Escolar Documentos

Profissional Documentos

Cultura Documentos

Scheduling in Flexible Manufacturing Systems: Dpto. de Admon. de Empresas y Contabilidad, University of Oviedo, Spain

Enviado por

kcvaraDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Scheduling in Flexible Manufacturing Systems: Dpto. de Admon. de Empresas y Contabilidad, University of Oviedo, Spain

Enviado por

kcvaraDireitos autorais:

Formatos disponíveis

SCHEDULING IN FLEXIBLE MANUFACTURING SYSTEMS

Alberto Gómez

Dpto. de Admon. De Empresas y Contabilidad, University of Oviedo, Spain.

agomez@.estiig.uniovi.es

David de la Fuente, José Parreño and Javier Puente

Dpto. Admon. De Empresas y Contabilidad, University of Oviedo, Spain.

david@.estiig.uniovi.es, parreno@.estiig.uniovi.es, jpuente@.estiig.uniovi.es

Abstract

One of the major problems confronting the search for efficiency in flexible

manufacturing systems is the problem of loading and scheduling. This abstract

presents a new method to solve such problems. The methodology, which is based on

the use of genetic algorithms, allows simple codification of problems and thus

facilitates its use. Two kinds of solution are proposed – that is, loading and

scheduling either jointly or separately – and comparisons are drawn to see which

offers the best solution.

1. Introduction

Flexible Manufacturing Systems (FMS) arose from the requirement to come up with a more

profitable system for manufacturing job lots. Hard automation, which can efficiently churn out

thousands or millions of identical pieces, is not the answer to the demands of the modern world,

where more flexible systems that can handle large numbers and different quantities of articles is

needed.

In the 70s, on-line computers and numerical control techniques made flexible automation

possible; thanks to this step forward, FMS began to become widely used in the electronic,

household electrical appliance, farming and construction components, and above all in the

machine tools industries [5].

This article is structured in the following way. The second section describes FMS’s. The third

section is an introduction to Genetic Algorithms (GA) and the operators that can be used to solve

the problem. The fourth part describes the problem at hand, setting forth the initial hypotheses and

the solution that is applied. The fifth part provides a set of experimental results which allow both

an evaluation of the two suggested versions and an estimation of their system parameters to be

carried out. Finally, section six draws some conclusions.

2. Fms And Scheduling

The simplest definition of an FMS is one that views it as a central-computer-controlled system

linked to several computerised centres or work stations with an automatic materials handling

system [8].

A Flexible Manufacturing Cell (FMC) is made up of at least one element from each of the

following four groups:

• Either specialised or universal machine tools, with automatic tool change.

• Computer-assisted, automated transport of materials along fixed or moving

components of all the pieces and tools in the process.

• A work in process (WIP) area for the products being processed, with automatic

loading and unloading.

• Computer-controlled sequencing of operations, rules and priorities, flow of

materials, types and quality of components, through a hierarchical system with

different levels of decentralisation.

A FMC basically works as follows. Machine operators transport the raw material for a group

of articles to the loading and unloading areas (work-in-process storage), after which the FMC

starts its work. Following instructions from a central computer, the transport system starts to move

materials towards the different work centres. Articles and pieces are transported according to a

given operating sequence. As can easily be deduced, the key to optimum working of the system is

the computer, and production scheduling is particularly critical.

These problems are even greater for FMS’s, which are made up of two or more FMC’s, where

each of the cells is independent but receives its jobs from a common queue. Thus, the problem of

loading is compounded to the problem of scheduling, as components get to the common queue and

the decision as to which cell they are assigned to has to be taken.

3. Description Of The Problem And Proposition Of Models

This study will deal with an FMS loading and scheduling process. This problem has been

analysed by other authors, as Roh et al. [7] who studied the loading and scheduling problems in

flexible :manufacturing systems (FMSs) in which each part visits only one machine for its entire

processing and Drake et al. [3], they studied this problem using simulation techniques. The aim of

the study is to analyse the possibilities that GA’s provide to solve the problem, not to compare

GA’s with other methodologies, as this approach is considered to have been already sufficiently

dealt with in the literature [4]. The genetic algorithm designed to solve these problems should

carry out the following activities:

• Assigning work to a cell.

• Scheduling work within each cell.

Logically, the whole scope of the problem cannot be dealt with, as the number of possible

combinations is practically infinite. For this reason, a series of restrictions were imposed. This

actually approximates the theoretical approach to industrial reality, as many of the restrictions are

imposed by the working mode of the machines. The following are considered as initial hypotheses:

• Operations of a job cannot be spread amongst several cells.

• At least one cell can carry out all the operations of each job.

• Jobs can be done by more than one cell.

• No cell has more than one machine of the same type.

• Cells need not have all the types of machines.

• All machines of the same type have identical characteristics.

• The scheduling problem is a job shop problems type.

The first solution we designed had two independent GA’s. Loading of each cell was calculated

by a GA, which balanced jobs out between different cells (sum of processing time on the

machines); another GA then proceeded to schedule the jobs independently in each of the cells

(using permutation with repetition [2]). But Concurring with the queue models formulated by

Stecke and Solberg[8], results were considered to be much better providing one managed to get

both loading and scheduling to evolve jointly.

To achieve this joint evolution we propose a structure made up of two GA’s, which will evolve

in synchronisation. With the first, loading is carried out (this algorithm will be called GALoad)

and the second does the scheduling (GASchedu). Each first GA individual (GALoad) is united in a

bijective way to another individual in the second GA (GASchedu). The algorithm proposed

calculates the maximum finishing time, this value acting as the system’s fitness. As a function of

it, the selection and reproduction process is carried out in both GA’s. The following GA design

characteristics should be noted for the GA’s that we have proposed:

The loading-evaluation algorithm (GALoad) uses decimal codification; each gene of the

individual represents a job, and its value indicates which cell carries out the task (one must check

that the cell the job is assigned to is actually capable of doing the task). As regards the question of

the GA’s’ main characteristics, it should be stressed that the sampling mechanism used was the

stochastic universal sampling, the reproduction operators are uniform mutation (the gene that has

to mutate should select another cell that can carry out the job), and crossover is simple.

So-called permutation with repetition is used for codification in the second GA (GASchedu)

and the reproduction operators used are order-based mutation [2], and Generalized Order

Crossover (GOX) [1][9]. This codification is used because of the excellent solutions it provides

through only working with feasible solutions.

The following process was used to calculate fitness. First, a GALoad individual is analysed

and jobs are assigned to its cells. With this information, the GASchedu individual associated to the

GALoad chromosome is analysed. Thanks to the manufacturing sequence provided by this second

individual, the job finishing time for each job carried out by each cell is calculated. The longest

time is the system’s fitness, and the proposed algorithm should try to minimise it.

An example of how the joint loading and scheduling methods works. The aim of this example

is to show the joint functioning of both algorithms (GALoad and GASchedu) clearly. Let us

suppose that three jobs are wanted, and the first has two operations, the second has three

operations and the third has two operations. One possible codification of a GALoad individual is

(1 2 1), which means that the first job is done in cell one, the second in cell 2, and the third in cell

1.

The GASchedu individual associated to the above chromosome has for example the following

codification (1 2 1 3 2 2 3). This means that the “1” that occupies the first position of the

individual indicates that the first operation of job “1” is carried out in cell “1”; the “2” in second

position indicates that the first operation of job “2” is carried out in cell “2”; the “1” in third

position indicates that the second operation of job “1” is carried out in cell “1”, and so on and so

forth.

4. Experiments Carried Out

Once the new algorithm had been designed, which was a basic aim of this study, it was

decided that experiments should be carried out to calculate optimum values that GA parameters

should have for ideal functioning. An FMS configuration which the experiments could be carried

out on was required to get these values. An FMS structure made up of four FMC was decided

upon. Each of them had a maximum of three machines, and twenty jobs were put into the system.

A series of experiments were carried out using this FMS. Once the optimum GA parameters

were obtained, the initial hypothesis, - that the algorithm works better by considering the loading

and scheduling system as a whole - based on the work of Stecke and Solberg [8], was considered

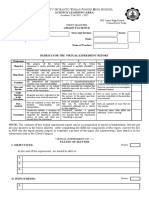

to need testing. Several experiments, some of which are shown in table 3, were carried out to

contrast this hypothesis. The meaning of the columns is:

The “Method” column shows whether the experiment was done with load and scheduling

evolving separately (part) or jointly (jointly).

The “Cell”, “Job”, and “Machine” columns respectively show the cells, jobs and the maximum

number of machines forming part of the FMS being studied.

Tabla 1. A comparison of different types of problem

Methods Generation Cell Jobs Machine Total

Jointly 200 4 20 3 206

Part 200 4 20 3 250

Jointly 1000 4 20 3 204

Part 1000 4 20 3 250

Jointly 200 4 50 3 572

Part 200 4 50 3 927

Jointly 1000 4 50 3 526

Part 1000 4 50 3 927

Jointly 200 7 50 6 564

Part 200 7 50 6 649

Jointly 1000 7 50 6 488

Part 1000 7 50 6 640

The “Total” column indicates the moment when the FMS finishes all its jobs.

All experiments were carried out with the same population (100), the same crossover (0.8) and

mutation probability (0.05). Table 1 shows that the solutions provided by the system that jointly

loading and scheduling are better than the solutions provided by the separate system. This

approach has also been tested for large size problems. Results were similar (the joint model is

best); results can be considered good and calculation speed continues to be acceptable.

5. Conclusions

This text is a study and description of the application of genetic algorithms to the loading and

scheduling problem in an FMS. It has been empirically demonstrated that better results are

obtained by applying this metaheuristic if the loading and scheduling problems are studied jointly

rather than individually. The text also investigated which combination of GA parameters was ideal

for solving the loading and scheduling problem in an FMS.

References

[1] Bierwirth, C (1995). “A generalized permutation approach to job-shop scheduling with

genetic algorithms”. Or Spektrum 17(2-3), 87-92.

[2] Davis, L. (1991). Handbook of Genetic Algorithms. Van Nostrand Reinhold, New York,

[3] Drake, G.R., Smith, J.S. and Peters, B.A. (1995), "Simulation as a Planning and Scheduling

Tool for Flexible Manufacturing Systems," Proceedings of the 1995 Winter Simulation

Conference, Washington, DC.

[4] Goldberg. D. (1989). Genetic Algorithms in Search, Optimization & Machine Learning.

Addison-Wesley Co., Inc, Reading, MA.

[5] Kouvelis, P. (1992). “Design and planning problems in flexible manufacturing systems: a

critical review”. Journal of Intelligent Manufacturing, 3, 75-99.

[6] Parrish, D. (1993). Flexible Manufacturing. Butterworth-Heinemann Ltd.

[7] Roh HK, Kim YD (1997). Due-date based loading and scheduling methods for a flexible

manufacturing system with an automatic tool transporter International Journal Of Production

Research ,35: (11) 2989-3003.

[8] Stecke, K.E. and Solberg, J. (1982). The optimality of unbalanced workloads and machine

group sizes for flexible manufacturing systems. WP 290, Graduate School of Business

Administration, The University of Michigan.

[9] Varela, R.; Vela, C.; Puente, J.; Gómez, A. and Vidal, A. (2001). Solving Job-Shop

Scheduling Problems by Means of Genetic Algorithms. In: The practical handbook of Genetic

algorithms. Applications. Ed.: Chapman & Hall/CRC. pp. 275-293.

Você também pode gostar

- Designs in Clinical ResearchDocumento29 páginasDesigns in Clinical ResearchAli KhanAinda não há avaliações

- Types of VariablesDocumento4 páginasTypes of VariablesJeffrey Mendoza TamayoAinda não há avaliações

- Ee RPPFDocumento3 páginasEe RPPFDouglas WeberAinda não há avaliações

- Test Bank For Social Psychology 13th EditionDocumento28 páginasTest Bank For Social Psychology 13th EditionJack Witters100% (25)

- International Perspective Mathematical ModellingDocumento618 páginasInternational Perspective Mathematical ModellingAdolfo Esteban100% (1)

- Practcal Research 2 Rex PublishingDocumento163 páginasPractcal Research 2 Rex PublishingLian DolojanAinda não há avaliações

- Operations Scheduling For Manufacturing Systems With Parallel ComputingDocumento6 páginasOperations Scheduling For Manufacturing Systems With Parallel ComputingSakshi SaxenaAinda não há avaliações

- Genetic Algorithms For Optimum Designing of Fuzzy ControllersDocumento6 páginasGenetic Algorithms For Optimum Designing of Fuzzy ControllersLukas NurHappyAinda não há avaliações

- A Genetic Algorithm For The Flexible Job-Shop Scheduling ProblemDocumento11 páginasA Genetic Algorithm For The Flexible Job-Shop Scheduling ProblemSilvia Adelina MateescuAinda não há avaliações

- A New Approach For Solving The Unit Commitment Problem by Cuckoo Search AlgorithmDocumento7 páginasA New Approach For Solving The Unit Commitment Problem by Cuckoo Search AlgorithmMarZiYaAinda não há avaliações

- GA Job SchedullingDocumento6 páginasGA Job Schedullingbudi2326Ainda não há avaliações

- A Genetic Algorithm Approach To Cellular Manufacturing SystemsDocumento20 páginasA Genetic Algorithm Approach To Cellular Manufacturing SystemsKumar NoriAinda não há avaliações

- Exploiting A Workstation Network For Automatic Generation of Test Patterns For Digital CircuitsDocumento17 páginasExploiting A Workstation Network For Automatic Generation of Test Patterns For Digital CircuitsDhwal MehtaAinda não há avaliações

- Modified immune algorithm for efficient job schedulingDocumento14 páginasModified immune algorithm for efficient job schedulingmv_raha001Ainda não há avaliações

- Study of Genetic Algorithm For Process Scheduling in Distributed SystemsDocumento4 páginasStudy of Genetic Algorithm For Process Scheduling in Distributed SystemsInternational Journal of computational Engineering research (IJCER)Ainda não há avaliações

- The Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemDocumento12 páginasThe Use of Simulation and Genetic Algorithm With Different Genetic Operators To Optimize Manufacturing SystemSam ArAinda não há avaliações

- Kim2001 PDFDocumento11 páginasKim2001 PDFKailash BhosaleAinda não há avaliações

- Manufacturing Management ProjectDocumento15 páginasManufacturing Management ProjectHazem ElbannaAinda não há avaliações

- Implementation of Regression Testing Using Fuzzy Logic: Volume 2, Issue 4, April 2013Documento3 páginasImplementation of Regression Testing Using Fuzzy Logic: Volume 2, Issue 4, April 2013International Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Task Scheduling in Multiprocessor System Using Genetic AlgorithmDocumento5 páginasTask Scheduling in Multiprocessor System Using Genetic AlgorithmAmit BansalAinda não há avaliações

- Genetic algorithm for unrelated parallel machine scheduling with sequence dependent setup timesDocumento11 páginasGenetic algorithm for unrelated parallel machine scheduling with sequence dependent setup timesOlivia brianneAinda não há avaliações

- European Journal of Operational Research: Luca Venditti, Dario Pacciarelli, Carlo MeloniDocumento9 páginasEuropean Journal of Operational Research: Luca Venditti, Dario Pacciarelli, Carlo MeloniOlivia brianneAinda não há avaliações

- GA for Power System Maintenance SchedulingDocumento7 páginasGA for Power System Maintenance Schedulingpinku1005Ainda não há avaliações

- Chapter - 1: Another Problem During The Time of Optimizing Any Objective FunctionsDocumento14 páginasChapter - 1: Another Problem During The Time of Optimizing Any Objective FunctionsHossein HosseinAinda não há avaliações

- Project Work (Uniben) RetouchedDocumento26 páginasProject Work (Uniben) RetouchedClement Ofoluwanyo100% (1)

- A Performance-Based Labor Allocation Model for Cellular ManufacturingDocumento6 páginasA Performance-Based Labor Allocation Model for Cellular ManufacturingAnupa De SilvaAinda não há avaliações

- Modeling The Scheduling Problem in Cellular Manufacturing Systems Using Genetic Algorithm As An Ef Ficient Meta-Heuristic ApproachDocumento7 páginasModeling The Scheduling Problem in Cellular Manufacturing Systems Using Genetic Algorithm As An Ef Ficient Meta-Heuristic ApproachabdstarAinda não há avaliações

- A Novel Imperialist Competitive Algorithm To Solve Flexible Flow Shop Scheduling Problem in Order To Minimize Maximum Completion TimeDocumento6 páginasA Novel Imperialist Competitive Algorithm To Solve Flexible Flow Shop Scheduling Problem in Order To Minimize Maximum Completion TimeAhmed HassanAinda não há avaliações

- Operations Scheduling For An Advanced Flexible Manufacturing System With Multi-Fixturing PalletsDocumento8 páginasOperations Scheduling For An Advanced Flexible Manufacturing System With Multi-Fixturing PalletsEduardo Jiménez ChavesAinda não há avaliações

- Hybrid Manufacturing System Design Using Evolutionary ProgrammingDocumento4 páginasHybrid Manufacturing System Design Using Evolutionary ProgramminganubhavAinda não há avaliações

- A Generic Approach To Measuring The Machine Flexibility of A Manufacturing SystemDocumento27 páginasA Generic Approach To Measuring The Machine Flexibility of A Manufacturing SystemAmrik SinghAinda não há avaliações

- Fully Parallel Particle LearningDocumento23 páginasFully Parallel Particle Learningnobody0215Ainda não há avaliações

- Parallel GA optimizes generation expansion planningDocumento8 páginasParallel GA optimizes generation expansion planningbhumaniAinda não há avaliações

- Hybrid Flow Shop Scheduling With Sequence Dependent Family Setup Time and Uncertain Due DatesDocumento35 páginasHybrid Flow Shop Scheduling With Sequence Dependent Family Setup Time and Uncertain Due Datesdaimon_pAinda não há avaliações

- Solving The Permutation Flow Shop Problem With Makespan Criterion Using GridsDocumento12 páginasSolving The Permutation Flow Shop Problem With Makespan Criterion Using Gridsferronatto11Ainda não há avaliações

- GRE Fens Tette 1986Documento7 páginasGRE Fens Tette 1986lovelyosmile253Ainda não há avaliações

- Minimising makespan in job-shops with deterministic machine availability constraintsDocumento14 páginasMinimising makespan in job-shops with deterministic machine availability constraintsjuan ardilaAinda não há avaliações

- Fast Coalgebraic Bisimilarity Minimization: Jules Jacobs, Thorsten WissmannDocumento32 páginasFast Coalgebraic Bisimilarity Minimization: Jules Jacobs, Thorsten Wissmanns.dedaloscribdAinda não há avaliações

- Intelligent Control:: Sub: Ai and Neural Networks Subject Code: MT-22 Semester: 2ndDocumento6 páginasIntelligent Control:: Sub: Ai and Neural Networks Subject Code: MT-22 Semester: 2ndUsha SreeAinda não há avaliações

- Content ServerDocumento13 páginasContent ServerAntoniojuarezjuarezAinda não há avaliações

- A Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentDocumento8 páginasA Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentInternational Journal of computational Engineering research (IJCER)Ainda não há avaliações

- Metaheuristic Algorithms Project IdeasDocumento5 páginasMetaheuristic Algorithms Project IdeasNicolasAinda não há avaliações

- Group13 - 13000119059 - Flow Shop SchedulingDocumento8 páginasGroup13 - 13000119059 - Flow Shop SchedulingKaustav DeyAinda não há avaliações

- Genetic Algorithms Short Term Unit CommitmentDocumento14 páginasGenetic Algorithms Short Term Unit CommitmentSaheem ZafarAinda não há avaliações

- Sensors: Metaheuristic Based Scheduling Meta-Tasks in Distributed Heterogeneous Computing SystemsDocumento12 páginasSensors: Metaheuristic Based Scheduling Meta-Tasks in Distributed Heterogeneous Computing SystemsalkimistuAinda não há avaliações

- Lahrichi 2021Documento26 páginasLahrichi 2021Youssef LahrichiAinda não há avaliações

- Fuzzy Logic in Critical Section of Operating SystemDocumento7 páginasFuzzy Logic in Critical Section of Operating SystemResearch Cell: An International Journal of Engineering SciencesAinda não há avaliações

- IFCM97 - An Integration Testing Method That Is Proved To Find All FaultsDocumento29 páginasIFCM97 - An Integration Testing Method That Is Proved To Find All Faultsصالح الشهرانيAinda não há avaliações

- Integrated Process Planning and Scheduling in Smart Manufacturing Using Genetic Based AlgorithmDocumento6 páginasIntegrated Process Planning and Scheduling in Smart Manufacturing Using Genetic Based Algorithmrizqy lovinaAinda não há avaliações

- Flow-Shop Sequencing Model Using Genetic Algorithm: Smita Verma and Paheli SinghalDocumento4 páginasFlow-Shop Sequencing Model Using Genetic Algorithm: Smita Verma and Paheli SinghalSaravanan GopalAinda não há avaliações

- Multiple and Bicriteria Scheduling - A Literature SurveyDocumento17 páginasMultiple and Bicriteria Scheduling - A Literature SurveybizAinda não há avaliações

- A Model For Integrated Production Planning in Cellular Manufacturing SystemsDocumento10 páginasA Model For Integrated Production Planning in Cellular Manufacturing SystemsAmrik SinghAinda não há avaliações

- Recursive and Residual Algorithms For The Efficient Numerical Integration of Multi-Body SystemsDocumento31 páginasRecursive and Residual Algorithms For The Efficient Numerical Integration of Multi-Body SystemsCleves AxiomaAinda não há avaliações

- How Factory Physics Helps SimulationDocumento6 páginasHow Factory Physics Helps SimulationJerome KozlowskiAinda não há avaliações

- Parametric Reconfiguration Improvement in Non-Iterative Concurrent Mechatronic Design Using An Evolutionary-Based ApproachDocumento15 páginasParametric Reconfiguration Improvement in Non-Iterative Concurrent Mechatronic Design Using An Evolutionary-Based ApproachIng. Omar SerranoAinda não há avaliações

- Bo 24437446Documento10 páginasBo 24437446Kelvin SudaniAinda não há avaliações

- AOR 2014 ObeidDauzere PeresYugmaDocumento14 páginasAOR 2014 ObeidDauzere PeresYugmaMohamed LaalouAinda não há avaliações

- A Genetic Approach For Multiprocessors Task SchedulingDocumento9 páginasA Genetic Approach For Multiprocessors Task SchedulingInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- A Simulated Annealing Method To Cover Dynamic Load Balancing in Grid EnvironmentDocumento10 páginasA Simulated Annealing Method To Cover Dynamic Load Balancing in Grid EnvironmentMauricio PalettaAinda não há avaliações

- Ga ResultsDocumento13 páginasGa ResultsWan IzhamAinda não há avaliações

- Human Designed vs. Genetically Programmed Differential Evolution OperatorsDocumento7 páginasHuman Designed vs. Genetically Programmed Differential Evolution Operators77451154Ainda não há avaliações

- Performance Analysis of A Flexible Manufacturing System: A Statistical ApproachDocumento13 páginasPerformance Analysis of A Flexible Manufacturing System: A Statistical ApproachAmrik SinghAinda não há avaliações

- Job Shop and Parallel Machine Scheduling Problems: Minimization of MakspanDocumento2 páginasJob Shop and Parallel Machine Scheduling Problems: Minimization of MakspanMarya MEeAinda não há avaliações

- An Improved Simulated Annealing For Facility Layout Problems in Cellular Manufacturing SystemsDocumento11 páginasAn Improved Simulated Annealing For Facility Layout Problems in Cellular Manufacturing SystemsAnonymous PsEz5kGVaeAinda não há avaliações

- 10 (1) 1 1 29 8749Documento16 páginas10 (1) 1 1 29 8749kcvaraAinda não há avaliações

- A Reinforcement Learning Approach To Job-Shop Scheduling: Wei Zhang Thomas G. DietterichDocumento7 páginasA Reinforcement Learning Approach To Job-Shop Scheduling: Wei Zhang Thomas G. DietterichkcvaraAinda não há avaliações

- ScribDocumento2 páginasScribkcvaraAinda não há avaliações

- 10 (1) 1 1 33 823Documento18 páginas10 (1) 1 1 33 823kcvara100% (1)

- 10 (1) 1 1 112 6217Documento28 páginas10 (1) 1 1 112 6217kcvaraAinda não há avaliações

- Stochastic Model For The Asynchronous Scheduling ProblemDocumento6 páginasStochastic Model For The Asynchronous Scheduling ProblemkcvaraAinda não há avaliações

- Integrated Scheduling and Tool Management in Exible Manufacturing SystemsDocumento26 páginasIntegrated Scheduling and Tool Management in Exible Manufacturing SystemskcvaraAinda não há avaliações

- 10 (1) 1 1 33 3230Documento10 páginas10 (1) 1 1 33 3230kcvaraAinda não há avaliações

- Planning and Scheduling in The Process Industry: Consolidated Review of Research and ApplicationsDocumento12 páginasPlanning and Scheduling in The Process Industry: Consolidated Review of Research and ApplicationskcvaraAinda não há avaliações

- 10 (1) 1 1 9 6327Documento35 páginas10 (1) 1 1 9 6327kcvaraAinda não há avaliações

- J. Appl. Prob., 16:658-689, 1979Documento13 páginasJ. Appl. Prob., 16:658-689, 1979kcvaraAinda não há avaliações

- 10 (1) 1 1 112 6217Documento28 páginas10 (1) 1 1 112 6217kcvaraAinda não há avaliações

- A General Stochastic Approach To Solving Problems With Hard and Soft ConstraintsDocumento14 páginasA General Stochastic Approach To Solving Problems With Hard and Soft ConstraintskcvaraAinda não há avaliações

- A Stochastic Programming Approach To Scheduling in TAC SCMDocumento10 páginasA Stochastic Programming Approach To Scheduling in TAC SCMkcvaraAinda não há avaliações

- 10 (1) 1 1 8 4433Documento37 páginas10 (1) 1 1 8 4433kcvaraAinda não há avaliações

- A Stochastic Programming Approach To Scheduling in TAC SCMDocumento10 páginasA Stochastic Programming Approach To Scheduling in TAC SCMkcvaraAinda não há avaliações

- Stochastic Reactive Production Scheduling by Multi-Agent Based Asynchronous Approximate Dynamic ProgrammingDocumento10 páginasStochastic Reactive Production Scheduling by Multi-Agent Based Asynchronous Approximate Dynamic ProgrammingkcvaraAinda não há avaliações

- Stochastic Programming For Nurse Assignment: AbstractDocumento26 páginasStochastic Programming For Nurse Assignment: AbstractkcvaraAinda não há avaliações

- 10 (1) 1 1 61 9371Documento5 páginas10 (1) 1 1 61 9371kcvaraAinda não há avaliações

- A Stochastic Programming Approach To Scheduling in TAC SCMDocumento11 páginasA Stochastic Programming Approach To Scheduling in TAC SCMkcvaraAinda não há avaliações

- 10 (1) 1 1 1 2128Documento10 páginas10 (1) 1 1 1 2128kcvaraAinda não há avaliações

- 10 (1) 1 1 83 5191Documento113 páginas10 (1) 1 1 83 5191kcvaraAinda não há avaliações

- An Experimental Study of LP-Based Approximation Algorithms For Scheduling ProblemsDocumento14 páginasAn Experimental Study of LP-Based Approximation Algorithms For Scheduling ProblemskcvaraAinda não há avaliações

- 10 (1) 1 1 54 6750Documento28 páginas10 (1) 1 1 54 6750kcvaraAinda não há avaliações

- Dedicated To The Memory of Gene LawlerDocumento12 páginasDedicated To The Memory of Gene LawlerkcvaraAinda não há avaliações

- Douglas R. Smith, Eduardo A. Parra, and Stephen J. WestfoldDocumento9 páginasDouglas R. Smith, Eduardo A. Parra, and Stephen J. Westfoldkcvara100% (1)

- Solving Stochastic Planning Problems With Large State and Action SpacesDocumento9 páginasSolving Stochastic Planning Problems With Large State and Action SpaceskcvaraAinda não há avaliações

- Flow and Stretch Metrics For Scheduling Continuous Job StreamsDocumento10 páginasFlow and Stretch Metrics For Scheduling Continuous Job StreamskcvaraAinda não há avaliações

- A Linear Programming Approach To Solving Stochastic Dynamic ProgramsDocumento39 páginasA Linear Programming Approach To Solving Stochastic Dynamic ProgramskcvaraAinda não há avaliações

- Preparing A Research ReportDocumento15 páginasPreparing A Research ReportAnafhia RahawarinAinda não há avaliações

- Extended Essay - MathematicsDocumento67 páginasExtended Essay - MathematicsFredrik ArentzAinda não há avaliações

- Yovel Yovel Levy 2001 - Hemispheric AsymmetriesDocumento17 páginasYovel Yovel Levy 2001 - Hemispheric AsymmetrieslifemagicAinda não há avaliações

- Unit-II Research Design and MeasurementDocumento127 páginasUnit-II Research Design and MeasurementSaravanan Shanmugam50% (2)

- Heating Curve Lab ReportDocumento11 páginasHeating Curve Lab Reportapi-460721221Ainda não há avaliações

- Rocket Lab ReportDocumento4 páginasRocket Lab Reportbishopclark98Ainda não há avaliações

- Practical Research 2 Module 4: Designs A Research Used in Daily LifeDocumento7 páginasPractical Research 2 Module 4: Designs A Research Used in Daily Life306947 Bancal Pugad ISAinda não há avaliações

- Inquiry Action PlanDocumento20 páginasInquiry Action PlanColton WilderAinda não há avaliações

- SBI4U 1-2H Osmosis Lab, SampleDocumento11 páginasSBI4U 1-2H Osmosis Lab, Sampletimi oshunAinda não há avaliações

- Decision Making BookletDocumento48 páginasDecision Making BookletDornenAinda não há avaliações

- Film, Television and Scenography: Department ofDocumento32 páginasFilm, Television and Scenography: Department ofShuchin ShenAinda não há avaliações

- 8604 - Solved Assignment 1 by AhmadDocumento16 páginas8604 - Solved Assignment 1 by Ahmadshangool mukhtarAinda não há avaliações

- Physics Gcse Coursework Resistance of A WireDocumento8 páginasPhysics Gcse Coursework Resistance of A Wiref5dq3ch5100% (2)

- EFFECTIVENESS OF HOT PEPPER (Capsicum Annuum) Extract As Alternative Disinfectant in Dental CuspidorsDocumento15 páginasEFFECTIVENESS OF HOT PEPPER (Capsicum Annuum) Extract As Alternative Disinfectant in Dental CuspidorsRachel BrionesAinda não há avaliações

- Education Question Bank - 358 Mcqs On "Psychological Foundations of Education"Documento15 páginasEducation Question Bank - 358 Mcqs On "Psychological Foundations of Education"sairaAinda não há avaliações

- Experimental DesignDocumento100 páginasExperimental DesignfainAinda não há avaliações

- Jayvi Joshua Paares Arcaya Lesson Plan On G8 ProbabilityDocumento6 páginasJayvi Joshua Paares Arcaya Lesson Plan On G8 ProbabilityKeno Martin AdvientoAinda não há avaliações

- Design of ExperimentsDocumento12 páginasDesign of ExperimentsSreehari ViswanathanAinda não há avaliações

- Q1 PR2 LAS WEEK 1 Characterisics, Strngths ND WeaknessDocumento14 páginasQ1 PR2 LAS WEEK 1 Characterisics, Strngths ND WeaknessAnalie CabanlitAinda não há avaliações

- The Scientific WorkDocumento24 páginasThe Scientific WorkhumanAinda não há avaliações

- Applied Social Research A Tool For The Human Services 9Th Edition Monette Solutions Manual Full Chapter PDFDocumento26 páginasApplied Social Research A Tool For The Human Services 9Th Edition Monette Solutions Manual Full Chapter PDFBethRyanoxcf100% (11)

- 4 - Solubility of Mgso4 ExperimentDocumento2 páginas4 - Solubility of Mgso4 ExperimentMrin03Ainda não há avaliações

- 2020-2021-PETA 1.1 States of MatterDocumento4 páginas2020-2021-PETA 1.1 States of Matternathaniel husolAinda não há avaliações

- SASTA Proceedings of The 37th Annual Congress 1963Documento177 páginasSASTA Proceedings of The 37th Annual Congress 1963Cecilio ValderramaAinda não há avaliações