Escolar Documentos

Profissional Documentos

Cultura Documentos

NFPA 33 Presentation

Enviado por

marciojunkDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NFPA 33 Presentation

Enviado por

marciojunkDireitos autorais:

Formatos disponíveis

!

nlA 33

SLandard for Spray Appllcauon uslng

llammable or Combusuble MaLerlals

llre revenuon Cmcers' Assoclauon

of 8rlush Columbla 2013 Annual

Semlnar

kelowna, 8rlush Columbla

May 9, 2013

NFPA 33 Scope

Applies to the spray application of

flammable or combustible materials by:

! Compressed air atomization

! Airless or hydraulic

atomization

! Electrostatic application

! Other atomized application

methods

Scope

This standard also applies to the application of

flammable or combustible materials applied by:

! Fluidized bed application methods.

! Electrostatic fluidized bed application methods.

! Other means of fluidized application.

! Automated Electrostatic Spray Equipment.

! Handheld Electrostatic Spray Equipment.

! Drying, Curing and Fusion Processes.

! Organic Peroxides and Plural Component

Coatings.

! Styrene Cross-Linked Composites

Manufacturing (Glass Fiber-Reinforced

Plastics)

Scope

Also applies to spray application of water-borne, water-based,

and water-reducible materials that:

! Contain flammable or combustible liquids.

! Produce combustible deposits or resin.

Scope

This standard does not apply to:

! Spray applications performed outdoors.

! Portable spraying equipment.

! Aerosol products up to 1 Liter.

! Application of noncombustible

materials.

! Address toxicity or industrial health and

hygiene.

Does NFPA 33 Apply?

Definitions

! Flash-Off Area- An open or enclosed area after a spray

application process where vapors are released due to

exposure to ambient air or a heated atmosphere.

! Spray Area- Any area in which dangerous quantities of

flammable or combustible vapors, mists, residues, dusts or

deposits are present due to the operation of spray processes

(any area in the direct path of a spray application process,

the interior of a spray booth or spray room, the interiors of

the exhaust plenum, eliminator/scrubber section, exhaust

duct or stack).

Definitions

! Fluidized Bed- A chamber holding powder coating material that is

aerated from below to form an air-supported, expanded cloud of

the powder.

! Electrostatic Fluidized Bed- Similar to above but the powder is

electrically charged with a charge opposite to that of the object

being coated.

! Nonincendive- Electrical equipment and associated wiring that are

incapable, under normal operating conditions, of releasing

sufficient electrical or thermal energy to cause ignition of specific

hazardous materials in their most easily ignited concentrations in

air.

Definitions

! Overspray- Any sprayed material that is not deposited on

the intended object.

! Spray Booth- A power-ventilated enclosure for a spray

application operation or process that confines and limits the

escape of the material being sprayed, including vapors,

mists, dusts and residues and conducts or directs these

materials to an exhaust system. The booths can be of the

Dry, or Water-Wash type.

Definitions

! Spray Room- A power ventilated fully enclosed room used

exclusively for open spraying of flammable or combustible

materials.

! Ventilation- Movement of air that is provided for the

prevention of fire and explosion and is sufficient to prevent

accumulation of vapor-air mixtures in concentrations over

25% of the lower flammable limit.

Location

! Spray application operations and processes shall be confined

to spray booths, spray rooms, or spray areas.

! Spray application operations and processes shall not be

conducted in any A, E, I or R occupancy unless they are

located in a room that is separated by 2 hour fire rated

construction and protected by an approved automatic fire

sprinkler system.

Design and Construction

! Walls and ceilings shall be constructed of noncombustible

or limited combustible materials with interior surfaces

smooth (cannot trap residue or restrict ventilation or

cleaning).

! Aluminum shall not be used unless it is limited to ancillary

devices.

Design and Construction

! Spray Rooms shall be constructed of

and separated from surrounding areas

of the building by 1 hour fire rated

construction.

! Enclosed spray booths/rooms shall be

provided with means of egress that meet

the requirements of NFPA 101.

! Conveyor openings that are necessary

for transporting or moving work into

and out of the spray area shall be as

small as practical.

Design and Construction

! Spray booths shall be separated from other operations by a

minimum distance of 915mm or by a partition, wall, or

floor/ceiling assembly with a minimum 1 hour fire

resistance rating.

! All parts must be readily accessible for cleaning.

! A clear space of not less than 915mm shall be maintained

on all sides and above (Exceptions for walls).

Design and Construction

! Panels for light fixtures or

observation shall be of heat-treated

glass, laminated glass, wired glass,

or hammered wired glass and shall

be sealed to confine vapors, mists,

residues, dusts and deposits to the

spray area.

! Panels for the light fixtures shall be

separated from the fixture to

prevent the surface temperature of

the panel from exceeding 93c

Design and Construction

Spray areas that are equipped with ventilation distribution or baffle plates or with

dry overspray collection filters shall:

! Have distribution plates or baffles constructed of noncombustible materials

and be readily accessible for cleaning.

! Not use filters when applying materials known to be highly susceptible to

spontaneous heating/ignition.

! Have filter supports constructed of noncombustible materials.

! Have filters readily accessible for cleaning or replacement.

! Not allow filters to be alternately used for different types of coating materials.

Electrical Area Classification

(Abbreviated)

Class I- Any location where flammable gas or vapor is present or

might be present in the air in quantities sufficient to produce an

explosive or ignitible mixture.

! Class I, Division 1- Above condition exists in normal operating

conditions. Condition can exist frequently due to repair or

maintenance operations, or leakage. Breakdown or faulty

operation of equipment can release ignitible concentration with

potential simultaneous failure of electrical equipment in such a

way that it becomes a source of ignition.

Electrical Area Classification

(Abbreviated)

! Class I, Division 2- Similar conditions to previous slide but

the flammable gas, vapor or liquid is confined within a

closed container or system and only escapes in cases of

accidental rupture or breakdown of the container/system or

abnormal operation of equipment. Ignitible concentration

is prevented by positive mechanical ventilation (unless

failure). An ignitible concentration may be transmitted from

a CI, D1 location if failure of positive mechanical

ventilation.

Electrical Area Classification

(Abbreviated)

Class I, Zone 0- Location where an ignitible concentration of

flammable gas or vapor is continuously present

Class I, Zone 1- Location where one of the following conditions

exist.

! Ignitible concentration of flammable gas or vapor exists under

normal conditions, during repair/maintenance. Breakdown may

cause ignitible concentration and simultaneous failure of electrical

system that could be an ignition source. Ignitible concentration

may be transmitted from a CI, Z1 location.

Electrical Area Classification

(Abbreviated)

Class I, Zone 2- Location where one of the conditions exist

! Ignitible concentration of flammable gas or vapor is not

likely to exist under normal operating conditions, or exists

for only a short period of time. Flammable gas or volatile

flammable liquid is present but is confined within a closed

container. Ignitible concentration is prevented by positive

mechanical ventilation. Ignitible concentration may be

transmitted from a CI, Z1 location.

Electrical Area Classifications

(Abbreviated)

Class II- Locations similar to Class I but containing combustible dust.

(Also includes dust interfering with dissipation of heat.)

Zone 20- Locations where an ignitible concentration of combustible

dust is present continuously or for long periods of time.

Zone 21- Similar to Class I, Zone 1 locations but refers to dust.

Zone 22- Similar to Class I, Zone 2 locations but refers to dust.

Electrical Devices

! Spray area shall be Class I,

Division 1; Class I, Zone 1;

Class II, Division 1; or Zone

21 (whichever is applicable).

! Electrical equipment and

wiring located in the spray

area (and not subject to

combustible residues) shall

conform to above

classifications (whichever is

applicable).

Electrical Devices

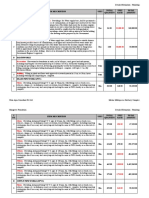

Equipment and wiring

located outside but within

6100mm horizontally and

3050mm vertically of an

unenclosed spray area shall be

designated as shown in Figure

6.5.1

Electrical Devices

If spray application

operations are conducted

within a closed-top, open-face

or open-front booth, or room,

any electrical wiring or

equipment located outside the

booth/room but within

915mm of any opening shall

be designated as shown in

Figure 6.5.2

Electrical Devices

If spray application

operations are confined to an

enclosed spray booth or

room, the electrical area

classification shall be as

shown in Figure 6.5.4

Misc. Electrical

Open containers with

Class I liquids shall be

located with the electrical

area classifications shown

in Figure 6.5.5.2

Misc. Electrical

! Light fixtures outside the spray

area shall be listed for use

according to the area they

occupy.

! All electrically conductive

objects in the spray area shall be

electrically connected to

ground.

! Portable electric light fixtures

shall not be used in any spray

area while spray application

operations are being conducted.

Ventilation

Ventilating and exhaust systems

shall be designed and installed in

accordance with the applicable

requirements of NFPA 91, Standard

for Exhaust Systems for Air Conveying

of Vapors, Gases, Mists, and

Noncombustible Particulate Solids.

Ventilation

Each spray area shall be provided with mechanical ventilation that is

capable of:

! Confining and removing vapors and mists to a safe location.

! Confining and controlling combustible residues, dusts and

deposits.

! Concentration of vapors and mists in the exhaust stream of the

ventilation system shall not exceed 25% of the lower flammable

limit.

Ventilation

! Mechanical ventilation shall

be kept in operation at all

times while spray operations

are being conducted, and for a

sufficient time thereafter to

allow vapors from drying

coated objects.

! An adequate supply of clean

make-up air shall be provided

to compensate for the air

exhausted from spray

operations (shall not

recirculate exhaust air).

Ventilation

Air exhausted to the atmosphere from liquid spray operations shall be

conducted by ducts directly to the outside of the building, and:

! Shall follow the most direct route to the point of discharge.

! Shall be directed away from any fresh air intakes.

! The discharge point shall be at least 1830mm from any exterior

wall or roof.

! Shall not discharge in the direction of any combustible

construction within 7625mm of the discharge point (or any

unprotected opening).

Misc. Ventilation

! Use caution when allowing recirculation of exhausted air.

! Exhaust ducts shall not be manifolded together.

! Exhaust plenums and ducts shall be constructed of steel

(smooth concrete allowed).

! Exhaust ducts shall be supported to prevent collapse under

fire conditions (The weight of residue and fire sprinkler

discharge must be taken into account).

! All exhaust ducts shall be provided with doors, panels, or

other means to facilitate inspection and maintenance.

Storage and Handling

Storage, handling, and mixing of flammable and combustible

liquids shall meet all the applicable requirements of NFPA 30,

Flammable and Combustible Liquids Code

Storage and Handling

! The volume of Class I, II, III,

IIIA liquids in a storage

cabinet shall not exceed 454L.

! The total aggregate volume of

the above listed liquids in a

group of storage cabinets shall

not exceed the maximum

allowable quantity of

flammable and combustible

liquids per control area.

Storage and Handling

Industrial Occupancies shall not exceed the

MAQ per control area.

The quantity of liquid located in in the vicinity

of spraying operations but outside of identified

storage areas shall not exceed either

! The amount required to supply spraying

operations for one continuous 24-hour

period, or

! The aggregate sum of 95L of (Class IA), or

454L of (ClassIB, IC, Class II, Class III), or

6000L of (Class IB, IC, II or IIIA liquids in

portable metal containers), or 3000L of

(Class II or Class IIIA in nonmetalic bulk

containers) or Twenty portable tanks each

not exceeding 3000L of Class IIIB liquids.

Mixing

Mixing rooms shall meet all of the following requirements:

! Shall meet the construction requirements of Section 5.1

! The area shall not exceed 14m squared.

! Shall be designed to contain a spill of the contents of the room.

! Shall be provided with continuous mechanical ventilation and shall be in

operation at all times.

! Shall have an electrical classification the same as an enclosed spray booth.

! Shall be provided with an approved automatic fire protection system.

! Shall be provided with portable fire extinguishers in accordance with NFPA

10

Mixing

! The amount of liquid permitted in a

single spray area shall not exceed 227L

! Where a separate mixing room is

provided and is located within 1830mm

of an adjacent spray area, the combined

quantities of liquids shall not exceed

454L.

! Where a separate mixing room is

provided and is located more than

1830mm from an adjacent spray area,

the quantity of liquid permitted in the

mixing room shall not exceed 80L/m

squared (maximum 1135L), spray area

shall not exceed 227L.

Protection

Spray areas, which include by definition any associated

exhaust plenums and exhaust ductwork, any particulate filters,

any solvent concentrator units, any recirculation air supply

units, and mixing rooms, shall be protected with an approved

automatic fire protection system.

Protection

The automatic fire protection system shall be permitted to be, and

shall be installed in accordance with, any of the following:

! An automatic water sprinkler system (NFPA 13).

! An automatic foam water sprinkler system (NFPA 16).

! A carbon dioxide extinguishing system (NFPA 12).

! A dry chemical extinguishing system (NFPA 17)

! A gaseous agent extinguishing system (NFPA 2001)

Protection

For continuous spray application operations,

activation of the automatic fire protection

system shall automatically accomplish all of

the following:

! Activate a local alarm in the vicinity of

the spraying operation.

! Transmit an alarm signal to the facilitys

fire alarm system.

! Shut down the coating material delivery

system.

! Shut down all spray application

operations.

! Stop any conveyors into and out of the

spray area.

Protection

Automatic Sprinkler Systems shall

take the following into

consideration:

! Shall be a wet pipe, dry pipe,

preaction, or open-head deluge

system (whichever is most

appropriate).

! Shall be designed for Extra

Hazard (Group 2) occupancies.

! Water supply shall be sufficient

to supply all sprinklers likely to

open without depleting the

available water for hose streams.

Protection

! System shall be controlled by a separate listed indicating valve,

operable at floor level.

! Stacks and exhaust ducts shall be provided with access openings

for inspection and cleaning of sprinklers.

! Sprinklers shall be protected against overspray residue, either by

location or covering (only by cellophane bags having a thickness

of .08mm or less or by thin paper bags).

! Sprinklers that have been painted or coated by overspray shall be

replaced with new sprinklers.

Protection

! Automatic Carbon Dioxide,

Dry Chemical, and Clean

Agent Systems shall be

capable of discharging its

contents into the entire

protected area simultaneously,

including the exhaust plenum

and exhaust ductwork.

! Portable fire extinguishers

shall be provided and located

in accordance with NFPA 10,

Standard for Portable Fire

Extinguishers.

Protection

Automated powder application equipment, and Automated

liquid electrostatic spray application equipment, both listed

and unlisted, shall be further protected by listed optical flame

detection, installed and supervised in accordance with NFPA

72, National Fire Alarm and Signaling Code. This action shall

stop all processes and conveyors, shut down ventilation and

electrical equipment, and activate the automatic protection

system.

Operations and Maintenance

Maintenance procedures shall be established to ensure that all

spray application apparatus and processes are operated and

maintained in accordance with the manufacturers

specifications and the requirements of this standard.

Maintenance shall be the responsibility of the users of the

apparatus and processes.

Operations and Maintenance

! All spray areas shall be kept free of excessive accumulation

of deposits of combustible residues.

! If residue accumulates to excess in booths, ducts, or duct

discharge points, or other spray areas, all spraying

operations shall be discontinued until conditions have been

corrected.

Operations and Maintenance

! Maintenance procedures shall be established to ensure that

overspray collector filters are replaced before excessive

restriction to airflow occurs.

! At the close of the days operation, all discarded overspray

collection filters, residue scrapings, and debris contaminated

with residue shall be removed and placed in a

noncombustible container with a tight fitting lid in a

designated storage location.

Operations and Maintenance

! Approved waste containers

shall be provided wherever

rags or waste are impregnated

with sprayed material, and all

such rags or waste shall be

deposited therein immediately

after use.

! Employee clothing

contaminated with sprayed

material shall not be left on

the premises overnight unless

kept in a metal locker.

Training

All personnel involved in the spray

application processes covered by this

standard shall be instructed in the

following:

! Potential safety and health

hazards.

! Operational, maintenance, and

emergency procedures required.

! Importance of constant operator

awareness.

Training

! Personnel required to handle or use flammable or

combustible materials shall be instructed in the safe

handling, storage, and use of the materials, as well as

emergency procedures.

! All personnel required to enter or to work within confined

or enclosed spaces shall be instructed as to the nature of the

hazard involved, the necessary precautions to be taken, and

the use of protective and emergency equipment required.

Training

All personnel shall be instructed

in the proper use, maintenance,

and storage of all emergency,

safety, or personal protective

equipment that they might be

required to use in their normal

work performance.

Documentation shall be

employed to record the type and

date of the training provided to

each individual involved in these

processes.

Cuesuons?

Cary !. Ponold, C.l..S.

8eglonal ulrecLor, norLhwesL lleld Cmce

2814 8rooks SL. SulLe 240

Mlssoula, MonLana 39803

406-241-3981

ghonold[nfpa.org

Thank You!

Você também pode gostar

- NFPA 33 Paint Booth Check SheetDocumento19 páginasNFPA 33 Paint Booth Check Sheetaravindappi100% (1)

- FM200 Fire Suppression System: 1-1/2" BS 336 MaleDocumento18 páginasFM200 Fire Suppression System: 1-1/2" BS 336 MaleSofiqAinda não há avaliações

- Promat PFPH Chapter 1 Introduction PDFDocumento16 páginasPromat PFPH Chapter 1 Introduction PDFHeba S. Al-saudiAinda não há avaliações

- Fire Damper - FDDocumento7 páginasFire Damper - FDZaw Moe KhineAinda não há avaliações

- TFP-315 Rociadores PDFDocumento4 páginasTFP-315 Rociadores PDFJosue' GonzalezAinda não há avaliações

- 14 Haz MaterialsDocumento81 páginas14 Haz MaterialsGrillin Gm0% (1)

- 800024-004 Diom Manual, Ihp Co2Documento47 páginas800024-004 Diom Manual, Ihp Co2rulo zamora mendez100% (1)

- Alarm Check Valve PurposeDocumento36 páginasAlarm Check Valve PurposeAbdul Majeed KottaAinda não há avaliações

- AS SA N: Fire Fighting CodesDocumento6 páginasAS SA N: Fire Fighting CodesadnanAinda não há avaliações

- 3M Fire Barrier, Fire Protection & Fire Stopping ProductsDocumento3 páginas3M Fire Barrier, Fire Protection & Fire Stopping ProductsOtto BorgesAinda não há avaliações

- 003 Diom Manual Ilp Novec 1230Documento49 páginas003 Diom Manual Ilp Novec 1230Jhonathan ArturoAinda não há avaliações

- Manual Llenado e Inspeccion Bladder TankDocumento83 páginasManual Llenado e Inspeccion Bladder TankPaulina Andrea Jiménez VarasAinda não há avaliações

- Application ManualDocumento28 páginasApplication ManualRoy Anthone LaysonAinda não há avaliações

- Dust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSDocumento18 páginasDust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSPedro Ceriolli100% (1)

- 2190 - First Aid Fire ExtinguishersDocumento20 páginas2190 - First Aid Fire ExtinguishersJitendra R. SharmaAinda não há avaliações

- Nfpa 72Documento6 páginasNfpa 72vijimurugan2003100% (3)

- Smoke Movement: FV 3002 Fire Protection EngineeringDocumento48 páginasSmoke Movement: FV 3002 Fire Protection EngineeringRaccoon Mr.Ainda não há avaliações

- FireSmokeDamperCompendiumRevised62215 PDFDocumento22 páginasFireSmokeDamperCompendiumRevised62215 PDFnunukanta100% (1)

- CO2 AnsulDocumento17 páginasCO2 AnsulJorge RVAinda não há avaliações

- ANSUL R-102 Restaurant Fire Suppression System ManualDocumento186 páginasANSUL R-102 Restaurant Fire Suppression System ManualGary AtenAinda não há avaliações

- BYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFDocumento3 páginasBYBU - XR711 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq AVI 2020 PDFCIAKAinda não há avaliações

- Fire Hose Cabinet & HydrantsDocumento21 páginasFire Hose Cabinet & HydrantsmostafaabdelrazikAinda não há avaliações

- Fire ProtectionDocumento7 páginasFire ProtectionRonaldAinda não há avaliações

- ANSUL High Pressure Carbon Dioxide Systems ManualDocumento248 páginasANSUL High Pressure Carbon Dioxide Systems ManualPablo SotoAinda não há avaliações

- Bukel Fire Aircraft - HangarsDocumento7 páginasBukel Fire Aircraft - HangarsmukeshsinghtomarAinda não há avaliações

- FSSA Guide To Estimating Pressure Relief Vent Area 2 EditionDocumento1 páginaFSSA Guide To Estimating Pressure Relief Vent Area 2 EditionLaura Galarza100% (1)

- En 60079 BSDocumento2 páginasEn 60079 BSSivagurunathan Sp100% (1)

- Tyco - Window Sprinklers As An Alternative To Fire PDFDocumento19 páginasTyco - Window Sprinklers As An Alternative To Fire PDFingenierosunidosAinda não há avaliações

- Behavior of Materials in A Vertical Tube Furnace at 750°C: Standard Test Method ForDocumento10 páginasBehavior of Materials in A Vertical Tube Furnace at 750°C: Standard Test Method ForPYDAinda não há avaliações

- Ammonium Bifluoride - SDSDocumento6 páginasAmmonium Bifluoride - SDSFerri AguswanAinda não há avaliações

- TG Fire Precautions and Fire ProtectionDocumento13 páginasTG Fire Precautions and Fire ProtectionKang Kawe Waone SetiaoneAinda não há avaliações

- UL Ul Logo UL LLC © 2016: and The Are Trademarks ofDocumento24 páginasUL Ul Logo UL LLC © 2016: and The Are Trademarks ofRishard Ahamed AkramAinda não há avaliações

- Silencer DimensioningDocumento14 páginasSilencer DimensioningAntonioVirardiAinda não há avaliações

- Clean Agent Suppression System Method of Statement PDFDocumento3 páginasClean Agent Suppression System Method of Statement PDFKo ZayAinda não há avaliações

- Durasteel DuctingDocumento37 páginasDurasteel DuctingMoriyasuNguyenAinda não há avaliações

- Halon vs. NovacDocumento7 páginasHalon vs. Novackmas1612Ainda não há avaliações

- University of Houston Master Construction SpecificationsDocumento8 páginasUniversity of Houston Master Construction SpecificationsTaher AmmarAinda não há avaliações

- REMBE - Explosion Protection BasicsDocumento95 páginasREMBE - Explosion Protection BasicsHH KevinAinda não há avaliações

- 3150 Verifying Fire Safety Design in Sprinklered BuildingsDocumento140 páginas3150 Verifying Fire Safety Design in Sprinklered BuildingshpoerbayaAinda não há avaliações

- Ansul - Electric Manual Pull Station PDFDocumento2 páginasAnsul - Electric Manual Pull Station PDFElieser JúnioAinda não há avaliações

- Fire PerformanceDocumento4 páginasFire PerformanceRamyaa LakshmiAinda não há avaliações

- Viking Foam Manual 001Documento24 páginasViking Foam Manual 001Trần VânAinda não há avaliações

- Fire Damper RequirementsDocumento10 páginasFire Damper Requirementssahota040Ainda não há avaliações

- History of Fire Protection Engineering - Professional Practice Content From Fire Protection EngineeringDocumento7 páginasHistory of Fire Protection Engineering - Professional Practice Content From Fire Protection Engineeringsomphong.bkk5576Ainda não há avaliações

- 81 Co2man 001 - Print PDFDocumento324 páginas81 Co2man 001 - Print PDFLupiAinda não há avaliações

- Sprinklers & High Pressure Water Mist System - ComparisonDocumento1 páginaSprinklers & High Pressure Water Mist System - ComparisonrjendranAinda não há avaliações

- 2013 NFPA 72 UpdatesDocumento43 páginas2013 NFPA 72 Updatesjrvaughn100% (2)

- NFPA-13-Sprinkler-System Plan ReviewDocumento5 páginasNFPA-13-Sprinkler-System Plan ReviewVenkatram AnnamdevaraAinda não há avaliações

- Fire ExtinguisherDocumento2 páginasFire Extinguisherusman javaidAinda não há avaliações

- NFSA - MayJune12 LRDocumento88 páginasNFSA - MayJune12 LRnfiresprinklerAinda não há avaliações

- Catalogue of Wet Chemical Fire Suppression SystemDocumento2 páginasCatalogue of Wet Chemical Fire Suppression SystemAlex ChinAinda não há avaliações

- Foam Liquid Concentrates - Ul Product Iq SolbergDocumento15 páginasFoam Liquid Concentrates - Ul Product Iq SolbergLuis Alberto Serrano MesaAinda não há avaliações

- Combustible DustDocumento9 páginasCombustible Dustingbarragan87100% (1)

- Transform Challenges With ExpertiseDocumento12 páginasTransform Challenges With ExpertiseKale SudipAinda não há avaliações

- Methods of Fire Protection of Steel StructuresDocumento10 páginasMethods of Fire Protection of Steel StructuresArbaz AhmedAinda não há avaliações

- Large Dry Chemical Fire Suppression Systems: AnsulDocumento8 páginasLarge Dry Chemical Fire Suppression Systems: AnsulLogan Marquez AguayoAinda não há avaliações

- Sis & SilDocumento65 páginasSis & SilGecAinda não há avaliações

- Hazardous Area Classification PONSL RevisedDocumento106 páginasHazardous Area Classification PONSL RevisedMuhamad Firdaus Bin AzizanAinda não há avaliações

- Appendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsDocumento12 páginasAppendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsNaveedAinda não há avaliações

- Hazardous Area Classification & Intrinsic SafetyDocumento35 páginasHazardous Area Classification & Intrinsic SafetyMukesh C ChavanAinda não há avaliações

- CPT2012 C1(周) PDFDocumento4 páginasCPT2012 C1(周) PDFmarciojunkAinda não há avaliações

- Calcium Citrate, Tetrahydrate MSDS: Section 1: Chemical Product and Company IdentificationDocumento5 páginasCalcium Citrate, Tetrahydrate MSDS: Section 1: Chemical Product and Company IdentificationmarciojunkAinda não há avaliações

- Isocure Catalyst 700Documento8 páginasIsocure Catalyst 700marciojunkAinda não há avaliações

- Resicoat R4-ES Fusion Bonded Epoxy: Product Data SheetDocumento2 páginasResicoat R4-ES Fusion Bonded Epoxy: Product Data SheetmarciojunkAinda não há avaliações

- Product Handling: Complete Solutions From A Single SourceDocumento24 páginasProduct Handling: Complete Solutions From A Single Sourcemarciojunk100% (1)

- Fluid Bed Systems: P Ro / P Lu SDocumento20 páginasFluid Bed Systems: P Ro / P Lu SmarciojunkAinda não há avaliações

- Manual RHM InglesDocumento28 páginasManual RHM InglesmarciojunkAinda não há avaliações

- ChampLED BrochureDocumento8 páginasChampLED BrochuremarciojunkAinda não há avaliações

- SERVOTOUGH Fluegas 2700ukDocumento0 páginaSERVOTOUGH Fluegas 2700ukmarciojunkAinda não há avaliações

- Pro Techn Descr Ed1Documento20 páginasPro Techn Descr Ed1marciojunkAinda não há avaliações

- Grundfosliterature 4112587Documento44 páginasGrundfosliterature 4112587marciojunkAinda não há avaliações

- General Brochure AVAPACDocumento37 páginasGeneral Brochure AVAPACmarciojunkAinda não há avaliações

- Pro Techn Descr Ed1Documento20 páginasPro Techn Descr Ed1marciojunkAinda não há avaliações

- Polytronxpex ManualDocumento65 páginasPolytronxpex ManualmarciojunkAinda não há avaliações

- The Dust ExplosionDocumento90 páginasThe Dust Explosionavinash_mokashi7073100% (1)

- Hazardous Area Classification Innoil & Gas IndustryDocumento34 páginasHazardous Area Classification Innoil & Gas Industrygastro9956Ainda não há avaliações

- Oliva - A Maturity Model For Enterprise Risk ManagementDocumento14 páginasOliva - A Maturity Model For Enterprise Risk ManagementErika FerreiraAinda não há avaliações

- Important Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)Documento4 páginasImportant Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)AFHAM JAUHARI BIN ALDI (MITI)Ainda não há avaliações

- Fss Operators: Benchmarks & Performance ReviewDocumento7 páginasFss Operators: Benchmarks & Performance ReviewhasanmuskaanAinda não há avaliações

- Mcqs Ethics and CSR)Documento9 páginasMcqs Ethics and CSR)Maida TanweerAinda não há avaliações

- CV HariDocumento4 páginasCV HariselvaaaAinda não há avaliações

- Paper 1 - 2017 EETDocumento10 páginasPaper 1 - 2017 EETRayAinda não há avaliações

- Elo BLP Neutral en Web.5573Documento8 páginasElo BLP Neutral en Web.5573Ichsanul AnamAinda não há avaliações

- FZCODocumento30 páginasFZCOawfAinda não há avaliações

- New CVLRDocumento2 páginasNew CVLRanahata2014Ainda não há avaliações

- Misurata UniversityDocumento11 páginasMisurata UniversityDustin EllisAinda não há avaliações

- (E-Brochure) Ginza HillDocumento6 páginas(E-Brochure) Ginza HillRenald 'Renald' RenaldAinda não há avaliações

- PRANIR ProfileDocumento14 páginasPRANIR ProfileManish VadanereAinda não há avaliações

- Which Among The Following Statement Is INCORRECTDocumento7 páginasWhich Among The Following Statement Is INCORRECTJyoti SinghAinda não há avaliações

- Attachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFDocumento24 páginasAttachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFMathias OnosemuodeAinda não há avaliações

- NMIMS Offer LetterDocumento4 páginasNMIMS Offer LetterSUBHAJITAinda não há avaliações

- Lampiran Surat 739Documento1 páginaLampiran Surat 739Rap IndoAinda não há avaliações

- System Description For Use With DESIGO XWORKS 17285 HQ enDocumento48 páginasSystem Description For Use With DESIGO XWORKS 17285 HQ enAnonymous US9AFTR02100% (1)

- Assignment3 (Clarito, Glezeri BSIT-3A)Documento9 páginasAssignment3 (Clarito, Glezeri BSIT-3A)Jermyn G EvangelistaAinda não há avaliações

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Documento52 páginas03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreAinda não há avaliações

- CV - Nguyen Quang HuyDocumento5 páginasCV - Nguyen Quang HuyĐoan DoãnAinda não há avaliações

- Lesson 2 - Graphing Rational Numbers On A Number LineDocumento9 páginasLesson 2 - Graphing Rational Numbers On A Number Linehlmvuong123Ainda não há avaliações

- Hyundai Monitor ManualDocumento26 páginasHyundai Monitor ManualSamAinda não há avaliações

- C28x WorkshopDocumento400 páginasC28x WorkshopMarcio De Andrade VogtAinda não há avaliações

- PDF 5Documento75 páginasPDF 5فرزاد ”Angra“ mavaraniAinda não há avaliações

- imageRUNNER+ADVANCE+C5051-5045-5035-5030 Parts CatalogDocumento268 páginasimageRUNNER+ADVANCE+C5051-5045-5035-5030 Parts CatalogDragos Burlacu100% (1)

- SYKES - Telework Work Area AgreementDocumento2 páginasSYKES - Telework Work Area AgreementFritz PrejeanAinda não há avaliações

- OTP Protocol PharmacistsDocumento14 páginasOTP Protocol PharmacistsericAinda não há avaliações

- BloodDocumento22 páginasBloodGodd LlikeAinda não há avaliações

- Tutorial MEP1553 - Insulation DiagnosticsDocumento4 páginasTutorial MEP1553 - Insulation DiagnosticsSharin Bin Ab GhaniAinda não há avaliações

- GMDS - Course - FinalDocumento282 páginasGMDS - Course - FinalLuisPazPerdomo100% (1)