Road, Unit C6, Burlington, Ontario, L7N 3G2 (905) 335-3441. www.jcbna.com

JCB reserves the right to change design, materials and/or specifications without notice. Specifications are applicable to units sold in the United States and Canada.

USA 3403 30K 3/99

Você também pode gostar

- Bosch LubricityDocumento24 páginasBosch LubricityvictorpoedeAinda não há avaliações

- Servo System, Solenoid Coil EC200DDocumento1 páginaServo System, Solenoid Coil EC200DHendry PardedeAinda não há avaliações

- Sk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustDocumento2 páginasSk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustPHÁT NGUYỄN THẾ0% (1)

- Hitachi ZX210LC 5 Spec en WebDocumento8 páginasHitachi ZX210LC 5 Spec en WebridofambudiAinda não há avaliações

- Date Tehnice 436 ZXDocumento6 páginasDate Tehnice 436 ZXMB ViorelAinda não há avaliações

- Manual Hitachi 130Documento20 páginasManual Hitachi 130yoharamyAinda não há avaliações

- Chapter 03Documento49 páginasChapter 03Ubeimar Rivera Ospina100% (1)

- SE210Documento2 páginasSE210වයඹ කිරිල් ලී ටූ0% (1)

- Komatsu PC40MR 1 S N 1001 UpDocumento1 páginaKomatsu PC40MR 1 S N 1001 UpDmitry100% (1)

- Kobelco Sk200 8 Excavator Parts Catalog Manual PDFDocumento5 páginasKobelco Sk200 8 Excavator Parts Catalog Manual PDFWahyu Yudi100% (1)

- Cat 320 GC (Gambar)Documento10 páginasCat 320 GC (Gambar)Budi PrayitnoAinda não há avaliações

- U50-5 SGP PDFDocumento12 páginasU50-5 SGP PDFAnonymous ivWnO5H100% (1)

- SYS600 Operation ManualDocumento166 páginasSYS600 Operation ManualDang Jinlong100% (1)

- PC200-7 PartbookDocumento481 páginasPC200-7 PartbookNguyễn Ngọc BáchAinda não há avaliações

- WA150-5 SEBM033805 TroubleshootingDocumento273 páginasWA150-5 SEBM033805 Troubleshootinghaimay118Ainda não há avaliações

- Palfinger 56000Documento3 páginasPalfinger 56000WaldomiroCanoAinda não há avaliações

- 99.67 101582411002 101582419999 Steering CylinderDocumento2 páginas99.67 101582411002 101582419999 Steering CylinderOecox Cah DjadoelAinda não há avaliações

- Serial and Parallel CommunicationDocumento21 páginasSerial and Parallel CommunicationHari KrishAinda não há avaliações

- Kobelco - SK130LDocumento2 páginasKobelco - SK130LJason RogersAinda não há avaliações

- sk200 DaDocumento20 páginassk200 DaEak Machinery100% (1)

- 390D L Excavator WAP00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5236 - 43) - Sistemas y ComponentesDocumento2 páginas390D L Excavator WAP00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5236 - 43) - Sistemas y ComponentesJuan Pablo Virreyra TriguerosAinda não há avaliações

- Standard Equipment Optional Equipment: Bucket Capacities 4.7 - 5.5 YdDocumento4 páginasStandard Equipment Optional Equipment: Bucket Capacities 4.7 - 5.5 Ydtemonggg100% (2)

- Doosan DX255LCDocumento20 páginasDoosan DX255LCForomaquinas0% (1)

- S150-41-K001 SK330-SK350-6E Main Pump & Software ChangeDocumento2 páginasS150-41-K001 SK330-SK350-6E Main Pump & Software ChangePHÁT NGUYỄN THẾ100% (2)

- Date Tehnice JS 220 NCDocumento12 páginasDate Tehnice JS 220 NCMB ViorelAinda não há avaliações

- PC210 (LC) - 10M0 Sen06701-C0 Standard Value TableDocumento47 páginasPC210 (LC) - 10M0 Sen06701-C0 Standard Value Tabledatphuong100% (1)

- SPESIFIKASIDocumento15 páginasSPESIFIKASIMuh DwikaAinda não há avaliações

- SK200-8 - Travel System (SHOP MANUAL) PDFDocumento64 páginasSK200-8 - Travel System (SHOP MANUAL) PDFGohan Jay100% (2)

- Volvo Single Drum Compactors Sd100 SeriesDocumento4 páginasVolvo Single Drum Compactors Sd100 SeriesChris BelgaAinda não há avaliações

- Daewoo Doosan DX480LC DX520LC Hydraulic Excavator Service Repair Shop Manual PDFDocumento10 páginasDaewoo Doosan DX480LC DX520LC Hydraulic Excavator Service Repair Shop Manual PDFАнатолий Подьяров100% (1)

- Hydraulic Excavators: Working Ranges SpecificationsDocumento2 páginasHydraulic Excavators: Working Ranges SpecificationsLittle AyaAinda não há avaliações

- 3G KPI Optimization Sheet NokiaDocumento356 páginas3G KPI Optimization Sheet NokiaMarwah100% (1)

- PC400 8 - PC400LC 8 - Cen00223 03 PDFDocumento24 páginasPC400 8 - PC400LC 8 - Cen00223 03 PDFhendra hardyAinda não há avaliações

- SK130-8 SK140LC-8液压泵分解Documento9 páginasSK130-8 SK140LC-8液压泵分解刘奇雄Ainda não há avaliações

- Total Waktu Waktu Proses Pelaksana: Diperiksa: Diketahui: Sub. Comp. MOD: PC200 - 7 S/N: Com: Main Pump SN: Sub PumpDocumento11 páginasTotal Waktu Waktu Proses Pelaksana: Diperiksa: Diketahui: Sub. Comp. MOD: PC200 - 7 S/N: Com: Main Pump SN: Sub Pumphanafi yusuf100% (1)

- 50 ZVDocumento8 páginas50 ZVArmaghani HaqqAinda não há avaliações

- PC300 - 8Documento52 páginasPC300 - 8Mg Roy100% (3)

- NZ0184 Kobelco SK130UR PDFDocumento1 páginaNZ0184 Kobelco SK130UR PDFEgi SugiantoAinda não há avaliações

- Excavator PC210 8Documento24 páginasExcavator PC210 8Bálint Géza100% (2)

- Doosan DX55 Midi ExcavatorDocumento3 páginasDoosan DX55 Midi ExcavatorDidik HartadiAinda não há avaliações

- s030 30 k004 Sk235sr 1es - sk200 6es Governor Motor AdjustDocumento2 páginass030 30 k004 Sk235sr 1es - sk200 6es Governor Motor AdjustPHÁT NGUYỄN THẾAinda não há avaliações

- Hitachi EX200LC-5 Hydraulic ExcavatorDocumento3 páginasHitachi EX200LC-5 Hydraulic Excavatorveera_swamy275% (4)

- Part Book PC130F-7 Electrical PDFDocumento6 páginasPart Book PC130F-7 Electrical PDFChimanAinda não há avaliações

- Komatsu PC200-7 Error Code On The Monitor, CMP Technology Co., LimitedDocumento5 páginasKomatsu PC200-7 Error Code On The Monitor, CMP Technology Co., Limitedkiagengbrantas heavyequipmentAinda não há avaliações

- Cat 308Documento5 páginasCat 308George PlishkoAinda não há avaliações

- Galeo Pc200-220lc-8-1009-Seno 0084-03 DemoDocumento50 páginasGaleo Pc200-220lc-8-1009-Seno 0084-03 DemoAns LombokAinda não há avaliações

- pc130 7Documento16 páginaspc130 7dwahyudiyanto100% (4)

- Ex 350Documento3 páginasEx 350rizwan159Ainda não há avaliações

- Wheel Loader Hyundai HL960HD-1-30Documento30 páginasWheel Loader Hyundai HL960HD-1-30Sri hartati100% (1)

- Lifting Capacities: Standard EquipmentDocumento20 páginasLifting Capacities: Standard EquipmentPrakash NiroulaAinda não há avaliações

- Om K1006408AE (DX300LC)Documento290 páginasOm K1006408AE (DX300LC)Diego Mauricio Zapata Garcia100% (1)

- Part Book PC130F-7 Fuel TankDocumento4 páginasPart Book PC130F-7 Fuel TankChiman100% (1)

- Sisweb Servlet Cat - Cis.sis - Pcontroller.cssiDocumento2 páginasSisweb Servlet Cat - Cis.sis - Pcontroller.cssiJonathan Javier Ceballos Bonilla86% (7)

- 2018 - sh235x 6 t3Documento10 páginas2018 - sh235x 6 t3Ralf MaurerAinda não há avaliações

- Pc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line R.H.) (Blade)Documento1 páginaPc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line R.H.) (Blade)februAinda não há avaliações

- Swing Bearing For Excavator PDFDocumento1 páginaSwing Bearing For Excavator PDFBoodee PrayAinda não há avaliações

- 20 - Excavadora Hyundai 330LC-9SDocumento10 páginas20 - Excavadora Hyundai 330LC-9SJosé Alejandro MuñozAinda não há avaliações

- Escavadeira 922D ApresentaçãoDocumento2 páginasEscavadeira 922D ApresentaçãoJeffsonFigueiredo100% (2)

- SM D 85 Ess-2 A Demo PDFDocumento33 páginasSM D 85 Ess-2 A Demo PDFArdy091Ainda não há avaliações

- 1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Documento14 páginas1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Irwan Firmansyah100% (2)

- Hitachi ZX30 Excavator PDFDocumento8 páginasHitachi ZX30 Excavator PDFBoodee PrayAinda não há avaliações

- R210LC 7A (Web)Documento10 páginasR210LC 7A (Web)Sebastian Ferreyra100% (2)

- 320C Perform Report (TEXR0335)Documento10 páginas320C Perform Report (TEXR0335)suwarjitechnicAinda não há avaliações

- Manual de Partes Pc200lc-8Documento98 páginasManual de Partes Pc200lc-8Brahian Mijael Garrado Gonzales100% (3)

- MTX 2802S Guide en v1p 0105Documento6 páginasMTX 2802S Guide en v1p 0105sam77qAinda não há avaliações

- Motorcycle, Solo (Harley-Davidson Model WLA)No EverandMotorcycle, Solo (Harley-Davidson Model WLA)Ainda não há avaliações

- Cabina Antonio CarraroDocumento1 páginaCabina Antonio CarraroMB ViorelAinda não há avaliações

- Stihl HP UltraDocumento6 páginasStihl HP UltraMB ViorelAinda não há avaliações

- Bobcat Kompaktlader T300 enDocumento2 páginasBobcat Kompaktlader T300 enMB ViorelAinda não há avaliações

- Gama Incarcatoare JCBDocumento24 páginasGama Incarcatoare JCBMB Viorel100% (1)

- Fisa Tehnica JCB Mini ExcavatorDocumento8 páginasFisa Tehnica JCB Mini ExcavatorMB ViorelAinda não há avaliações

- John Bean Aligner Routine Maintenance ManualDocumento8 páginasJohn Bean Aligner Routine Maintenance ManualBraulio NobreAinda não há avaliações

- Ap 1800 IgetstartDocumento42 páginasAp 1800 IgetstartSilvester Ditya AriwibowoAinda não há avaliações

- Tecspg 3001Documento402 páginasTecspg 3001TrkAinda não há avaliações

- Super Duty Power Pack (OPP20)Documento4 páginasSuper Duty Power Pack (OPP20)Manikandan GurunathanAinda não há avaliações

- GPU NreconDocumento6 páginasGPU NreconAngga SantosoAinda não há avaliações

- Automation and Relay FunctionsDocumento5 páginasAutomation and Relay FunctionsbuturcasAinda não há avaliações

- Solutions For Missing Data in Structural Equation ModelingDocumento6 páginasSolutions For Missing Data in Structural Equation ModelingstevyroriwoAinda não há avaliações

- Answers To Final ExamDocumento4 páginasAnswers To Final ExamSyed Mohammad RizwanAinda não há avaliações

- Graphs in Python: Origins of Graph TheoryDocumento21 páginasGraphs in Python: Origins of Graph TheorytuadongsongAinda não há avaliações

- Instructions: 4 Aaa BatteriesDocumento2 páginasInstructions: 4 Aaa BatteriesJRAinda não há avaliações

- Dell Precision R5500 Server Spec SheetDocumento2 páginasDell Precision R5500 Server Spec SheetTim ChegeAinda não há avaliações

- Dell Vostro A840 A860 A1088 Quanta Vm9 Vm8 Rev 1a SCHDocumento46 páginasDell Vostro A840 A860 A1088 Quanta Vm9 Vm8 Rev 1a SCHRodolfo ArosemenaAinda não há avaliações

- Concrete Duct Cable Chambers - Highways Agency Cable Pits PDFDocumento28 páginasConcrete Duct Cable Chambers - Highways Agency Cable Pits PDFAdhitya DwijayanthoAinda não há avaliações

- Acer E1572p V5we2ea Eg La9532p Laptop SchematicDocumento42 páginasAcer E1572p V5we2ea Eg La9532p Laptop Schematicglauberedif50% (2)

- Smk1060f - MosfetDocumento8 páginasSmk1060f - Mosfetagus2kAinda não há avaliações

- AN200 Smart Digital MagnetometerDocumento2 páginasAN200 Smart Digital MagnetometerJayant KirpekarAinda não há avaliações

- Computer ScienceDocumento120 páginasComputer ScienceLakshmi Narayan100% (1)

- Glue Logic Family SelectionDocumento6 páginasGlue Logic Family Selectionapi-3762100100% (1)

- Quadrics in Opengl: Glupartialdisk To Render The Object GludeletequadricDocumento8 páginasQuadrics in Opengl: Glupartialdisk To Render The Object GludeletequadricmarcelopipoAinda não há avaliações

- CS201 - Introduction To ProgrammingDocumento17 páginasCS201 - Introduction To ProgrammingAsadAinda não há avaliações

- Panasonic Th-50phd5 50phw5 CH Gph5d2Documento196 páginasPanasonic Th-50phd5 50phw5 CH Gph5d2Jesus MartinezAinda não há avaliações

- ICT Folio...Documento68 páginasICT Folio...musang22693100% (2)

- Working With Yocto To Build LinuxDocumento55 páginasWorking With Yocto To Build LinuxJanet PamAinda não há avaliações

- Oracle: Part I: The Questions As I RememberDocumento29 páginasOracle: Part I: The Questions As I RememberKauam SantosAinda não há avaliações

- Ace 27 28XX Env3Documento2 páginasAce 27 28XX Env3imsofakinglazyAinda não há avaliações

- Firmware Functional Description MPH-, MPB-, MPD-, MPC-08 R911332643 - 01 PDFDocumento1.186 páginasFirmware Functional Description MPH-, MPB-, MPD-, MPC-08 R911332643 - 01 PDFCristopher Entena100% (1)