Escolar Documentos

Profissional Documentos

Cultura Documentos

After Crack FRC 2

Enviado por

Mani KumarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

After Crack FRC 2

Enviado por

Mani KumarDireitos autorais:

Formatos disponíveis

Experimental Mechanics DOI 10.

1007/s11340-011-9556-2

A Test Method to Characterize Flexural Creep Behaviour of Pre-cracked FRC Specimens

S.E. Arango & P. Serna & J.R. Mart-Vargas & E. Garca-Taengua

Received: 26 April 2011 / Accepted: 13 September 2011 # Society for Experimental Mechanics 2011

Abstract This paper presents a proposal of test setup and methodology for testing the flexural creep behaviour of precracked Fibre Reinforced Concrete (FRC) specimens, aimed at providing a basis for standardization. The design criteria used to define the equipment and methodology are presented. A test results sheet and a curve are established to present the results of creep tests, and some experimental results are shown so that the test can be validated. The equipment and methodology proposed make it possible to research the influence of factors such as concrete type, fibres type and content, applied load, and crack opening value. Keywords Test method . Fibre reinforced concrete . Creep . Cracked state . Bending

Introduction Fibre Reinforced Concrete (FRC) has been widely studied, this resulting in significant advances in knowledge regarding toughness and residual strength characterization. In most of its applications FRC elements are designed to be subjected to cracking, this way the material works in the cracked state, where residual strength gives the element further mechanical resistance and the capacity to control

S.E. Arango : P. Serna (*) : J.R. Mart-Vargas : E. Garca-Taengua ICITECH, Institute of Concrete Science and Technology, Universitat Politcnica de Valncia, Camino de Vera, s/n., 46022 Valencia, Spain e-mail: pserna@cst.upv.es

crack propagation. For structural applications different codes (MC 2010 [1]; EHE-08 [2]; ACI 318 [3]) propose design methods that consider this possibility and assess the FRC contribution by means of the bending test (as the EN 14651:2007 [4]) and the evaluation of parameters that define flexural behaviour. Creep is a term used to define the tendency of materials to develop increasing strains through time when under a sustained load, thus having an increase in deflection or elongation with time in relation to the short-term strain [5]. Long-term deformations can be beneficial to some types of structures because they lead to a stress redistribution which can limit the extent of cracking. At the same time, in the case of decreasing residual strength or significant deformations the influence of creep will be negative. Long-term behaviour of FRC has not been considered in codes yet. Studies on creep of FRC in compression indicate that fibres restrain creep strains when compared to plain mortar and concrete [6, 7]. As FRC contribution to structural load-bearing capacity is based on its flexural response, and mainly in the cracked state, the capacity of the material to keep the crack opening values low enough to guarantee the reinforcement effectiveness should be assessed [8]. The knowledge of the concrete materials and properties is essential to better assess their structural applications, and the development of measurement techniques and experimental methods is required [9, 10]. The analysis of flexural creep behaviour of cracked FRC elements is a relatively new topic (it has attracted important research attention for the last 10 years only) which has not been entirely researched yet. There is no standardized method to assess such behaviour at this time. Publications directly related to flexural creep behaviour of pre-cracked FRC beams are scarce [8, 11, 12]. Most of

Exp Mech

Fig. 1 Second class lever scheme

them analyze the contribution of plastic and, in some cases, of glass fibres to such behaviour, and consider steel fibres only on a comparative basis [5, 1318], not as one of their main objectives. Several serious differences are observed between such studies that compromise the possibility of considering their results as comparable: different methodologies and test setups, different concrete and fibre types, fibre contents, crack openings or deflections considered, load levels, test specimen, standards, and procedures. As a result, some attempt to establish a methodology and a convenient test setup to study the flexural creep behaviour of pre-cracked FRC specimens was necessary.

Fig. 3 Creep frames at the time test (overview and test specimen column detail)

Test Method Approach It comes out of the definition of creep that an adequate test setup must guarantee the application of a constant load for a long period of time, a number of months or even years, and allow the increase of deformations through time. Taking into account the methodologies and test setups proposed in previous studies [5, 8, 1220] and the requirements identified, a test methodology has been established and the corresponding equipment has been defined to carry out creep tests on cracked specimens under bending loads. In the design process of the test equipment three parts have been defined: the creep frame and its components, the measurement devices, and the data acquisition system (DAS).

Fig. 2 Scheme of the creep frame

The creep frame and its components have to be stiff enough to guarantee the application of a constant load and to keep test conditions steady as long as the test lasts in spite of the deformation of the specimens. The best way to do so is by applying gravity loading directly on top of the test specimen. The relatively high loads to be applied (60 kN) lead to the need of combining this gravity loading with a lever system. A second class lever is employed (Fig. 1). Because of time and space limitations, the possibility of working with at least three test specimens forming a column in every creep frame has been considered. The stability of the test specimens (support and loading conditions) in the column must be guaranteed, the induced moments must be prevented and it has to be possible to continue the test when one of the test specimens in the column fails. Therefore, a set of elements to apply the load and to support the test specimens has been designed. Measurement devices are used to quantify crack opening and compressive strain values as well as the load applied for all the time the test takes. Additionally, environmental conditions (humidity and temperature) must be measured and registered.

Exp Mech

Fig. 4 Positioning and loading elements (schemes and pictures)

The DAS has to be able to take readings from the measurement devices with the proper reading cadence and to save the data in order to be analyzed later. Because of the long time that creep tests take, the system is required to be able to auto-restart so that as few data as possible are lost in case of error. & Creep Frame and Components The creep frame is made with steel profiles. Figure 2 shows schematics of a testing fixture and Fig. 3 shows general view of a fixture during the testing. & A support base (a) composed of two pairs of steel profiles: the two main ones are longitudinal, and the other two are shorter and disposed transversely to the longitudinal ones. The column of test specimens is supported on two vertical profiles (b) welded to the longitudinal ones of the support base. The lever (c) is made up of two long profiles, each one placed at a side of the specimens column and supported on two vertical profiles (d) both placed at a lower height than the specimens. A plate (e) to hold the counterweights is disposed on the lever, at the opposite end to the support point. This plate and the two transversal profiles guarantee the parallelism of the two lever arms by avoiding any relative movement between them. The load is transmitted through a couple of screwed bars (f) placed between the support points and the counterweights plate. Each one is connected to one of the lever long profile. To do that each lever profile has holes dimensioned to allowing screwed bars traverse it without friction to avoid any parasite load application. This way the two screwed bars are placed vertically at same plane than the specimens column central section. A transversal load plate (g) placed on top of the column

of test specimens connect both screwed bars and is supported over the upper specimen by means of the load transmission element (h). A nut and a washer at the top and at the bottom of the screwed bars complete the system to transmit the load from the lever to the specimens column. In Fig. 3 a setup adapted for 3 specimens is shown, though this number may be increased by simply modifying the screwed bars length. The lever, as designed, multiplies the applied force by 15. Frame and components detailed dimensions and specifications can be found in [21].

& &

&

&

Fig. 5 Displacement transducer placed on the test specimen (bottom surface)

Exp Mech Fig. 6 Scheme bending test concerning to EN 14651 [4] (a) and presents creep frame (b)

&

&

Positioning and loading (h and i) elements and the dimensions of the level hole have been designed to guarantee the adequate placement and stability of both the load transducer and the test specimens. This way load transmission is produced properly, isostatically and avoiding the transmission of induced efforts. Creep of the load transmission bar would lead to the increase of its length and the lever slope would vary accordingly. The effect of this and of the creep of other frame components on the evolution of transmitted load has been evaluated and it is negligible due to their high stiffness when compared to that of concrete samples being tested. To this end, the load transmission element (h) (on top of the column of test specimens) consists of a rigid steel plate and two semicircular loading points at a distance of 150 mm. One of them allows transversal turning (to prevent the transmission of induced moments) and the other one is fixed (Fig. 4(a)). This element has a slot on top to guarantee the right placement of the load transducer above. The support and load transmission element (i) (one under every specimen of the test specimens column) is formed by a rigid steel plate, two semicircular support points at a distance of 450 mm (top surface), and two semicircular load points at a distance of 150 mm (bottom surface). One of the supports allows transversal turning (to prevent the transmission of induced moments) and the other one is fixed. On the top surface two flanges have been disposed to preserve the displacement transducers in case of failure of some test specimen in order to be able to continue the test (Fig. 4(b)).

measurement. The load cell is placed between the load plate (g) and the load transmission element (h) (Fig. 4(a)). To measure crack openings displacement transducers are placed under the test specimen bridging the notch, where cracking occurs (Fig. 5). To measure concrete strains strain gauges are placed on top of the test specimens, i.e. the compression surface. Creep tests have been carried out inside a chamber where temperature and humidity are controlled: temperature is kept at 20C, and relative humidity at 50%. A transducer is used to monitor temperature and humidity levels during the test. Data Acquisition System (DAS) The data acquisition system consists of a field point and a computer, required to read and save the readings from the load cells, displacement transducers, strain gauges, and the temperature and humidity transducer. The computer has been configured to continuously save data and, if there is a power failure, it is able to auto-restart and to continue saving data. This way only the data corresponding with the power failure time are loss. The software used, which has

Measurement Devices The creep test requires to control and measure: the applied load, crack openings, concrete strains, temperature and humidity. To control and measure the load applied to the test specimens load cells are used with a loading head accessory to guarantee an adequate load transmission and load

(kN)

(mm)

Fig. 7 Pre-cracking process scheme

Exp Mech Fig. 8 Placement of first support element over neoprene (a) and load transmission element and load cell placement (b)

been specifically developed for this test by the ICITECH technicians, measures and saves the readings in two different files: one with slow cadence (one reading every 3600 s), and the other one with fast readings (one reading every 5 s), to simplify further analysis.

on them by sawing through the width of the test specimen at mid span. A series of concrete characterization tests must be developed to control the actual concrete mechanical properties, in particular: compressive strength, elastic modulus, and flexural behaviour. The bending test results will be used to define the applied load for the creep test. Bending Test Methodology

Test Operative Procedure The creep test is performed by applying a constant bending load on a 150150600 mm pre-cracked notched specimen and by controlling the load-crack opening evolution for all the time the test takes. Once the specimens have been prepared, a creep test consists of three stages: Specimen pre-cracking up to a nominal crack opening value wn. Creep test on the pre-cracked specimens under an applied load level IFa. Final bending test until failure of the specimen that has experienced the creep process.

The creep test procedure is based on the principles of the EN 14651:2007 [4] standard. Nevertheless, as it is not possible to dispose a test specimens column with one point loading system, to guarantee the stability of the column of specimens the test setup requires some aspects to be modified. For this reason specimens for the pre-cracking, creep test and final bending test stages are tested as shown in Fig. 6: with a 450 mm span and two load points placed at a distance of 150 mm. Figure 6 comparing schemes of load according to EN 14651:2007 [4] (a) and proposed on the testing fixture (b). Test Specimens Pre-cracking

Specimens Casting, Curing and Preparation Specimens are casted, cured, and prepared by following the recommendations of the EN 14651 standard [4] (bending test) and other standards and recommendations [2225]. Compaction shall be carried out in order to avoid any influence on the fibre orientation along the control section. In this case compaction was produced by external vibration. Prior to the test, specimens are rotated by 90 around their longitudinal axis and then a 25 mm notch is executed

Fig. 9 Lever arm lifted due to preload (a) and counterweights placed on lever arm creep frame working (b)

Test specimens pre-cracking is carried out by following the bending test methodology at the controlled crack opening rate according with the EN 14651:2007 [4] standard requirements, but when the nominal crack opening value wn is reached the test is stopped and the specimen unloaded. The load crack opening evolution during the loading, unloading and recovery process is registered. Figure 7 presents a scheme of idealization of the precracking process, where the following parameters are

Exp Mech Fig. 10 Unloading process by using a hydraulic manual jack (a), and unloaded creep frame (b)

identified: FL-first crack load, wp-maximum crack opening value at the pre-cracking process, Fw-load at wp, wprresidual crack opening value at the pre-cracking process. Creep Test After the pre-cracking process the test specimens are moved to the test chamber where the creep frames are located. The specimens are left inside the chamber for at least two hours to acclimatize before the creep tests are set up. The DAS is set to recording mode and then the creep stage begins: the first support element is placed on top of the vertical support profiles using neoprene to improve contact and stability (Fig. 8(a)), then the first test specimen is placed over this first support element. Subsequently a support and load transmission element is placed on top of the test specimen previously placed, and so on, until the last test specimen in the column is placed, always minding the transducers and assuring the right placement of all test specimens. Once the last test specimen has been placed, the setup procedure continues by placing the load transmission element on top of the last test specimen, then the load cell is located in the slot left on the top surface of the load transmission element followed by the load plate placed on top of the head of the load cell (Fig. 8(b)). The free side of the lever arm is placed at a height of 0.35 m from the ground by using a temporary wooden support, and the nuts are tightened (on the

screw bars) by controlling the horizontality of the plate with a bubble level. A 4 kN preload (by tightening the nuts) is applied to free the lever arm (Fig. 9(a)). Then the temporary support is removed, the counterweights needed to reach the nominal load are placed on the free end of the lever arm, and the actual applied load value is controlled with the load cells (Fig. 9(b)). The loading must be carried out very carefully, avoiding sudden load increases. The load to be applied Fa is related to the previously defined applied load level IFa by this expression: IFa Fa =Fw % 1

Once the creep test is set up and thus initialized, it continues without interruption until it is time to unload the specimens according to the lapse of time previously defined for the test. The unloading process takes place by using a manual hydraulic jack to lift the free end of the lever arm (Fig. 10(a)), then the nuts that hold the load plate are untightened, and the load plate, load cell, load transmission element, and counterweights are removed (Fig. 10 (b)). Test specimens remain unloaded but the DAS remains activated for 2 weeks in order to record the recovery of deformations. The test ends when specimens are removed from the creep frame to be tested in bending until failure. Figure 11 presents a scheme of idealization of the crack opening parameters to be obtained from transducer meas-

Fig. 11 Definition of crack opening parameters on idealized curves: crack opening relation at the time and load relation at the crack opening (creep loading stage)

(mm)

Load (kN)

(min)

(mm)

Exp Mech Fig. 12 Definition of crack opening parameters on idealized curves: crack opening relation at the time and load relation at the crack opening (post-creep unloading and recovery stage)

(mm)

Load (kN)

(min)

(mm)

urements during the creep test loading stage. The parameters of this process are: Fa, kNapplied load. wci, mminitial crack opening (at the beginning of the creep test after stabilizing the load for 1 min). w jcd, mmdeferred crack opening at time j. w jct, mmtotal crack opening at time j, expressed as:

j j wci wcd wct

wcut, mmtotal recovery crack opening after the unloading and recovery stage, expressed as:

tt wcut wtf ct wcr wcui wcud

Post-creep Bending Test Until Failure When the creep test is over (loading, unloading and recovery stages), the test specimens are subject to postcreep bending tests until their failure by following the bending test methodology exposed above, reaching crack opening values higher than 4 mm.

Figure 12 presents an idealization of the parameters to be obtained from measurements during the post-creep unloading and recovery stage. The parameters of this process are: wtfct, mmtotal crack opening at the time of unloading (final time tf). wcui, mminstantaneous recovery crack opening at the beginning of the unloading stage, after stabilizing the load for minute. wcud, mmdeferred recovery crack opening after unloading at the recovery stage (crack opening accumulated after stabilizing the test specimens unloaded for minute). wttcr, mmdeferred crack opening at the end of the creep test (time tt), after the recovery stage.

Fig. 13 Complete test results diagram

Test Results Presentation The results of the creep test are presented in a curve of load relation and crack opening and a test summary sheet. Test Results Diagram Each test specimen, during the creep test process, is subjected to: an initial pre-cracking process, a loading, an unloading, and a strains recovery at the creep frame, and to

Exp Mech Fig. 14 Test results sheet

Exp Mech

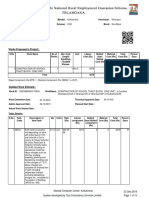

a final bending test until failure. Assembling the experimental results of all the aforementioned stages and plotting diagram loadcrack opening, the evolution of the whole test is shown in a single curve (Fig. 13), thus making possible to establish a common origin for all crack opening values. The first part of the diagram corresponds to the precracking stage. The curve begins at zero with an ascending linear branch until the first crack occurs (A). After this, the test specimen is gradually loaded until the pre-cracking load value previously defined (B) is reached, and then it is totally unloaded, thus recording its capacity for recovery. Point (C) stands as the starting point for the creep test. The second part of the diagram is the creep test: it starts with an ascending line (CD) corresponding to the creep loading process, which is followed by a horizontal branch (DE) corresponding to the increasing deferred deformations that end up when the test specimen is unloaded. A new descending line (EF) describes the post-creep unloading and recovery stage. The third part of the diagram is the post-creep bending test, which begins with an ascending line (FG) and continues with the curve which informs of the residual performance of the test specimen (GH). Test Results Sheet For every creep test that is performed, a test results sheet must be filled in, this sheet containing the most relevant data (Fig. 14): General data: identifying concrete casting data, and creep process, including: Creep test basic information, with the series, batch and concrete identification; test specimen position in the specimens column (1: top, 3: bottom), and nominal test parameters (wnpre-cracking, IFncreep load level). Test agenda. Concrete compressive strength, and elastic modulus. The characterization bending test results, the actual creep test parameters for each specimen (Faapplied load Fa, and IFacreep load level), and the results of the creep test, as defined in this paper (pre-cracking, loading, unloading, and recovery stages at the creep frames, and final bending test until failure).

Table 1 Concretes and test parameters for the creep tests presented Concrete Cement Type I-80/35-70-10 II-50/30-40-10 CEM I 52.5R CEM I 42.5SR Amount (kg/m3) 375 325 Fibre Type

If the failure of any test specimens occurs during the creep test, some elements are loaded, unloaded and reloaded; the test results sheet must include the number of reloading processes for such specimens (incidences).

To make the analysis of all results easier, the test results sheet evaluates creep behaviour through three groups of parameters: 1. 8 cwjcreep coefficient in the creep stage at different times, evaluated as the ratio between the deferred crack opening at time j (w jcd) and the initial crack opening during the creep test (wci).

j 8c wj wcd =wc

2. 8 owjcreep coefficient referred to the origin at different times, evaluated as the ratio between the deferred crack opening at time j (wjcd) and the crack opening at the beginning of the creep test in the complete curve (woci).

j o 8o wj wcd =wci Where:

wo ci wpr wci

3. CORt1-t2crack opening rate for different time periods, evaluated as the ratio between the crack opening increase during the period t1 to t2 (wt2cdwt1cd) and the lapse of time t2t1. 2 1 CORt1t2 wtcd wtcd = t 2 t 1 7

The proposed times to evaluate the crack opening rate are: 14, 30, 90, 365 days, and final creep test time. Compressive strains in the top specimen surface may be evaluated if a strain gage is used to measure them as it has been aforementioned (see Measurement Devices). The parameters previously defined for crack opening values to facilitate the analysis of results can be employed for compressive strains as well. This way the strain rate for different time periods (SRt1t2) is evaluated as the ratio

Pre-crack opening (mm) Amount (kg/m3) 70 40 0.5 0.5

Nominal applied load level (IFa)

Dramix RC80/35BN F-DUE 50/30

80 60

Exp Mech

specimen 1

specimen 2

specimen 3

Fig. 15 Creep curves for I-80/35-70

between the strain increase during the period t1 to t2 (t2cdt1cd) and the lapse of time t2t1.

2 1 "tcd =t2 t1 SRt1t2 "tcd

If so, the test results sheet (Fig. 14) would have to include the same parameters for strains as those defined for crack opening values.

Experimental Test Method Validation To validate the creep test setup and methodology presented herein, an ambitious experimental program has been developed at ICITECH laboratories comprising 9 different concretes, one column per concrete with 3 specimens each [21]. The variables considered were: concrete matrix (type and amount of cement, water/cement ratio, maximum aggregate size), type and amount of steel fibres, and test parameters (pre-crack opening value and applied load level during the creep test stage). As an example, the results from two columns of test specimens are presented. In order to expose the test method adaptability those results were obtained from two concretes designed to have a very different structural behaviour. Concrete mix designs and

testing parameters for the creep test considered are described in Table 1. The Fibre Reinforced Concrete typified as I 80/35-7010 was made with a 56.1 MPa compressive strength concrete matrix replicating a concrete designed for structural precasting concrete purposes. 70 kg/m3 of 35 mm length steel cold drawn fibres with hooked ends were used. Fibres length/diameter ratio was 80. With this concrete, in the characterizations bending tests, a clear hardening postcrack behaviour was obtained. On the other hand the Fibre Reinforced Concrete typified as II 50/30-40-10 was made with a 41.3 MPa compressive strength concrete matrix replicating a general purpose concrete. 70 kg/m3 of 40 mm length steel cut sheet fibres were used. Fibres length/diameter ratio was 50. With this concrete a clear softening post-crack behaviour was obtained. Creep curves for both concretes showing the crack opening experienced in loading, creep, and unloading and recovery stages are presented in Figs. 15 and 16 for the three specimens in a column. Creep test assembled curves including those of precracking, creep test and bending test to failure stages are shown in Figs. 17 and 18. The characterization bending test is included.

specimen 1

specimen 2

specimen 3

Fig. 16 Creep curves for II-50/30-40

Exp Mech

specimen 1

specimen 2

specimen 3

Fig. 17 Creep test assembled curve for I-80/35-70

As it can be seen in Figs. 16, 17 and 18, the test method is capable of performing flexural creep tests on pre-cracked FRC beams satisfactorily, registering the behaviour of the specimens when being loaded, at the sustained load period (creep stage) and during the unloading and recovery process. Though only the results for two concretes have been presented in this paper, the test method has proved to be equally valid in the remaining 13 concretes that were produced and tested. In some cases (when high load levels were applied), the failure of one out of the three test specimens in the column occurred, but this did not damage the other specimens in the same test frame nor affected their curves.

&

&

& Conclusions & & An experimental methodology to study flexural creep behaviour of cracked FRC specimens has been conceived. The creep frame designed optimizes the load application capacity, guarantees a constant load for whatever lapse of time desired and offers the possibility of testing more than one element at the same time in one frame. Besides it has been complemented with load transmission and support elements to avoid the transmission of undesirable induced moments and to allow creep tests to continue without any interruption even when the failure of some specimen occurs.

&

&

The proposed methodology allows studying the influence on FRC cracked beams of variables such as: type of concrete, type and amount of fibres, applied load and pre-crack opening values. This methodology for creep testing is susceptible of being standardized. Standardization criteria can be defined in two directions: to analyze creep behaviour in a determined set of conditions (for a determined concrete type, mix design, load level, etc.), or to characterize the behaviour of a fibre type in standard conditions (materials and concrete mix design, fibre content, pre-cracking and load level, etc.). The feasibility of the application of this creep test setup and methodology has been verified in an experimental program to evaluate long-term flexural behaviour of FRC elements in cracked state. Experimental results for two different concretes have been shown to support this statement. Specific terminology and analysis parameters for the different stages of the test process (pre-cracking, loading, unloading and recovery at the creep test, and a following bending test until failure) have been proposed. Experimental results obtained by using the equipment and methodology proposed herein allows analyzing the flexural creep behaviour of cracked FRC specimens, based on the measurement of crack opening values and compressive strains.

specimen 1

specimen 2

specimen 3

Fig. 18 Creep test assembled curve for II-50/30-40

Exp Mech Acknowledgements The present study was supported by the Spanish Universitat Politcnica de Valncia (UPV), Valncia, Spain; by the project BIA 200912722 of the Spanish Ministry; and by the project HABITAT 2030 [PS-380000-2008-11] funded by both the Spanish Ministry of Science and Innovation and the European Regional Development Found. The authors would like to express their gratitude for this support. Cement Composites (HPFRCC3). RILEM publications, Mainz, pp 239250 Mackay J, Trottier JF (2004) Post-crack behaviour of steel and synthetic FRC under flexural loading. In: Shotcrete: More Engineering Developments. Taylor & Francis Group, London, pp 183192 Cochrane JT (2003) Flexural creep behaviour of fibre reinforced concrete under high temperatures. Master of applied science thesis, Dalhousie University. Canada Mackay J (2002) Behaviour of steel and synthetic fibre reinforced concrete under flexural creep loading. Master of applied science thesis, Dalhousie University. Canada Bast T, Eder A, Kusterle W (2007) Kriechversuche an kunststoffmakrofaserbetonen-Untersuchungen zum langzeitverhalten von faserbetonen unter biegezugbeanspruchung. Ein zwischenbericht. Faserbeton beitrge zum 11. Vilser Baustofftag, pp 3235 Swamy RN, Theodorakopoulos DD (1979) Flexural creep of fibre reinforced cement composites. Int J Cem Lightweight Concr 1 (1):3747 Kurtz S, Balaguru P (2000) Postcrack creep of polymeric fibrereinforced concrete in flexure. Cem Concr Res 30:18390 Buratti N, Mazzotti C, Savoia (2010) Long-term behaviour of fiber reinforced SCC beams. In: Proceedings of the 6th Int. RILEM Symposium on Self Compacting Concrete. Montreal, pp 439450 Torrijos MC, Barragn BE, Zerbino RL (2010) Placing conditions, mesostructural characteristics and post-cracking response of fibre reinforced self-compacting concretes. Constr Build Mater 24:10781085 Arango SE (2010) Fluencia a flexin del hormign reforzado con fibras de acero (SFRC) en estado fisurado. PhD Thesis, Universitat Politcnica de Valncia. Spain AENOR (2004) UNE 83.502:2004. Hormigones con fibras. Fabricacin en laboratorio. Asociacin Espaola de Normalizacin y Certificacin, Madrid AENOR (2004) UNE 83.503:2004. Hormigones con fibras. Medida de la docilidad por medio del cono invertido. Asociacin Espaola de Normalizacin y Certificacin, Madrid AENOR (2004) UNE 83.504:2004. Hormigones con fibras. Fabricacin y conservacin de probetas para los ensayos de laboratorio. Asociacin Espaola de Normalizacin y Certificacin, Madrid AENOR (2009) UNE-EN 123502:2009. Ensayos de hormign fresco. Parte 2: Ensayo de asentamiento. Asociacin Espaola de Normalizacin y Certificacin, Madrid

13.

14.

References

1. fib (2010) MODEL CODE 2010 (First complete draft) 2. Ministerio de Fomento (2008) EHE-08 Instruccin de Hormign Estructural. Real Decreto 1247/2008 3. American Concrete Institute (2008) ACI 31808. ACI Committee 318: Building Code Requirements for reinforced Concrete. Farmington Hills, MI 4. European Standards (2007) EN 14651:2007. Test method for metallic fibre concrete - Measuring the flexural tensile strength (limit of proportionality (LOP), residual) 5. Bernard ES (2004) Creep of cracked fibre reinforced shotcrete panels. In: Shotcrete: More Engineering Developments. Taylor & Francis Group, London, pp 4757 6. Mangat PS, Motamedi M (1986) Compression creep behaviour of steel fibre reinforced cement composites. Mater Struct 19 (113):361369 7. Chern JC, Young CH (1989) Compressive creep and shrinkage of steel fibre reinforced concrete. Int J Cem Lightweight Concr 11 (4):205214 8. Barragn BE, Zerbino RL (2008) Creep behaviour of cracked steel fibre reinforced concrete beams. In: Proceedings of the 7th Int. RILEM Symp. on Fibre Reinforced Concrete: Design and Applications (BEFIB 2008). Chennai, pp 577586 9. Erzar B, Forquin P (2010) An experimental method to determine the tensile strength of concrete at high rates of strain. Exp Mech 50:941955. doi:10.1007/s11340-009-9284-z 10. Chen TC, Yin WQ, Ifju PG (2010) Shrinkage measurement in concrete materials using cure reference method. Exp Mech 50:9991012. doi:10.1007/s11340-009-9300-3 11. Granju JL, Rossi P, Chanvillard G, et al (2000) Delayed behaviour of cracked SFRC beams. In: Proceedings of the 5th Int. RILEM Symp. on Fibre Reinforced Concrete (BEFIB 2000). Lyon, pp 511520 12. Chanvillard G, Roque O (1999) Behaviour of fibre reinforced concrete cracked section under sustained load. In: Proceedings of the 3rd Int. Workshop on High Performance Fibre Reinforced

15.

16.

17.

18. 19.

20.

21.

22.

23.

24.

25.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Rewised Creamatorium Target Fixed For CompletionDocumento2 páginasRewised Creamatorium Target Fixed For CompletionMani KumarAinda não há avaliações

- Covering Letter MOMB Data AddDocumento1 páginaCovering Letter MOMB Data AddMani KumarAinda não há avaliações

- Pragathi Nivedika KCLDocumento44 páginasPragathi Nivedika KCLMani KumarAinda não há avaliações

- State Formation Day - Duties OrderDocumento2 páginasState Formation Day - Duties OrderMani KumarAinda não há avaliações

- Third Phase/ Special Round Schedule: Signature Not VerifiedDocumento1 páginaThird Phase/ Special Round Schedule: Signature Not VerifiedMani KumarAinda não há avaliações

- DLP Routine Bill 833437Documento1 páginaDLP Routine Bill 833437Mani KumarAinda não há avaliações

- Village List-7637Documento1 páginaVillage List-7637Mani KumarAinda não há avaliações

- Farm Pond DrawingDocumento1 páginaFarm Pond DrawingMani KumarAinda não há avaliações

- A.40.2020 Haritha Haram NurseriesDocumento1 páginaA.40.2020 Haritha Haram NurseriesMani KumarAinda não há avaliações

- Percolation Tank DrawingDocumento1 páginaPercolation Tank DrawingMani KumarAinda não há avaliações

- School Toilet EstimateDocumento15 páginasSchool Toilet EstimateMani KumarAinda não há avaliações

- Pattana PragathiDocumento1 páginaPattana PragathiMani KumarAinda não há avaliações

- Telangana Health,'Kashana': I&CadDocumento1 páginaTelangana Health,'Kashana': I&CadMani KumarAinda não há avaliações

- MPPS ToiletDocumento1 páginaMPPS ToiletMani KumarAinda não há avaliações

- Vibrations Solutions Section2 7Documento17 páginasVibrations Solutions Section2 7Mani Kumar100% (1)

- JR - Engineers 2013 NOMDocumento1 páginaJR - Engineers 2013 NOMMani KumarAinda não há avaliações

- Act Ii SCENE I. A Wood Near Athens.: ExeuntDocumento1 páginaAct Ii SCENE I. A Wood Near Athens.: ExeuntMani KumarAinda não há avaliações

- Appeal To Pilgrims in Connection With Vaikunta Dwara DarshanamDocumento1 páginaAppeal To Pilgrims in Connection With Vaikunta Dwara DarshanamMani KumarAinda não há avaliações

- Final QuesDocumento5 páginasFinal QuesMani KumarAinda não há avaliações

- Exit Hermia: Scene IiDocumento1 páginaExit Hermia: Scene IiMani KumarAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Business Graphic CollectionDocumento213 páginasBusiness Graphic CollectionHimansu Sekhar PradhanAinda não há avaliações

- Mosquito Repellent Finish of Cotton Fabric by Extracting Castor OilDocumento6 páginasMosquito Repellent Finish of Cotton Fabric by Extracting Castor OilTRUSHA PITHADIYAAinda não há avaliações

- Incy Wincy SpiderDocumento16 páginasIncy Wincy SpiderOlarteCatalinaAinda não há avaliações

- SQL Server Stored Procedures For BeginnersDocumento13 páginasSQL Server Stored Procedures For BeginnersDaryll Joe CananAinda não há avaliações

- OP5142 User Manual-ADocumento40 páginasOP5142 User Manual-AJignesh MakwanaAinda não há avaliações

- STAT1008 Cheat SheetDocumento1 páginaSTAT1008 Cheat SheetynottripAinda não há avaliações

- BSBINews 78Documento96 páginasBSBINews 78Anonymous dEztzVueAinda não há avaliações

- Sustainable Architecture WikiDocumento9 páginasSustainable Architecture WikisiddiqueaquibAinda não há avaliações

- Final Introduction To Community Based Management PowerpointDocumento36 páginasFinal Introduction To Community Based Management PowerpointJazmine AlgerAinda não há avaliações

- CV - Nhan - EnglishDocumento4 páginasCV - Nhan - EnglishnhanpcAinda não há avaliações

- Death of A SalesmanDocumento34 páginasDeath of A SalesmancrispycatzAinda não há avaliações

- PIT Error Overview - ParetoDocumento208 páginasPIT Error Overview - ParetoHariharan Yelomalei50% (2)

- Morane 4 PFN FffsDocumento20 páginasMorane 4 PFN FffsFatmen FataAinda não há avaliações

- "Uncontrolled Desires": The Response To The Sexual Psychopath, 1920-1960Documento25 páginas"Uncontrolled Desires": The Response To The Sexual Psychopath, 1920-1960ukladsil7020Ainda não há avaliações

- C#Documento3 páginasC#Dung RieuAinda não há avaliações

- flowswitchHFS25 PDFDocumento2 páginasflowswitchHFS25 PDFlajosmolAinda não há avaliações

- VoIPmonitor Sniffer Manual v5Documento19 páginasVoIPmonitor Sniffer Manual v5Allan PadillaAinda não há avaliações

- 2004 Schuhly Major Herbs of Ayurveda E M Williamson Ed Churchill Livingstone New York 2002 361pp Price 49 95 ISBN 0 443 07203 5 HCDocumento2 páginas2004 Schuhly Major Herbs of Ayurveda E M Williamson Ed Churchill Livingstone New York 2002 361pp Price 49 95 ISBN 0 443 07203 5 HCnermal93Ainda não há avaliações

- 1200單字分類表Documento14 páginas1200單字分類表joanne0049Ainda não há avaliações

- 21 Clever Ways To Make Him Chase YouDocumento1 página21 Clever Ways To Make Him Chase YouMagdalena SekulovaAinda não há avaliações

- Electrical Tender Package1-Section - 5Documento13 páginasElectrical Tender Package1-Section - 5nakul4491_88890127Ainda não há avaliações

- 2nd Year English Send Up 22Documento2 páginas2nd Year English Send Up 22Keats 28Ainda não há avaliações

- 36-217 Fall 2013 HW04Documento2 páginas36-217 Fall 2013 HW04Gabriel Bernard MullenAinda não há avaliações

- Aunty Maria': Come Home For A Coffee: Teaching NoteDocumento4 páginasAunty Maria': Come Home For A Coffee: Teaching NoteAditya DesaiAinda não há avaliações

- MK2 ManualDocumento55 páginasMK2 ManualJFrink333100% (1)

- 1st Opp ExamPaper - CISM 122Documento4 páginas1st Opp ExamPaper - CISM 122Sbu JohannesAinda não há avaliações

- Agarwal Packers ReviewDocumento10 páginasAgarwal Packers ReviewAnonymous eDOS7RLyAinda não há avaliações

- MedigpsDocumento8 páginasMedigpsAlex HillAinda não há avaliações

- Jnu PDFDocumento3 páginasJnu PDFvinitauppalAinda não há avaliações

- A Framework For Engaging Diverse Communities in Citizen Science in The USDocumento4 páginasA Framework For Engaging Diverse Communities in Citizen Science in The UStesemar010Ainda não há avaliações