Escolar Documentos

Profissional Documentos

Cultura Documentos

LM Ece Ew Manual 01112012

Enviado por

Shoaib MughalTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

LM Ece Ew Manual 01112012

Enviado por

Shoaib MughalDireitos autorais:

Formatos disponíveis

ELECTRICAL

WORKSHOP LAB

ELECTRICAL WORKSHOP LAB

This laboratory gives an exposure to students in their third semester on basic

electrical devices and fittings like mercury vapour lamp, energy meter, MCBs, etc.

Through this, the students shall be able to appreciate the intricacies involved in

domestic and industrial electrical wiring.

LIST OF EXPERIMENTS

1. INTRODUCTION OF TOOLS, ELECTRICAL MATERIALS, SYMBOLS

AND ABBREVIATIONS.

2. TO MAKE T J OINT AND STRAIGHT J OINT.

3. TO STUDY STAIRCASE WIRING.

4. TO STUDY HOUSE WIRING.

5. TO STUDY FLUORESCENT TUBE LIGHT.

6. TO STUDY HIGH PRESSURE MERCURY VAPOUR LAMP (H.P.M.V.).

7. TO STUDY SODIUM VAPOUR LAMP.

8. TO STUDY SINGLE PHASE INDUCTION MOTOR USING SINGLE

PHASE ENERGY METER AND DOUBLE POLE MAIN SWITCH.

9. TO STUDY THREE PHASE INDUCTION MOTOR USING THREE PHASE

ENERGY METER, TRIPPLE POLE IRON CLAD MAIN SWITCH AND

DOL STARTER.

10. TO STUDY REPAIRING OF HOME APPLIANCES SUCH AS HEATER,

ELECTRIC IRON AND FANS ETC.

EXPERIMENT- 1

AIM: Introduction of tools, electrical materials and abbreviations.

TOOLS

PLIER: Generally three types of pliers are used in the electrical workshop. They are:-

FLAT NOSE PLIER: Used for holding jobs or holding wires. It has got only two slotted

jaws, which are tapered. Thus it is used for tightening or loosening small nuts.

SIDE CUTTING PLIER: Used for cutting of thin wires and removing insulations from

them. It has got cutting edge on its one of its sides.

ROUND NOSE PLIER: Used only to hold or cut the wires. It has no gripping jaws. Its

cutting edge is long and rounded on the top.

SCREW DRIVER: It is used to loosen or tighten or to keep screws in position. It has a wooden

or plastic handle and a blade of high carbon steel.

CHISEL:

FIRMER CHISEL: Generally used for carpentry works and can be used by hand pressure

or with the help of mallet. It has flat blade, which varies from 12mm to 15mm.

COLD CHISEL: Used for cutting iron pieces (cold). It has cutting angle from 30 to

45and is made of high carbon steel.

HAMMER: Most commonly used in the workshop. The head is made of cast iron or forged; the

claw is hardened and tampered. The striking place is slightly convex. The head is fitted with a

wooden handle of various lengths.

HACKSAW: Used to cut metal such as iron strips, core pipes etc. it has a blade made of high

steel or tungsten.

ELECTRICAL TOOLS

TUMBLER SWITCH: (6 A for light), this switch was used 3-4 decade ago. It is made of

Bakelite.

MCB BOX: Known as the Miniature Circuit Breaker Box.

METAL CONDUIT PIPE WITH JUNTION BOX: Metallic hollow pipe, which is used as a

passage for electrical house, hold wires. It is fixed to walls with the help of metallic saddle.

METAL BEND: Hollow metallic pipe bend to an angle of 90 to allow smooth movement of

wires inserted through the walls during wiring .

BATTEN WIRING: It is an old fashioned wiring used 4-5 decades ago.

PVC CASING AND LAPPING: Long rectangular box made of 2 parts. It is made of PVC and

used mainly to pass wires through walls during wiring.

PVC BEND: Work similarly as metal bends but it is made up of PVC that makes it lighter,

cheaper and more durable.

BATTEN LAMP HOLDER: mainly used to hold electric bulbs and lamps.

SWITCH BOARD WITH SWITCHES: it contains the following:

SOCKET OUTLETS: it is a type of electrical material through which electric current

flows from wires to various electrical appliances. It is of 6A.

TWO WAY SWITCH: it is mainly used in staircase wiring to either on or off the light.

It is of 6A.

ONE-WAY SWITCH: it is a device used to switch on lights of 6A.

7/20 SWG (POWER WIRE): they are used in power purposes for duty electrical appliances.

7/20 means 7 numbers of wires in the cable and 20 strands for thickness or gauge size.

3/20 SWG (PHASE WIRING): mostly used for house wiring purposes.

3/22 SWG (NEUTRAL WIRE): it is also used for house wiring purposes.

1/18 SWG: it is used for earthing.

FLEXIBLE CABLE: This is a temporary wire used for both power and light but temporarily. It

is used as extension wire.

ABBREVIATIONS:

S.NO.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

NAME OF THE UNIT

VOLTS

AMPERES

LOW TENSION

HIGH TENSION

OIL CIRCUIT BREAKER

KILO-VOLTS

MAIN SWITCH

SUB-MAIN SWITCH

DISTRIBUTION BOARD

IRON CLAD DISTRIBUTION BOARD

CONTROL BOARD

SWITCH BOARD

NORMALLY OPEN

NORMALLY CLOSED

ABREVIATION

V

Amp

LT

HT

OBC

KV

MS

SMS

DB

ICDB

CB

SB

NO

NC

15.

16.

17

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

TIME DELAY RELAY

NO VOLT RELEASE

SUB-DISTRIBUTION BOARD

OVER LOAD RELEASE

DIRECT ON LINE

DOUBLE POLE IRON CLAD

ALL ALLUMINIUM CONDUCTOR

ALTERNATING CURRENT

DIRECT CURRENT

TRIPLE POLE IRON CLAD

AIR CIRCUIT BREAKER

CURRENT TRANSFORMER

CAB TYPE SHEATHED

CAPACITIVE VOLTAGE TRANSFORMER

EARTH LEAKAGE CIRCUIT BREAKER

EXTRA HIGH VOLTAGE

ELECTROMOTIVE FORCE

FIELD EFFECTIVE TRANSISTOR

HIGH PRESSURE Hg VAPOUR LAMP

HIGH RAPTURE CAPACITY FUSE

HIGH VOLTAGE

LOW VOLTAGE

INTRIGATED CIRCUIT

J UNCTION FIELD EFFECT TRANSISTOR

KILO VOLT AMPERE

KILO WATT

KILO WATT HOUR

LIGHTENING ARRESTER

LIGHT DEPENDENT RESISTANCE

LOW PRESSURE Hg VAPOUR LAMP

LOW VOLTAGE

LIGHT EMITTING DIODE

MINIATURE CIRCUIT BREAKER

METAL OXIDE FIELD EFFECT TRANSISTOR

MEGA WATT

NEUTRAL LINK

OVER LOAD TRIP COIL

PHASE

POTENTIAL TRANSFORMER

POLYVINYL CHLORIDE

PAPER INSULATED LEAD COVERED

SERIES

SHUNT

SILICON CONTROL SWITCH

LIGHT ACTIVATED SILICON CONTROL SWITCH

SUB MAIN SWITCH

SINGLE POLE

SINGLE POLE DOUBLE THROW

TDR

NVR

SDB

OLR

DOL

DPIC

AAC

AC

DC

TPIC

ACB

CT

CTS

CVT

ELCB

EHV

EMF

FET

HPMVL

HRCF

HV

LC

IC

J FET

KVA

KW

KWh

LA

LDR

LPMVL

LV

LED

MCB

MOFET

MW

NL

OLPEC

Ph

PT

PVC

PILC

Se

Sh

SCS

LASCS

SMS

SP

SPDT

63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

SINGLE POLE SINGLE THROW

STANDARD WIRE GAUGE

TRIPLE POLE SWITCH

SODIUM VAPOUR LAMP

SODIUM UNILATERAL SWITCH

SILICON CONTROL RECTIFIER

TRIPLE POLE WITH NEUTRAL

TRIPLE POLE IRON CLAD

TRIPLE POLE DOUBLE THROW

TRIPLE POLE SINGLE THROW

THERMAL RELAY

TOUGH RUBBER SHEATHED

UNIJ UNCTION TRANSISTOR

VOLT AMPERE

VULCANISED INDIAN RUBBER

WATER TIGHT

WEATHER-PROOF CABLE

CATHODE RAY OSCILLATOR

RESISTANCE

CAPACITOR

INDUCTANCE

BATTERY

UNIJ UNCTION TRANSISITOR

SPST

SWG

TPS

SWL

SUS

SCR

TPN

TPIC

TPDT

TPST

TR

TRS

UJ T

VA

VIR

WT

WPC

CRO

R

C

L

E

UJ T

QUIZ/ANSWERS

Q1. What is the abbreviation of kva? Kilo Watt Amperes

Q2. Name the standard of the wires according to their

gauges?

1/8, 3/20, 7/20, 7/22

Q3. What is the use of lamp holder? Hold in particular position

Q4. What is the symbol of the ceiling fan?

Q5. What is the function of hawk saw? To cut pipes, metal sheet &

wooden pieces

Q6. How many types of pliers we used? Flat nose, long nose, cutting

& combination

Q7. What do you meant by RPM? Revolutions per minute

Q8. What is the function of chisel? Cutting metal pieces

Q9. What is the function of screwdriver? According to length of a bit

Q10. Why we use flexible wires? Increasing the length of the

supply cable

EXPERIMENT -2

AIM: Two make a T joint of Copper 1/18 SWG wire and straight joint of 3/22 SWG wire.

APPERATUS USED: Side-cutting plier, 1/18 SWG and 3/22 SWG wires.

THEORY:

T-JOINT :It is used to tape the connection from running horizontal line. It is also known as

parallel joint.

STRAIGHT JOINT: it is used to increase the length of the 3 standard wires.

PROCEDURE: T JOINT

1. Take 2 horizontal and vertical lengths of wires 30cm and 20cm respectively to which the

joint is to be made.

2. Remove the insulation of taping vertical length of 7.5cm

3. Remove the insulation of straight length middle portion

4. Remove the insulation of 12mm on each side of the base wire.

5. Hold the wire at 90 to running and make a neck turn to void slipping of joint

6. Wrap off conduction closely and tightly 6-8 turns on horizontal wire.

7. Round off the conductor with the help of a plier.

8. The joint is soldered and insulated with tape.

CIRCUIT DIAGRAM:

(3)

(1)

(4)

(2)

STRAIGHT JOINT:

1. Cut two pieces of cable of nearly the same length.

2. Remove the insulation from the end of both the cable pieces.

3. Separate the wire from both the cables and join the 2 cables in such a way that the

individual wires are joint separately

4. For half of the length of the di-insulated cable overlapped make a trust with the help of a

plier.

5. Complete the remaining half-length on the twist with the help of a plier.

CIRCUIT DIAGRAM:

(1)

(2)

(3)

(4)

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly.

5)

QUIZ/ ANSWER

Q1. Why we make a T joint? To tap the supply

Q2. What does you meant by 3/22 SWG? 3 wires &22 is the diameter of

the wire

Q3. What is the application of straight joint? Increase the length of the wire

Q4. What is the main precaution to make the joints? Tight and properly Insulated

Q5. Which joint we use for tap connection from

horizontal line?

T-joint

Q6. Which tool is used for twisting the wires? Plier

Q7. Which joint is used for Fan connection? T-joint

Q8. What is swg. Of earthing wire? 1/18 SWG

Q9. How we increase the length of conductor? Straight joint

Q10. What is the function of a cutter? Cutting cables

EXPERIMENT -3

AIM: To study staircase wiring.

APPARTUS: 3/22 SWG wires, lamp holders, two way switch, 40w bulb 3

PVC casing, strips and pliers.

THEORY: It is that wiring which makes use of 2 switches to operate bulb at the beginning of

the stair lights and the bulb gives off by pushing the button in the end. One of the terminals of

the bulb is connected to the main line whose power line is connected to middle slot of two-way

switch. Remaining first of there slots is connected in parallel as in crossed node.

CIRCUIT DIAGRAM:

(1)

(2)

(3)

(4)

PROCEDURE:

1. Plan the wiring and casing according to the circuit diagram.

2. With the help of plier and stripper share the ends of wire of required length.

3. Connect the wire carrying the current to the central pin of the two-way switch.

4. Connect the remaining ends A and B to the corresponding other two way switch.

5. Connect the center pin wire of second two-way switch to the lamp.

6. Connect the second point to the neutral for completing the circuit.

7. Use PVC case wiring to cover expose wiring.

8. Switch ON and OFF the two switches alternatively to the bulb.

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly.

QUIZ/ANSWER

Q1. Which type of switch we use in stair case wiring? Two way switch

Q2 What do you meant by CTS? Tough Sheath

Q3. Where we use two-way switches? Staircase wiring & long

godown

Q4. Which tools are used for wiring? Plier, cutter,

screwdriver, hammer.

Q5. What is TW batten? Teak Wood Batten

Q6. What is the main precaution for staircase wiring? No connection should be

naked

Q6. What is the function of saw? Cutting sheet, wood &

pipes

Q7. What is the link clips? Holding wires

Q8. Where we use three pin plugs? Connecting the load

Q9. What is the function of megger? Measure insulation of

cable

Q10. What do you meant by 3/22 3- wires & 22gauge of

wire

EXPERIMENT 4

AIM: To study hose wiring.

TOOL USED: Tenon saw screwdriver 8 cm (8), Screwdriver 15(6), connector Screwdriver, Hammer, Plier

drill machine, Try square, chisel, File, Poker knife.

MATERIAL AND QUATITY:

1) T.W Batten 19mm x 13mm 42m

2) T.W batten 13mm x 13mm 10m

3) CTS/ T.R.S wire 13/. 039(3/22) 250v

4) Batten holder 2 no.

5) Plug 3pin, 5amp 1 no.

6) Tumbler Switch one-way 5amp 3 no.

7) T.W round blocks (7.75cm x 2.5) 3 no.

8) T.W board 40 mm(1+1/2)

9) Hink clip 40 mm(1/2)

10) Wood Screw

THEORY: This type of wiring is used in houses. The two terminal of supply are connected to

meter and other two terminals are joined to DPIC. One end is attached to N-link of fuse is joined

to switch board of a room and neutral pole is also connection to switch board according to our

need.

CIRCUIT DIAGRAM:

LAMP

12

N

P

TWO WAY SWITCH

TWO WAY SWITCH

TYPES OF HOUSE WIRING:

1) CLEAT WIRING: - This is of wiring suitable only for temporary wiring purpose. In lamp

or wet location the wire used should be moisture proof and a weather proof.

2) P.V.C OCNDUCT WIRING:- This uses a conduit pipe for the mechanical protection of

wire. In this system of wiring, wires are carried through P.V.C conduit pipe for giving

converging to pipes conduit pipe has certain advantage like it is moisture proof and durable.

3) P.V.C CASTING WIRING: -This type of wiring is mostly used for fixing cables on a

wooden structure called batten by means of metal. It is the surface wiring system whenever

wires are broken for connecting to switch on the right point junction box made up of either

part plastic or metal C.I must be used and provided same means of earthing.

4) P.V.C CASTING WIRING: -This type of wiring is mostly used for indoor and domestic

wiring carried through a P.V.C casing wiring

PROCEDURE:

1) Draw the tangent or wiring on the board with cholk.

2) Cut the required length of T.W batten file and link chips on then and file the batten with

screw of 3mm size.

3) Cut the C.T.S wire in required length and put them on batten gripped by link chips or per

circuit diagram.

4) Fix the T.W round blocks and board after drilling the holes for wire.

5) Fix the batten holder, 3-pin plug and switch on round block.

6) After completing wiring it should be checked before supplying current.

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly.

QIUZ/ANSWER

Q1. How much voltage in a single-phase supply? AC 230 volt

Q2. What do you meant by DPIC? Double pole iron clad

Q3. What is the bus bar? To take many connections

Q4. How we represent the lamp?

Q5. Why we use regulator? To regulate supply voltage

Q6. What is the max. Load on a switchboard? 10 switches or 1000W

Q7. What is MCB? Miniature circuit breaker

Q8. What is cleat wiring? Used for moist wiring

Q9. What is the colour code of wiring? R-Y-B phase

Q10. What do you meant by PVC? Polyvinyl chloride

EXPERIMENT 5

AIM: To study fluorescent tube light.

APPARATUS: tube, tube base, starter, choke, and wire.

CONSTRUCTION: Fluorescent tube is a low-pressure mercury vapour lamp. The lamp is in the

form of long glass tube due to low pressure, with fluorescent powder coating to its inner surface.

Tungsten filaments coated with barium oxide are placed at each side of the tube. The tube

contains small amount of mercury with small quantity of argon gas at low pressure. When the

temperature increases mercury changes into vapour form. At each end of the tube, electrode in

spiral form is made of tungsten coated with electrons emitting barium. A capacitor is connected

across the circuit to improve the power factor.

CIRCUIT DIAGRAM:

PROCEDURE:

1. Fix the tube holder and the choke on the tube base.

2. Phase wire is connected in the choke and neutral direct to the tube.

3. Fix the fluorescent tube between the holders.

4. Finally connect the starter in series with the tube.

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly

TUBE ELECTRODES

STARTER

CHOKE

N

230V

SUPPLY

C

P

QUIZ/ANSWER

Q1. What is the standard dia. of the tube light? 25 mm

Q2. Which material is used for coating the tube? Argon gas or neon

Q3. Which gas is used in tube light? Zinc silicate cadmium

silicate.

Q4. What are the standard lengths of tube light? 6m, 1.2m and 1.5m.

Q5. What is the function of starter? Yes, by shorting the two

wires temporarily.

Q6. Why we use choke in tube light? To supply high voltage

during starting

Q7. Name any two types of the starter? Glow type, thermal type.

Q8. How much power consumed by the tube light? 40 watt approximately.

Q9. At which supply the tube is operated? 230 volt ac

Q10. Can we start the tube light with out a starter? To complete the circuit

initially

EXPERIMENT-6

AIM: To study High Pressure Mercury Vapour (HPMV) Lamp.

APPARATUS: HPMV lamp, connecting wires.

THEORY: Light could be of different colours depending upon the wavelength of radiation

falling on material. A HPMV lamp contains mercury at high pressure in a highly evacuated tube.

It is basically based on the discharge tube phenomenon under which electric discharge through

gases takes place at some pressure and perceived as light by our eyes.

The pressure inside the inner tube is 1-2 times of mercury column. A capacitor and choke are

connected in the outer circuit. Chokes function is to limit the current to safety limit, capacitor

increases power factor.

The cause for colour is due to the collision between charged particles and atoms that excite gas

atoms and the gas atoms while returning to the ground state emit light of colours characteristics

of the wavelength of the radiations emitted.

CIRCUIT DIAGRAM:

STARTING ELECTRODE

MAIN ELECTRODE

RESISTANCE

OUTER TUBE

C

P

230V

SUPPLY

N

PRECAUTIONS:

1.It can only be used in vertical position.

2.It can be used on AC supply.

3.It takes some time to give full light.

4.Wattage of choke and bulb should be same.

5.It is available at 80, 125, 250, 400 and 1000watts etc

QUIZ/ANSWER

Q1. How many tubes in HPMV lamb? Two- inner & outer

Q2. What do you meant by HPMV? High Pressure Mercury Vapour Lamp

Q3. Which gas is filled in inner tube of lamp? Neon or Argon

Q4. What is the pressure of gas? 50-60mm Hg

Q5. Starter is used or not in HPMV lamp circuit? Yes in the form of igniter

Q6. What is the wattage of HPMV lamp? 200-250 watt

Q7. What is the lumen efficiency of HPMV lamp? 30-40 lumens per watt

Q8. How much average life of lamp? 5000 working hours

Q9. Where we use the HPMV lamp? High ways, Airports, Stadium and

Railway yards

Q10. How much time HPMV lamps take to glow? Low pressure

EXPERIMENT -7

AIM: To study Sodium Vapour Lamp.

THEORY: Sodium vapuor lamp consists of an inner tube (made of special sodium vapor

resistant glass) housing two tungsten electrode, which are connected across an autotransformer.

Inner U tube containing neon gas at a pressure of about 10mm Hg and a small amount of sodium.

Inner U tube is well insulated in order to conserve the heat required to vaporize sodium.

CIRCUIT DIAGRAM:

MAIN ELECTRODE

P

INNER TUBE

CHOKE

220V AC

SUPPLY

OUTER GLASS

N

HIGH LEAKAGE

REACTANCE

AUTOT/F

CAPACITOR

WORKING

The sorting is effected by means of high leakage autotransformer, which delivers an open circuit

voltage of about 450-480 V, which is sufficient to initiate the discharge through the neon gas.

After a few minutes, the heat discharge through the neon gas becomes sufficient to vapuorise

sodium; the lamp starts its operation, emitting yellow light. The static capacitor improves the P.F

of the circuit.

CHARACTERISTICS:

1. It has a yellow glow having a temperature of 270C

2. Its average life span is about 6000working hours.

3. Its efficiency is high (about 110 lumen/watt).

4. Its takes little time to completely glow to its maximum value and cant is switched ON

immediately after switching it OFF.

5. The lamp should be operated only horizontally, so that hot sodium doesnt

collect at one end

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

5) Wire should be on the conduit, power gripped properly

QUIZ/ANSWER

Q1. What do you meant by SVL? Sodium Vapour Lamp

Q2. How many electrodes in SVL. Two Electrodes

Q3. Which gas we used in this type of lamp. Neon gas

Q4. Which material used for electrodes. Tungsten material

Q5. Which colour of light it produces. Light Yellow

Q6. What is the life time of this lamp? 6000 Working hours

Q7. How it hangs vertically or horizontally? Horizontally

Q8. Its power factor is low or high? Low power factor

Q9. What is the operating temp. of this lamp?

270 C

Q10. What is the pressure of gas? 10mm Hg

EXPERIMENT-8

AIM: To study the single phase induction motor using one phase energy meter, (DPIC) Double

pole iron clad main switch.

APPARATUS REQUIRED: Single phase squirrel caged induction motor, insulated comb,

plier(20cm), screw driver with insulated handle, series testing lamp, voltmeter, connecting wires

3/22 PVC wire, wire brush, spanner, etc.

THEORY: The most common type of electric motor is the single- phase type, which finds wide

domestic, commercial and industrial applications. Single phase motors are small- size motors

of fractional kilowatt applications. Single phase motors are small size motors of fractional

kilowatt ratings. Domestic appliances like fans, hair driers, washing machines, vacuum

cleaners, mixers, refrigerators, food processors and other kitchen equipment employ these

motors. These motors also find applications in air- conditioning fans, blowers, office machinery,

small power tools, dairy machinery, small farming equipment etc.

Single- phase motors are classified as follows:

1) Induction motors

2) Commentator motors

3) Synchronous motors

CIRCUIT DIAGRAM:

DPIC

1 PHASE

ENERGY METER

N

1 PHASE

SUPPLY

M

P

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly

QUIZ/ANSWER

Q1. In which unit we measure the readings of energy

meter?

KWH

Q2. How much voltage is providing to 1--phase inductor

motor?

AC 220 volt

Q3. At which P.F. of induction motor works? 0.6 Lagging

Q4. What is the name of rotatary part of motor? Rotor

Q5. Which material of coils we used in motor? Copper

Q6. What is DPMS? Double pole main switch

Q7. Which energy meter is used for single-phase induction

motor?

single phase meter

Q8. A.C. supply is given to which part of motor stator or

rotor?

Stator

Q9. What are the main parts of induction motor? Stator, Rotor, Yoke, Field,

Winding

Q10. What is function of Yoke? To protect motor

EXPERIMENT- 9

AIM: To study three-phase induction motor using three phase energy meter, TPIC (Tripple Pole

Iron Clad) Switch & DOL (Direct On Line) starter.

APPARATUS REQUIRED: A three-phase induction motor, energy meter, triple pole

main switch, direct on line starter.

THEORY: Three-phase induction motor is the most popular type of a.c. motor. It is very

commonly used for industrial drives since it is cheap, robust, efficient and reliable. It has good

speed regulation and high staring torque. It requires little maintenance. It has a reasonable

overload capacity.

A three- phase induction motor essentially consists of two parts: the stator and the rotor. The

stator is the stationary part and the rotor is the rotating part. The stator is built up of high grade

alloy steel laminations to reduce eddy current losses. The laminations are slotted laminations

are supported in a stator frame of cast iron or fabricated steel plate. The insulated stator

conductors are placed in these slots. The stator conductors are connected to from a three- phase

winding. The phase winding may be either star or delta connected.

The rotor is also built up of thin laminations of the material as stator. The laminated cylindrical

core is mounted directly on the shaft or a spider carried by the shaft. These laminations are

slotted on their outer periphery to receive the rotor conductors. There are two types of induction

motor rotors:

(a) Squirrel cage rotor or simply cage rotor.

(b) Phase wound or wound rotor. Motors using this type of rotor are also called slip- ring

motors.

CIRCUIT DIAGRAM:

PRECAUTIONS:

1) Tools should be used carefully.

2) Fitting should be tightly fitted.

3) Connection should be tight.

4) Wire should be on the conduit, power gripped properly

QUIZ/ANSWER

Q1. How much voltage in 3-phase AC supply? 440 Volts A.C.

Q2. What do you meant by DOL? Direct online starter.

Q3.

Which type of energy meter we used for 3-phase

supply?

3-0 energy meter

Q4. What do you meant by TPIC switch? Tripple pole iron clad switch

Q5. Where we use squirrel cage type motor? Industrial purpose

Q6. Name two types of I.M.? Squirrel Cage and phase

wound type

Q7. Up to which rating we use DOL starter? Up to 5 HP

Q8. What is the main function of slots? To receive the windings

Varnish & Sleeves

Q9. Name any two laminations? Varnish & Sleeves

Q10. What do you meant by (a) OLRC

(b) NVRC

Over load release coil

No volt release coil

EXPERIMENT- 10

AIM To study repairing of home appliances such as heater, iron and fans

APPARATUS REQUIRED Electric Heater, fan, electric iron, screw driver, pliers, tester etc.

THEORY Electric Heater consists of cast iron plate housing. The heating element of micron,

wire embedded in heat resistant insulated material likes a fire clay element. It takes less time to

get heated up then retain heat for a longer time after switching off the power supply. The usual

rating of hot plate is 1KW or 2 KW.

Heaters are of two types

Table heater: It consists of four parts: base of the heater, the heating plate (made up of cast iron),

circular in shape made up of china clay in which grooves are provided

Room Heater: It consists of stand made up of casted MS steel reflector with metal plate to reflect

more heat and connection of brass and copper.

S.No.

1.

2.

3.

Defects

Short Circuit on Heater

Defects in plug

Change in length

Remedies

Remove Short Circuit

Change the plug

Check the length of wire

Defects and remedies for electric iron(press)

S.No.

1.

2.

Defects

Iron doesnt work after

supply is on.

Iron gives shock due to

mica part of the element,

may get short circuited

Remedies

There must be damage of

wire if somewhere circuit

is open

Repair the element to

check the contact strip.

Defect and Remedies for electric fan

S.No.

1.

Defects

Fan dosent work even

after the supply is on.

Remedies

Check for switch socket,

capacitor.

QUIZ/ANSWERS

Q1.

Names some home appliances? Electric Heater, Fan, Iron etc.

Q2. What material we used in heating

element of a heater?

Nicrome

Q3.

What is resistance of heating element? .High resistance

Q4.

What is the voltage of Hot plate in

heater?

1 to 2 kilo watt

Q5. What are the types of heaters? Table heater and Room heater.

Q6. What is the plating on reflection of

room heater?

Chromium

Q7. What is the rating of ceiling fan? 35 to 80 watt

What is the insulating material in

iron?

Mica

Q9. Which motor is used in fan? 1 Phase induction motor.

Q10. What is the function of thermostat in

iron?

For automatic switching OFFand

ON.

Você também pode gostar

- Course Outline-EE360 Control Systems Spring 2020Documento5 páginasCourse Outline-EE360 Control Systems Spring 2020Shoaib MughalAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- How To Write A Letter of MotivationDocumento1 páginaHow To Write A Letter of MotivationShoaib MughalAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Assignment # 2 Chapter # 2 & 3 Control SystemsDocumento1 páginaAssignment # 2 Chapter # 2 & 3 Control SystemsShoaib MughalAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- EEG Based Machine Control: Department of Electronics and Communication EngineeringDocumento4 páginasEEG Based Machine Control: Department of Electronics and Communication EngineeringShoaib MughalAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- 09 Clippers & ClampersDocumento6 páginas09 Clippers & ClampersJian LastinoAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- FYP - 1 ReportDocumento10 páginasFYP - 1 ReportShoaib MughalAinda não há avaliações

- Chapter 4Documento39 páginasChapter 4Shoaib MughalAinda não há avaliações

- Engineering ManagementDocumento26 páginasEngineering ManagementShoaib MughalAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Measurement of Power and EnergyDocumento2 páginasMeasurement of Power and EnergyShoaib MughalAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Milling: VFT RPM DinDocumento3 páginasMilling: VFT RPM Dinhammada1001Ainda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- M.shoaib Matlab Assignment 3bDocumento15 páginasM.shoaib Matlab Assignment 3bShoaib MughalAinda não há avaliações

- Power Factor and Power Factor CorrectionDocumento8 páginasPower Factor and Power Factor CorrectionShoaib MughalAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

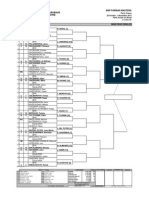

- BNP Paribas Masters: Main Draw SinglesDocumento1 páginaBNP Paribas Masters: Main Draw SinglesShoaib MughalAinda não há avaliações

- Principle of LVDTDocumento3 páginasPrinciple of LVDTShoaib MughalAinda não há avaliações

- Cryogenic Insulation TechnologyDocumento61 páginasCryogenic Insulation Technologyeduard.turon100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Energy and FluctuationDocumento10 páginasEnergy and Fluctuationwalid Ait MazouzAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- CON21 6th EditionDocumento65 páginasCON21 6th EditionDavid WeeAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- MCQ Unit 3Documento15 páginasMCQ Unit 3gaur1234Ainda não há avaliações

- German Din Vde Standards CompressDocumento3 páginasGerman Din Vde Standards CompressYurii SlipchenkoAinda não há avaliações

- Commissioning/Troubleshooting: Check List: C B A Yellow Grey Black TBPDocumento2 páginasCommissioning/Troubleshooting: Check List: C B A Yellow Grey Black TBPmohamedAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Prince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyDocumento1 páginaPrince Hydraulics Wolverine Adjustable Flow Control Valve Offered by PRC Industrial SupplyPRC Industrial SupplyAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1091)

- Elevator ControlDocumento3 páginasElevator ControlNATHANAinda não há avaliações

- ISNGI 2017 ProgrammeDocumento6 páginasISNGI 2017 ProgrammeJoanna JohnsonAinda não há avaliações

- Radiant ThinkingDocumento4 páginasRadiant Thinkingeehwa88Ainda não há avaliações

- Telmisartan, ISMNDocumento8 páginasTelmisartan, ISMNDenise EspinosaAinda não há avaliações

- Schueco+FW+50+SG+ +FW+60+SGDocumento1 páginaSchueco+FW+50+SG+ +FW+60+SGDaniel Nedelcu100% (1)

- Trucks Fin Eu PCDocumento117 páginasTrucks Fin Eu PCjeanpienaarAinda não há avaliações

- BookDocumento28 páginasBookFebrian Wardoyo100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Mathematics Specialist Unit 3A: VectorsDocumento4 páginasMathematics Specialist Unit 3A: VectorsMahir MahmoodAinda não há avaliações

- Board of Technical Education Uttar Pradesh Lucknow: CODE 2298Documento2 páginasBoard of Technical Education Uttar Pradesh Lucknow: CODE 2298Md Shaaz100% (1)

- Kyocera 1800Documento2 páginasKyocera 1800gendoetzAinda não há avaliações

- The Effective SpanDocumento4 páginasThe Effective SpanMohamed FarahAinda não há avaliações

- Compaction - AsphaltDocumento32 páginasCompaction - Asphaltrskcad100% (1)

- Mechanical Smoke Ventilation Calculations For Basement (Car Park)Documento7 páginasMechanical Smoke Ventilation Calculations For Basement (Car Park)Mahmoud Abd El-KaderAinda não há avaliações

- Manual Placa Mae Ga 945gcmx-s2 6.6Documento72 páginasManual Placa Mae Ga 945gcmx-s2 6.6luisb3toAinda não há avaliações

- TM TC For NanosatelliteDocumento4 páginasTM TC For NanosatelliteSreeja SujithAinda não há avaliações

- Tycho BraheDocumento3 páginasTycho BraheAienna Lacaya MatabalanAinda não há avaliações

- Air Quality Index Analysis & PredictionDocumento34 páginasAir Quality Index Analysis & PredictionGottumukkala Sravan KumarAinda não há avaliações

- GROUP1 MicroscaleDocumento3 páginasGROUP1 MicroscalefsfdsAinda não há avaliações

- r315 Quick Start PDFDocumento80 páginasr315 Quick Start PDFfdsfasdsfadsAinda não há avaliações

- Proyector SNF 111Documento3 páginasProyector SNF 111Liliana Patricia PederneraAinda não há avaliações

- BOQ For Softscape and Hardscape Bendungan Karian-3Documento23 páginasBOQ For Softscape and Hardscape Bendungan Karian-3greenorchidresidenceAinda não há avaliações

- Ace of Spades + Outlaw 125 2019Documento85 páginasAce of Spades + Outlaw 125 2019Nelson RodrigoAinda não há avaliações

- Morality Speaks of A System of Behavior in Regards To Standards of Right or Wrong Behavior. The WordDocumento3 páginasMorality Speaks of A System of Behavior in Regards To Standards of Right or Wrong Behavior. The WordTHEO DOMINIC REQUERME SILVOSAAinda não há avaliações