Escolar Documentos

Profissional Documentos

Cultura Documentos

Business Plan On Plastic Recycling Manufacturing

Enviado por

anilkolekarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Business Plan On Plastic Recycling Manufacturing

Enviado por

anilkolekarDireitos autorais:

Formatos disponíveis

Busness Pan

Ra|nsh

Chaubey

IBMR Bangalore

QUASAR PLASTICS

Quality at the BEST

| y e a r - 2 0 0 8 - 2 0 1 0 |

1 | O u a s a r P a s t c s

2 | O u a s a r P a s t c s

This is business plan is submitted to the IBMR Bangalore as a part of

curriculum.

Submitted by:

Rajnish umar !haubey

"#$M %&''()&'*'+

3 | O u a s a r P a s t c s

T,B-. /0 !/1T.1T

EXECUTIVE

SUMMARY

.

C!MPA"Y

!VERVIE#

..$

MISSION........

.......................................

.....5

MARKET AND

PRODUCT..................................

.........6

OB|ECTIVE.................................

..................6

KEY TO SUCCESS..

.......................................

........6

PR!%UCT A"% SERVICE

%ESCRIPTI!".

.&

MARKET COMPARISON...........

................................7

POSSIBLE OBSTACLES.................

.............................7

I"%USTRY A"% MAR'ET PLACE A"ALYSIS.

.(

INDUSTRY ANALYSIS......................

........................6

MARKETPLACE ANALYSIS...........................

................6

| O u a s a r P a s t c s

CUSTOMER

ANALYSIS..................................

.........11

COMPETITOR

ANALYSIS..................................

.......12

MAR'ETI") STRATE)Y.

12

PRODUCT SERVICE STRATEGY..

......................................13

PRICING STRATEGY..................

...........................13

DISTRIBUTION

STRATEGY..................................

......13

ADVERTISEMENT AND PROMOTION

STRATEGY............................13

SALES

STRATEGY..................................

...........13

SALES

FORECAST.................................

............13

%EVEL!PME"T

.1

DEVELOPMENT STRATEGY..

.......................................1

4

MA"A)EME"T.

.1$

$ | O u a s a r P a s t c s

!PERATI!"S.

..1*

SCOPE OF

OPERATIONS................................

...........20

SUPPLY CHAIN........

.......................................

.21

PROCESS FLOWCHART...........

................................22

GANTT

CHART...................................

............23

FACILITY

LAYOUT...................................

...........24

+I"A"CIAL STATEME"T.

..2$

STARTUP

EXPENCES..................................

.........25

INCOME

STATEMENT.................................

..........26

BALANCE SHEET..........

.....................................27

BREAK EVEN

POINT....................................

........28

APPE"%IX

.2(

* | O u a s a r P a s t c s

Bi,li-./a0hy

33

Executive summary

Plastic is the basic need of our day to day life. During recent years the plastic

industry has grown with a substantial growth rate. This growth is driven by three

sectors viz packaging, infrastructure and agriculture. There are the various

verities of plastics out of which PVC (Polyvinyl chloride and P!T (Polyethylene

terephthylene plastics have their considerable contribution. P!T plastics are

generally used in the "anufacturing of beverage bottles for the packaging and

PVC plastic is used in the production of household plastic "aterials. The growing

utilization of plastics in industrial and consu"er applications and surrounding

solid waste recycling, has led to an increased de"and for recycled plastic resins

and products.

#e the $uasar plastics provide a wide range of plastic solutions for household

and raw "aterial for packaging of various co"panies. %s a part of our ongoing

efforts to e&ploit this opportunity we will recycle the plastics and then produce

kitchen ware ite"s and other related plastic "aterial. #e will also sell the

recycled plastics to the co"panies in the plastic business. #e will have a

& | O u a s a r P a s t c s

recycling plant along with the production unit. The raw "aterial will be procured

fro" the waste collectors. The raw "aterial will be post consu"ed beverage

bottles and other soft plastic "aterials

'ur "ain focus is our industrial custo"er who" we will sell P!T bottles and P!T

flakes. (t will contribute "ore than )*+ of our sales. #e will also focus on the

household plastic business which is the part of our portfolio. The initial set up

cost will be ,s -., .*,***.

$uasar plastics will be a solution proprietorship business run by the pro"oter

,a/nish 0u"ar Chaubey who is a 12% graduate with finance and "arketing as

specialization.

3ince plastic "aterial does not carry any brand na"e so it will give us an addition

benefit in long ter" to establish our brand na"e. To e&ploit the "arket we will

use penetration pricing as our "arketing strategy and utilize our stringent

distribution network and strong industrial relationship.

%s a future plan in co"ing years we will increase the variety of plastics like 4DP!

(4ow density polyethylene and 5DP! (5igh density polyethylene. 2y doing this

we will be able to produce plastic carry bags and raw "aterial for production for

plastic chairs and tables and other fiber based products.

COMPANY OVERVIEW

$uasar Plastics provide a wide range of plastic solutions for households and raw

"aterial for packaging to the various co"panies. %llahabad is the place where

the facility will be established and other operation will co""ence.

#e will collect the plastic garbage like consu"er beverage bottles, plastic bags

fro" various garbage stores and then our recycle unit will process it which

eventually be used for the production of finished goods.

The plastic garbage we are getting as raw "aterial has two co"ponents one is

PVC (Polyvinyl chloride and other is P!T (Polyethylene terephthylene . 6irstly

the whole garbage is "elted and then PVC and P!T are separated fro" each

other by froth flotation techni7ue.

1 | O u a s a r P a s t c s

#e will create a plant (actual facilities to be shared with the recycling unit to

"anufacture e&truded plastic flakes (purified plastic. The e&truded plastic is then

"olded in the various products.

#e will produce two types of replay plastics

PVC( Polyvinyl chloride

P!T( Polyethylene terephthylene

Mission Statement

$uasar Plastics

3trive to provide the e&cellent plastic solution to the custo"ers at

co"petitive prices.

Continually e&pands our range of products.

(s poised to service both large and s"all custo"ers.

Markets and Products

The plastic products usually do not carry a brand na"e so intruding in the

business like plastic will not be too hard with low price strategy. The population of

%llahabad and the cities around it like Varanasi, 8orakhpur, 9ohnpur is around

-Cr. and this area is basically co"prises of low to "iddle inco"e group fa"ilies

so they focus on plastic products rather than fiber since it is a cheaper. 5ence it

is huge "arket to e&ploit.

6ro" %llahabad city :** tons of solid waste is produced fro" that ;:tons of

plastic bags and around < tons of plastic bottles is generated per day. 3o the

supply of raw "aterial will be continuous.

%part fro" this we will sell raw "aterial for packaging to the various s"all

co"panies in this area. %round -* s"all and "ediu" scale co"panies are

working in this region. 3o a large a"ount of industrial custo"er is also available.

There are two folds of products that we are providing one is industrial and other

is household.

( | O u a s a r P a s t c s

O!ectives

Develop a business that survives on its own cash.

Create a co"pany which e&ceeds custo"er satisfaction level.

!&pand the service to whole =P in first five years and then to Delhi.

!&tending the services to electronic co"ponent "anufacturing co"panies

for production of capacitors printed circuit boards etc.

"ey to success#

The "ain keys to the success of the Co"pany are>

3ecure 3upply? Contract for supply of post?consu"er bottles and post?

industrial "anufacturing waste for P!T raw "aterial feed stock.

3atisfy our custo"er so that we can retain the"

1aintain low overhead and operating costs

Provide better prices than all our co"petitors

Product and services

#e will provide a wide range of plastic products for households and raw "aterial

for packaging.

The recycled plastic is processed to Polyethylene Terephthalate (P!T. P!T is a

ther"oplastic poly"er viscous of polyester fa"ily. The biggest property of this

co"pound is it transparent. This is the reason why it is used for packaging. %part

fro" this P!T have good strength, ductility, stiffness and hardness. %fter the

recycling process co"pleted an e&truded plastic is generated. Plastics e&trusion

is a high volu"e "anufacturing process in which raw plastic "aterial is "elted

and for"ed into a continuous profile.

The products we are producing are

Cleaned and recycled plastic flakes of P!T and bottles, recovered fro"

post?consu"er beverage bottles. (this P!T will work as raw "aterial for

packaging to various fir"s, not for the end user

5ousehold finished plastic goods. #e are "anufacturing plastic tubes of

various dia"eter, plastic kitchen ware. ( for the end user

12 | O u a s a r P a s t c s

P!T flake will be sold to ther"o for"ers (those who "old plastic sheets into

usable products pri"arily to be used to produce high?visibility packaging. %nd

also to the beverage co"panies for packaging.

,ecycled plastic is widely used in "ainstrea" construction products such as

da"p proof "e"brane, drainage pipes, ducting and flooring. 2ins, street signs

and planters are fre7uently "ade fro" plastic. They are cost co"petitive and

resistant to da"age. 4ocal authorities and schools are able to de"onstrate

recycling in action by specifying recycled products

5igh strength P!T is used in the clothing, furnishings, tyre cord and technical

te&tiles

%part fro" P!T the household plastic will be directly sold to the end custo"ers.

(n day to day life plastic ite"s like water bottles, shop case scrubber etc is

fre7uently used. 3o there is a big de"and of these in local "arket.

Market com$arison

#hile 7uality and delivery are i"portant factors to our potential clients, price is

"ost often the deter"ining factor in a buying decision. 8ood?7uality packaging

products "anufactured fro" recycled (less e&pensive resins, as close as

practical to the end custo"er@s operations, will be "ost co"petitive and achieve

a significant "arket share. These factors have helped to deter"ine the business

para"eters of ,eplay Plastics.

Possi%e ostac%e

The product is co"pleted and ready for the "arket launch. The possible

obstacles are

&navai%a%e or scarce ra' materia% stock (or $roduction

,eplay is confident that it has secured good availability of low cost post?

consu"er P!T bottles (feed stock derived fro" post?consu"er beverage

bottles. (t "ay be possible that we would not get desired raw "aterial.

Com$any may not meet environmenta% standards

This environ"entally?favorable venture provides for the develop"ent of

technically feasible and econo"ically viable solutions to P!T plastic

beverage bottle recycling, as well as environ"entally aware in?house re?

use practices which filter and return nearly all of the process water to the

production lines

11 | O u a s a r P a s t c s

Industry and market$%ace ana%ysis

Industry ana%ysis

Plastic recycling is an industry in itself in (ndia. %ccording to the Crisil research

<-)* co"panies are working in this industry with a turnover of ,s AB** Crore

provides e"ploy"ent to -.: "illion people. (n (ndia per capita plastic

consu"ption in lowest in the world. The per capita consu"ption is /ust one fifth of

world average which is :kg. the do"estic de"and of plastic has grown by A+

and reached to ..:11T in year B**:.The 8DP has grown during this period at

).-+ and plastic industry ;.- ti"es of 8DP. %ccording to the Crisil report the

de"and of plastic by B*;B will be around ;B11T. The plastic consu"ption in

(ndia is boo"ing. De"and for co""odity plastics is growing at the rate of ;:+

per year. .(ndia holds i""ense potential for the use of plastic in the infrastructure

and agriculture. (n case of packaging industry we are using "ore plastic than the

developed countries. The growth is driven in three "a/or sectors C infrastructure

which is ;-++ of the total, packaging is ;:+ of the total and ;*+ for plastic

consu"er durables. (t is pro/ected that the plastic waste generation will reach the

will reach the level of ;.) "illion tons annually.

(ndia produces :)** tons of plastic waste per day.

,egion wise and poly"er wise turnover of recycling industry in ,s.Crore

,egion PVC P!T

#est ;:) -D-

!ast <: D)

Eorth --D ;:D

3outh ;;; ;-A

Total )D* <))

!ach region is specialized in one type of plastic viz south> P!TF north> PVCF

The current plastic recycling rate is esti"ated as )*+ by Plastic (ndia

6oundation. 'ne esti"ate is that about B*,*** "icroenterprises are engaged in

reprocessing and recovery of plastic waste in addition to ;D*,*** of various

sorting and washing units, )*+ of which are unregistered .Delhi alone has

esti"ated :-,.** units and Delhi and 2o"bay together process over :*+ of

(ndia@s waste plastics.

12 | O u a s a r P a s t c s

S)R&C)&RE O* )+E P,AS)ICS IN-&S)RY

The following pattern is likely to be general but there will be so"e variation fro"

country to country.

Ra' Materia% Producers

These are che"ical and petroleu" co"panies who produce GvirginG plastic

(so"eti"es called resin or poly"er in huge 7uantities. The "ain influence they

have on the recycler is to fi& prices and availability of virgin "aterials. Virgin

"aterial is delivered in powder or pellet for", in plastic or paper sacks of around

B* kilos weight, in large cardboard dru"s that hold "any ti"es that 7uantity or

even by road tanker.

Com$ounders

These specialist co"panies, usually s"all, stock various poly"ers and provide

the "anufacturers of plastic goods with technical advice and the "ost suitable

"aterials or "i&tures for each individual need. The co"pounder is often the best

"arket for the recycler because he possesses superior technical knowledge and

has a large volu"e throughput of virgin "aterial, in which s"all percentages of

reclai" will reduce cost without seriously affecting the 7uality re7uired by the

"older.

Stockists

These warehouses stock poly"ers and co"pounds but neither "anufacture

the"selves, nor provide a co"pounding service. They "ay be agents or

subsidiaries of the producer co"panies or depart"ents of co"panies concerned

with the supply of other "aterials such as che"ical, rubber or paper. They "ay

be willing to stock reclai" alongside virgin "aterials, especially if these are in

short supply.

S$ecia%ist Manu(acturers or Mo%ders

These buy their raw "aterials fro" co"pounders. (f they do their own

co"pounding, or if the "aterial is used as produced and does not need

co"pounding, they "ay buy direct fro" stockists or producers. They are

specialists in plastics and do not perfor" other types of "anufacturing. They "ay

be an attractive "arket to the recycler because they operate at high volu"e, but

rarely have as "uch fle&ibility to vary product 7uality as "olders who know,

accurately, the final "arket for the product.

Ot.er Manu(acturers

1any co"panies are not plastics specialists but e"ploy "olding operations in

the "anufacture of so"e other product. 6or e&a"ple shoe and boot "akers use

plastics e&tensively and "ay carry out the various plastics "olding operations in

the sa"e production se7uence as the work in leather, canvas, rubber etc. 1any

13 | O u a s a r P a s t c s

"anufacturers use plastic packaging "achinery at the end of a production

operation.

*aricators

These fir"s cut and /oin sheet, rod or e&trusion to "anufacture a variety of

products. They have no opportunity to use reclai". 1achinery and Tool 1akers

'ne other sector of the plastics industry /ustifies "ention although not custo"ers

for reclai". The "akers and suppliers of plastics "anufacturing "achinery, tools,

"oulds and dies are well infor"ed about who does what, who "akes what and

who uses what within the local plastics industry. They "ay advise who is likely to

buy "aterial.

Market$%ace ana%ysis

Various overseas players wish to e&plore the (ndian "arket and invest in

opportunities thrown open by the country, pro/ected to be world nu"ber - in

plastics consu"ption by B*;*.%s shown above the north region of (ndia is

specialized in recycling of PVC. 3o there is a great scope of P!T recycling.

%part fro" this the other

% huge "arket with full of opportunity.

%bsence of standard product and service

#ell connected with other rural areas

5aving good transportation facility

Customer ana%ysis

3ince we are new player in the "arket so we need to "ake so"e stringent

strategies to penetrate "arket and grab custo"ers. The custo"ers of the plastic

industry are scattered due to lack well known brand na"es. 3o our first priority

will be to accu"ulate the defused custo"ers.

The direct custo"ers are the custo"ers who" we are selling our product

regularly. 3o for us households who" we are selling plastic goods and

co"panies who are getting raw "aterials for packaging are direct custo"ers

(P!T bottles. 3o only in %llahabad around B*,*** fa"ilies are our direct

prospective custo"ers and in ter"s of business to business "arket around B*

s"all and "ediu" scale co"panies are our direct custo"ers

%part fro" the" there are few s"all co"panies which are giving co"pounding

services. They use to collect various types of plastics flakes along with the virgin

plastic and suggest custo"er (co"panies in choosing appropriate plastic. %n

%sha enterprise is one co"pounder who" we will sell our plastics.

1 | O u a s a r P a s t c s

Com$etitor ana%ysis

(n plastic "anufacturing "arket there is no specific brand na"e is e&isting so the

"arket is flooded by s"all co"panies which are in this business. 3o they are our

biggest direct co"petitors.

%s we are also not alone as a supplier of P!T to the co"panies as raw "aterials

there are "any co"panies in this region which are supplying P!T. (ndira Plastics

is one of the" who is currently selling all types of plastics ite"s. 3o in case of

business to business "arket they are our direct co"petitors. 0anpur is plastic

recycling city of =P. The direct threat we will also have is with the co"panies

operating in 0anpur. 2ut as the distance between 0anpur and %llahabad is

)**k" as well as the road is not in good condition, so it will not affect "uch.

Marketin/ strate/y

The Co"pany has chosen to focus on the production of plastic packaging

"aterials fro" recycled post?consu"er beverage bottles. we have identified a

significant available "arket in the eastern part of =P. %ll of our initial "arketing

strategy will be to secure contracts in that seg"ent, and after reaching full

planned capacity, look to grow in concert with that seg"ent and related "arkets.

#e see little need at present for further "arket research and develop"ent, and

will focus on continually updating our production technology in an effort to re"ain

in the forefront of our chosen "arketplace.

Product0 service strate/y

The packaging co"panies re7uire high 7uality and highly transparent P!T

bottles. The co"panies which are producing "ineral water will re/ect P!T bottles

with even a s"all i"purityH opa7ueness. 3o we the $uasar Plastics provide high

end P!T flakes for the perfect packaging.

$uasar Plastics will apply recycling and e&trusion technology "anaged by

decades of industry specific e&pertise to create a co"petitive advantage for its

clients. These processes will produce clean, cost?efficient, recycled raw "aterial

for "anufacturers of ther"ofor", la"inate and other high value?added products,

and high strength packaging strapping for shippers of large products and pallets,

thereby reducing costs and creating a clear pricing edge a"ong their

co"petitors.

Plastic bags and plastic sheets are now in high de"and. %nd this de"and is

driven by continuously increasing pro"otional activities.

Pricin/ strate/y

%s plastic products do not carry any brand na"e so only pricing and distribution

strategies will works to achieve co"petitive edge. The pricing strategy we will

use is penetration pricing. The price of all household plastic goods we will sell will

1$ | O u a s a r P a s t c s

be lower than the "arket price. %lso for the P!T flakes and bottles the price will

be lower than the co"petitors. % lower price enables "e to get contracts of P!T

bottles and sheets fro" various co"panies.

(n case of kitchenware and other household products we will provide co"bo

offers and discounts which a co""on custo"er e&pects.

-istriution strate/y

%s ( described before that firstly we will target %llahabad city and villages close to

it. #e will have a distribution center in the %llahabad city which continuously

"aintains the supply of goods. 3o the household plastics will be sold through

s"all local grocery shops fro" which the custo"ers can get the" easily. %part

fro" this we will hire street hawkers who will roa" around the city and sell the

goods door to door.

P!T bottles will be stored in warehouse which is close to the facility itself. The

sales people will directly contact to the co"panies which re7uire these bottles for

packaging and look for the contracts. (n city as stated above that we will have a

distribution center, fro" that center we will distribute to whole sellers.

Advertisin/ 1 $romotion strate/y

%s ( described we are in both 2BC and 2B2 so for this we will use two different

pro"otional strategies. 6or 2BC business we will use flyers which will have full

detail of our product range, price, co"bo offers and discounts. These flyers will

circulate through the newspapers across whole city. 6or 2B2 business we will

pro"ote through online social "edia and we will also develop our website

through which enable us to widely spread our contact a"ong various co"panies.

the site will have full details of product which are available for co"panies as well

as end user.

Sa%es strate/y

The strategy of sales effort will be to convert potential and first ti"e custo"ers

into long ter" custo"ers. 'ur sales strategy is totally based upon the distribution

channel and the pricing strategies. #e will have a distribution centre in the city

that will take care of sales of household and also supply products to the

wholesalers. #e will also give the industrial custo"ers a facility to order the

products through our website which will help the" in reducing the delivery ti"e.

To "arket the products, the Co"pany will use a nu"ber of sales agentsHbrokers.

They have a custo"er base of their own, having developed successful

relationships with their client over the years. Their custo"er base is currently

de"anding product so they can e&pand upon their current base. 'f course, they

will e&pand that to new custo"ers when product is available.

(f the Co"pany grows faster than its pri"e custo"er base, additional capacity

"ay be developed. #e will identify additional prospective custo"ers who can be

attracted for our products.

1* | O u a s a r P a s t c s

Marketin/ 1 sa%es (orecast

The first "onth prior to the opening will be used to get the new office in order, set

up appoint"ent and begin "arketing activities. (n the first "onth we will focus on

the generating public visibility. The sales forecast is based on the assu"ption

that we will sell all of the highest volu"e P!T bottles that we can produce.

This flake will be sold to other "anufacturing co"panies. ,ecycling industry is

growing with ;:?B*+ each year. 3o we can assu"e that we will grow with at

least B*+. There is a continuing strong de"and for flake and e&truded

products "ade fro" recycled P!T.

Sale3 4-/e5a3t

yea/ 1 yea/ 2 yea/ 3 yea/

A66ual

3ale3 1620000 2106000 2737800 3559140

M-6thly

3ale3 135000 175500 228150 296595

PET Sale3 94500 122850 159705 207617

7-u3eh-l8

ite93 40500 52650 68445 88978.5

-eve%o$ment

The develop"ent of $uasar plastics re7uired to acco"plish a series of action

and for"alities. 3ince we are new in the "arket we kept our production is low

initially, as de"and will increase the production will be enhanced respectively.

Eow we are recycling and producing only two types of plastics i.e. PVC and P!T,

as we grow we will produce a wide the range of plastics and its finished product. .

The develop"ent process involves following steps>

4egal for"alities

'fficeHbusiness setup

6uture offerings and e&pansion plan

-eve%o$ment strate/y

(n future we are looking for the production of a variety of plastic. These plastics

will be

4DP! ( 4ow density polyethylene

5DP! ( 5igh density polyethylene

1& | O u a s a r P a s t c s

4DP! plastic is used in the production carry bags and other plastic sheets as well

as cling wrap, car covers, s7ueeze bottles, liners for tanks and ponds, "oisture

barriers in construction. %nd 5DP! plastics are used in production of freezer

bags, water pipes, wire and cable insulation, e&trusion coating.

'ur develop"ent strategy will base on ti"ely co"pletion of the establish"ent of

the business centre with low e&ecution cost. 'ur strategy will focus not only the

current uninterrupted production of PVC and P!T and ac7uisition of custo"er as

fast as we can, but we will also look for the future e&pansion plan and e&ecution

strategy.

'ur future develop"ent strategy will focus on to chart out a careful plan for the

future e&pansion and growth of our business. The develop"ent strategy will

address following issue>

5ow will we e&pand our servicesI

#hich are the new areas we will include to provide our servicesI

#hat will be the for"at of the business

'ur develop"ent strategy will address all those above "entioned point. %s

we will grow and our earning will increase, we will produce "ore of PVC and

P!T as well as e&pand in new area. #e have a develop"ent strategy to

e&pand our facility size in order to "eet the production size.

11 | O u a s a r P a s t c s

Mana/ement

The co"pany will be "anaged by pro"oter and si& supporting staff.

,a/nish 0u"ar Chaubey, a 12% graduate with specialization in 1arketing and

6inance is the owner and pro"oter of $uasar Plastics. 5e has intensive

knowledge and vast understanding in financial areas like ,isk and ,eturn

"anage"ent, (nvest"ent portfolio and Capital 2udgeting, which undoubtedly will

be of intense help in the business. %part fro" this he also has a good knowledge

of che"icals and their properties

1arketing skills like convincing power, negotiating ability, creating pro"otional

strategies and sales skills will all be e&tre"ely helpful in taking the business a

long way and will prove intensely valuable to take $uasar Plastics to flaring

heights.

Thus with such potential skills, and other 7ualities like efficient interpersonal

skills, leadership skills and decision "aking 7uality, aptly "akes hi" the best

pro"oter and eligible founder and owner of $uasar Plastics

%long with pro"oter five "ore e"ployees will work for the acco"plish"ent of

co"paniesJ ob/ective. 'ne supervisor will work on the facility along with two

supporting staff. 3upervisor who will work upon the facility does not need to be a

che"ical engineer a si"ple technician has e&perience on working upon the

facility can be able to do this.

2o descri$tion

Process No o( em$%oyees Pro(iciency

3orting B unskilled

1( | O u a s a r P a s t c s

2elt Conveyer ; se"iskilled

P!T 3eparator ; se"iskilled

Packaging . unskilled

O$erations

The operations is defined as the process used to deliver your products and

service to the custo"er "arket place and also include "anufacturing

transportation logistics travel and after sales services.

The facility is located at outside the city. 6acility is divided in two parts

,ecycling and Production unit

#arehouse

The facility is located in an area of -*** s7ft..%part fro" these two units there

will be an office which will look for the perpetual supply of re7uired raw "aterial

and also take care about the outbound logistics. The production capacity is

D*kgHhr.

The operations will be based upon 9(T i.e. /ust in ti"e. #e will have contracted

with the suppliers who can supply the raw "aterial as 7uickly as we want. The

raw "aterial contains post consu"er beverage bottles and other plastic

"aterials. The bottles and other plastic "aterial that can be recycled have a

specific sign fro" which it can be identified that it can be recycled or not.

The plastic is then transferred to respective unit to be recycled because P!T and

PVC cannot be recycled si"ultaneously due to their different properties. There

will be two units running parallel to each other. 'n unit will recycle and produce

PVC plastic and other will perfor" the sa"e for the P!T plastic.

The recycled PVC is then "oved for the plastic in/ection "olding unit in the

various shapes. 3ince there are a variety of product is being produced so the

preference will be given to that product whose de"and is high. %ll the products

will not be produced each and every day. There will be different products which

will be produced on different day according to the de"and in "arket.

%fter the recycling process is co"pleted one part of P!T flake is "oved to the

warehouse according to the de"and of raw "aterial which different co"panies

need and other part will "ove for the "olding in bottles.

22 | O u a s a r P a s t c s

The recycled P!T flake is then heated and "ade the viscous solution of it. The

P!T resin is then feeded to the "older and "older will give it various shape

bottles. %nd then it left for drying. Those products which further need for

processing like buckets, the handle will be inserted after the bucket is dried.

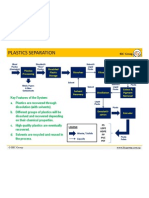

Stages of Recycling and "roduction

The process of recycling of waste plastics into products of varying usefulness

involves the following essential steps>

3izing H Chipping

Cleaning

3egregation.

%gglo"erating H Colouring

!&trusion H Palletisation

6abrication into end Product.

C.i$$in/#

The plastics waste is then re7uired to be properly sized so that those "ay be

fed into the e&truders for processing and palletizing. The sizing operation

depends on the type and shape of the waste plastics.

During this process, attention is re7uired to separate any powdery "aterial

fro" the sized H chipped plastics.

Se/re/ation#

Certain poly"eric "aterials are co"patible with each other at all proportions.

6or e&a"ple 4DP! and 4ldpe are generally co"patible to each other at all

proportions.

The advanced technology of separating H segregating different types of waste

plastics involves K6loatation ProcessJ. (n this process the property of the

varying densities of different plastics is "ade use of for segregating different

types of plastics.

5owever in the (ndian Conte&t, this separation or segregation process, in

"any cases, are done by "anual process utilizing the availability of cheap

and e&pert labor force. (n case the waste is conta"inated with e"bedded

"etals, proper "ethod of separating the "etals H other conta"inants is

re7uired.

C%eanin/#

The scale of cleaning depends on the type of waste. #henever a cleaning

operation is involved, it is to be ensured that the water or any other cleaning

21 | O u a s a r P a s t c s

"aterial used, should be discharged after ascertaining that the discharge

does not contain any ob/ectionable substance. % proper Treat"ent Device

"ay have to be deployed C like a water treat"ent plant H effluent treat"ent

plant. 6or drying, a suitably designed drier is used.

1any industries situated outside the "etropolises, use open space for natural

drying of the cleaned waste.

A//%omeratin/ 0 Co%ourin/

(n the ne&t operation the sized plastics waste is "i&ed with colour "aster

batch in high?speed "i&ers H agglo"erators and the output is ready for

e&trusion into pellets.

Extrusion 0 Pa%%etisation

This is the "ost i"portant part of the process wherein the sized H chipped

plastics are plasticized and granulated to "ake the plastics "aterial ready for

fabrication ne&t.

The type and size of the !&truder depend on the type and volu"e of the

plastics waste.

*arication into end Product

6inally the reprocessed plastics granules are used as raw "aterial for

producing end products using si"ilar fabrication "achines like (n/ection

1olding H !&trusion etc., depending upon specific re7uire"ent.

Sco$e o( o$erations

Eow presently our production capacity is B**kgHday fro" which in initial stages

we are utilizing around :*+ of it. %s the business e&pands we will reach to

opti"u" capacity utilization. #e are e&pecting that we will start producing "ore

advance plastics in the fourth year of our operations and accordingly the sales

will increase and the facility will have to be e&panded.

Su$$%y c.ain

(n the city there are various s"all post consu"er plastic bottle collectors. To

"ake a continuous supply of raw "aterial we will have four suppliers with us.

There will be one per"anent supplier which will continuously supply the raw

"aterial. (n case of e&cess de"and other suppliers will be taken into

consideration. The transportation cost will be covered by supplier only. The

finished product will be stored in the warehouse and according to the de"and it

will be send to city distribution centre. The distribution center will directly sell the

finished household plastics as well as to the s"all shops.

'ur average daily de"and of raw "aterial is -**kg and the lead ti"e we will

keep lead ti"e of )hrs. #e keep a safety stock of :* kg. 3o the reorder point is

given by

,eorder pointL average daily uses & lead ti"e M safety stock

22 | O u a s a r P a s t c s

,eorder point L -** N .B:day M :*

L ;B: kg.

3o at each and every day we will have "ini"u" of ;B:kg (safety stockM reorder

point of raw "aterial in our inventory.

This "eans that when the raw "aterial level reaches to ;B:kg we will place the ne&t

order. The difference ti"e in which we will place the order and receive the order is the

lead ti"e which is )hrs.

23 | O u a s a r P a s t c s

Process flow chart

3antt c.art

2 | O u a s a r P a s t c s

%s it is an asse"bly line the output of one stage is feeded to the input of ne&t stage. The

whole process will run in series for"at. That is the reason why no parallel process is

"entioned in the gantt chart.

*aci%ity ,ayout

2$ | O u a s a r P a s t c s

*inancia%s

2* | O u a s a r P a s t c s

The startup cost of our business is as follows:

Start )up

Requirements A9-u6t

Start-up Expenses

egal !"###

Stationer$ %##

Business &ar's %##

Initial Mailing (##

)rocess *un'ing +##

,ffice Equipment -"%##

Total Start-up Expenses (#"###

Start-up .ssets

&ash Require' ("##"###

,ther &urrent .ssets #

ong-term .ssets //"/#"###

Total .ssets /+"/#"###

Total Requirements /+"+#"###

Income statement

The pro0ecte' income is as shown below it shows that first $ear we will en'

up with loss but from secon' $ear we will start ma1ing profits.

Pa/ti5ula/3

YEAR

1 YEAR 2 YEAR 3 Yea/

2& | O u a s a r P a s t c s

net saes

16200

00

210600

0

273780

0 3285360

cost of good

saes

89100

0

115830

0

150579

0 1806948

gross margn

72900

0 947700

123201

0 1478412

-0e/ati6.

e:0e63e3;

admn exp. 3000 3150 3308 3473

Advertsement 6000 7200 8640 10368

Saares

19200

0 211200 232320 255552

Transportaton 96000 105600 116160 127776

Mantenance 15000 15750 16538 17364

Eectrcty 4800 5040 5292 5557

Teephone 10000 11000 12100 13310

Lega exp. 10000 1000 1000 1000

Insurance 20000 20000 20000 20000

Rent 24000 26400 29040 31944

other exp 6000 6600 7260 7986

38680

0 412940 451657 494330

EBITDA

34220

0 534760 780353 984082

ess

deprecaton

30300

0 272700 245430 220887

EBIT 39200 262060 534923 763195

Less nterest

pad

17555

0 165061 153243 139926

EBT

-

13635

0 96999 381680 623269

tax @ 30% 0 29100 114504 186981

21 | O u a s a r P a s t c s

PAT

-

13635

0 67899 267176 436288

4a%ance s.eet

The pro/ected balance sheet of four years is as follows>

Sources o( *unds Year56 Year57 Year58 Year59

Ca$ita%

'wner@s capital ;A-**** ;A-**** ;A-**** ;A-****

3urplus ?;-)-:* ?)D.:; ;-*B<. <):BD<

Eet worth ;<A-):* ;D);:.A B*)*B<. B)A:BD<

,on/ )erm %oan

4oan ;.;<-*B ;-B.;;) ;B;A;;; ;;**<DA

Current ,iai%ities

Creditors <*:** :)<BB )D*)) D;)D*

)ota% %iai%ities -BD;.:B -B.B-D< --.<.:; -D<<<:)

A$$%ication o( (und

Plant O 1HC -*-**** B<B<*** B.:.-** BB*DD<*

4ess depreciation -*-*** B<B<** B.:.-* BB*DD<

B<B<*** B.:.-** BB*DD<* ;AD<AD-

4and -***** -***** -***** -*****

%ctual 6i&ed %sset 8:7;::: 7;<98:: 7<:==;: 77=;>=8

Current Assets#

(nventory A<B** -;:A** .;*)<* DB;-.*

2ank ;**** .**** ;***** ;*****

Debtors ;.<B:B ;-B;D< ;;<A;; B-B<*-

%dvance to suppliersJ * * B;**** --:<-*

(nvest"ent ;*****

)ota% Assets 87=69<7 87978=; 889;9<6 8=;;;<?

2( | O u a s a r P a s t c s

4reak Even Point

VC

A9-u6t

i6 R3 +C

A9-u6t

i6 R3

Admn 3000

other exp 6000 Interest 175550

transportat

on 96000

advertsem

ent 6000

teephone 10000 Insurance 20000

wages 119250 Saary 192000

carrage

nward 238500 Rent 24000

power 119250

mantenan

ce 15000

raw matera 414000

deprecato

n 303000

Lega 10000

t-tal 1223222 T-tal &1$$2

5-6t/i,uti-

6 *1&222

pv rato 0.3808642

BEP unts

1965398.70

3 135000

BEP SALES 1$ i6 9-6th3

1.21 In years

32 | O u a s a r P a s t c s

.s the BE) is (%months it means that at (%

th

month we will be in a tra'e off

total expenses an' re2enue.

,ppendi2

,nnuity table:

t-tal l-a6

a9t.<

09t=1>1?@1>

iAB6C?i

6 i3 6u9,e/ -4

yea/3

i i3 i6te/e3t /ate

oan amount

150000

0

###

###

nterest rate

annuay 0.12

###

###

pmt

= 21521

21520.

64

9-6th EMI I6te/e3t

0/i65i

0le

,ala65

e !?S

A66ual

i6te/e3t

1

2152

1 15000 6521

149347

9

2

2152

1 14935 6586

148689

4

3

2152

1 14869 6652

148024

2

4

2152

1 14802 6718

147352

4

5

2152

1 14735 6785

146673

8

6

2152

1 14667 6853

145988

5

7

2152

1 14599 6922

145296

3

8

2152

1 14530 6991

144597

2

9

2152

1 14460 7061

143891

1

10

2152

1 14389 7132

143178

0

11

2152

1 14318 7203

142457

7

31 | O u a s a r P a s t c s

12

2152

1 14246 7275

11&32

2 175550

13

2152

1 14173 7348

140995

4

14

2152

1 14100 7421

140253

3

15

2152

1 14025 7495

139503

8

16

2152

1 13950 7570

138746

8

17

2152

1 13875 7646

137982

2

18

2152

1 13798 7722

137209

9

19

2152

1 13721 7800

136430

0

20

2152

1 13643 7878

135642

2

21

2152

1 13564 7956

134846

6

22

2152

1 13485 8036

134043

0

23

2152

1 13404 8116

133231

3

24

2152

1 13323 8198

13211

* 165061

25

2152

1 13241 8279

131583

6

26

2152

1 13158 8362

130747

4

27

2152

1 13075 8446

129902

8

28

2152

1 12990 8530

129049

8

29

2152

1 12905 8616

128188

2

30

2152

1 12819 8702

127318

0

31

2152

1 12732 8789

126439

1

32

2152

1 12644 8877

125551

5

33

2152

1 12555 8965

124654

9

34

2152

1 12465 9055

123749

4

35

2152

1 12375 9146

122834

8

32 | O u a s a r P a s t c s

36

2152

1 12283 9237

121911

1 153243

37

2152

1 12191 9330

120978

2

38

2152

1 12098 9423

120035

9

39

2152

1 12004 9517

119084

2

40

2152

1 11908 9612

118122

9

41

2152

1 11812 9708

117152

1

42

2152

1 11715 9805

116171

6

43

2152

1 11617 9903

115181

2

44

2152

1 11518 10003

114181

0

45

2152

1 11418 10103

113170

7

46

2152

1 11317 10204

112150

4

47

2152

1 11215 10306

111119

8

48

2152

1 11112 10409

110078

9 139926

49

2152

1 11008 10513

109027

7

50

2152

1 10903 10618

107965

9

51

2152

1 10797 10724

106893

5

52

2152

1 10689 10831

105810

3

53

2152

1 10581 10940

104716

4

54

2152

1 10472 11049

103611

5

55

2152

1 10361 11159

102495

5

56

2152

1 10250 11271

101368

4

57

2152

1 10137 11384

100230

0

58

2152

1 10023 11498 990803

59

2152

1 9908 11613 979190

33 | O u a s a r P a s t c s

60

2152

1 9792 11729 967461 124920

61

2152

1 9675 11846 955615

62

2152

1 9556 11964 943651

63

2152

1 9437 12084 931567

64

2152

1 9316 12205 919362

65

2152

1 9194 12327 907035

66

2152

1 9070 12450 894584

67

2152

1 8946 12575 882010

68

2152

1 8820 12701 869309

69

2152

1 8693 12828 856481

70

2152

1 8565 12956 843526

71

2152

1 8435 13085 830440

72

2152

1 8304 13216 817224 108010

73

2152

1 8172 13348 803876

74

2152

1 8039 13482 790394

75

2152

1 7904 13617 776777

76

2152

1 7768 13753 763024

77

2152

1 7630 13890 749134

78

2152

1 7491 14029 735104

79

2152

1 7351 14170 720935

80

2152

1 7209 14311 706624

81

2152

1 7066 14454 692169

82

2152

1 6922 14599 677570

83

2152

1 6776 14745 662825

3 | O u a s a r P a s t c s

84

2152

1 6628 14892 647933 88957

85

2152

1 6479 15041 632892

86

2152

1 6329 15192 617700

87

2152

1 6177 15344 602356

88

2152

1 6024 15497 586859

89

2152

1 5869 15652 571207

90

2152

1 5712 15809 555398

91

2152

1 5554 15967 539432

92

2152

1 5394 16126 523305

93

2152

1 5233 16288 507018

94

2152

1 5070 16450 490567

95

2152

1 4906 16615 473952

96

2152

1 4740 16781 457171 67486

97

2152

1 4572 16949 440222

98

2152

1 4402 17118 423104

99

2152

1 4231 17290 405814

100

2152

1 4058 17462 388352

101

2152

1 3884 17637 370715

102

2152

1 3707 17813 352901

103

2152

1 3529 17992 334910

104

2152

1 3349 18172 316738

105

2152

1 3167 18353 298385

106

2152

1 2984 18537 279848

107

2152

1 2798 18722 261126

3$ | O u a s a r P a s t c s

108

2152

1 2611 18909 242216 43293

109

2152

1 2422 19098 223118

110

2152

1 2231 19289 203829

111

2152

1 2038 19482 184346

112

2152

1 1843 19677 164669

113

2152

1 1647 19874 144795

114

2152

1 1448 20073 124722

115

2152

1 1247 20273 104449

116

2152

1 1044 20476 83973

117

2152

1 840 20681 63292

118

2152

1 633 20888 42404

119

2152

1 424 21097 21308

120

2152

1 213 21308 0 16031

Bibliography

&risil report on plastic in'ustr$

3* | O u a s a r P a s t c s

)lastic waste option for small scale recourse reco2er$ b$ Inge

ar'inois

Small scale rec$cling of plastic b$- 3on 4ogler

3& | O u a s a r P a s t c s

Você também pode gostar

- Business Plan On Manufacturing Knitted and Woven BagsDocumento40 páginasBusiness Plan On Manufacturing Knitted and Woven BagsBijoy Salahuddin82% (17)

- Business PlanDocumento44 páginasBusiness PlanAnubhav Sood50% (2)

- Sample PPT Business Plan PPT PowerPoint Presentation Outline StylesDocumento47 páginasSample PPT Business Plan PPT PowerPoint Presentation Outline StylesLiza Nashielly GrandeAinda não há avaliações

- Plastic Recycling Business PlanDocumento36 páginasPlastic Recycling Business PlanAnkur Verma98% (40)

- Beauty & Spa Marketing PlanDocumento10 páginasBeauty & Spa Marketing Planhamzeh abo hammour0% (1)

- Recycling of PET Plastic Waste - Literature ReviewDocumento57 páginasRecycling of PET Plastic Waste - Literature ReviewHala Hashim Merghani91% (43)

- Plastic Recycling Business PlanDocumento37 páginasPlastic Recycling Business PlanMichael Antwi100% (1)

- Business Plan For Plastic in Ethiopia DoDocumento38 páginasBusiness Plan For Plastic in Ethiopia DofekadeAinda não há avaliações

- Department of Business AdministrationDocumento31 páginasDepartment of Business AdministrationAyush BishtAinda não há avaliações

- Business Plan On Plastic Recycling ManufacturingDocumento13 páginasBusiness Plan On Plastic Recycling ManufacturingAmman Abedin100% (2)

- Plastic Recycling Business PlanDocumento13 páginasPlastic Recycling Business PlanKennedy Njagi100% (1)

- Business Plan On Plastic RecycleDocumento25 páginasBusiness Plan On Plastic RecycleShailendra Joshi83% (6)

- Potato Chips Project ProposalDocumento43 páginasPotato Chips Project ProposalMohammed100% (6)

- Entretien AnglaisDocumento3 páginasEntretien AnglaisSalma JaafariAinda não há avaliações

- A Sample Business Plan of Recycling IndustryDocumento15 páginasA Sample Business Plan of Recycling IndustrySiddhardha Karanam77% (13)

- Plastic Recycling Business Plan PresentationDocumento38 páginasPlastic Recycling Business Plan PresentationAnkur Verma92% (13)

- Business Plan On Plastic Recycling ManufacturingDocumento34 páginasBusiness Plan On Plastic Recycling Manufacturingbydyacbs100% (1)

- Providing Plastic SolutionsDocumento19 páginasProviding Plastic SolutionsSah Sanjiv KumarAinda não há avaliações

- Plastic PVC Pipe Production Business Plan For The OIPDocumento15 páginasPlastic PVC Pipe Production Business Plan For The OIPuche eke75% (8)

- Recycling Waste Materials Business PlanDocumento53 páginasRecycling Waste Materials Business Planbilalcivic100% (4)

- PET Plastic RecyclingDocumento42 páginasPET Plastic RecyclingDavid MuneneAinda não há avaliações

- Plastic Recycling Business PlanDocumento22 páginasPlastic Recycling Business PlanManoj YadavAinda não há avaliações

- ROT2ROTI-Business-Plan Biogas PDFDocumento25 páginasROT2ROTI-Business-Plan Biogas PDFSakhawat Husain75% (4)

- Project Profile-Pet PreformsDocumento4 páginasProject Profile-Pet Preformsbravehear030100% (2)

- Recycled Waste Fertilizer BusinessDocumento54 páginasRecycled Waste Fertilizer BusinessHimadri Himu0% (1)

- Project On The Production of Woven PP BagsDocumento29 páginasProject On The Production of Woven PP BagsZeyinu Ahmed Moh100% (2)

- Business Plan For Plastic in Ethiopia DoDocumento39 páginasBusiness Plan For Plastic in Ethiopia DoTesfaye Degefa100% (3)

- Business Plan Plastic TilesDocumento34 páginasBusiness Plan Plastic TilesAcecream LampitocAinda não há avaliações

- Profile On The Production of Woven PP Bags MulugetaDocumento29 páginasProfile On The Production of Woven PP Bags MulugetaEndayenewMolla50% (2)

- Plastic Jerry CanDocumento26 páginasPlastic Jerry CanSivaratnam NavatharanAinda não há avaliações

- PET Plastic Waste Recycling Business Plan Presentaton - 2020Documento23 páginasPET Plastic Waste Recycling Business Plan Presentaton - 2020sylvester ekpenAinda não há avaliações

- Profitable Plastic Industries Manufacturing GuideDocumento44 páginasProfitable Plastic Industries Manufacturing GuideHarshith Gowda100% (2)

- Fuel Oil from Waste PlasticDocumento41 páginasFuel Oil from Waste Plasticcreativemadhusr100% (2)

- Project Proposal On Dairy FarmDocumento15 páginasProject Proposal On Dairy FarmJibachha Shah89% (139)

- Cement ProjectDocumento66 páginasCement Projectmesfin esheteAinda não há avaliações

- Plastic Recycling SCM ProjectDocumento68 páginasPlastic Recycling SCM Projectrajmeha100% (2)

- Plastic RecyclingDocumento11 páginasPlastic RecyclingDaisy75% (4)

- Ba Dipper-Pt-Ptec Mds 500 501 575 eDocumento124 páginasBa Dipper-Pt-Ptec Mds 500 501 575 eparakhurd0% (1)

- Business Plan: Unique PlasticsDocumento32 páginasBusiness Plan: Unique Plasticslaxman19100% (1)

- Manufacturing Plastic Crates, Fiber Glass Containers & PET PreformsDocumento98 páginasManufacturing Plastic Crates, Fiber Glass Containers & PET PreformsTefera Asefa100% (5)

- Entrepreneurship Plastic Recycling ProjectDocumento21 páginasEntrepreneurship Plastic Recycling Projectlushcheese95% (78)

- Pet Bottle Recycling Project ReportDocumento22 páginasPet Bottle Recycling Project ReportAnkit Banka78% (9)

- Pet Bottels - FinalDocumento16 páginasPet Bottels - FinalSantosh SinghAinda não há avaliações

- Green Zone: Bipin Vijayan Malini Mohan Sajini Sarun P S Sreeraj M KDocumento40 páginasGreen Zone: Bipin Vijayan Malini Mohan Sajini Sarun P S Sreeraj M KsachusachuAinda não há avaliações

- Design and Manufacture of Plastic Recycling MachinesDocumento16 páginasDesign and Manufacture of Plastic Recycling Machinessirajlove2000Ainda não há avaliações

- Plastic Recycling SurveyDocumento43 páginasPlastic Recycling SurveyMahmoud KamelAinda não há avaliações

- BUSINESS Plan On PlasticDocumento23 páginasBUSINESS Plan On PlasticCHALCHISA soboksa100% (5)

- PET Bottle Recycling Udyami - Org.inDocumento22 páginasPET Bottle Recycling Udyami - Org.inAndreea DeeaAinda não há avaliações

- Business Plan (Pet Bottle)Documento7 páginasBusiness Plan (Pet Bottle)Imran Hossain83% (12)

- Kenova Plastix (FINAL)Documento27 páginasKenova Plastix (FINAL)Rukmani GuptaAinda não há avaliações

- Selling Polyethylene PlasticDocumento27 páginasSelling Polyethylene PlasticSileshAinda não há avaliações

- Plastic Bottle and CapsDocumento51 páginasPlastic Bottle and CapsPhilippe Dubost100% (2)

- BUS 5112 - Marketing Management-Written Assignment Unit 7Documento6 páginasBUS 5112 - Marketing Management-Written Assignment Unit 7YoYoAinda não há avaliações

- Akhilesh Kumar Project ReportDocumento8 páginasAkhilesh Kumar Project ReportRamesh Gupta86% (7)

- Getu Marketing Strategy and PlanDocumento21 páginasGetu Marketing Strategy and PlanGetachew Mekonnen100% (4)

- Business Plan RecycleDocumento13 páginasBusiness Plan RecycleSanjay WahalAinda não há avaliações

- Report On Reprocessing of Plastic and Manufacturing A Plastic GranulesDocumento4 páginasReport On Reprocessing of Plastic and Manufacturing A Plastic GranulesKukaswadiya Ibrahim67% (3)

- Business Plan WorkDocumento21 páginasBusiness Plan WorkumarAinda não há avaliações

- Plan de Afacari Reciclare PlasticDocumento30 páginasPlan de Afacari Reciclare PlasticMarinela Stoica100% (2)

- Plastic Recycling Business Plan SynopsisDocumento5 páginasPlastic Recycling Business Plan SynopsisAyush Bisht100% (1)

- Pet Bottles Flakes - RoughDocumento19 páginasPet Bottles Flakes - RoughSivaraman P. S.Ainda não há avaliações

- Disposal Syringe MFG Plant IndiaDocumento8 páginasDisposal Syringe MFG Plant IndiaSK Reddy KotlaAinda não há avaliações

- Plastic RecyclingDocumento1 páginaPlastic RecyclingkerenpkpAinda não há avaliações

- Evaluating a Plastic Recycling Business ProposalDocumento46 páginasEvaluating a Plastic Recycling Business ProposalVishal SinghAinda não há avaliações

- Dawn 2014-2015 Tariff - PKRDocumento21 páginasDawn 2014-2015 Tariff - PKRkashif2006khi0% (1)

- Marketing Strategies: 1. Marketing PenetrationDocumento2 páginasMarketing Strategies: 1. Marketing PenetrationHammad Bin Azam HashmiAinda não há avaliações

- Brands and Brand ValuesDocumento18 páginasBrands and Brand ValuesChalani KaushalyaAinda não há avaliações

- JD - Senior Partnerships & Business Development ManagerDocumento2 páginasJD - Senior Partnerships & Business Development ManagerlocngoAinda não há avaliações

- IKEA's Manufacturing and Marketing StrategiesDocumento26 páginasIKEA's Manufacturing and Marketing StrategiesSatvik R kundargiAinda não há avaliações

- Lcci Examination Timetable 2022Documento10 páginasLcci Examination Timetable 2022ShweHein 2002Ainda não há avaliações

- Scaling Right: Joel's Pace DilemmaDocumento4 páginasScaling Right: Joel's Pace DilemmaEdward KennaAinda não há avaliações

- Chapter 13 The Marketing Mix PriceDocumento19 páginasChapter 13 The Marketing Mix PriceENG ZI QINGAinda não há avaliações

- International Marketing Strategy Analysis, Development Implementation (Robin Lowe, Alexandra Kenyon, Isobel Doole) (Z-lib.org)Documento497 páginasInternational Marketing Strategy Analysis, Development Implementation (Robin Lowe, Alexandra Kenyon, Isobel Doole) (Z-lib.org)Sơn Nguyễn NgọcAinda não há avaliações

- Advertising Campaign On: Khadim's Footwear in RanchiDocumento31 páginasAdvertising Campaign On: Khadim's Footwear in RanchiannietopnoAinda não há avaliações

- Analisis Strategi Bauran Pemasaran Dalam Meningkatkan Ekspor (Studi Pada Bali Pasadena Rattan)Documento6 páginasAnalisis Strategi Bauran Pemasaran Dalam Meningkatkan Ekspor (Studi Pada Bali Pasadena Rattan)nindiawatiAinda não há avaliações

- Emerging Paradigms in The Bottom of Pyramid (Bop) Marketing: Science, Technology and Development Issn: 0950-0707Documento9 páginasEmerging Paradigms in The Bottom of Pyramid (Bop) Marketing: Science, Technology and Development Issn: 0950-0707Pratik PatilAinda não há avaliações

- Presentation - Writing Business Proposal and Business PlansDocumento12 páginasPresentation - Writing Business Proposal and Business Plansjhovel justiceAinda não há avaliações

- SM Project Suzuki Motors-1Documento19 páginasSM Project Suzuki Motors-1Medic GuruAinda não há avaliações

- Chapter 8 Organizational Design and Strategy in A Changing Global EnvironmentDocumento42 páginasChapter 8 Organizational Design and Strategy in A Changing Global EnvironmentHaritaa Varshini BalakumaranAinda não há avaliações

- MMQ2Documento2 páginasMMQ2sidAinda não há avaliações

- Strategic MGMT MSADocumento25 páginasStrategic MGMT MSAShellon LebertAinda não há avaliações

- FINAL Module 2 MKTG Research and Consumer BehaviorDocumento12 páginasFINAL Module 2 MKTG Research and Consumer BehaviorAngelique Claire de VeraAinda não há avaliações

- 6 Steps in The IMC Planning ProcessDocumento7 páginas6 Steps in The IMC Planning Processravinder grewalAinda não há avaliações

- Chapter 12 - Art Science of MarketingDocumento41 páginasChapter 12 - Art Science of MarketingCem YurdakulAinda não há avaliações

- Solutions CPG PDFDocumento5 páginasSolutions CPG PDFTELUGU WHAT'S APP STATUS TECH BUDDYAinda não há avaliações

- 1770 6684 1 PBDocumento15 páginas1770 6684 1 PBTriyani WulandariAinda não há avaliações

- Session 8 Six Month Planning and ComponentsDocumento40 páginasSession 8 Six Month Planning and ComponentsAmisha SinghAinda não há avaliações

- A Study On Customer Satsifaction With Special Reference To Lux Soap in Fathima Nagar Township-TiruchirappalliDocumento88 páginasA Study On Customer Satsifaction With Special Reference To Lux Soap in Fathima Nagar Township-TiruchirappalliAllwin JoseAinda não há avaliações

- Internship at The Outlook Group Task-1: Customer Relationship ManagementDocumento15 páginasInternship at The Outlook Group Task-1: Customer Relationship Managementrohit koyandeAinda não há avaliações

- Indo-Russian Friendship Celebration 2020 Sponsorship ProposalDocumento7 páginasIndo-Russian Friendship Celebration 2020 Sponsorship ProposalDhruva RGAinda não há avaliações