Escolar Documentos

Profissional Documentos

Cultura Documentos

Section 3 Wellhead Control Test and Injection Units

Enviado por

tongsabaiDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Section 3 Wellhead Control Test and Injection Units

Enviado por

tongsabaiDireitos autorais:

Formatos disponíveis

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Section 3: Wellhead Control, Test and Injection Units

Contents S3

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

HYDRAULIC CONTROL UNITS:

Portable Hydraulic BOP Unit ................................................ 49

Portable Hydraulic Actuator .................................................. 50

Dual Output 10,000 psi Control Unit ..................................... 51

DHSV/MV/2-BOP/SB Control Unit ....................................... 52

Mini Series 2 or 3-BOP Hydraulic Module ............................ 53

15 Series 3-BOP Hydraulic Module ...................................... 54

Smart Control Module ........................................................ 55

GREASE CONTROL UNITS:

Single Pump Grease Unit ..................................................... 56

Mini Series Grease Module .................................................. 57

15 Series Grease Module ..................................................... 58

+ 5D+ Control Module ............................................................. 59

+ 20,000 - 30,000 psi Diesel Driven Grease

Intensifier Module ................................................................. 60

COMBINED GREASE AND

HYDRAULIC CONTROL UNITS:

5 Series 2-BOP Control Module ........................................... 61

10 Series 3-BOP Control Module ......................................... 62

5 Series E-Lite Control Module .......................................... 63

+ Smart Inject Control Module ............................................... 64

Truck Mounted 5 Series Control Module .............................. 65

N.B. The technical data contained within these pages was correct at the

time of publication but should not be used as operational guidelines.

For operational guidelines please refer to the operation and maintenance

manual supplied with the equipment.

+ Indicates new product.

PRESSURE TESTING WORKSHOPS:

+ Containerised Pressure Testing Workshop (Mobile) ............ 66

TEST AND INJECTION UNITS:

Portable Glycol Injection and Pressure Test Unit ................. 67

Portable 10,000 psi Pressure Test Unit ................................ 68

700 Series Pressure Test Unit ............................................. 69

800 Series Pressure Test Unit ............................................. 70

900 Series Pressure Test Unit ............................................. 71

Maxsafe Workshop Pressure Test Unit ............................. 72

Wall Mounted Pressure Test Unit ......................................... 73

Gas Booster Unit ................................................................. 74

ACCESSORIES:

Air Driven Grease Injection Pumps and Accessories .......... 75/6

Hand Pump Assemblies ....................................................... 77

Stand Alone Mechanical

and Electronic Chart Recorders ........................................... 78

Stand Alone "Wet Centre" Reels

and Remote Emergency Shutdown Units ............................ 79

Hose End Fittings and Accessories ..................................... 80

Grease Line Connectors and Accessories ........................... 81

Portable Hydraulic BOP Unit

This compact unit is ideal for opening and closing all sizes

from single to quad hydraulic BOPs.

Hydraulic Control Units 49

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

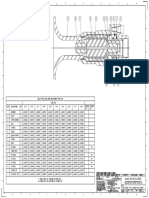

PART NUMBER L-691050

WEIGHTS AND DIMENSIONS

Weights Dry 38kg (84lbs) Wet 52kg (114lbs) Dimensions cm (in) L 40 (16) W 47 (19) H 40 (16)

FEATURES:

Lightweight and economical

Positive control - leaves no doubt whether BOP is

open or closed

Air driven hydraulic pump

Machine engraved, stainless steel, colour coded

panel

High quality valves, gauges and fittings used

throughout

All stainless steel construction

OPTIONS:

Choice of hoses and fittings

Choice of pump ratios

Choice of controls from single to quad BOPs

Steel frame and tank

CE marked, ATEX approved

HOSE OPTIONS

Part Number Working Pressure Description

L-691000 5,000 psi 1 x 1/4 I.D. (6.4mm) Y Hose BOP Open

L-691100 5,000 psi 1 x 1/4 I.D. (6.4mm) Y Hose BOP Close

L-690760 5,000 psi 2 x 50ft (15.2m) 1/4 I.D. (6.4mm) Hose

UNIT OPTIONS

Part Number Description

L-691050 Single BOP

L-691060 Dual BOP

L-690778 Dual BOP accumulator plus hand pump back-up

L-6901010891 Quad BOP accumulator plus hand pump back-up

Control panel for part number L-691050 single BOP

Control panel for part number L-691060 dual BOP

Dual BOP part number L-690778

Part number L-690778

Portable Hydraulic Actuator

This portable hydraulic actuator is designed for those wireline pressure operations which do not require larger and more

expensive Elmar units.

Hydraulic Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

50

PART NUMBER L-690170

WEIGHTS AND DIMENSIONS

Weights 95kg (210lbs) Dimensions cm (in) L 84 (33) W 33 (12) H 66 (26)

FEATURES:

5 gallon reservoir

All stainless steel construction

2.6 gallon (10 litre) accumulator

Machine engraved, stainless steel, colour

coded panel

Air driven hydraulic pump with back-up manual pump

High quality valves, gauges and fittings used

throughout

OPTIONS:

Choice of panel controls

Choice of hoses and fittings

Choice of pump ratios

Stainless steel back-up hand pump

CE marked, ATEX approved

This package offers a flexible, lightweight and cost effective means of

controlling various combinations of wireline pressure control equipment.

HOSE OPTIONS

Part Number Working Pressure Description

L-691080 5,000 psi 1 x 25ft (7.6m) 1/4 I.D. (6.4mm) Hose

L-690586 5,000 psi 1 x 50ft (15.2) 1/4 I.D. (6.4mm) Hose

L-690740L075 5,000 psi 1 x 75ft (22.8m) 1/4 I.D. (6.4mm) Hose

L-690740 5,000 psi 1 x 100ft (30.4m) 1/4 I.D. (6.4mm) Hose

L-690740L120 5,000 psi 1 x 120ft (36.5m) 1/4 I.D. (6.4mm) Hose

L-691000 5,000 psi 1 x 1/4 I.D. (6.4mm) Y Hose BOP Open

L-691100 5,000 psi 1 x 1/4 I.D. (6.4mm) Y Hose BOP Close

TYPICAL PANELS (more available on request)

L-690160 L-690170

Line Wiper Line Wiper

Tool Catcher Stuffing Box

BOP 3 Tool Catcher

BOP 2 BOP 2

BOP 1 BOP 1

L-690190 L-691110

Line Wiper Line Wiper

Tool Catcher Tool Catcher

Tool Trap BOP 3

BOP 2 BOP 2

BOP 1 BOP 1

L-691120 L-691130

Stuffing Box Line Wiper

Tool Catcher Stuffing Box

Tool Trap Tool Catcher

BOP 2 Tool Trap

BOP 1 BOP 1

L-690341

Stuffing Box

Tool Catcher

Tool Trap

Line Wiper

BOP 3

BOP 2

BOP 1

Control panel

for part number

L-690170

Dual Output 10,000 psi Control Unit

These multipurpose control units are used to actuate or pressure test master valves, sub surface safety valves, downhole

safety valves and other hydraulically actuated equipment.

Hydraulic Control Units 51

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-691710

WEIGHTS AND DIMENSIONS

Weights 65kg (143lbs) Dimensions cm (in) L 70 (28) W 50 (20) H 58 (23)

FEATURES:

Dual outlets

Two air driven hydraulic pumps

All stainless steel construction

10,000 psi maximum output pressure

Adjustable relief valves on each circuit

Tank mounted return filter with bypass valve

External drain facility to eliminate contaminated

hydraulic fluid

Stainless steel back-up hand pumps

OPTIONS:

All required connectors can be supplied

All hose configurations/pressures can be

accommodated

CE marked, ATEX approved

HOSE ASSEMBLY OPTIONS

Part Number Working Pressure Description

L-690183L010 10,000 psi 2 x 10ft (3.1m) 1/4 I.D. (6.4mm) Hose

L-690183L050 10,000 psi 2 x 50ft (15.2m) 1/4 I.D. (6.4mm) Hose

L-690183L100 10,000 psi 2 x 100ft (30.4m) 1/4 I.D. (6.4mm) Hose

HOSE REEL OPTION

Part Number Working Pressure Description

L-690674 10,000 psi 1 x 150ft (45.7m) 1/4 I.D. (6.4mm) Hose

Control panel c/w stainless steel back-up hand pumps

Stand alone reel assembly L-690674

These stand alone reel assemblies can be used to

connect hydraulic lines between equipment.

Side view

DHSV/MV/2-BOP/SB Control Unit

This Elmar hydraulic unit has been developed to control a downhole safety valve, a master valve, two wireline BOPs,

test line and stuffing box.

Hydraulic Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

52

PART NUMBER L-690267

WEIGHTS AND DIMENSIONS

Weights 855kg (1,881lbs) Dimensions cm (in) L 120 (47) W 85 (33) H 154 (61)

FEATURES:

Alarm system

Large hydraulic oil reservoir

Relief valves on each circuit

Machine engraved, stainless steel, colour coded

panel

Two 5 gallon (20 litre) accumulators

Air driven hydraulic pumps with back-up stainless

steel hand pumps

Emergency shutdown facility

Test line facility

Hoses on Elmar wet centre reels

OPTIONS:

Remote ESD system

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

3-BOP version part number L-6901010507

The unit features an audible warning air horn which operates whenever the DHSV,

MV or air lines fall below their preset pressures.

Rear view

Control panel

Typical reel assembly

Mini Series 2 or 3-BOP Hydraulic Module

This module and the mini-series hydraulic control module form the controls for the mini-series pressure equipment system.

Either module may be used separately.

Hydraulic Control Units 53

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-696740

WEIGHTS AND DIMENSIONS

Weights 450kg (992lbs) Dimensions cm (in) L 137 (54) W 68 (27) H 135 (53)

This hydraulic module has been designed to operate various combinations of 2 or 3

wireline BOPs, a tool trap, tool catcher, line wiper and stuffing box. This module is

suitable for well pressure up to 10,000 psi.

Side view

Control panel

Typical reel assembly

FEATURES:

Air driven hydraulic pump

2.6 gallon (10 litre) accumulator

Hoses on Elmar wet centre reels

Machine engraved stainless steel colour

coded panel

Back-up stainless steel hand pumps

Lightweight compact unit

Multiple choice of controls

Storage locker

OPTIONS:

Transport frame for pressure equipment

Glycol/chemical injection facility/pressure test facility

5.3 gallon (20 litre) accumulator

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

15 Series 3-BOP Hydraulic Control Module

This module and the 15 series grease control module form the controls for the 15 series pressure equipment system for up to

15,000 psi maximum wellhead pressure.

Hydraulic Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

54

Control panel

Typical reel assembly

Rear view

PART NUMBER L-697830

WEIGHTS AND DIMENSIONS

Weights 770kg (1,700lbs) Dimensions cm (in) L 137 (54) W 85 (33) H 137 (54)

FEATURES:

Air driven hydraulic pump

5.3 gallon (20 litre) accumulator

Hoses on Elmar wet centre reels

Machine engraved stainless steel, colour

coded panel

Back-up stainless steel hand pumps

Glycol/chemical injection facility

Pressure test facility

Compliments 15 Series Grease Module

(part number L-695740 page 3/58 )

OPTIONS:

Transport frame for pressure equipment

(page 4/125)

Single stuffing box control and air reel

(part number L-695800)

CE marked, ATEX approved

This hydraulic module has been designed to

operate 3 wireline BOPs, a tool trap, tool

catcher, line wiper and a dual stuffing box.

Smart Control Module

Well Control Module and Remote Control Unit with central processing unit and monitor. To operate (1) shear/seal BOP, (2)

wireline BOP's and grease injection to BOP.

Hydraulic Control Units 55

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-690544

WEIGHTS AND DIMENSIONS

Weights 3,400kg (7,480lbs) Dimensions cm (in) L 200 (79) W 180 (71) H 193 (76)

FEATURES:

Remote electronic operation and process monitoring

based on a Zone 1 membrane keypad P.C. with

hard wire connector

Full override operation of module using conventional

valves

Certified to DNV 2.7-1, Norsok and NPD require

ments, with CE marking and ATEX approval for use

in a Category 2 (Zone 1) hazardous area

(2) Air-hydraulic pumps, 35:1 and 60:1

(1) Air-grease pump 175:1

(4) x 37 litre Accumulators to control a 6 3/8 ID 10k

Triple BOP

Back-up hand pump

Forklift pockets

Storage locker

Hoses on Elmar Wet Centre reels

OPTIONS:

Primary Well Control for Grease Injection Head/Line

Wiper/Stuffing Box/ Tool Catcher/Tool Trap etc

L-690579 Air rewind tool for hose reels

Control panel

Typical reel assembly

Note: UK pat. 2337545B

US pat. 6 305 471

Australia pat. 30/10/3959

Europe pat EPO959225B

Norway pat. 317364

Singapore pat. 90051

Zone 1 membrane keypad P.C

with hard wire connector

PART NUMBER L-696810

WEIGHTS AND DIMENSIONS

Weights 550kg (1,212lbs) Dimensions cm (in) L 135 (53) W 71 (28) H 160 (63)

Single Pump Grease Unit

This Elmar air powered single pump grease injection unit supplies

grease at up to 10,000 psi to the grease head and BOP.

Grease Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

56

FEATURES:

Bulkhead mounted outlet for grease injection to BOP

Storage facility for spare grease barrel

96 gallon (363 litre) grease tank

120ft (36.5m) grease supply and grease return

hoses mounted on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Either 175:1 or 85:1 grease pumps

OPTIONS:

Grease transfer pump (part number L-698420

page 3/75)

CE marked, ATEX approved

Storage for spare grease barrel

Control panel

Typical Reel assembly

Mini Series Grease Control Module

This module and the mini-series hydraulic control module form the controls for the mini-series pressure equipment system.

Either module may be used separately.

Grease Control Units 57

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Control panel

Typical reel assembly

Rear view

PART NUMBER L-691420

WEIGHTS AND DIMENSIONS

Weights 1,400kg (3,080lbs) Dimensions cm (in) L 137 (54) W 72 (28) H 137 (54)

FEATURES:

Two air driven grease pumps 175:1

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Large grease tank with divider

Lightweight compact unit

Multiple choice of controls

OPTIONS:

Transport frame for pressure equipment

Wellhead pressure monitoring facility

Two air driven 85:1 grease injection pumps

(part number L-840880)

Grease transfer pump (part number L-698420

page 3/75)

CE marked, ATEX approved

The grease module has been designed to

operate 2 grease pumps. This module is

suitable for well pressure up to 10,000 psi.

15 Series Grease Module

This module and the 15 series hydraulic control module form the controls for the 15 series pressure equipment system for up to

15,000 psi wellhead pressure. Either module may be used separately.

Grease Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

58

PART NUMBER L-695740

WEIGHTS AND DIMENSIONS

Weights 1,100kg (2,425lbs) Dimensions cm (in) L 137 (54) W 98 (38) H 130 (51)

FEATURES:

Two air driven grease pumps 235:1

Maximum grease output pressure 22,500 psi

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Large grease tank

Two Grease Head and one BOP grease

injection lines

Individual pump stroke counters

Storage locker

Compliments 15 Series Hydraulic Module

(part number L-697830 page 3/54 )

OPTIONS:

Transport frame for pressure equipment

(page 4/125)

Grease transfer pump (part number L-698420

page 3/75)

CE marked, ATEX approved

It has been developed to eliminate problems which conventional

diesel driven intensifiers present when used on an offshore

installation.

Typical reel assembly

Control panel

5D+ Control Module

This diesel driven grease and hydraulic control module is designed to operate 3 BOPs, tool trap, tool catcher, stuffing box, line

wiper, grease injection and optional water/glycol pressure test.

Grease Control Units 59

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Control panel with throttle control lever

Typical reel assembly complete with optional test line

PART NUMBER L-690693-V03

WEIGHTS AND DIMENSIONS

Weights 3,250kg (7,165lbs) Dimensions cm (in) L 252 (99) W 130 (51) H 163 (64)

This module is suitable for well pressure up to 10,000 psi.

Throttle control lever

FEATURES FOR L-690693-V03:

Rigsafe, air cooled, electric start diesel engine

Two Elmar hydraulically driven grease intensifiers

each capable of delivering 0.6 US gal/min (2.3 l/min)

at 40 strokes/min

5.3 gallon (20 litre) accumulator for BOP

back-up supply

Twin x 60 gallon (2 x 225 litres) grease tank for

different viscosities

Low fuel consumption

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Back-up stainless steel hand pumps

Cupboard for accessory storage

OPTIONS:

60 gallon (225 litre) water/glycol pressure test

unit with hydraulically driven volume and

pressure pumps

Stainless steel panel covers with sound

deadening material

Back-up air driven grease pump in place of one

intensifier

Variant V04: As V03 but including (1) air driven

grease pump and (1) hydraulically

driven grease intensifier

Variant V05: As V03 but including a hydraulically

driven PTU and no cupboard

Variant V06: As V04 but including a hydraulically

driven PTU and no cupboard

WEIGHTS AND DIMENSIONS

Part Number L-6901017786-V01

Weights 2,250kg (4,960lbs) Dimensions cm (in) L 158 (62) W 132 (52) H 190 (75)

Part Numbers L-6901017786-V02/V03/V04/V05

Weights V02: 2,775kg (6,118lbs) V03: 2,650kg (5,842lbs) V04: 3,000kg (6,614lbs) V05: 3,000kg (6,614lbs)

Part Numbers L-6901017786-V02/V03/V04/V05

Dimensions cm (in) L 250 (98) W 132 (52) H 190 (75)

20,000 - 30,000 psi Diesel Driven Grease Intensifier Module

This diesel driven grease control module features an Elmar high pressure grease intensifier pump in a compact package.

The intensifier delivers high flow rates at high pressures.

Grease Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

60

FEATURES FOR L-6901017786-V01:

Maximum working pressure 30,000 psi

(limit can be specified)

Rigsafe, air cooled, electric start 44hp Deutz

diesel engine

Elmar hydraulically driven grease intensifier pump

capable of delivering 1.6 US gal/min (6 l/min) at 50

strokes/min

Air driven back-up 235:1 grease pump

(2) grease supply outlets, 1 grease to BOP outlet,

1 grease return outlet

120 USgal (454 litre) grease capacity in twin tanks

53 USgal (200 litre) fuel tank capacity

Elmar mimic control panel for easy logical control

BS EN12079 frame with full drip pan

Operating temperature range -20C to +50C

OPTIONS:

Low temperature kit (-40C)

Sound deadening panels for power pack

Variant V02: As standard but including powered

grease hose reels and storage

cupboard

Variant V03: As standard but including hydraulic

control facility for quad BOP control,

tooltrap, toolcatcher, dual stuffing box

and line wiper. Accumulator storage

for emergency BOP operation

Variant V04: As V03 but including powered grease

hose reels and manual hydraulic

hose reels

Variant V05: As V04 but suitable for use in

hazardous areas up to ATEX category

II (Zone 2)

Electronic switching and seal-less liquid ends ensure that the pump delivers

superior performance, reliability and longevity. The main intensifier is primed

using a charge pump.

The module features dual 60USgal (227litre) grease tanks or a single

120USgal (454litre) tank and a 53 USgal (200litre) fuel tank giving stand

alone grease control capacity for prolonged well site operations.

The compact dimensions allow transport on smaller vehicles reducing

transport and handling costs.

This module is suitable for controlling well pressures up to 25,000psi.

Part number L-6901017786-V04

Control panel

Standard Module

Part number L-6901017786-V01

5 Series 2-BOP Control Module

This combination module is designed to operate 2 wireline BOPs, a tool trap, tool catcher, stuffing box, line wiper and grease

injection. It is suitable for well pressure up to 10,000 psi.

Combined Grease and Hydraulic Control Units 61

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Control panel showing optional accumulator panel (left)

Optional chemical injection control panel

Typical reel assembly

Rear view

WEIGHTS AND DIMENSIONS

Weights 920kg (2,024lbs) Dimensions cm (in) L 146 (58) W 82 (32) H 147 (59)

FEATURES:

Air driven hydraulic pump

Two air driven grease pumps 175:1

2.6 gallon (10 litre) accumulator

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour coded

panel

Back-up stainless steel hand pumps

Large grease tank with divider

OPTIONS:

Transport frame for pressure equipment

(page 4/122)

Glycol/chemical injection facility

Galvanised base skid (part number L-696670)

Grease transfer pump (part number L-698420

page 3/75 )

85:1 grease pumps

CE marked, ATEX approved

OPTIONS - PUMP AND GLYCOL/CHEMICAL INJECTION

Part Number Pump Type Glycol/Chemical Injection Facility

L-690299 175:1 Pump No

L-696950 85:1 Pump No

L-690369 175:1 Pump Yes

L-690309 85:1 Pump Yes

10 Series 3-BOP Control Module

This combination module is designed to operate 3 wireline BOPs, a tool trap, tool catcher, stuffing box, line wiper and grease

injection. It is suitable for well pressure up to 10,000 psi.

Combined Grease and Hydraulic Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

62

PART NUMBER L-697200

WEIGHTS AND DIMENSIONS

Weights 1,200kg (2,645lbs) Dimensions cm (in) L 174 (69) W 112 (44) H 146 (57)

FEATURES:

Air driven hydraulic pump

Two air driven grease pumps 175:1

2.6 gallon (10 litre) accumulator

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Back-up stainless steel hand pumps

OPTIONS:

Transport frame for pressure equipment

(page 4/123)

L-697210 c/w glycol/chemical injection

Galvanised base skid (part number L-699050)

5.3 gallon (20 litre) accumulator

Grease transfer pump (part number L-698420

page 3/75)

CE marked, ATEX approved

Rear view

Optional chemical injection control panel

Control panel

Typical reel assembly

5 Series E-Lite Control Module

This combination grease and hydraulic control module is designed to operate 3 wireline BOPs, a tool trap, tool catcher, stuffing

box, line wiper and grease injection during wireline intervention up to 10,000 psi maximum wellhead pressure.

Combined Grease and Hydraulic Control Units 63

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s Control panel

Typical reel assembly

Rear view

PART NUMBER L-6901010860

WEIGHTS AND DIMENSIONS

Weights Dry 920kg (2,024lbs) Wet 1,300kg (2,860lbs) Dimensions cm (in) L 146 (58) W 82 (32) H 147 (59)

FEATURES:

Air driven hydraulic pump

Two air driven 175:1 grease injection pumps

Two x 10 litre accumulator

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Back-up stainless steel hand pumps

Large grease tank with divider for use with two

grease types

Large bore grease return valve

Frame designed to BS EN 12079-1 (2006)

OPTIONS:

Transport frame for pressure equipment

(page 4/124). Note: L-6901010860-V02 not

suitable for transport frames L-690598/690665

Grease transfer pump (L-698420 Wiwa 4:1 page

3/75 or L-840689 Alemite 5:1)

Two air driven 85:1 grease injection pumps

(part number L-840880)

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

Smart Inject Control Module

Allows Automatic Grease Control during wireline operations. Primarily designed to be a bolt on feature to the

Elmar 5 Series E-lite Control Module.

Combined Grease and Hydraulic Control Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

64

5 Series E-Lite Control Module Control panel

WEIGHTS AND DIMENSIONS

PART NUMBER L-6901020153

Weights 300kg (661lbs) Dimensions cm (in) L 146 (58) W 82 (32) H 50 (20)

WEIGHTS AND DIMENSIONS

5 Series E-Lite Control Module

Weights Dry 920kg (2,024lbs) Wet 1,300kg (2,860lbs) Dimensions cm (in) L 146 (58) W 82 (32) H 147 (59)

FEATURES:

Well pressure monitoring

Automatic grease injection

System automatically maintains grease pressure at

specified level above well pressure

Inject grease at 5-30% above well pressure

Instant reaction to changes in well pressure and

line speed

Auto control of individual or both grease pumps

Alarm system

Battery back up for power supply

Normal manual control of control module can be

taken at any time

Monitors well pressure at BOP and Injected Grease

pressure at grease control head

5 Series E-Lite Control Module reel assembly

Note: UK pat. 2337545B

US pat. 6 305 471

Australia pat. 30/10/3959

Europe pat EPO959225B

Norway pat. 317364

Singapore pat. 90051

Smart Inject

Control Module

L-6901020153

5 Series E-LiteControl Module

Option: Control via remote PC

Bolt on design

LCD screen to show system status

Automatic data logging - internal SD card

records job

Rated for Zone 1 and ATEX compliant

OPTION:

Control via remote PC - could be in logging cabin

Truck Mounted 5 Series Control Module

This combination module is designed to operate 3 wireline BOPs, a tool trap, tool catcher, stuffing box, line wiper, grease

injection and glycol injection.

Combined Grease and Hydraulic Control Units 65

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-698711

WEIGHTS AND DIMENSIONS

Weights Dry 860kg (1,892lbs) Wet 1,100kg (2,420lbs) Dimensions cm (in) L 150 (59) W 65 (26) H 212 (83)

FEATURES:

Air driven hydraulic pump

Two air driven grease pumps 175:1

2.6 gallon (10 litre) accumulator

Hoses on Elmar wet centre reels

Machine engraved, stainless steel, colour

coded panel

Back-up stainless steel hand pumps

OPTION:

Two air driven 85:1 grease injection pumps

(part number L-840880 page 3/75)

CE marked, ATEX approved

HOSES SUPPLIED LOOSE C/W QUICK COUPLINGS

BOP Hose (L-651192) Tool Trap Hose (L-651192)

25ft Twin Hose (7.6m) 25ft Twin Hose (7.6m)

2 x 3/16 I.D. (4.8mm) 2 x 3/16 I.D. (4.8mm)

5,000 psi W.P. (345 bar) 5,000 psi W.P. (345 bar)

Control panel

Accumulator control panel

Typical reel assembly

It is specifically designed for use on a wireline

mast truck and the control panel on the unit

replaces an existing cupboard on the truck,

with the module located on the rear bed.

It is suitable for well pressure up to 10,000 psi.

Glycol injection control panel

Truck mounted wireline mast

(section 2 page 47)

Truck mounted module in position

Containerised Pressure Testing Workshop (Mobile)

This Elmar Pressure Testing Workshop has been designed to provide a safe and controlled environment for pressure testing

and maintenance operations.

Pressure Testing Workshops

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

66

PART NUMBER L-6901013720

WEIGHTS AND DIMENSIONS

Weights 18,000kg (39,672lbs) Dimensions m (ft) L 9.15 (30.01) W 2.44 (8.00) H 2.85 (9.35)

The workshop allows testing to be carried out on

location or on a company base. The cabin gives

the operator full control of testing and monitoring

up to maximum 24,000 psi working pressure.

FEATURES:

Max-Safe (24,000 psi WP) pressure test unit

(4) x colour camera CCTV system and DVD

recorder

(3) x roof mounted air conditioners

10ft work bench complete with vice

Removable Baker vice

Chain hoist rated to (1) tonne

220V/110V electrical system

Removable steel blast panels (internal)

Door locks when pressure applied

Warning light

Operators control cabin

Designed, built and certified in accordance with

DNV.2.7-1 (2007)

Floor mounted test stump (removable)

Internals lined with wood

Fully load tested

Max-Safe pressure test unit

(24,000 psi) wall mounted panel

FEATURES:

Air driven high volume and high pressure pump

systems

56.8 gallon (215 litre) stainless steel reservoir

Wall mounted Elmar wet centre reel

Diaphragm pump to return drained fluid to tank

Electronic chart recorder

MONITORING SYSTEM:

(4) x colour camera CCTV system

24 hour DVD recorder

Flat screen monitor

Roof mounted air conditioners CCTV camera Wall mounted Max-Safe pressure test unit

Flat screen monitor and CCTV controls

Workshop with test unit, Baker vice and chain hoist

Portable Glycol Injection and Pressure Test Unit

This Elmar com pact stand-alone port able press ure test unit has been designed for gly col injec tion, or to pump water for

press ure test ing up to 10,000 psi.

Test and Injection Units 67

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-697240-V02-001 (European CE compliant)

WEIGHTS AND DIMENSIONS

Weights Dry 60kg (132lbs) Wet 83kg (183lbs) Dimensions cm (in) L 89 (35) W 31 (12) H 43 (17)

FEATURES:

5.3 gal lon (20 litre) stain less steel test fluid tank

Machine engraved, stain less steel, col our

coded panel

Air driven high press ure pump

Stroke counter to moni tor injec tion rate

CE marked, ATEX approved for use in a Category 3

(Zone 2) hazardous area

OPTIONS:

Non CE marked and non ATEX approved version

50ft hose assembly (part number L-690183-L050)

Typical 10,000 psi pump chart

Control panel for CE marked and ATEX approved version

Portable 10,000 psi Pressure Test Unit

This Elmar com pact stand-alone port able press ure test unit has been designed to pump water, or gly col for press ure test ing

up to 10,000 psi.

Test and Injection Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

68

PART NUMBER L-696820

WEIGHTS AND DIMENSIONS

Weights 217kg (477lbs) Dimensions cm (in) L 90 (35) W 95 (37) H 80 (31)

FEATURES:

54 gal lon (200 litre) stain less steel test fluid tank

Machine engraved, stain less steel, col our

coded panel

100ft test line hose on Elmar wet centre reel

Air driven high press ure pump

OPTION:

15,000 psi unit (part number L-696830)

CE marked, ATEX approved

Rear view

Control panel

Test fluid tank and reel assembly

Typical reel assembly

Control panel

Typical 10,000 psi pump chart

700 Series Pressure Test Unit

This Elmar 700 series press ure test unit has been designed for press ure test ing up to 22,500 psi. Two air driven pumps are

provided; a vol ume pump for rapid fill ing and a high press ure pump. A chart recorder allows the press ure test to be rec orded.

Test and Injection Units 69

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Side view

Control panel for part number L-690240 CE marked

Typical reel assembly

PART NUMBER L-690240 (European CE compliant option)

WEIGHTS AND DIMENSIONS

Part Numbers L-690268/L-690240/L-690250

Weights 190kg (420lbs) Dimensions cm (in) L 69 (27) W 76 (30) H 102 (40)

FEATURES:

Machine engraved, stainless steel, col our

coded panel

8 chart recorder with 2/8 hour mech anical clock

Air driven high vol ume and high press ure pumps

Hoses mounted on Elmar wet centre reels

14 gal lon (53 litre) stain less steel res er voir tank

Stainless steel front pro tec tive covers

OPTIONS:

0-10,000 and 0-22,500 psi high press ure pump

Galvanised 4 wheel trol ley

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

UNIT OPTIONS

Part Number Working Pressure Reservoir

L-690268 10,000 psi (690 bar) 52 Litre Tank

L-690240 15,000 psi (1,035 bar) 52 Litre Tank

L-690250 22,500 psi (1,552 bar) 52 Litre Tank

CHART OPTIONS

Part Number Description

L-570040 0-15,000 psi

L-570030 0-20,000 psi

L-571490 0-30,000 psi

CONVERSION FACTORS

277 cu. in. = 1 Imp gallon

231 cu. in. = 1 U.S. gallon

800 Series Pressure Test Unit

This compact air driven pressure test unit is designed to operate horizontally or vertically in workshop or field environments

and will stow into a logging truck compartment.

Test and Injection Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

70

Rear view

WEIGHTS AND DIMENSIONS

Part Number L-690646-V02

Weights Dry 82kg (181lbs) Wet 112kg (247lbs) Dimensions cm (in) L 76 (30) W 45 (18) H 61 (24)

FEATURES:

Stainless steel frame

Lightweight, 110 pounds (50 kg)

Vertical or hori zon tal oper ation

5 gal lon (19 litre) stain less steel res er voir tank

Air driven high vol ume and high press ure pumps

Machine engraved, stain less steel, col our

coded panel

OPTIONS:

30ft long press ure hose

Free standing chart recorder with 10ft long hose

External suction

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

These units feature a high volume pump for

fast filling and a high pressure pump for testing

up to a maximum 10,000 psi (690 bar), 15,000

psi (1,035 bar) or 22,500 psi (1,550 bar).

UNIT OPTIONS

Part Number Working Pressure Reservoir Features

L-690535-V01 0-10,000 psi (690 bar) 19 Litre Tank

L-690535-V02 0-10,000 psi (690 bar) 30 Litre Tank CE

L-690646-V01 0-15,000 psi (1,035 bar) 30 Litre Tank

L-690646-V02 0-15,000 psi (1,035 bar) 30 Litre Tank CE/ATEX

L-690801 0-22,500 psi (1,552 bar) 19 Litre Tank

L-690802 0-22,500 psi (1,552 bar) 19 Litre Tank with chart recorder

L-692610-V01 0-15,000 psi (1,035 bar) 19 Litre Tank

L-692610-V02 0-15,000 psi (1,035 bar) 19 Litre Tank with external suction

L-697850 0-20,000 psi (1,379 bar) 19 Litre Tank with chart recorder

CONVERSION FACTORS

277 cu. in. = 1 Imp gallon

231 cu. in. = 1 U.S. gallon

OPTIONAL EXTRAS

Part Number Description

L-690538 10,000 psi 6mm ID hose assembly x 50 ft, 10,000 psi WP, with quick couplings and (1) 1/2 NPT (M) adapter

L-691220 15,000 psi 8mm ID hose assembly x 30ft, 18,850 psi WP, with quick couplingsand (1) 1/2 NPT (M) adapter

L-691221 22,500 psi 8mm ID hose assembly x 30ft, 30,450 psi WP, with quick couplings and (1) 9/16 AE (M) adapter

Control panel CE marked version

T

y

p

i

c

a

l

1

0

,

0

0

0

p

s

i

p

u

m

p

T

y

p

i

c

a

l

v

o

l

u

m

e

p

u

m

p

T

y

p

i

c

a

l

1

5

,

0

0

0

p

s

i

p

u

m

p

T

y

p

i

c

a

l

2

2

,

5

0

0

p

s

i

p

u

m

p

900 Series Pressure Test Unit

These systems have been developed for oil or service company use. Each pumping unit has a large reservoir for injection fluids

such as water and glycol. The high volume and high pressure pumps allow rapid fill and pressure build up.

Test and Injection Units 71

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

Control panel for part number L-696902

Reel assembly for part number L-696902

Rear view

PART NUMBER L-696902

WEIGHTS AND DIMENSIONS

Part Numbers L-696902/L-696905

Weights 770kg (1,700lbs) Dimensions cm (in) L 160 (60) W 92 (35) H 176 (69)

Part Numbers L-696903/L-696904

Weights 850kg (1,870lbs) Dimensions cm (in) L 160 (60) W 130 (53) H 176 (69)

FEATURES:

6,000 psi, 10,000 psi, 15,000 psi or 22,500 psi W.P.

Air driven high volume and high pressure pumps

Choice of reservoir capacity (1,000 litre/1,500 litre)

Stroke counter switchable between pumps

Output hose and reel

Air supply hose and reel

OPTIONS:

Free standing chart recorder c/w hose

Stainless steel frame

Stainless steel protective covers

Forklift runners

Methanol service

Gas driven

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

Reduced height version (part number L-696913)

suitable for use with mast truck

Test fluid return pump

Test fluid return pump for part number L-696902-V04

UNIT OPTIONS

Part Number Working Pressure Reservoir

L-696902 10,000 psi (690 bar) 1,000 Litre Tank

L-696903 6,000 psi (414 bar) 1,500 Litre Tank

L-696904 10,000 psi (690 bar) 1,500 Litre Tank

L-696905 6,000 psi (414 bar) 1,000 Litre Tank

L-690546 15,000 psi (1,035 bar) 1,000 Litre Tank

L-690554 22,500 psi (1,552 bar) 1,500 Litre Tank

Maxsafe Workshop Pressure Test Unit

This Elmar Maxsafe two piece workshop pressure test unit has been designed for mounting either side of a workshop

pressure test bay wall.

Test and Injection Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

72

PART NUMBER L-6901003825

WEIGHTS AND DIMENSIONS

Control Panel Unit

Weights 240kg (529lbs) Dimensions cm (in) L 103 (41) W 61 (24) H 179 (70)

Tank Pump Unit

Weights 290kg (639lbs) Dimensions cm (in) L 111 (44) W 91 (36) H 110 (43)

Reel/Bracket

Weights 90kg (198lbs) Dimensions cm (in) L 66 (26) W 46 (18) H 58 (23)

Typical Hose Installation Kit

Weights 70kg (154lbs)

FEATURES:

Air driven high volume and high pressure

pump systems

Diaphragm pump to return fluid (drained from test

piece) back to tank

56.8 gal lon (215 litre) stain less steel res er voir tank

15,000 psi electronic strip chart recorder

Wall mounted Elmar wet centre reel with 12mm ID

x 75ft (23m) long hose

Installation kit options to suit clients test bay design

and dimensions

Safety features include:

- Flashing lights indicate when unit is in use

- Door interlock relays prevent pressure build up

when personnel or test bay door is open

- Automatic bleed-off if door is opened

OPTIONS:

(4) x Camera colour CCTV system

24 hour VCR

Data aquisition software for PC or laptop

0-24,000 psi unit (1,632 bar) (part number

L-6901003825-VO3)

CE marked, ATEX

approved

Pressure transducers have been used to remove all

fluid pressure from behind the operator panel making

this the safest most efficient hydrostatic pressure test

unit available.

Control panel

Reel assembly

Note: Installation kit needs to be confirmed at time of

order. Client to supply pressure test bay dimensions.

Rewind Mechanism

Wall Bracket Crank Handle

Complete assembly

Tank pump unit

Control panel unit

Wall Mounted Pressure Test Unit

This Elmar two piece pressure test unit has been designed for mounting either side of a workshop pressure test bay wall,

and includes features essential for safe and efficient hydrostatic pressure testing up to 22,500 psi.

Test and Injection Units 73

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-690708

WEIGHTS AND DIMENSIONS

Weights Overall 140kg (309lbs)

Dimensions Frame and Reel cm (in) L 63 (25) W 77 (30) H 125 (49)

Dimensions Control Panel cm (in) L 28 (11) W 61 (24) H 61 (24)

FEATURES:

Air driven high volume and high pressure

pump systems

Diaphragm pump to return fluid (drained from test

piece) back to tank

Adjustable gauge cut-off pump at preset

test pressure

0-30,000 psi 8 2/8 hour chart recorder

Wall mounted Elmar wet centre reel with 8mm ID

x 82ft (25m) long hose

Installation kit options to suit clients test bay design

and dimensions

Safety features include:

- Flashing lights indicate when unit is in use

- Door interlock relays prevent pressure build up

when personnel or test bay door is open

- Automatic bleed-off if door is opened

OPTIONS:

(4) x Camera colour CCTV system

Electronic pressure recorder and digital display

24 hour VCR

8mm I.D. x 40ft (12m) hose

Charts (part number L-571490)

CE marked, ATEX approved

Control panel

Typical reel assembly

Note: Installation kit needs to be confirmed at time of

order. Client to supply pressure test bay dimensions.

Gas Booster Unit

The Elmar compact, stand-alone, portable gas booster unit has been designed for pressure testing/charging up to 5,000 psi

using nitrogen gas.

Test and Injection Units

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

74

PART NUMBER L-6901003451

WEIGHTS AND DIMENSIONS

Weights 85kg (187lbs) Dimensions cm (in) L 85 (33) W 54 (21) H 40 (16)

FEATURES:

Air driven hydraulic pump

Machine engraved, stainless steel, colour

coded panel

Air driven gas booster pump

Stainless steel protective covers

Emergency shutdown and exhaust function

Supply hoses for air and gas, output gas hose

CE marked, ATEX approved for use in a Category 3

(Zone 2) hazardous area

Control panel

Test Line Pressure

Start Button

Emergency Stop Button

Gas Inlet Pressure

Air Supply Pressure

Machine engraved, stainless steel,

colour coded panel

Air Driven Grease Injection Pumps and Accessories

Elmar air-operated Grease Pumps, developed in conjunction with WIWA, are designed for use in Elmar's Grease Control

Modules. Elmar high-pressure Grease Pumps consist of a reciprocating air drive, coupled to a piston fluid pump.

Accessories 75

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBER L-840750

There are three pumps ratios available: 85:1, 175:1, and 235:1. With an air input of 100 psi the maximum

output pressure is respectively 8,500 psi, 17,500 psi and 22,500 psi, to suit well operations to 5,000, 10,000

and 15,000 psi. A 4:1 ratio pump is also available for fast transfers from a drum to grease reservoir on Elmar

modules. Driving the pump through an air regulator allows an infinitely variable control of the grease flow rate

and pump stall pressure. An Air Line Lubricator is required at the pump air input for reliable performance.

ELMAR WIRELINE GREASE

Elmar Wireline Greases are polybutene base fluids,

specially formulated for effective pressure control and

wireline lubrication. Elmar Wireline greases contain

inhibitors, and provide protection during wireline

operations against corrosion from hydrogen sulphide

(H2S), acids, caustics and saline brines. Elmar

Wireline Greases have a clear amber colour, and

because of their cohesive and adhesive properties

minimise drip and spatter, thus reducing well site

contaminations. Elmar Wireline Greases are supplied

in 55 US gallon (205 litres) drums and are available in

a range of viscosities to cover applications in ambient

temperatures ranging from -20C to in excess of

+60C. A Bio-Degradable version is available in

selected viscosities. On special request, greases are

available for temperatures down to -40C, and

specially inhibited for well fluids with high CO2

content.

GREASE FOR WIRELINE GREASE INJECTION SYSTEMS

Part Number Grease Type Operating Temp. Range (C) Biodegradeable Grease Type Part Number

L-8871010730 OCR 767-VIS 10 -40C to -15C

L-8871010731 OCR 768-VIS 12 -23C to +7C OCR 780-VIS 12 L-8871010729

L-880194 OCR 770-VIS 16 +7C to +30C OCR 780-VIS 16 L-880284

L-880195 OCR 774-VIS 20 +18C to +40C OCR 780-VIS 20 L-880285

L-880102 OCR 776-VIS 24 +27C to +55C OCR 780-VIS 24 L-880104

L-880103 OCR 778-VIS 28 +32C to >+55C OCR 780-VIS 28 L-880101

L-880217 OCR 779-VIS 30 +35C to >+60C OCR 780-VIS 30 L-880286

L-880247 Poly Multi K -20C to +5C

L-882800 Poly Multi -5C to +20C

L-882802 Poly Multi HP-HT +5C to +35C

WIWA Pump Ratio: 175:1 Ratio: 85:1 Ratio: 235:1 Ratio: 4:1

WIWA GREASE INJECTION AND TRANSFER PUMPS

Part Number Ratio Air Motor Size Output per Cycle Max Cycles per Min. Max Air Pressure Maximum Pressure

L-840890 235:1 12 (30cm) 2.6 cu.in. (43cc) 75 100 psi (6.9 bar) 23,500 psi (1,621 bar)

L-840750 175:1 8 (20cm) 2.6 cu.in. (43cc) 75 100 psi (6.9 bar) 17,500 psi (1,207 bar)

L-8401005837* 175:1 8 (20cm) 2.6 cu.in. (43cc) 75 100 psi (6.9 bar) 17,500 psi (1,207 bar)

L-840880 85:1 6 (15cm) 2.6 cu.in. (43cc) 75 115 psi (8 bar) 8,500 psi (586 bar)

L-698420 4:1 3 (7.5cm) 1.8 cu.in. (29cc) 75 100 psi (6.9 bar) 460 psi (32 bar)

FEATURES:

Air driven hydraulic pump

Relief valve on air motor to set maximum

working pressure

Oil bath above upper packing for long service life

Large built-in air silencer

High pressure pump tube of rugged construction

Replaceable packing sets in pump tube

Foot valve can be examined/replaced without pump

strip-down

ATEX approved versions are available*

L-840888 L-840890 L-698420

Filter

Air Lubricator

Air Driven Grease Injection Pumps

and Accessories Continued

Accessories

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

76

AIR MOTOR KITS FOR 175:1 WIWA GREASE INJECTION PUMP L-840750

Part Number Description

L-660770 Air Motor Seal Kit

L-660340 Air Motor Repair Kit (includes items in above seal kit)

FLUID SECTION KITS

L-660350 Fluid Section Repair Kit

L-838750 Upper Packing Mixed Assembly

L-838930 Lower Packing Mixed Assembly

L-838890 Bottom Valve Assembly

AIR MOTOR KITS FOR 85:1 WIWA GREASE INJECTION PUMP L-840880

Part Number Description

L-661430 Air Motor Seal Kit

L-661440 Air Motor Repair Kit (includes items in above seal kit)

FLUID SECTION KITS

L-660350 Fluid Section Repair Kit

L-838750 Upper Packing Mixed Assembly

L-838930 Lower Packing Mixed Assembly

L-838890 Bottom Valve Assembly

GENERAL ITEMS

Part Number Description

L-661470 85:1 Pump Repair Kit (Kits L-661440 and L-660350 combined)

L-660360 175:1 Pump Repair Kit (Kits L-660340 and L-660350 combined)

L-661480 235:1 Pump Repair Kit (Kits L-661460 and L-660506 combined)

L-837241 Engineering Adhesive for Air Motor

L-837242 Lubricator Grease for Air Motor

L-880000 Killfrost Airline Lubricant

L-690207 Flow Test Unit for Grease Pump

AIR MOTOR KITS FOR 235:1 WIWA GREASE INJECTION PUMP L-840890

Part Number Description

L-661450 Air Motor Seal Kit

L-661460 Air Motor Repair Kit (includes items in above seal kit)

FLUID SECTION KITS

L-660506 Fluid Section Repair Kit

L-830016 Upper Packing Mixed Assembly

L-831429 Lower Packing Mixed Assembly

L-838890 Bottom Valve Assembly

Ratio: 235:1

PART NUMBER L-840890

WIWA Pump Ratio: 175:1

PART NUMBER L-840750

WIWA Pump Ratio: 85:1

PART NUMBER L-840880

Hand Pump Assemblies

Elmar lightweight portable hand pumps have been designed to

be used with wireline pressure control equipment.

Accessories 77

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

FEATURES:

3,000 psi maximum working pressure on BOP

hand pump

6,500 psi maximum working pressure on stuffing

box hand pump

10,000 psi maximum working pressure on Quick

Test Sub and Wireline Cable Cutter hand pump

Lightweight portable construction

Aluminium base channel

Integral hydraulic reservoir

OPTIONS:

15,000 psi maximum working pressure on Q.T.S.

(part number L-690676)

FEATURES:

Naval brass cylinder

All other parts stainless steel

O ring and PolyPak Seals

Improved check valve

Dust seal on top of cylinder

Easy to maintain

No more seized-up hand pumps

PART NUMBERS

Part Number Output Pressure Output Volume In Port Out Port

L-793400 0-3,000 psi 0.66 cu.in./stroke 1/4 N.P.T.-F 1/4 N.P.T.-F

Service Kit L-663820 (0-207 bar) (11cc)/stroke

L-790013 0-6,000 psi 0.36 cu.in./stroke 1/4 N.P.T.-F 1/4 N.P.T.-F

Service Kit L-663830 (0-414 bar) (5.9cc)/stroke

L-792000 0-10,000 psi 0.28 cu.in./stroke 1/4 N.P.T.-F 1/4 N.P.T.-F

Service Kit L-663810 (0-690 bar) (4.6cc)/stroke

L-790008 0-15,000 psi 0.13 cu.in./stroke 1/4 N.P.T.-F 3/8 A.E.S.L.

Service Kit L-660487 (0-1,035 bar) (2.1cc)/stroke

STUFFING BOX OR PACK-OFF HAND PUMP

Part Number Description

L-690730 Hand Pump Assembly 6,000 psi Working Pressure

HYDRAULIC HOSE ASSEMBLY

Part Number Description

QUICK TEST SUB & WIRELINE CABLE CUTTER HAND PUMP

Part Number Description

L-690573 Hand Pump Assembly 10,000 psi Working Pressure

HYDRAULIC HOSE ASSEMBLY

Part Number Description

SINGLE BOP HAND PUMP

Part Number Description

L-690750 Hand Pump Assembly 3,000 psi Working Pressure

HYDRAULIC HOSE ASSEMBLIES

Part Number Description

PART NUMBER L-690730

Stuffing box or

pack-off hand pump

Single BOP hand pump

part number L-690750

L-691080

L-690760

L-690740

25ft

50ft

100ft

Hose Assembly

1/4 ID 100 R2AT Hose with 1/4 NPT Male Hose Ends

and Snaptite Male and Female Connectors

L-690587

L-690586

L-6901004505

25ft

50ft

100ft

Hose Assembly

6mm ID, 10,000 psi Hose with

Quick Connectors and Dust Covers

L-691000

L-691100

Y Hose Assembly for BOP Opening

Y Hose Assembly for BOP Closing

L-691080

L-690760

L-690740

25ft

50ft

100ft

Hose Assembly

1/4 ID 100 R2AT Hose with 1/4 NPT Male Hose Ends

and Snaptite Male and Female Connectors

STAINLESS STEEL HYDRAULIC HAND PUMP

Elmar-designed, stainless steel, modular hand pumps. These are now fitted to all our

hydraulic modules. They are completely interchangeable with the former steel hand

pumps.

Stainless steel hydraulic

hand pump

Stand Alone Mechanical and Electronic Chart Recorders

These chart recorders are designed as an Add on to existing Pressure Test Units to produce a paper or paper and

electronic pressure test record.

Accessories

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

78

UNIT OPTIONS

Part Number Description

L-690772 for 6,000 psi Pressure Test Unit

L-690767 for 10,000 psi Pressure Test Unit

L-690696 for 15,000 psi Pressure Test Unit

L-690768 for 22,500 psi Pressure Test Unit

WEIGHTS AND DIMENSIONS

Weights 45kg (99lbs) Dimensions cm (in) L 36 (14) W 26 (10) H 50 (20)

FEATURES:

Mechanical Chart Recorder

Paper type output

Mounted on anti-vibration mounts within a hand

portable stainless steel frame

Suitable for up to 22,500 psi test pressure

Complete with 10ft hose and quick connectors

OPTIONS:

CE marked, ATEX approved for use in a Category 2

(Zone 1) hazardous area

Transport Peli case (fully water proof)

Full range of adapters for connection to equipment

Electronic chart recorder

part number L-6901004669

ELECTRONIC CHART RECORDER

PART NUMBER L-6901004669

WEIGHTS AND DIMENSIONS

Weights 15kg (33lbs) Dimensions cm (in) L 40 (16) W 23 (9) H 23 (9)

FEATURES:

Electronic Chart Recorder

Digital display

Record to memory function

Supplied c/w computer software for viewing

collected data

Anti tamper file transfer

CE marked

Supplied in stainless steel trimmed flight case

Suitable for up to 22,500 psi test pressure

30,000 psi test pressure transducer included

OPTION:

Full range of adapters for connection to equipment

Mechanical chart recorder

Stand Alone Wet Centre Reels

and Remote Emergency Shutdown Units

Accessories 79

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

PART NUMBERS

Part Number Working Pressure Description

L-690754 10,000 psi 1 x 150ft (45.7m) 1/2 I.D. (12.7mm) Hose

L-690728 10,000 psi 3 x 150ft (45.7m) 3/8 I.D. (9.5mm) Hose

L-690674 10,000 psi 1 x 150ft (45.7m) 1/4 I.D. (6.4mm) Hose

L-690147 10,000 psi 3 x 150ft (45.7m) 1/4 I.D. (6.4mm) Hose 120 psi

1 x 60ft (18.2m) 1/2 I.D. (12.7mm) Air Hose

L-690166 5,000 psi 3 Reel No Hose

L-690167 5,000 psi 1 x 150ft (45.7m) 1/4 I.D. (6.4mm) Hose

10,000 psi 1 x 150ft (45.7m) 1/4 I.D. (6.4mm) Hose

120 psi 1 x 60ft (18.2m) 1/2 I.D. (12.7mm) Air Hose

L-690588 150 psi 1 x 150ft (45.7m) 3/8 I.D. (9.5mm) Hose

L-690608 10,000 psi 1 x 50ft (15.2m) 1/2 I.D. (12.7mm) Hose

L-697560 10,000 psi 1 x 60ft (18.2m) 1/4 I.D. (6.4mm) Hose

PART NUMBERS

Part Number Working Pressure Description

L-690131 120 psi 1 x 150ft (45.7m) 3/8 I.D. (9.5.mm) Hose

L-690219 120 psi 1 x 100ft (30.4m) 3/8 I.D. (9.5mm) Hose

L-690319* 120 psi 1 x 82ft (25m) 3/8 I.D. (9.5mm) Hose

L-690321* 120 psi 1 x 197ft (60m) 3/8 I.D. (9.5mm) Hose

L-690403* 120 psi 2 x 82ft (25m) 1/4 I.D. (6.4mm) Hose

*Note: Positive shutdown version.

PART NUMBER L-690403

WEIGHTS AND DIMENSIONS

Weights 35kg (77lbs) Dimensions cm (in) L 65 (26) W 25 (10) H 65 (26)

Remote ESD Unit

Stand Alone 4 x Wet Centre

Reel Assembly

PART NUMBER L-690147

WEIGHTS AND DIMENSIONS

Weights 140kg (309lbs) Dimensions cm (in) L 160 (60) W 92 (35) H 176 (69)

OPTIONS:

All required connectors can be supplied

All hose configurations/pressures can be

accomodated

CE marked

These stand alone reel assemblies can be used to connect air/hydraulic lines

between equipment.

OPTIONS:

All required connectors can be supplied

All hose configurations/pressures can be

accomodated

CE marked

REMOTE EMERGENCY SHUTDOWN (ESD) UNIT

The ESD System can be operated during an emergency either

by a pilot operated manual reset valve on the control panel of

the hydraulic control module, or by a push button valve on a

Remote Emergency Shut Down System.

Hose End Fittings and Accessories

The fittings shown are types of fittings most commonly used on Elmar equipment. Other fittings as specified by a client can

also be supplied.

Accessories

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

80

Air Line Connectors

CHICAGO CONNECTORS 250 PSI WORKING PRESSURE

Part Number Description

L-580200 1/2 I.D. 1/2 N.P.T. M

L-583400 1/2 I.D. 1/2 N.P.T. F

L-580300 3/4 I.D. 3/4 N.P.T. M

L-583300 3/4 I.D. 3/4 N.P.T. F

ARO CONNECTORS 250 PSI WORKING PRESSURE

Part Number Description

L-582800 1/4 I.D. 1/4 N.P.T. - M, Nipple

L-582700 1/4 I.D. 1/4 N.P.T. - F, Nipple

L-582900 1/4 I.D. 1/4 N.P.T. - F, Coupling

L-580100 1/2 I.D. 1/2 N.P.T. - M, Nipple

L-585400 1/2 I.D. 1/2 N.P.T. - F, Nipple

L-580000 1/2 I.D. 1/2 N.P.T. - F, Coupling

Hydraulic Line Connectors - Steel and Stainless Steel

SNAPTITE H SERIES 6,500 PSI WORKING PRESSURE

Part Number Description

L-585200 1/4 I.D. 1/4 N.P.T. - M, Nipple

L-586800 1/4 I.D. 1/4 N.P.T. - M, Stainless Steel Nipple

L-585300 1/4 I.D. 1/4 N.P.T. - M, Coupling

L-586700 1/4 I.D. 1/4 N.P.T. - M, Stainless Steel Coupling

L-581000 1/4 I.D. 1/4 N.P.T. - F, Nipple

L-583800 1/4 I.D. 1/4 N.P.T. - F, Stainless Steel Nipple

L-581100 1/4 I.D. 1/4 N.P.T. - F, Coupling

L-583700 1/4 I.D. 1/4 N.P.T. - F, Stainless Steel Coupling

WALTHER CONNECTORS

Part Number Description

L-500165 6mm I.D. 3/4 Type - M, Nipple 30,000 psi Working Pressure - without check valve

L-580129 6mm I.D. 3/4 Type - M, Coupling 30,000 psi Working Pressure

L-582100 6mm I.D. 1/4 N.P.T. - F, Nipple 10,000 psi Working Pressure - with check valve

L-581870 6mm I.D. 1/4 N.P.T. - M, Nipple 10,000 psi Working Pressure - without check valve

L-582000 6mm I.D. 1/4 N.P.T. - F, Coupling 10,000 psi Working Pressure

BAYONET CONNECTORS 10,000 PSI WORKING PRESSURE

Part Number Description

L-580800 1/2 N.P.T. - F, Upper Element

L-580700 1/2 N.P.T. - M, Lower Element

Chicago Connectors

Aro Connectors

Snaptite H Series Connectors

Walther Connectors

Walther Connectors

Grease Line Connectors

and Accessories

Accessories 81

Copyright National Oilwell Varco, Inc. 2008

www.nov.com/Elmar

S

e

c

t

i

o

n

3

W

e

l

l

h

e

a

d

C

o

n

t

r

o

l

,

T

e

s

t

a

n

d

I

n

j

e

c

t

i

o

n

U

n

i

t

s

SNAPTITE STAINLESS STEEL COUPLINGS

Part Number Description

L-585600 1/2 I.D. 1/2 N.P.T. - F, Coupling

L-585700 1/2 I.D. 1/2 N.P.T. - F, Nipple

L-585800 3/4 I.D. 3/4 N.P.T. - M, Nipple

PIONEER COUPLINGS 10,000 PSI WORKING PRESSURE

Part Number Description

L-587940 3/8 I.D. 3/8 N.P.T. - M, Coupling

L-587930 3/8 I.D. 3/8 N.P.T. - M, Nipple

HEX UNION ASSEMBLY 10,000 PSI WORKING PRESSURE

Part Number Description

L-580900 Complete Assembly

L-587300 1/2 I.D. 1/2 N.P.T. - F, Insert

L-587500 2 1/4 Hex Nut

L-587400 1/2 I.D. 1/2 N.P.T. - F, Adapter

L-871500 Adapter O Ring

HIGH PRESSURE ADAPTERS 10,000 PSI WORKING PRESSURE

Part Number Description

L-202500 1/2 N.P.T. - M, Adapter

L-204900 1/2 - 1/4 N.P.T. - M, Reducing Adapter

L-202300 1/4 N.P.T. - M, Adapter

MANIFOLD VALVE AND CHECK VALVE

Part Number Description

L-500060 1/2 N.P.T. - M - F, 10,000 psi Working Pressure Manifold Valve

L-505590 1/2 N.P.T. - F, 10,000 psi Working Pressure Check Valve

MANIFOLD BLOCKS 10,000 PSI WORKING PRESSURE

Part Number Description

L-740300 4 Port 1/2 N.P.T. F

L-740410 3 Port 1/2 N.P.T. F

L-740510 2 Port 1/2 N.P.T. - F

WALTHER CONNECTORS 10,000 PSI WORKING PRESSURE

Part Number Description

L-582300 10mm I.D. 1/2 N.P.T. - F, Coupling

L-582400 10mm I.D. 1/2 N.P.T. - F, Nipple

Snaptite Stainless Steel Couplings

Pioneer Couplings

Hex Union Assembly

High Pressure Adapters

Manifold Blocks

Manifold Valve Check Valve

Walther Connectors

Você também pode gostar

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!No EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Nota: 5 de 5 estrelas5/5 (2)

- SP - FlyLine WinchFrameDocumento24 páginasSP - FlyLine WinchFramehardevAinda não há avaliações

- Ws Wireline UnitDocumento1 páginaWs Wireline Unithesam abbaszadehAinda não há avaliações

- PCE Wireline Technology CatalogueDocumento120 páginasPCE Wireline Technology CatalogueWaled Fekry100% (1)

- A1 002 Wireline Unit PP SwapBody 24ftDocumento2 páginasA1 002 Wireline Unit PP SwapBody 24ftkiriungAinda não há avaliações

- Manual SpoolerDocumento118 páginasManual Spooleryubelly gómezAinda não há avaliações

- Sliding Sleeves Catalog Evolution Oil ToolsDocumento35 páginasSliding Sleeves Catalog Evolution Oil ToolsEvolution Oil Tools100% (1)

- Section 4: Pressure Control EquipmentDocumento47 páginasSection 4: Pressure Control Equipmentgonzalito777Ainda não há avaliações

- 5 Mandrels & Landing NipplesDocumento34 páginas5 Mandrels & Landing NipplesWaled FekryAinda não há avaliações

- Bha Coil Tubing CatalogDocumento82 páginasBha Coil Tubing CatalogJose Leonardo Materano PerozoAinda não há avaliações

- BO Shifting ToolDocumento1 páginaBO Shifting ToolJaime Andres Villegas Mansilla0% (1)

- A1 001 Wireline Unit PTO SwapBody 24ftDocumento2 páginasA1 001 Wireline Unit PTO SwapBody 24ftRio de MarioAinda não há avaliações

- A1119468 - Man - Mp16ii Rev ADocumento100 páginasA1119468 - Man - Mp16ii Rev Ahardev100% (8)

- Standing Valve FB2Documento3 páginasStanding Valve FB2Luis ChavarroAinda não há avaliações

- Completion 4Documento36 páginasCompletion 4AboZaidAinda não há avaliações

- SS2800 Side Pocket Mandrel GaugesDocumento2 páginasSS2800 Side Pocket Mandrel GaugesGonza PfAinda não há avaliações

- B-Positioning XA RA XO XDDocumento2 páginasB-Positioning XA RA XO XDSorin100% (1)

- 247 - AM5K Manual Standard 2016-12-08Documento129 páginas247 - AM5K Manual Standard 2016-12-08EbukaAinda não há avaliações