Escolar Documentos

Profissional Documentos

Cultura Documentos

Minimum Wall Thickness Welded Low Carbon Cylinder Low Pressure LPG

Enviado por

NakkolopDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Minimum Wall Thickness Welded Low Carbon Cylinder Low Pressure LPG

Enviado por

NakkolopDireitos autorais:

Formatos disponíveis

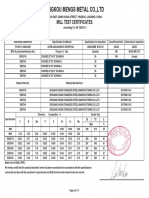

Minimum Wall Thickness Calculations for Two-Piece Welded Low Carbon Steel Cylinders for Low Pressure Liquefiable

Gases of water capacity ! liters as per "S# $%&' ( )

The agreed finished wall thickness shall not be less than that calculated from the following formulae (Clause 7.1) a) 1) )here* 'h D "e# ! = = = = = &0 bar &1+., 1.0 &,0.7 Side wall thickness shall not be less than a = D $$ ( 10 ! "e# $ %& '# $$$$$$$$$$$$$$$$$$$$$$$ 10 ! "e#

1$%

Substituting the abo.e in the abo.e formula* a = &1+., $$$$$$$ ( 1$ % 10 / 1.0 / 0.7 / &,- $ %& / &0 $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ 10 / 1.0 / 0.7 / &,-

1-0.( 1$ %

(,1- $ -1.07 $$$$$$$$$$$$$$$$$$$$$$$ (,1-

= 7.( 7.(.(

1-0.( / 0.010+

= 1.7( mm Design of ends conca.e to 1ressure b = a1C C = 1.0 a1 = a as ( = 1 in a)

Therefore* 2inimum thickness is 1.7( mm

Minimum Wall Thickness Calculations for Two-Piece Welded Low Carbon Steel Cylinders for Low Pressure Liquefiable Gases of water capacity ! liters

as per "S# **++) a = calculated minimum thickness of the c3lindrical shell 4 = 1ercentage elongation after fracture b = calculated minimum thickness of the end of the c3linder C = sha1e factor (see Table ( and !igure () D = outside diameter of the c3linder as gi.en in the design drawing (see !igure 1) D1 = outside diameter of a bend tests former (see !igure 10) h = height of the c3lindrical 1art of the end (see !igure 1) # = outside height of the domed 1art of the end (see !igure 1) = stress reduction factor 5 = length of the c3linder 5o = original gauge length of the test 1iece in accordance with 6S7 8+0( n = ratio of diameter of bend test former to the thickness of the test 1iece (see Table () 'c = calculation 1ressure used to calculate the minimum re9uired thickness of the c3lindrical shell and ends (see 8.1.&) 'b = ma/imum 1ressure attained during the burst test 't = actual test 1ressure* a11lied to the c3linder b3 the manufacturer 'tmin = minimum 1ermissible test 1ressure bar r inside knuckle radius of the end r = inside dishing radius of the end "g = minimum guaranteed tensile strength "0 = minimum .alue of 3ield stress guaranteed b3 the c3linder manufacturer for the finished c3linder "m= actual .alue of tensile strength determined b3 the tensile test s1ecified in +.1.(.( 6.2 Calculation of cylindrical shell thickness The wall thickness of the cylindrical shell shall be not less than that calculated using the formula: Pc x D . a = 20 X o X ! . " Pc #$% for cylinders without a longitudinal weld: ! = &'0. %0 x%&(.# . 20x%#)x& " %0 #$% = *))2 . )20) = &.(%mm.

Minimum Wall Thickness Calculations for Two-Piece Welded Low Carbon Steel Cylinders for Low Pressure Liquefiable Gases of water capacity ! liters

as per ,- )$)$& a = Calculated minimum thickness of the c3lindrical shell* in millimeters. 4 = 'ercentage elongation after fracture. b = Calculated minimum thickness of the end of the c3linder* in millimeters. C = Sha1e factor for ends (see Table 1 and !igure (). D = 7utside diameter of the c3linder as gi.en in the design drawing (see !igure 1)* in millimeters. D1 = 7utside diameter of a bend tests former (see !igure +)* in millimeters. e = 4ctual thickness of the material used* in millimeters. h = #eight* in millimeters* of the c3lindrical 1art of the end (see !igure 1). # = 7utside height* in millimeters* of the domed 1art of the end (see !igure 1). = Stress reduction factor. l = 5ength of the c3linder* in millimeters. 5o = 7riginal gauge length of the test 1iece* in accordance with :; 1000($1* in millimeters. n = "atio of diameter of bend test former to the thickness of the test 1iece* (see Table -). 5.2 Calculation of cylindrical shell thickness The wall thickness of the cylindrical shell shall be not less than that calculated using the formula: a= Pc x D . +&) X o X !, " Pc

a = %0x%&(.# . +&)x%#)x&, " %0 = *))2 . )#-) = &.-#mm

Minimum Wall Thickness Calculations for Two-Piece Welded Low Carbon Steel Cylinders for Low Pressure Liquefiable Gases of water capacity ! liters

as per ,- )$$* a = calculated minimum thickness of the c3lindrical shell 4 = 1ercentage elongation after fracture b = calculated minimum thickness of the end of the c3linder C = sha1e factor (see Table ( and !igure () D = outside diameter of the c3linder as gi.en in the design drawing (see !igure 1) D1 = outside diameter of a bend tests former (see !igure 10) h = height of the c3lindrical 1art of the end (see !igure 1) # = outside height of the domed 1art of the end (see !igure 1) = stress reduction factor 5 = length of the c3linder 5o = original gauge length of the test 1iece in accordance with 6S7 8+0( n = ratio of diameter of bend test former to the thickness of the test 1iece (see Table () 'c = calculation 1ressure used to calculate the minimum re9uired thickness of the c3lindrical shell and ends (see 8.1.&) 'b = ma/imum 1ressure attained during the burst test 't = actual test 1ressure* a11lied to the c3linder b3 the manufacturer 'tmin = minimum 1ermissible test 1ressure bar r inside knuckle radius of the end r = inside dishing radius of the end "g = minimum guaranteed tensile strength "0 = minimum .alue of 3ield stress guaranteed b3 the c3linder manufacturer for the finished c3linder "m= actual .alue of tensile strength determined b3 the tensile test s1ecified in +.1.(.( 6.2 Calculation of cylindrical shell thickness The wall thickness of the cylindrical shell shall be not less than that calculated using the formula: Pc x D . a = 20 X o X ! . " Pc #$% for cylinders without a longitudinal weld: ! = &'0. %0 x%&(.# . 20x%#)x& " %0 #$% = *))2 . )20) = &.(%mm.

Você também pode gostar

- Price Comparison Template 22Documento4 páginasPrice Comparison Template 22NakkolopAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Appendix A of AC10Documento3 páginasAppendix A of AC10NakkolopAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Develve SupportDocumento1 páginaDevelve SupportNakkolopAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Jha New Format Painting Revision PDFDocumento8 páginasJha New Format Painting Revision PDFNakkolopAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Jha New Format Painting Revision PDFDocumento8 páginasJha New Format Painting Revision PDFNakkolopAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- General Flange ChartDocumento4 páginasGeneral Flange ChartNakkolopAinda não há avaliações

- Sea Water For HydrotestDocumento2 páginasSea Water For HydrotestNakkolopAinda não há avaliações

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocumento27 páginasNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Item 04 - Redução Concentrica Inox A403 316L SCH40 4 X 3 - Ew2744Documento1 páginaItem 04 - Redução Concentrica Inox A403 316L SCH40 4 X 3 - Ew2744Augusto De DimaAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- World Standard Specifications - ListDocumento24 páginasWorld Standard Specifications - ListJose Luis RojasAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Modul Pecutan Kimia SPM 2021Documento25 páginasModul Pecutan Kimia SPM 2021Nuan Ting NgAinda não há avaliações

- Acetone Production Process From Iso-propyl-Alcohol (IPA)Documento36 páginasAcetone Production Process From Iso-propyl-Alcohol (IPA)Serkan91% (44)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Zinc Coatings PDFDocumento12 páginasZinc Coatings PDFMuhammadImaduddienSalamAinda não há avaliações

- Epd Pa66 gf25 Recycled EnglishDocumento26 páginasEpd Pa66 gf25 Recycled EnglishShantha Kumar ParameswaranAinda não há avaliações

- Chapter 4 Solid BedDocumento27 páginasChapter 4 Solid BedTaha Azab MouridAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Solid Waste-LandfillDocumento27 páginasSolid Waste-LandfillMahmoud I. MahmoudAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Carbon As Support For Precious Metal CatalystsDocumento13 páginasCarbon As Support For Precious Metal CatalystsDevdatta Potnis100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Reference #08 - JNL-SO73-1 Bleacher SeatsDocumento7 páginasReference #08 - JNL-SO73-1 Bleacher SeatsAriel Gonzalez100% (1)

- Wastewater Characterization Lab 020409 FinalDocumento9 páginasWastewater Characterization Lab 020409 FinalgiabrunAinda não há avaliações

- Microwave Smelter 8 Steps (With Pictures)Documento22 páginasMicrowave Smelter 8 Steps (With Pictures)ArifDarmawanAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Weight Tables Mild Steel Round Bars and High Tensile Deformed BarsDocumento6 páginasWeight Tables Mild Steel Round Bars and High Tensile Deformed BarsSyed ShareefAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- Sesv8010 Antifriction BearingsDocumento160 páginasSesv8010 Antifriction BearingsFrancisco Abarca G.Ainda não há avaliações

- PET Fibers, Films, and Bottles: V. B. Gupta, Z. BashirDocumento45 páginasPET Fibers, Films, and Bottles: V. B. Gupta, Z. BashirAryan KumarAinda não há avaliações

- Leidenfrost EffectDocumento5 páginasLeidenfrost EffectJagdeep SekhonAinda não há avaliações

- دوسية فيصل عناية كاملة PDFDocumento269 páginasدوسية فيصل عناية كاملة PDFSuhaib TelfahAinda não há avaliações

- Cobalt MSDS: Section 1: Chemical Product and Company IdentificationDocumento5 páginasCobalt MSDS: Section 1: Chemical Product and Company IdentificationAnyberta Dwi ListyantiAinda não há avaliações

- Development of CuZnAl SMADocumento5 páginasDevelopment of CuZnAl SMAYudha PradhanaAinda não há avaliações

- Adjuvant SDocumento33 páginasAdjuvant SNugroho HartonoAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Energy Elastic Strain EnergyDocumento14 páginasEnergy Elastic Strain EnergyamirwmAinda não há avaliações

- Experimental and Numerical Analysis For Determining The Mass Flow Rate of Two Phase Fluid Using Laminar Flow Rectangular ChannelDocumento11 páginasExperimental and Numerical Analysis For Determining The Mass Flow Rate of Two Phase Fluid Using Laminar Flow Rectangular Channelsaju_s_rajAinda não há avaliações

- Rough DraftDocumento10 páginasRough Draftapi-282200449Ainda não há avaliações

- Eup 10221 Chem MechDocumento1 páginaEup 10221 Chem MechNisarg PandyaAinda não há avaliações

- Monopol 456 HBDocumento2 páginasMonopol 456 HBPammy JainAinda não há avaliações

- 31 Final ReportDocumento28 páginas31 Final ReportMohit ChoudharyAinda não há avaliações

- 2014 AFPM Q&A - Answer BookDocumento93 páginas2014 AFPM Q&A - Answer Booksaleh4060Ainda não há avaliações

- Advanced SDOF Model For Steel Members Subject To Explosion LoadingDocumento35 páginasAdvanced SDOF Model For Steel Members Subject To Explosion LoadingAkhlaq HussainAinda não há avaliações

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Documento31 páginasStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaAinda não há avaliações

- CH 21Documento51 páginasCH 21Mostafa AhmedAinda não há avaliações