Escolar Documentos

Profissional Documentos

Cultura Documentos

Www-Mywheelhorse-Com: Power Take-Off Pt-7

Enviado por

theimproviser0 notas0% acharam este documento útil (0 voto)

23 visualizações2 páginaswheel horse 1055 power takeoff

Título original

PT-7_320

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentowheel horse 1055 power takeoff

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

23 visualizações2 páginasWww-Mywheelhorse-Com: Power Take-Off Pt-7

Enviado por

theimproviserwheel horse 1055 power takeoff

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

w

w

w

-

M

y

W

h

e

e

l

H

o

r

s

e

-

c

o

m

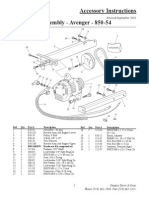

ASSEMBLY

Mount clutch rod mounting assembly plate and rod,

Part 7270 to engine face with two hex head bolts,

Part 908032-4 and lock washer, Part 920083-4

in the two lower right hand holes of the engine face.

Install the plate adapter, Part 7273, to the hood

stand, using the two Y.$-20 x X whlzlock bolts. Fasten

the clutch rod brocket to the plate adapter with two

~

18 x % Hex Bolts and Nuts. See exploded view

drawing.

Place clutch plate assembly, Part 6655 over engine

shaft and align the four holes with the holes in the

engine pulley. Slide the sleeve over the engine

shaft. Place the two retainers in the groove of the

sleeve and secure with the four whizlock bolts, Part

960151-4.

Slide clutch housing, Part 6660 on the sleeve until

it comes in contact with the clutch plate.

Install clutch rod assembly, Part 4355 down thru

the opening in the bracket, Part 4383 until the forked

shaped part of the rod is between the two nuts on the

clutch rod mounting assembly plate, Part 7270. Now

insert hairpin cotter, Port 933506-4 thru clutch housing

and plate on clutch rod.

POWER TAKE-OFF

PT-7

CLUTCH OPERATION AND ADJUSTMENT

Attaching tools are started and stopped by oper-

ating the engine mounted clutch. By moving the clutch

rod from the outside notch in the bracket, to the inside

notch, (toward the tractor), the friction disc is engaged.

The other end of this rod is fork shaped with a Ya''

locknut on each side. By moving these nuts in toward

the tractor, more tension will be applied to the dutch.

Adjust nuts so that clutch just disengages with dutch

rod in middle notch (above arrow) of bracket, Port

4383. Refer to decal on bracket.

LUBRICATION

The clutch housing has a needle bearing pressed

inside with a grease seal. This bearing has been

greased at tne factory. Every 25 hours the clutch

housing should be removed and a SMALL amount of

good quality multipurpose-type grease applied to

partially fill tne spaces between the rollers.

ENGINE PULLEYS

For all 8 H.P. tractors witn standard geared trans-

missions and model 1046 use the 2,X" dia. pulley,

Part No. 7363. For all 8 H.P. tractors with the Wneei-

A-Matic transmission (Hydro-Static) and model 1075

use the 3,X" dia. pulley, Part No. 7362. Space pulley

No. 7362 1" away from engine face. Space pulley No.

7363 X" away.

w

w

w

-

M

y

W

h

e

e

l

H

o

r

s

e

-

c

o

m

PARTS LIST

When ordering parts always list Part No. and Name of Part.

Item Part No. Item Part No.

No. No. Description Req'd. No. No. Description leq'd.

1 7270 Ass'y. - Plate and Shaft 1

2 908032-4 Bolt Hex %-16 x 2

3 920083-4 lock washer

%

Dia. 2

1-4 6935 Race - Bearing 1

15 6659 Retainer - Race 2

16 960151--4 Bolt - Whizlock x

X 6

4 908017-4 Bolt Hex K

6

-18 x 2 17 6660 Housing - Clutch 1

5 915112-6 Nut X

6

-18 Nylok 2 18 6662 Bearing 1

6 4355 Ass'y. Clutch Rod 1 19 6663 Seal 1

7 933506-4 Hair Pin 1

8 2709 Knob 1

9 4383 Bracket 1

20 5196 Boll Bearing 1

21 935032 Snap Ring Internal 1

22 936125 Snap Ring External 1

10 6655 Ass'y. Clutch Plate and Facing 1 23 5197 Shaft - Clutch 1

11 6656 Plate Clutch 1 2-4 7273 Plate Adaptor 1

12 -4365 Facing 1

13 6657 Rivet 6

25 7359 Decal - Clutch Adj. 1

26 915663-4 Nut Ya-16 Elastic Stop 2

1-17-67 FORM NO. 320

Você também pode gostar

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Wheelhorse Snow Attachments ManualsDocumento35 páginasWheelhorse Snow Attachments ManualsKevins Small Engine and Tractor Service100% (10)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- WheelHorse Power Take Off Manual 8-3112Documento4 páginasWheelHorse Power Take Off Manual 8-3112Kevins Small Engine and Tractor ServiceAinda não há avaliações

- WheelHorse Power Take Off Manual 8-3411Documento4 páginasWheelHorse Power Take Off Manual 8-3411Kevins Small Engine and Tractor ServiceAinda não há avaliações

- Camshaft Thrust 3 PDFDocumento2 páginasCamshaft Thrust 3 PDFvictoverAinda não há avaliações

- Adjustment of The Valve Lash and The Valve Bridge With The 147-5482Documento8 páginasAdjustment of The Valve Lash and The Valve Bridge With The 147-5482victor.cipriani50% (2)

- PD InjectorDocumento5 páginasPD InjectorTomas NoneeAinda não há avaliações

- Traxxas Revo Slipper RebuildDocumento1 páginaTraxxas Revo Slipper RebuildbernadysroseAinda não há avaliações

- Harley Davidson 250 and 350 SprintDocumento8 páginasHarley Davidson 250 and 350 SprintElan Mutt Schwartz75% (4)

- Cams Andrews 99 Gear-01Documento4 páginasCams Andrews 99 Gear-01dsgoodrichAinda não há avaliações

- 1 634 TechnicalDocumento11 páginas1 634 Technicalmarsianin1_702850066Ainda não há avaliações

- WheelHorse Power Take Off Manual 8-3111Documento2 páginasWheelHorse Power Take Off Manual 8-3111Kevins Small Engine and Tractor ServiceAinda não há avaliações

- Operating Manuals - MaestralDocumento10 páginasOperating Manuals - Maestralbillytheblack67Ainda não há avaliações

- 1971 Chevy Overhaul ManualDocumento505 páginas1971 Chevy Overhaul ManualCharlie Moretti100% (1)

- Remove & Install Connecting Rod BearingsDocumento4 páginasRemove & Install Connecting Rod BearingsRichard ChuaAinda não há avaliações

- Service Manual PDFDocumento2 páginasService Manual PDFvictoverAinda não há avaliações

- Pinion Assemblies - AssembleDocumento4 páginasPinion Assemblies - Assemblemijael1393Ainda não há avaliações

- Honda Trx400ex NoPWDocumento7 páginasHonda Trx400ex NoPWJose Le MartinezAinda não há avaliações

- Motor Eaton 1000 A PartsDocumento12 páginasMotor Eaton 1000 A PartsJuan Hernan Valdiviezo DiasAinda não há avaliações

- Remove and Install Crankshaft Main BearingsDocumento4 páginasRemove and Install Crankshaft Main BearingsMax Will Carrasco SantiAinda não há avaliações

- Remove and Install Crankshaft Main BearingsDocumento4 páginasRemove and Install Crankshaft Main BearingsMayumi Lizarme BuezoAinda não há avaliações

- Rear SealDocumento9 páginasRear SealHammad Uddin JamilyAinda não há avaliações

- Installation - Service Instructions: Front Brake KitsDocumento2 páginasInstallation - Service Instructions: Front Brake KitsCokhiducminh VinhphucAinda não há avaliações

- Specifications 5.1: Starter Torque ValuesDocumento14 páginasSpecifications 5.1: Starter Torque Valuesvette512Ainda não há avaliações

- Y70, Y90 NewDocumento9 páginasY70, Y90 NewJavierAinda não há avaliações

- Orbit RolDocumento12 páginasOrbit RolFabio MartinsAinda não há avaliações

- V Twin - XL TRANNYDocumento8 páginasV Twin - XL TRANNYLang78Ainda não há avaliações

- 03-04 SID Rear Service Guide - Rev - BDocumento5 páginas03-04 SID Rear Service Guide - Rev - Bmaxpower2004Ainda não há avaliações

- Transmision 02G StandarDocumento141 páginasTransmision 02G Standargayt333100% (3)

- Banks SidewinderDocumento20 páginasBanks Sidewinderpino2234Ainda não há avaliações

- Hazet 2588-1-4 EnglishDocumento4 páginasHazet 2588-1-4 EnglishTumase Pyar KarataAinda não há avaliações

- Crankshaft - InstallDocumento7 páginasCrankshaft - InstallLeonardo PerezAinda não há avaliações

- 850-54 Alternator Kit Hdi - AvgDocumento6 páginas850-54 Alternator Kit Hdi - Avgcristi_stoiciucAinda não há avaliações

- M551 M552Documento96 páginasM551 M552Игорь100% (1)

- GEARBOX MANUAL SF Revision DDocumento37 páginasGEARBOX MANUAL SF Revision DaliAinda não há avaliações

- 1991 Nissan-Datsun 240SX Cylinder Head RemovalDocumento11 páginas1991 Nissan-Datsun 240SX Cylinder Head Removalgigabyte3235840Ainda não há avaliações

- Access - Air Kelly Spinner Manual PDFDocumento9 páginasAccess - Air Kelly Spinner Manual PDFadjoudj100% (1)

- 2 Gear LinkageGolf Mk1Documento46 páginas2 Gear LinkageGolf Mk1SteggosAinda não há avaliações

- Single Line Hose Reels: Nstallation InstructionsDocumento12 páginasSingle Line Hose Reels: Nstallation InstructionsLuisYaguiAinda não há avaliações

- Special Features of The Twingo Fitted With The D7F EngineDocumento314 páginasSpecial Features of The Twingo Fitted With The D7F EngineGyula75% (4)

- Jari Chief Manual 2015Documento7 páginasJari Chief Manual 2015Dara Donelson100% (1)

- AC Compressor ServicingDocumento28 páginasAC Compressor Servicinggentiles mdqAinda não há avaliações

- Steel Piston PDFDocumento14 páginasSteel Piston PDFvictoverAinda não há avaliações

- Invert SuspensionDocumento20 páginasInvert Suspensionsatya100% (1)

- Instructions: 6 Speed Transmission Super KitDocumento14 páginasInstructions: 6 Speed Transmission Super KitthailanAinda não há avaliações

- Valve - Clearance Adjustment (6068) (Two-Valve Head) - ctm104 - Service ADVISOR™Documento4 páginasValve - Clearance Adjustment (6068) (Two-Valve Head) - ctm104 - Service ADVISOR™Timothee MbambaAinda não há avaliações

- Ski Daddler 1966 1970Documento4 páginasSki Daddler 1966 1970Paul MartinAinda não há avaliações

- คู่มือบำรุงรักษา root blowerDocumento17 páginasคู่มือบำรุงรักษา root blowervarayutjAinda não há avaliações

- Figure 1-301 Gasket Eliminator Application: Series 60 Service ManualDocumento2 páginasFigure 1-301 Gasket Eliminator Application: Series 60 Service ManualvictoverAinda não há avaliações

- 5330 New Carriage Drive Motor ReplacementDocumento15 páginas5330 New Carriage Drive Motor ReplacementBrenda ClayAinda não há avaliações

- Removing and Installing Camshaft Drive Gear: ChapterDocumento6 páginasRemoving and Installing Camshaft Drive Gear: ChapterDomonique BermanAinda não há avaliações

- Yanmar PDFDocumento13 páginasYanmar PDFmarcosluna68100% (1)

- CCW Two Cylinder ModelsDocumento6 páginasCCW Two Cylinder ModelsPaul MartinAinda não há avaliações

- Eng 5.4-97Documento25 páginasEng 5.4-97Alexey KolmakovAinda não há avaliações

- Serie 60 Informacion AdicionalDocumento51 páginasSerie 60 Informacion AdicionalMauricio Campos QuirosAinda não há avaliações

- C Molo TM003 eDocumento8 páginasC Molo TM003 ejcclaAinda não há avaliações

- L Series 1770Documento76 páginasL Series 1770JuprayAinda não há avaliações

- 07-124 Motor CharlynDocumento12 páginas07-124 Motor CharlynMiguel Angel Santos Pintado100% (2)

- SM - Volvo g960 Motor GraderDocumento21 páginasSM - Volvo g960 Motor GraderLuan Max100% (1)

- Pellet Stove T300P Tech ManualDocumento29 páginasPellet Stove T300P Tech Manualtheimproviser100% (1)

- Portable Puller 4 Ton: Set Up and Operating InstructionsDocumento12 páginasPortable Puller 4 Ton: Set Up and Operating InstructionstheimproviserAinda não há avaliações

- Generator Selection Guide and Applications Chart: All LightsDocumento2 páginasGenerator Selection Guide and Applications Chart: All LightstheimproviserAinda não há avaliações

- Mikasa mt74Documento50 páginasMikasa mt74theimproviserAinda não há avaliações

- Bikers Choice Parts CatalogDocumento1.300 páginasBikers Choice Parts CatalogtheimproviserAinda não há avaliações

- Tech Spec For Centrifugal PumpDocumento5 páginasTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Typical Exam Questions With Answers 2Documento17 páginasTypical Exam Questions With Answers 2Khadem Nuristani100% (1)

- Datasheet (API 610 - 1 Page)Documento8 páginasDatasheet (API 610 - 1 Page)Rudin Fahrudin RahmanAinda não há avaliações

- RecitationDocumento4 páginasRecitationSavaliya HardikAinda não há avaliações

- Powerpoint Images: Failures Resulting From Static LoadingDocumento11 páginasPowerpoint Images: Failures Resulting From Static LoadingKTMOAinda não há avaliações

- Strengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewDocumento16 páginasStrengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewHÙNG Trần MạnhAinda não há avaliações

- Fleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixDocumento48 páginasFleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixCesar G.Ainda não há avaliações

- Multi ElementDocumento1 páginaMulti Elementapi-3703371Ainda não há avaliações

- En EQP17 ALIVA-263-285 GB 0607Documento3 páginasEn EQP17 ALIVA-263-285 GB 0607Gonçalo Duarte AntunesAinda não há avaliações

- D77003 enDocumento57 páginasD77003 enzliangAinda não há avaliações

- IRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualDocumento172 páginasIRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualNikolay VelchevAinda não há avaliações

- Design Standards and SpecificationsDocumento47 páginasDesign Standards and Specificationsabhi0912Ainda não há avaliações

- I.S. Code - 456 Recommendation:: 1. For ConcreteDocumento4 páginasI.S. Code - 456 Recommendation:: 1. For ConcreteSonu PanwarAinda não há avaliações

- AFRC - Improving Performance of Coker HeatersDocumento29 páginasAFRC - Improving Performance of Coker Heatersashutosh_garg_10Ainda não há avaliações

- Tablas Medidas Tubos de Acero API5L - ASTM A53 - A106Documento6 páginasTablas Medidas Tubos de Acero API5L - ASTM A53 - A106Reinaldo AndaraAinda não há avaliações

- CatalogoDocumento18 páginasCatalogocarlosorizabaAinda não há avaliações

- Spare Parts For Powerplant-And Marine Diesel EnginesDocumento3 páginasSpare Parts For Powerplant-And Marine Diesel EnginesJavedAinda não há avaliações

- Technical Specifications For ValvesDocumento32 páginasTechnical Specifications For ValvesEr Hussain GhadialiAinda não há avaliações

- Ne6 3911gb-MidlumDocumento234 páginasNe6 3911gb-MidlumDinu GabrielAinda não há avaliações

- w73621 Int Gcse Physics 4ph1 4sd0 Exam AidDocumento4 páginasw73621 Int Gcse Physics 4ph1 4sd0 Exam AidjenifaAinda não há avaliações

- Liquid Limit Arugolanu 1Documento3 páginasLiquid Limit Arugolanu 1Durga Rama Swamy KalvakolanuAinda não há avaliações

- Geared Motor: Product ManualDocumento178 páginasGeared Motor: Product Manualsanjibkrjana100% (1)

- Cobalt Chromium Implant Grade TubingDocumento2 páginasCobalt Chromium Implant Grade Tubingkunalkp88Ainda não há avaliações

- Piper Lance II - Turbo Lance II-Maintenance - smv1986Documento568 páginasPiper Lance II - Turbo Lance II-Maintenance - smv1986willkobiAinda não há avaliações

- Thermodynamics: AllenDocumento9 páginasThermodynamics: AllenronakAinda não há avaliações

- Chassis Design Report PDFDocumento8 páginasChassis Design Report PDFPrakhar YadavAinda não há avaliações

- SWD Pipe Size Calculation For South CampusDocumento4 páginasSWD Pipe Size Calculation For South Campussalmaan mastanAinda não há avaliações

- Poster On Quantifying Atomic Vibration at Solid Liquid InterfaceDocumento1 páginaPoster On Quantifying Atomic Vibration at Solid Liquid InterfaceDeep PatelAinda não há avaliações

- Electrification in MotorsportDocumento8 páginasElectrification in Motorsportddi11Ainda não há avaliações

- Special Tools: CatalogueDocumento160 páginasSpecial Tools: CatalogueKot8780% (1)