Escolar Documentos

Profissional Documentos

Cultura Documentos

Artcl Mortise and Tenon Joints

Enviado por

reader_jimDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Artcl Mortise and Tenon Joints

Enviado por

reader_jimDireitos autorais:

Formatos disponíveis

http://www.bing.com/images/search? q=mortise+and+tenon&view=detail&id=A42D7 A!4"A#$ $#A2D % &&A"'2!DAD() "#$!$&*irst=( +&',-.

=/D'-/-

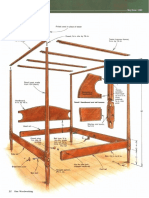

Mortise And Tenon Joints

August 16, 2011 By admin Leave a Comment A framing joint used in carpentry and joinery, the mortise and tenon has great mechanical strength and creates a large gluing area. A rectangular tenon sa n at one end of a rail slots into the mortise, an elongated hole in the other part. !he rail is usually hori"ontal and the stile vertical. #ortise and tenon are generally one$third the thic%ness of the tim&er.

#ortise And !enon 'oints Tools you need

2( pencil #allet )teel rule Cramps !ry s*uare !enon sa #ortise gauge )moothing plane #ar%ing %nife +lue #ortise chisel

How to make a through mortise and tenon joint

#ortise And !enon 'oints 1. After selecting appropriate face sides and edges, mar% the position of the joint on &oth pieces of tim&er ith pencil and try s*uare. !he mortise chisel should &e a&out one$third the thic%ness of the tim&er. ,n practice, this is rounded up to the ne-t chisel si"e. Adjust the t o pins on the mortise gauge until they are the same idth as the &lade. !o ensure the joint is centrali"ed in the tim&er, slide the stoc% on the gauge so that the pins mar% the tim&er precisely the same distance from either side. Chec% &y lightly pressing the pins into the ood, and readjust the stoc% if necessary, tightening once the setting is correct. !his setting is used to mar% out &oth the mortise and tenon, so treat the tool ith care to avoid distur&ing the adjustment.

#a%e A !hrough #ortise And !enon 'oint 1 2. )cri&e the gauge lines for the mortise &et een the idth mar%s on the stile .B/. #ar% lines on &oth edges, al ays using the tool from the face side. 0ithout distur&ing the setting, mar% out the tenon on part A. !he gauge lines should continue along the end grain.

#a%e A !hrough #ortise And !enon 'oint 2 3. Cramp part B to the &ench top, prefera&ly so that the mortise sits directly a&ove the &ench leg. )tart the cut ith the chisel a&out 1 mm .123 in/ in from the mar%ed lines at one end, the &evel facing into the middle of the joint. 4eeping the &lade vertical and s*uare to the or%, stri%e the chisel ith the mallet. Cut to a depth of a&out 1 mm .123 in/, counting the num&er of &lo s to the chisel. #ove the &lade along the mortise and repeat in 1 mm .123 in/ steps. #a%ing the same num&er of &lo s each time means the depth ill remain constant across the idth. )top hen you are 1 mm .123 in/ a ay from the opposite end of the mortise.

#a%e A !hrough #ortise And !enon 'oint 1 4. Clean out the chippings, using the chisel ith the &evel side face do n. Lever the &lade against the short section of aste at each end of the mortise. 5o ma%e another series of cuts across the idth, removing the aste in the same ay. Continue cutting in steps until you have reached just over half the depth of the mortise.

#a%e A !hrough #ortise And !enon 'oint 6 5. 7emove the aste at each end of the mortise &y holding the chisel vertical. 4eep the &lade just inside the mar%ed line, ith the &evel facing in ards. )tri%e ith the mallet and chop do n to just over half the depth.!urn the or% piece the other ay up, tip out the loose chips and &rush

any de&ris from the &ench top. Cramp the or% piece do n again and start afresh from the other side. !his prevents the ood from splitting out at the &ottom of the mortise. Assuming you have %ept the chisel vertical, the final cuts ill match up ith those on the reverse.

#a%e A !hrough #ortise And !enon 'oint 8 6. 0hen cutting the tenon rail to si"e, leave a fraction e-tra on its length. 9ou ill plane this off once the joint is assem&led. ,n furniture construction the tenon rail .A/ is often thic%er than the stile !". ,f so, you ill need to reset the mortise gauge to mar% out the tenon. !he t o pins remain the same distance apart, ho ever, as these still match the idth of the chisel &lade.

#a%e A !hrough #ortise And !enon 'oint 6

#. )cri&e the shoulder lines of the tenon ith the %nife and s*uare. #ar% the aste .the chee%s/ in pencil. )et the rail .A/ upright in the vice and ma%e several hori"ontal sa cuts on the aste side of the gauged lines to a depth of a&out 1 mm .123 in/.

#a%e A !hrough #ortise And !enon 'oint : $. Adjust the rail so that it is facing a ay from you at an angle of 68 degrees. Continue sa ing do n &oth gauged lines until you reach the shoulder mar%. 7emove the rail and turn it around so that it is again facing you at an angle of 68 degrees. Again, sa do n until you reach the shoulder.

#a%e A !hrough #ortise And !enon 'oint 3

%. 9ou ill no have sa n lines along &oth sides and across the top. 7eposition the rail in the vice so that it is upright. ;inish cutting do n &oth chee%s to the shoulder line. (old the tenon rail flat on the &ench hoo% and sa carefully across the shoulder lines to remove the aste. !urn the rail over and repeat on the reverse side. !ry inserting the tenon into the mortise &efore gluing. 9ou may need to pare the chee%s carefully ith the chisel to remove any high spots. <o this ith the tim&er either cramped to the &ench top or held in the vice.

#a%e A !hrough #ortise And !enon 'oint =

&ariations

'tu( Mortise And Tenon Joint

>ften used in furniture$ma%ing, the stu&, or stopped, mortise$and$tenon joint is a neater alternative as the end grain of the tenon is not visi&le. !his stops short of the outside edge of the stile, so the mortise is %no n as ?&lind@. #ortise depth should &e a&out three$*uarters of the idth of the stile, so there is a sufficient amount of ood remaining.

How to make a stu( mortise and tenon joint

1.#easuring three$*uarters of the tim&er idth from the end of the rail .A/, scri&e the shoulder line of the tenon all the ay round ith the mar%ing %nife. Adjust the mortise gauge to the chisel idth and ma%e sure the pins are central on the or% piece. +auge the lines around the tenon and across the end grain, then pencil in the aste. Alace the rail .A/ on the inner edge of stile .B/ and mar% the idth of the mortise. Continue these lines across ith the s*uare, then scri&e the mortise &et een them ith the gauge. Aencil in the aste.

#a%e A )tu& #ortise An !enon 'oint 1 2.!o ma%e sure you do not cut the mortise too deep, rap mas%ing tape around the &lade of the chisel, allo ing a&out 1.8 mm .1216 in/ e-tra depth. !his is so that the tenon does not foul the &ottom of the mortise hen the joint is assem&led.

#a%e A )tu& #ortise An !enon 'oint 2 3.0ith the stile cramped to the &ench top, chop out the mortise from the inside edge. 0hen the tape on the chisel is level ith the tim&er, you have reached the full depth. Clean out the aste, ma%ing sure the &ottom of the mortise is level. )a the tenon in the same ay as for the through tenon .see page 20=/. Chec% the tenon fits into the mortise and adjust ith the chisel if necessary &efore gluing.

#a%e A )tu& #ortise An !enon 'oint 1

Haun)hed Hortise And Tenon Joint

Corners of frame or% can present a pro&lem hen mortise$and$tenon joints are used, particularly if the top edges must finish flush ith each other. A full$ idth tenon is actually a &ridle joint .see page 211/. Because the resulting mortise is open$ended, the joint &ecomes much ea%er. By introducing a haunch, the tenon idth is reduced and the mortise does not e-tend to the end of the stile. A haunch can &e either s*uare or sloping, and helps prevent the frame from t isting. !his joint is commonly used in joinery for door and indo construction. 0here stiles and rails are re&ated or grooved, a s*uare haunch is used. 0here a groove runs around the inside edges of a frame, the groove normally e-tends all the ay along each edge. !he tenon@s s*uare haunch fills the outside end of the joint as ell as the groove. )houlders are usually staggered to accommodate re&ates on frame or%. ,n ca&inet$ma%ing, here appearance is important, the sloping haunch is often used. Bnli%e the s*uare version, this haunch is not visi&le once the joint is assem&led. ,t is commonly used &et een the seat rails and legs in chair construction.

(ounched #ortise And !enon 'oint

(ounched #ortise And !enon 'oint

(ounched #ortise And !enon 'oint T*+'

Al ays cut a mortise &efore sa ing the tenon. 9ou can adjust the tenon to fit the mortise more easily than vice versa. Al ays use a mortise chisel hen cutting the joint &y hand. >ther chisel &lades are less sturdy and could &rea%.

,edged Mortise And Tenon Joint

!o strengthen through mortise$andtenon joints, edges can &e driven into the ends of the tenons. !his also prevents them opening up on items of joinery such as doors, hich are su&jected to heavy use. Before assem&ling the joint, the ends of the mortise are enlarged ith sloping cuts. )a cuts are then made in the end of the tenon, and the edges driven into these slots hen gluing up. !he tenon is splayed out ards, loc%ing the joint together. Cnds of the edges are sa n off once the glue has dried.

Twin Mortise And Tenon Joint

0here the mortise is cut into the face of the tim&er, rather than into the edge .as in the dou&le version, a&ove/, a t in mortise$and$tenon joint provides e-tra strength. !he tenons sit alongside each other, rather than &eing stac%ed one a&ove the other. !his time there is no haunch &et een the tenons and the gap &et een them should ideally &e the same as their thic%ness. Carcase con$ struction may call for a multiple version of the joint, hich has several tenons. (ere, a stopped housing may &e introduced to increase strength further.

-o. ,edged Mortise Andtenon Joint

0hen a stu& mortise$and$tenon joint needs e-tra strength, edges can &e inserted into the tenon. Bnli%e edges driven in from the outside, these must &e cut to length and idth precisely. >nce the joint is cramped together it cannot &e ta%en apart.

0edged #ortise And !enon 'oint

+osts /elated to Mortise And Tenon Joints

!ridle Joints

A &ridle joint is very similar to a mortiseand$tenon joint, &ut cut in reverse. 7emoving the aste is more a%in to cutting a halving joint. ...

T0hal1ing Joints

Bsed for construction such as frame or% and soft ood joinery, halving joints have little structural integrity. )trength comes from glue or reinforcing scre s, hile shoulders increase ...

Mortisers

!he &ench$top or floor$standing mortiser is designed specifically for cutting mortises accurately in tim&er. A hollo chisel feeds do n into the ood, ma%ing a s*uare ...

Housing Joints

(ousing joints .dadoes/ are used for fitting shelves and dividers in ca&inets of solid tim&er or sheet materials. A housing is a precisely cut groove ...

2a3 Joints

Bsed for corners in ca&inet and &o- construction the lap, or re&ate, joint is one of the easiest to ma%e ith hand tools. ,t consists ...

Aost on +oogle Bu"" Aost to ;ace&oo% )end via +mail )end via C$mail program

;iled BnderD 'oints !agged 0ithD &ench, &lade, carpentry and joinery, Clean, Continue, Cramps, face, face side, gauge lines, glue, haunch, level, line, mechanical strength, mortise, mortise and tenon, mortise and tenon joints, mortise chisel, pencil, pins, slots, smoothing plane, steel rule, stop, tape, tenon, vice, aste, ay, ood

Você também pode gostar

- Ulmia Workbench (55p)Documento55 páginasUlmia Workbench (55p)pippitiamo100% (1)

- Jointech Reference ManualDocumento25 páginasJointech Reference ManualDave G Brown100% (2)

- Mortise and Tenon JointDocumento1 páginaMortise and Tenon JointPraveen Kumar100% (1)

- A Heavy Duty WorkbenchDocumento16 páginasA Heavy Duty Workbenchjohnflory123445100% (1)

- Basic Wood JointsDocumento2 páginasBasic Wood JointsJonathan Delos SantosAinda não há avaliações

- Domino Zigzag ChairDocumento6 páginasDomino Zigzag ChairAlex Johnston0% (1)

- Cabinets & Drawers: Shaker Cupboard: Rejuvenated Drawer Slips Roy Underhill's Nail CabinetDocumento20 páginasCabinets & Drawers: Shaker Cupboard: Rejuvenated Drawer Slips Roy Underhill's Nail Cabineto100% (2)

- III. Sill Floor JointsDocumento8 páginasIII. Sill Floor JointsCristian Morar-BolbaAinda não há avaliações

- WoodPlans Online - Mortise & Tenon JointsDocumento14 páginasWoodPlans Online - Mortise & Tenon JointsHannes Michaelis100% (2)

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolNo EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolAinda não há avaliações

- Perfect Mortise and Tenon JointsDocumento8 páginasPerfect Mortise and Tenon Jointspiedrahec100% (1)

- Carpentry Joints (Woodwork)Documento16 páginasCarpentry Joints (Woodwork)KadambiniAinda não há avaliações

- Lapped Dovetail: To The Data FilesDocumento6 páginasLapped Dovetail: To The Data Filescimentamos100% (1)

- Jig Creation Instruction ManualDocumento14 páginasJig Creation Instruction ManualBig Deal VolumesAinda não há avaliações

- WJ157 Easy Chair Side TablesDocumento9 páginasWJ157 Easy Chair Side Tablesmiclark100% (1)

- Adjustable Taper Ripping JigDocumento6 páginasAdjustable Taper Ripping Jiggmand68Ainda não há avaliações

- Coffe TableDocumento15 páginasCoffe TableJun Vargas100% (1)

- Carpentry III - Specialized CarpentryDocumento66 páginasCarpentry III - Specialized CarpentryChuck Achberger100% (1)

- Bentwood CarryallDocumento7 páginasBentwood CarryallDalmatino100% (1)

- Sliding Bookrack: Woodworks: Intermediate ProjectDocumento8 páginasSliding Bookrack: Woodworks: Intermediate ProjectEucap Mdz100% (1)

- 10 Best Saw JigsDocumento7 páginas10 Best Saw JigsBenoitDeCooman100% (1)

- Jig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsDocumento6 páginasJig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsJd Diaz100% (1)

- Woodwork JointsDocumento5 páginasWoodwork JointsAbdul Sukur Kamsir100% (3)

- 3-In-1 Drill Press Upgrade Derevyannoe KruzhevoDocumento12 páginas3-In-1 Drill Press Upgrade Derevyannoe KruzhevoTanja MartinovicAinda não há avaliações

- Wood Joints PDFDocumento9 páginasWood Joints PDFGlennAinda não há avaliações

- Making Strong Wood JointsDocumento7 páginasMaking Strong Wood JointsDaniel Jiménez ChacónAinda não há avaliações

- Clamping & AssemblyDocumento8 páginasClamping & AssemblyGsmHelp100% (1)

- FinishDocumento4 páginasFinishGsmHelpAinda não há avaliações

- Dovetail Jig: ©2021 Active Interest Media Holding CoDocumento11 páginasDovetail Jig: ©2021 Active Interest Media Holding CoFrancois Vaaltyn100% (2)

- Five Cut Method To Square Table SawDocumento9 páginasFive Cut Method To Square Table Sawhankgurdjieff100% (1)

- UNIT - IV CarpentryDocumento14 páginasUNIT - IV CarpentryAjay SonkhlaAinda não há avaliações

- Chapter One: A Simple Lift-Lid Box: Excerpted FromDocumento20 páginasChapter One: A Simple Lift-Lid Box: Excerpted FromChuck Osuchowski0% (1)

- Tle05 - Module 1Documento292 páginasTle05 - Module 1Lifmark Villacorte TalamayanAinda não há avaliações

- BookshelfDocumento4 páginasBookshelfJerry Kn100% (2)

- Adega ModularDocumento15 páginasAdega ModularJairoViolinistaAinda não há avaliações

- ArtofWoodworking WorkbenchDocumento4 páginasArtofWoodworking Workbenchsalulai100% (1)

- 5 Drawer DeskDocumento13 páginas5 Drawer DeskĠëǿřge PètrǿpoũloŝAinda não há avaliações

- Pocket Hole JoineryDocumento5 páginasPocket Hole JoineryJessica Sanders100% (3)

- Ebooks Woodworking Plans - Five Plywood ProjectsDocumento10 páginasEbooks Woodworking Plans - Five Plywood Projectsalexrodriguezigt100% (2)

- Stowaway Bench: Woodworks: Intermediate ProjectDocumento8 páginasStowaway Bench: Woodworks: Intermediate ProjectfdarelaAinda não há avaliações

- Lumber Grading ChartDocumento2 páginasLumber Grading ChartKeith BibelhausenAinda não há avaliações

- Shaker-Style Coat and Mitten Rack PDFDocumento6 páginasShaker-Style Coat and Mitten Rack PDFEucap MdzAinda não há avaliações

- Sanding BlockDocumento3 páginasSanding BlockOlavo Pastore100% (1)

- Wood Working Plans - Toys - Rocking Horse PDFDocumento6 páginasWood Working Plans - Toys - Rocking Horse PDFBen GerezAinda não há avaliações

- Woodworking Crafts - Issue 75, 2022 UKDocumento124 páginasWoodworking Crafts - Issue 75, 2022 UKGery DemarcoAinda não há avaliações

- Woodworking Joints: List of Wood JointsDocumento5 páginasWoodworking Joints: List of Wood Jointsgalaxy82yngelAinda não há avaliações

- Carpenter 3 Month 2Documento17 páginasCarpenter 3 Month 2Kishore Kumar100% (1)

- English Workbench: ©2020 Active Interest Media Holding CoDocumento11 páginasEnglish Workbench: ©2020 Active Interest Media Holding CoFrancois Vaaltyn100% (3)

- Adirondack Chair: Woodworks: Intermediate ProjectDocumento8 páginasAdirondack Chair: Woodworks: Intermediate ProjectEucap MdzAinda não há avaliações

- Traditional Bookcase: Woodworks: Intermediate ProjectDocumento6 páginasTraditional Bookcase: Woodworks: Intermediate ProjectDúctil De La Gran Raza de YithAinda não há avaliações

- Intermediate Project Charging StationDocumento6 páginasIntermediate Project Charging StationGultainjeeAinda não há avaliações

- Ian Kirby Marking ToolsDocumento6 páginasIan Kirby Marking ToolsGiovanni Cenci100% (1)

- Wood JointsDocumento34 páginasWood JointsJefforyAinda não há avaliações

- Build A Wall ShelfDocumento3 páginasBuild A Wall Shelfcaballo_blanco_2Ainda não há avaliações

- Finger Joints: Fast and EasyDocumento4 páginasFinger Joints: Fast and EasyIlberto FortunaAinda não há avaliações

- How To Build A DoorDocumento12 páginasHow To Build A DoorWalter Ramirez100% (3)

- Bowl Basics 2Documento5 páginasBowl Basics 2api-522254901Ainda não há avaliações

- Wood Working Spot On Measuring & MarkingDocumento5 páginasWood Working Spot On Measuring & MarkingAmanjotAinda não há avaliações

- Weekend & Evening Projects (Woodsmith Custom Woodworking) PDFDocumento130 páginasWeekend & Evening Projects (Woodsmith Custom Woodworking) PDFMaria Mesa100% (2)

- Roof Carpentry - Practical Lessons in the Framing of Wood Roofs - For the Use of Working CarpentersNo EverandRoof Carpentry - Practical Lessons in the Framing of Wood Roofs - For the Use of Working CarpentersAinda não há avaliações

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Ainda não há avaliações

- Woodwork Joints How they are Set Out, How Made and Where Used.No EverandWoodwork Joints How they are Set Out, How Made and Where Used.Nota: 5 de 5 estrelas5/5 (1)

- Grundrisse Intro FragmentDocumento2 páginasGrundrisse Intro Fragmentreader_jimAinda não há avaliações

- Letter From Marx To Nikolai Danielson Re RRsDocumento4 páginasLetter From Marx To Nikolai Danielson Re RRsreader_jimAinda não há avaliações

- Commodity FetishismDocumento19 páginasCommodity Fetishismreader_jimAinda não há avaliações

- Marx Character Mask 2Documento24 páginasMarx Character Mask 2reader_jimAinda não há avaliações

- Fragment Marx On ProtestantismDocumento5 páginasFragment Marx On Protestantismreader_jimAinda não há avaliações

- Alienation FRGMNTDocumento1 páginaAlienation FRGMNTreader_jimAinda não há avaliações

- Bourne War and The IntellectualsDocumento16 páginasBourne War and The Intellectualsreader_jimAinda não há avaliações

- Coleridge Essay Re Const EssayDocumento18 páginasColeridge Essay Re Const Essayreader_jimAinda não há avaliações

- Grundrisse Intro FragmentDocumento2 páginasGrundrisse Intro Fragmentreader_jimAinda não há avaliações

- Corporation SoleDocumento2 páginasCorporation Solereader_jimAinda não há avaliações

- Marshall Cherokee Nation V GeorgiaDocumento4 páginasMarshall Cherokee Nation V Georgiareader_jimAinda não há avaliações

- Poetical WrksDocumento350 páginasPoetical Wrksreader_jimAinda não há avaliações

- Habeas Corpus ActDocumento5 páginasHabeas Corpus Actreader_jimAinda não há avaliações

- Decision Bush V Vera TexasDocumento93 páginasDecision Bush V Vera Texasreader_jimAinda não há avaliações

- Turner Frontier in Amrcn HstryDocumento195 páginasTurner Frontier in Amrcn Hstryreader_jimAinda não há avaliações

- Act of Supremacy 1534Documento2 páginasAct of Supremacy 1534reader_jimAinda não há avaliações

- Sullivan BallouDocumento1 páginaSullivan Balloureader_jimAinda não há avaliações

- Declaratory ActDocumento1 páginaDeclaratory Actreader_jimAinda não há avaliações

- Lincoln First InauguralDocumento7 páginasLincoln First Inauguralreader_jimAinda não há avaliações

- Jefferson First InauguralDocumento4 páginasJefferson First Inauguralreader_jimAinda não há avaliações

- Adam Smith and Modern SociologyDocumento107 páginasAdam Smith and Modern Sociologymacariof1904Ainda não há avaliações

- Faust Fragmnt 1322 T 1446Documento8 páginasFaust Fragmnt 1322 T 1446reader_jimAinda não há avaliações

- Machiavelli City Over Souls QuoteDocumento1 páginaMachiavelli City Over Souls Quotereader_jimAinda não há avaliações

- Madison SovereigntyDocumento3 páginasMadison Sovereigntyreader_jimAinda não há avaliações

- Hamilton On BankDocumento32 páginasHamilton On Bankreader_jimAinda não há avaliações

- GilgameshDocumento92 páginasGilgameshreader_jimAinda não há avaliações

- BushidoDocumento65 páginasBushidoreader_jimAinda não há avaliações

- Artcl Betting Money LineDocumento3 páginasArtcl Betting Money Linereader_jimAinda não há avaliações

- Deuterocanonical Books of The Bible Apocrypha by AnonymousDocumento457 páginasDeuterocanonical Books of The Bible Apocrypha by AnonymousGutenberg.orgAinda não há avaliações

- Artcl Betting The NHLDocumento2 páginasArtcl Betting The NHLreader_jimAinda não há avaliações

- Carpentry ToolsDocumento19 páginasCarpentry ToolsRitsy Pantallano100% (1)

- Vidy-Laussane Folded Plate CasestudyDocumento6 páginasVidy-Laussane Folded Plate CasestudyAjay KushwahaAinda não há avaliações

- Prehistoric Methods of ConstructionDocumento7 páginasPrehistoric Methods of Constructiongrizz teaAinda não há avaliações

- EWS Manual 21-22Documento29 páginasEWS Manual 21-22Vivek ReddyAinda não há avaliações

- Fine Woodworking: Photos: Anissa KapsalesDocumento8 páginasFine Woodworking: Photos: Anissa Kapsalesjpl.guedes6842Ainda não há avaliações

- Ancient India Temple ConstructionDocumento6 páginasAncient India Temple ConstructionZuni SomerAinda não há avaliações

- Workshop ManualDocumento96 páginasWorkshop ManualDatta YallapuAinda não há avaliações

- WOOD PRODUCTS (Compatibility Mode)Documento29 páginasWOOD PRODUCTS (Compatibility Mode)BackupFilesAinda não há avaliações

- Practice Test A - Reading: Question 1-10Documento10 páginasPractice Test A - Reading: Question 1-10Yulyy FaziiraaAinda não há avaliações

- Svist - Engineering Workshop ManualDocumento74 páginasSvist - Engineering Workshop ManualChanti BodeddulaAinda não há avaliações

- 101 Projects For Woodworkers SDocumento256 páginas101 Projects For Woodworkers Sayam100% (2)

- UNICEF Garowe Compound Project BoQ v3 BlankDocumento170 páginasUNICEF Garowe Compound Project BoQ v3 BlankCOSOB BILAAinda não há avaliações

- Practice Test A - Reading: Question 1-10Documento12 páginasPractice Test A - Reading: Question 1-10Isaac CarrilloAinda não há avaliações

- Types of Wood JointDocumento8 páginasTypes of Wood JointMache SebialAinda não há avaliações

- Woodwork JointsDocumento5 páginasWoodwork JointsAbdul Sukur Kamsir100% (3)

- Crucial Influence Leadership Skills To Create Lasting Behavior Change 3Rd Edition Joseph Grenny 2 Full ChapterDocumento51 páginasCrucial Influence Leadership Skills To Create Lasting Behavior Change 3Rd Edition Joseph Grenny 2 Full Chapterryan.spengler150100% (6)

- Sam MalofDocumento5 páginasSam MalofMarcos SalazarAinda não há avaliações

- Practice Reading 1-25Documento8 páginasPractice Reading 1-25evaAinda não há avaliações

- The Pencil Post BedDocumento6 páginasThe Pencil Post BedAnonymous QJ5j94luLmAinda não há avaliações

- An Illustrated Woodwork GlossaryDocumento21 páginasAn Illustrated Woodwork GlossaryA.B.AtchiaAinda não há avaliações

- Jigs and XyxwDocumento247 páginasJigs and XyxwThe ash Designe GalaryAinda não há avaliações

- Woodworking 150606073133 Lva1 App6892Documento84 páginasWoodworking 150606073133 Lva1 App6892bereket gAinda não há avaliações

- M. Sedgwick & Co. LTD: UK Manufacturer of Classical Woodworking MachinesDocumento5 páginasM. Sedgwick & Co. LTD: UK Manufacturer of Classical Woodworking MachinesbigbangAinda não há avaliações

- Grandfather ClockDocumento69 páginasGrandfather ClockMeaghan Nicholson100% (1)

- 4chapter BAMBOO STRUCTURES - BNBC 2020 CommentaryDocumento23 páginas4chapter BAMBOO STRUCTURES - BNBC 2020 CommentaryTarif Aziz MarufAinda não há avaliações

- Woodworking With Kids The Ultimate Guide To Easy Techniques and Basic Tools With Essential Safety Tips. 33 Step-By-Step... (White, Woody (White, Woody) ) (Z-Library)Documento142 páginasWoodworking With Kids The Ultimate Guide To Easy Techniques and Basic Tools With Essential Safety Tips. 33 Step-By-Step... (White, Woody (White, Woody) ) (Z-Library)GordinhorsAinda não há avaliações

- Tools CatalogDocumento138 páginasTools CatalogflerziAinda não há avaliações