Escolar Documentos

Profissional Documentos

Cultura Documentos

Canadian Steel Codes IP 10-5

Enviado por

jackapisit0 notas0% acharam este documento útil (0 voto)

311 visualizações18 páginasCanadian Steel Codes IP 10-5

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoCanadian Steel Codes IP 10-5

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

311 visualizações18 páginasCanadian Steel Codes IP 10-5

Enviado por

jackapisitCanadian Steel Codes IP 10-5

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 18

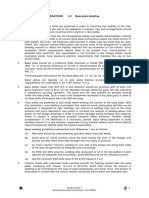

As described above there are recommended values for

steel strength which can be used in absence of more

detailed information available. The summary of chrono-

logical research summarized above clearly supports the

default value selection. The default value of steel

strength is yield strength of 210 N/mm and ultimate

strength of 380 N/mm . If the welded connections are to

be used, it is important to carry out chemical analysis of

steel to determine its weldability. Caution should be

exercised when the unidentified steel is to be used on a

project for rigid and braced frames member in seismic

zones. When the frame is designed for seismic load with

reduction factor R of 2 or greater, the accurate determi-

nation of yield strength is very important as it control

structural behaviour of a frame.

Codes and Standards

Although, the codes and standards are focusing on

new materials and new construction, their scope

accommodates reused material and adaptive building

reuse. They may not be as specific as designers would

like, but they give a sufficient framework which can be

followed. The codes and standards should not be seen

as an obstacle to material reuse and adaptive building

reuse. Certainly, with the emergence of new set of

objective based codes, it will be easier in the future to

develop innovative solutions.

ConcIusion

Over the period of last 35 years there have been signifi-

cant changes in loading. Very important was the emer-

gence of the limit state approach to design in 1980?s in

the NBC. New material standards since then started to

adopt the limit states approach leading to full adoption of

this design philosophy. Typically, the working stress

steel design underestimates the capacity of the section

by around 10% when compared with the ultimate design

strength for the same grade of steel. As deflection crite-

ria often govern the selection of sections for non-

composite steel construction, both approaches yield the

same section. Therefore, there should not be a problem

when checking a steel section today which was

designed to working stress design provided there were

no changes to design loads.

The first NBC was issued in 1941 which in many

instances provided only guidance to load determination.

The occupancy loads provided for in this code are quite

similar to the current practice. One wind pressure is

given for all locations. Its value is significantly greater for

low rise buildings but generally satisfactory for most of

the locations. The seismic provisions on the NBC 1941

are very general and generally inadeq uate. Between

1941 and 1970, the code has been republished four

times with snow, wind and earthquake loads being more

defined as well as climatic data building more readily

available (shift from contour maps to tables). The load

due to snow is generally greater than today's standards.

Wind loads continue to be overestimated for low rise

buildings.

1. General requirements

Steel-Reuse Information Paper No.4

www.reuse-steel.org

The Ontario Building Code (OBC) 1997 has additional

provisions which deal with existing buildings. Part 10 of

the OBC deals with performance requirements related

to change in use. Part 11 deals with Renovation. This

part considers extensively the issue of fire safety result-

ing from change in use and increase in occupant load.

It does not require a change in performance level in the

case of alteration or repair which is consistent with the

original design intention and use. However when the

occupancy load is increased, this code requires reme-

dial action to support the extra loads, although it

accepts postings of restricted loading requirements for

a portion of a floor.

The NBC 2005 has adopted a different, objective based

approach. It specifies the objectives which the code

aspires to achieve and in a separate division it describes

how these can be met. There are no longer firm require-

ments which designers have to comply with. This

approach will result in a significant change in the build-

ing approval process and the mind set of the building

officials. There is no longer the norm and prescriptive

solution but the designer has the freedom to address the

objectives of the code and provide relevant documenta-

tion. This should make the approval process for innova-

tive or non-standard construction far more readily

achievable.

CSA, (1960), CSA G40.8, Structural Steels with Improved Resistance to Brittle Fracture. Canadian Standards

Association, Canada.

CSA, (1959), CSA G40.7, Steel Sheet Piling. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966.), CSA G40-6, Structural Silicon Steel. Canadian Standards Association,

Canada.

Further Information

CSA, (1950, 1959, 1963, 1966), CSA G40-5, Carbon steel plates of structural quality, Plates 2" and under in

thickness. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-4, Medium Structural Steel. Canadian Standards Association,

Canada.

CSA, (1959, 1963, 1966.), CSA G40-3, Structural steel for locomotives and cars. Canadian Standards Associa-

tion, Canada.

CSA, (1950), CSA G40-3, Mild Structural Steel. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-2. Structural Steel Rivets. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-1 to G40-6, General requirements for delivery of rolled steel plates,

shapes and bars for structural use. Canadian Standards Association, Canada.

CSA, (2000), CAN/CSA-S6-00. 2000. Canadian Highway Bridge Code. CSA, Ca.

CSA, (2001,2003), CAN/CSA-S16-01. - Limit States Design of Steel Structures. Canadian Standards Associa-

tion, Canada.

CSA, (1964), CSA G40.12, General Purpose Steel. Canadian Standards Association, Canada.

CSA, (1971, 1973, 1976, 1978, M1978, M81, 87, 98, 04), CSA G40.20/G40.21. General Requirements for

Rolled or Welded Structural Quality Steel/ Structural Quality Steel. Canadian Standards Association, Canada.

NRC. (1953,1960, 1965, 1970, 1975, 1977, 1980, 1985, 1990, 1995, 2005). The National Building Code of

Canada. NRC, Ottawa, Canada.

NRC. (1996). User's Guide - NBC 1995: Structural Commentaries (Part4). NRC, Ottawa, Canada.

Bussell, M. (1997). Appraisal of Existing Iron and Steel Structures. SCI 138. The Steel Construction Institute,

Silwwod Park, Berkshire, UK.

CISC, 2004. Handbook of Steel Construction. Eighth edition. CISC & Quadratone Graphics Ltd, Toronto,

Canada.

2. Loading

The NationaI BuiIding Code

History of steeI

as refIected in standards

The reason for this research work arose as a result of

interviews and surveys of the professionals associated

with steel industry which suggested that there is a concern

that the main difficulty when reusing steel is the problem

of identification of steel and its structural properties.

Another issue which was brought up was related to the

approval by building officials. It was decided that the

investigation will be done to look into the national codes

and steel standards to trace the evolution and identify

potential problems, and ways to establish the characteris-

tics of old steel.

Although national standards and codes encourage new

construction and use of new materials, the National Build-

ing Codes (NBC) definition of the scope includes "altera-

tion, reconstruction, demolition, removal, relocation and

occupancy of existing buildings". Not only does the scope

reiterate the application to old construction and new /

different materials, but it has contained the following

clause since 1985 - "Unless otherwise specified, used

materials, appliances and equipment are permitted to be

reused where they meet the requirements of this Code for

new materials and are satisfactory for the intended use". It

should be noted that equivalence is defined for materials

and components failing to comply with Part 4 and past

performance, tests (for structure a full-scale test) or model

analogue are accepted.

The third revision of the 1990 NBC included for the first

time the relationship between NBC and other standards,

testing and certification organizations, defining for design-

ers authorities which can assist them to determine equiva-

lencies. The 1995 Code was accompanied by the Struc-

tural Commentaries on the National Building Code of

Canada 1995 which for the first time included a section

entitled "Application of NBC Part 4 for the Structural

evaluation and Upgrading of Existing Buildings", assisting

designers to deal with issues related to buildings designed

to previous codes in the context of Part 4. This document

is very important as it recognizes the shortcomings of Part

4 of the NBC with its focus on new construction (new or

addition) and the lack of its application to existing build-

ings which may contain a structural system or materials

no longer in use.

Used materials and systems are permitted if they

comply with the NBC requirements for new construction.

There is reasonable freedom given to designers to

prove equivalency but the problem is that it is a depar-

ture from the prescriptive, requirement based process.

The non-prescriptive approach challenges building

department officials leading to inconsistent interpreta-

tion and varying attitudes and requirements. From the

designer's point of view it results in uncertainty about

what may be required and acts as a deterrent to taking

an alternative design approach.

1. Review of steel properties

It should be noted that the chemical composition of "old"

steel is very similar irrespective of its origin.

CAN/CSA-S16-01 (5.2) considers steel suitable for

building construction only if its properties can be identi-

fied by a mill or producer certificate or a colour marking

which is defined in all the structural steel standards

above. The two main alternatives which are open to the

designer who wants to reuse steel components without

documentation are to approve steel and use the

prescribed properties (yield strength of 210 N/mm and

ultimate strength of 380 N/mm ) or to have a testing

agency carry out tests to determine the mechanical and

chemical properties and thus identify the steel. Once

the steel type is identified, the minimum values of yield

and ultimate strength given in the product specifications

for that type of steel (not actual tested values) must be

used. It should be noted that the determination of

2

3

2

2

2

introduced carbon content (previously ladle analysis

done by the manufacturer checked the carbon content),

while phosphorus and sulphur remained unchanged,

and further introduced limits on manganese and silicon.

The maximum carbon content decreases with the

increased steel strength. The next major revision of

CSA-G40.21 was in 1973. The metric version was pub-

lished in 1981. This revision covered a wide range of

steel strengths and the types described above. The

2004 version of CSA-G40.21 is similar to the 1981

version in terms of strengths but the general construc-

tion steel type was eliminated and corrosion resistant

weldable and notch-tough steel, and quenched and

tempered low alloy notch-tough steel types were add-

edIt should be noted that all standards dealt with steel

marking using colour codes to identify different steels.

This is important for mills but through the fabrication

process the marking gets lost.

It should be noted that the Canadian Highway Bridge

Code CAN/CSA-S6-00, Section 14.6 may be used as

guidance. Besides identification of steel using project

documentation including the mill certificates, the Code

offers alternative approaches, namely: testing of

samples to identify steel and use the minimum product

specifications; selecting yield and ultimate strength from

a given table based on the year of construction; or more

rigorous testing described in that standard which

includes the procedure for the evaluation of test result

and strength determination. Table 2 gives the estimation

of properties of structural steel by the age of construction

which are recommended by S6 in the absence of more

specific information.

chemical composition to determine its weldability may

be more important than its strength. A third alternative is

an affidavit from the fabricator stating that the fabricated

material conforms to material specifications.

Table 1 Properties of steel in Canadian history

From CAN/CSA-S6-00.

Table 2 Properties of steel by the age of construction

2)

2)

1)

From CAN/CSA-S6-00, Canadian Highway Bridge Code

Recommendations

The most significant changes are related to modifica-

tions in seismic loads and snow loads. The major impact

on the adaptive reuse of buildings designed before 1985

are the seismic loads. The previous code (NBC 1980)

was based on peak horizontal acceleration and seismic

contour map from 1970 with probability on 0.01 per

annum. The 1985 NBC included a new zoning map,

including both, peak accelerations and peak velocities

and increased probability of 10% in 50 years. Other

changes included the treatment of seismic load by limit

state design approach. The load factor for seismic load

since 1990 equals to 1.0. What this means for adaptive

reuse is that all buildings designed prior to adoption on

the 1980 NBC will require seismic retrofit and buildings

designed prior to 1970 in some locations were not

Steel components have great potential for reuse. The

knowledge of steel history is important for the designer

if reuse of components is to be adopted. The first Cana-

dian steel code for buildings (C.E.S.A. S16) dates from

1935 and remained in place until 1948. The steel which

is described in that code is mild and medium steel

(governed by C.E.S.A.-S40). This latter standard after

1950 became the CSA - G40.x series. Carbon steel for

plates and silicon steel appeared after the Second

World War in addition to the original mild and medium

steel which was used until 1964 (see Table 1). The

injection of preheated oxygen rather than air into the

modified Bessemer furnace and electric arc steel-

making processes, led to better quality and the emer-

gence of higher strength steels. Several types have

appeared: general construction steel, weldable steels

(regular and low temperature), corrosion resistant steels

(regular and with improved low temperature properties),

and quenched and tempered low alloy plates. The

chemical analysis in CSA-G40.21 1964 for the first time

The 1990 NBC introduced the rain components of snow

load and the ground snow load was changed (generally

for most areas ground snow load decreased) as well as

the default snow density was increased from 2.4 kN/m

to 3.0 kN/m3. This had a minor impact on the magnitude

and the extent of snow accumulation on lower roofs

adjacent to higher buildings. Since 1995, the snow

accumulation was typically decreased in recognition of

the fact that the amount of snow on upper is limited by

the size of the upper roof and there is often not enough

snow to fill the step. The extent of the lower roof zone

impacted by snow accumulation increased. Generally,

there should not be a problem resulting from snow load-

ing if a component or building remains in the same geo-

graphical location.

designed for seismic load at all or much smaller load.

Post 1990 buildings comply with current code seismic

provisions. When comparing the current maximum seis-

mic shear to the 1985 NBC, for ductile design, the

design shears are almost identical, however for nominal

ductility or non-ductile detailing, the 1990 and subse-

quent NBC result in greater loads, 40% and 36%

respectively.

If the components are older than 70 years (prior to

1935), there are potentially other materials than steel

available, such as cast and wrought iron, and it is more

difficult to assess the properties. The following refer-

ences are recommended:

ASTM Standards A7 and A9.

The publication "Appraisal of existing iron and

steel structures" by The Steel Construction Insti-

tute of the United Kingdom [Bussell, 1997].

CAN/CSA-S6-00 (Canadian Highway Bridge

Code).

FACILITATING GREATER REUSE AND RECYCLING OF STRUCTURAL STEEL IN THE CONSTRUCTION AND DEMOLITION PROCESS

Action Plan 2000

on Climate Change

www.reuse-steel.org

This information paper was prepared by Vera Straka at the Department of ArchitecturaI Science, Ryerson

University, with support from the Enhanced Recycling component of the Government of Canada Action Plan 2000

on Climate Change, Minerals and Metals Program and by the Canadian Institute for Steel Construction (CISC).

Period

Pre - 1905

1)

1905 - 1935

1)

1935 - 1964

1964

- 1973

1973 - 1981

From 1981

Yield Strength

N/mm

2

180

210

186

227

303

230

480

260

480

Tensile Strength

N/mm

2

360

360

344 - 427

413 - 497

427

380

- 500

590 - 790

410 - 590

590

- 790

Date of bridge construction

Specified

Fy, MPa

Specified

Fu, MPa

Before 1905

1905 - 1932

1933 - 1975

After 1975

180

210

230

250

360

420

420

420

As described above there are recommended values for

steel strength which can be used in absence of more

detailed information available. The summary of chrono-

logical research summarized above clearly supports the

default value selection. The default value of steel

strength is yield strength of 210 N/mm and ultimate

strength of 380 N/mm . If the welded connections are to

be used, it is important to carry out chemical analysis of

steel to determine its weldability. Caution should be

exercised when the unidentified steel is to be used on a

project for rigid and braced frames member in seismic

zones. When the frame is designed for seismic load with

reduction factor R of 2 or greater, the accurate determi-

nation of yield strength is very important as it control

structural behaviour of a frame.

Codes and Standards

Although, the codes and standards are focusing on

new materials and new construction, their scope

accommodates reused material and adaptive building

reuse. They may not be as specific as designers would

like, but they give a sufficient framework which can be

followed. The codes and standards should not be seen

as an obstacle to material reuse and adaptive building

reuse. Certainly, with the emergence of new set of

objective based codes, it will be easier in the future to

develop innovative solutions.

ConcIusion

Over the period of last 35 years there have been signifi-

cant changes in loading. Very important was the emer-

gence of the limit state approach to design in 1980?s in

the NBC. New material standards since then started to

adopt the limit states approach leading to full adoption of

this design philosophy. Typically, the working stress

steel design underestimates the capacity of the section

by around 10% when compared with the ultimate design

strength for the same grade of steel. As deflection crite-

ria often govern the selection of sections for non-

composite steel construction, both approaches yield the

same section. Therefore, there should not be a problem

when checking a steel section today which was

designed to working stress design provided there were

no changes to design loads.

The first NBC was issued in 1941 which in many

instances provided only guidance to load determination.

The occupancy loads provided for in this code are quite

similar to the current practice. One wind pressure is

given for all locations. Its value is significantly greater for

low rise buildings but generally satisfactory for most of

the locations. The seismic provisions on the NBC 1941

are very general and generally inadeq uate. Between

1941 and 1970, the code has been republished four

times with snow, wind and earthquake loads being more

defined as well as climatic data building more readily

available (shift from contour maps to tables). The load

due to snow is generally greater than today's standards.

Wind loads continue to be overestimated for low rise

buildings.

1. General requirements

Steel-Reuse Information Paper No.4

www.reuse-steel.org

The Ontario Building Code (OBC) 1997 has additional

provisions which deal with existing buildings. Part 10 of

the OBC deals with performance requirements related

to change in use. Part 11 deals with Renovation. This

part considers extensively the issue of fire safety result-

ing from change in use and increase in occupant load.

It does not require a change in performance level in the

case of alteration or repair which is consistent with the

original design intention and use. However when the

occupancy load is increased, this code requires reme-

dial action to support the extra loads, although it

accepts postings of restricted loading requirements for

a portion of a floor.

The NBC 2005 has adopted a different, objective based

approach. It specifies the objectives which the code

aspires to achieve and in a separate division it describes

how these can be met. There are no longer firm require-

ments which designers have to comply with. This

approach will result in a significant change in the build-

ing approval process and the mind set of the building

officials. There is no longer the norm and prescriptive

solution but the designer has the freedom to address the

objectives of the code and provide relevant documenta-

tion. This should make the approval process for innova-

tive or non-standard construction far more readily

achievable.

CSA, (1960), CSA G40.8, Structural Steels with Improved Resistance to Brittle Fracture. Canadian Standards

Association, Canada.

CSA, (1959), CSA G40.7, Steel Sheet Piling. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966.), CSA G40-6, Structural Silicon Steel. Canadian Standards Association,

Canada.

Further Information

CSA, (1950, 1959, 1963, 1966), CSA G40-5, Carbon steel plates of structural quality, Plates 2" and under in

thickness. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-4, Medium Structural Steel. Canadian Standards Association,

Canada.

CSA, (1959, 1963, 1966.), CSA G40-3, Structural steel for locomotives and cars. Canadian Standards Associa-

tion, Canada.

CSA, (1950), CSA G40-3, Mild Structural Steel. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-2. Structural Steel Rivets. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-1 to G40-6, General requirements for delivery of rolled steel plates,

shapes and bars for structural use. Canadian Standards Association, Canada.

CSA, (2000), CAN/CSA-S6-00. 2000. Canadian Highway Bridge Code. CSA, Ca.

CSA, (2001,2003), CAN/CSA-S16-01. - Limit States Design of Steel Structures. Canadian Standards Associa-

tion, Canada.

CSA, (1964), CSA G40.12, General Purpose Steel. Canadian Standards Association, Canada.

CSA, (1971, 1973, 1976, 1978, M1978, M81, 87, 98, 04), CSA G40.20/G40.21. General Requirements for

Rolled or Welded Structural Quality Steel/ Structural Quality Steel. Canadian Standards Association, Canada.

NRC. (1953,1960, 1965, 1970, 1975, 1977, 1980, 1985, 1990, 1995, 2005). The National Building Code of

Canada. NRC, Ottawa, Canada.

NRC. (1996). User's Guide - NBC 1995: Structural Commentaries (Part4). NRC, Ottawa, Canada.

Bussell, M. (1997). Appraisal of Existing Iron and Steel Structures. SCI 138. The Steel Construction Institute,

Silwwod Park, Berkshire, UK.

CISC, 2004. Handbook of Steel Construction. Eighth edition. CISC & Quadratone Graphics Ltd, Toronto,

Canada.

2. Loading

The NationaI BuiIding Code

History of steeI

as refIected in standards

The reason for this research work arose as a result of

interviews and surveys of the professionals associated

with steel industry which suggested that there is a concern

that the main difficulty when reusing steel is the problem

of identification of steel and its structural properties.

Another issue which was brought up was related to the

approval by building officials. It was decided that the

investigation will be done to look into the national codes

and steel standards to trace the evolution and identify

potential problems, and ways to establish the characteris-

tics of old steel.

Although national standards and codes encourage new

construction and use of new materials, the National Build-

ing Codes (NBC) definition of the scope includes "altera-

tion, reconstruction, demolition, removal, relocation and

occupancy of existing buildings". Not only does the scope

reiterate the application to old construction and new /

different materials, but it has contained the following

clause since 1985 - "Unless otherwise specified, used

materials, appliances and equipment are permitted to be

reused where they meet the requirements of this Code for

new materials and are satisfactory for the intended use". It

should be noted that equivalence is defined for materials

and components failing to comply with Part 4 and past

performance, tests (for structure a full-scale test) or model

analogue are accepted.

The third revision of the 1990 NBC included for the first

time the relationship between NBC and other standards,

testing and certification organizations, defining for design-

ers authorities which can assist them to determine equiva-

lencies. The 1995 Code was accompanied by the Struc-

tural Commentaries on the National Building Code of

Canada 1995 which for the first time included a section

entitled "Application of NBC Part 4 for the Structural

evaluation and Upgrading of Existing Buildings", assisting

designers to deal with issues related to buildings designed

to previous codes in the context of Part 4. This document

is very important as it recognizes the shortcomings of Part

4 of the NBC with its focus on new construction (new or

addition) and the lack of its application to existing build-

ings which may contain a structural system or materials

no longer in use.

Used materials and systems are permitted if they

comply with the NBC requirements for new construction.

There is reasonable freedom given to designers to

prove equivalency but the problem is that it is a depar-

ture from the prescriptive, requirement based process.

The non-prescriptive approach challenges building

department officials leading to inconsistent interpreta-

tion and varying attitudes and requirements. From the

designer's point of view it results in uncertainty about

what may be required and acts as a deterrent to taking

an alternative design approach.

1. Review of steel properties

It should be noted that the chemical composition of "old"

steel is very similar irrespective of its origin.

CAN/CSA-S16-01 (5.2) considers steel suitable for

building construction only if its properties can be identi-

fied by a mill or producer certificate or a colour marking

which is defined in all the structural steel standards

above. The two main alternatives which are open to the

designer who wants to reuse steel components without

documentation are to approve steel and use the

prescribed properties (yield strength of 210 N/mm and

ultimate strength of 380 N/mm ) or to have a testing

agency carry out tests to determine the mechanical and

chemical properties and thus identify the steel. Once

the steel type is identified, the minimum values of yield

and ultimate strength given in the product specifications

for that type of steel (not actual tested values) must be

used. It should be noted that the determination of

2

3

2

2

2

introduced carbon content (previously ladle analysis

done by the manufacturer checked the carbon content),

while phosphorus and sulphur remained unchanged,

and further introduced limits on manganese and silicon.

The maximum carbon content decreases with the

increased steel strength. The next major revision of

CSA-G40.21 was in 1973. The metric version was pub-

lished in 1981. This revision covered a wide range of

steel strengths and the types described above. The

2004 version of CSA-G40.21 is similar to the 1981

version in terms of strengths but the general construc-

tion steel type was eliminated and corrosion resistant

weldable and notch-tough steel, and quenched and

tempered low alloy notch-tough steel types were add-

edIt should be noted that all standards dealt with steel

marking using colour codes to identify different steels.

This is important for mills but through the fabrication

process the marking gets lost.

It should be noted that the Canadian Highway Bridge

Code CAN/CSA-S6-00, Section 14.6 may be used as

guidance. Besides identification of steel using project

documentation including the mill certificates, the Code

offers alternative approaches, namely: testing of

samples to identify steel and use the minimum product

specifications; selecting yield and ultimate strength from

a given table based on the year of construction; or more

rigorous testing described in that standard which

includes the procedure for the evaluation of test result

and strength determination. Table 2 gives the estimation

of properties of structural steel by the age of construction

which are recommended by S6 in the absence of more

specific information.

chemical composition to determine its weldability may

be more important than its strength. A third alternative is

an affidavit from the fabricator stating that the fabricated

material conforms to material specifications.

Table 1 Properties of steel in Canadian history

From CAN/CSA-S6-00.

Table 2 Properties of steel by the age of construction

2)

2)

1)

From CAN/CSA-S6-00, Canadian Highway Bridge Code

Recommendations

The most significant changes are related to modifica-

tions in seismic loads and snow loads. The major impact

on the adaptive reuse of buildings designed before 1985

are the seismic loads. The previous code (NBC 1980)

was based on peak horizontal acceleration and seismic

contour map from 1970 with probability on 0.01 per

annum. The 1985 NBC included a new zoning map,

including both, peak accelerations and peak velocities

and increased probability of 10% in 50 years. Other

changes included the treatment of seismic load by limit

state design approach. The load factor for seismic load

since 1990 equals to 1.0. What this means for adaptive

reuse is that all buildings designed prior to adoption on

the 1980 NBC will require seismic retrofit and buildings

designed prior to 1970 in some locations were not

Steel components have great potential for reuse. The

knowledge of steel history is important for the designer

if reuse of components is to be adopted. The first Cana-

dian steel code for buildings (C.E.S.A. S16) dates from

1935 and remained in place until 1948. The steel which

is described in that code is mild and medium steel

(governed by C.E.S.A.-S40). This latter standard after

1950 became the CSA - G40.x series. Carbon steel for

plates and silicon steel appeared after the Second

World War in addition to the original mild and medium

steel which was used until 1964 (see Table 1). The

injection of preheated oxygen rather than air into the

modified Bessemer furnace and electric arc steel-

making processes, led to better quality and the emer-

gence of higher strength steels. Several types have

appeared: general construction steel, weldable steels

(regular and low temperature), corrosion resistant steels

(regular and with improved low temperature properties),

and quenched and tempered low alloy plates. The

chemical analysis in CSA-G40.21 1964 for the first time

The 1990 NBC introduced the rain components of snow

load and the ground snow load was changed (generally

for most areas ground snow load decreased) as well as

the default snow density was increased from 2.4 kN/m

to 3.0 kN/m3. This had a minor impact on the magnitude

and the extent of snow accumulation on lower roofs

adjacent to higher buildings. Since 1995, the snow

accumulation was typically decreased in recognition of

the fact that the amount of snow on upper is limited by

the size of the upper roof and there is often not enough

snow to fill the step. The extent of the lower roof zone

impacted by snow accumulation increased. Generally,

there should not be a problem resulting from snow load-

ing if a component or building remains in the same geo-

graphical location.

designed for seismic load at all or much smaller load.

Post 1990 buildings comply with current code seismic

provisions. When comparing the current maximum seis-

mic shear to the 1985 NBC, for ductile design, the

design shears are almost identical, however for nominal

ductility or non-ductile detailing, the 1990 and subse-

quent NBC result in greater loads, 40% and 36%

respectively.

If the components are older than 70 years (prior to

1935), there are potentially other materials than steel

available, such as cast and wrought iron, and it is more

difficult to assess the properties. The following refer-

ences are recommended:

ASTM Standards A7 and A9.

The publication "Appraisal of existing iron and

steel structures" by The Steel Construction Insti-

tute of the United Kingdom [Bussell, 1997].

CAN/CSA-S6-00 (Canadian Highway Bridge

Code).

FACILITATING GREATER REUSE AND RECYCLING OF STRUCTURAL STEEL IN THE CONSTRUCTION AND DEMOLITION PROCESS

Action Plan 2000

on Climate Change

www.reuse-steel.org

This information paper was prepared by Vera Straka at the Department of ArchitecturaI Science, Ryerson

University, with support from the Enhanced Recycling component of the Government of Canada Action Plan 2000

on Climate Change, Minerals and Metals Program and by the Canadian Institute for Steel Construction (CISC).

Period

Pre - 1905

1)

1905 - 1935

1)

1935 - 1964

1964

- 1973

1973 - 1981

From 1981

Yield Strength

N/mm

2

180

210

186

227

303

230

480

260

480

Tensile Strength

N/mm

2

360

360

344 - 427

413 - 497

427

380

- 500

590 - 790

410 - 590

590

- 790

Date of bridge construction

Specified

Fy, MPa

Specified

Fu, MPa

Before 1905

1905 - 1932

1933 - 1975

After 1975

180

210

230

250

360

420

420

420

As described above there are recommended values for

steel strength which can be used in absence of more

detailed information available. The summary of chrono-

logical research summarized above clearly supports the

default value selection. The default value of steel

strength is yield strength of 210 N/mm and ultimate

strength of 380 N/mm . If the welded connections are to

be used, it is important to carry out chemical analysis of

steel to determine its weldability. Caution should be

exercised when the unidentified steel is to be used on a

project for rigid and braced frames member in seismic

zones. When the frame is designed for seismic load with

reduction factor R of 2 or greater, the accurate determi-

nation of yield strength is very important as it control

structural behaviour of a frame.

Codes and Standards

Although, the codes and standards are focusing on

new materials and new construction, their scope

accommodates reused material and adaptive building

reuse. They may not be as specific as designers would

like, but they give a sufficient framework which can be

followed. The codes and standards should not be seen

as an obstacle to material reuse and adaptive building

reuse. Certainly, with the emergence of new set of

objective based codes, it will be easier in the future to

develop innovative solutions.

ConcIusion

Over the period of last 35 years there have been signifi-

cant changes in loading. Very important was the emer-

gence of the limit state approach to design in 1980?s in

the NBC. New material standards since then started to

adopt the limit states approach leading to full adoption of

this design philosophy. Typically, the working stress

steel design underestimates the capacity of the section

by around 10% when compared with the ultimate design

strength for the same grade of steel. As deflection crite-

ria often govern the selection of sections for non-

composite steel construction, both approaches yield the

same section. Therefore, there should not be a problem

when checking a steel section today which was

designed to working stress design provided there were

no changes to design loads.

The first NBC was issued in 1941 which in many

instances provided only guidance to load determination.

The occupancy loads provided for in this code are quite

similar to the current practice. One wind pressure is

given for all locations. Its value is significantly greater for

low rise buildings but generally satisfactory for most of

the locations. The seismic provisions on the NBC 1941

are very general and generally inadeq uate. Between

1941 and 1970, the code has been republished four

times with snow, wind and earthquake loads being more

defined as well as climatic data building more readily

available (shift from contour maps to tables). The load

due to snow is generally greater than today's standards.

Wind loads continue to be overestimated for low rise

buildings.

1. General requirements

Steel-Reuse Information Paper No.4

www.reuse-steel.org

The Ontario Building Code (OBC) 1997 has additional

provisions which deal with existing buildings. Part 10 of

the OBC deals with performance requirements related

to change in use. Part 11 deals with Renovation. This

part considers extensively the issue of fire safety result-

ing from change in use and increase in occupant load.

It does not require a change in performance level in the

case of alteration or repair which is consistent with the

original design intention and use. However when the

occupancy load is increased, this code requires reme-

dial action to support the extra loads, although it

accepts postings of restricted loading requirements for

a portion of a floor.

The NBC 2005 has adopted a different, objective based

approach. It specifies the objectives which the code

aspires to achieve and in a separate division it describes

how these can be met. There are no longer firm require-

ments which designers have to comply with. This

approach will result in a significant change in the build-

ing approval process and the mind set of the building

officials. There is no longer the norm and prescriptive

solution but the designer has the freedom to address the

objectives of the code and provide relevant documenta-

tion. This should make the approval process for innova-

tive or non-standard construction far more readily

achievable.

CSA, (1960), CSA G40.8, Structural Steels with Improved Resistance to Brittle Fracture. Canadian Standards

Association, Canada.

CSA, (1959), CSA G40.7, Steel Sheet Piling. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966.), CSA G40-6, Structural Silicon Steel. Canadian Standards Association,

Canada.

Further Information

CSA, (1950, 1959, 1963, 1966), CSA G40-5, Carbon steel plates of structural quality, Plates 2" and under in

thickness. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-4, Medium Structural Steel. Canadian Standards Association,

Canada.

CSA, (1959, 1963, 1966.), CSA G40-3, Structural steel for locomotives and cars. Canadian Standards Associa-

tion, Canada.

CSA, (1950), CSA G40-3, Mild Structural Steel. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-2. Structural Steel Rivets. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-1 to G40-6, General requirements for delivery of rolled steel plates,

shapes and bars for structural use. Canadian Standards Association, Canada.

CSA, (2000), CAN/CSA-S6-00. 2000. Canadian Highway Bridge Code. CSA, Ca.

CSA, (2001,2003), CAN/CSA-S16-01. - Limit States Design of Steel Structures. Canadian Standards Associa-

tion, Canada.

CSA, (1964), CSA G40.12, General Purpose Steel. Canadian Standards Association, Canada.

CSA, (1971, 1973, 1976, 1978, M1978, M81, 87, 98, 04), CSA G40.20/G40.21. General Requirements for

Rolled or Welded Structural Quality Steel/ Structural Quality Steel. Canadian Standards Association, Canada.

NRC. (1953,1960, 1965, 1970, 1975, 1977, 1980, 1985, 1990, 1995, 2005). The National Building Code of

Canada. NRC, Ottawa, Canada.

NRC. (1996). User's Guide - NBC 1995: Structural Commentaries (Part4). NRC, Ottawa, Canada.

Bussell, M. (1997). Appraisal of Existing Iron and Steel Structures. SCI 138. The Steel Construction Institute,

Silwwod Park, Berkshire, UK.

CISC, 2004. Handbook of Steel Construction. Eighth edition. CISC & Quadratone Graphics Ltd, Toronto,

Canada.

2. Loading

The NationaI BuiIding Code

History of steeI

as refIected in standards

The reason for this research work arose as a result of

interviews and surveys of the professionals associated

with steel industry which suggested that there is a concern

that the main difficulty when reusing steel is the problem

of identification of steel and its structural properties.

Another issue which was brought up was related to the

approval by building officials. It was decided that the

investigation will be done to look into the national codes

and steel standards to trace the evolution and identify

potential problems, and ways to establish the characteris-

tics of old steel.

Although national standards and codes encourage new

construction and use of new materials, the National Build-

ing Codes (NBC) definition of the scope includes "altera-

tion, reconstruction, demolition, removal, relocation and

occupancy of existing buildings". Not only does the scope

reiterate the application to old construction and new /

different materials, but it has contained the following

clause since 1985 - "Unless otherwise specified, used

materials, appliances and equipment are permitted to be

reused where they meet the requirements of this Code for

new materials and are satisfactory for the intended use". It

should be noted that equivalence is defined for materials

and components failing to comply with Part 4 and past

performance, tests (for structure a full-scale test) or model

analogue are accepted.

The third revision of the 1990 NBC included for the first

time the relationship between NBC and other standards,

testing and certification organizations, defining for design-

ers authorities which can assist them to determine equiva-

lencies. The 1995 Code was accompanied by the Struc-

tural Commentaries on the National Building Code of

Canada 1995 which for the first time included a section

entitled "Application of NBC Part 4 for the Structural

evaluation and Upgrading of Existing Buildings", assisting

designers to deal with issues related to buildings designed

to previous codes in the context of Part 4. This document

is very important as it recognizes the shortcomings of Part

4 of the NBC with its focus on new construction (new or

addition) and the lack of its application to existing build-

ings which may contain a structural system or materials

no longer in use.

Used materials and systems are permitted if they

comply with the NBC requirements for new construction.

There is reasonable freedom given to designers to

prove equivalency but the problem is that it is a depar-

ture from the prescriptive, requirement based process.

The non-prescriptive approach challenges building

department officials leading to inconsistent interpreta-

tion and varying attitudes and requirements. From the

designer's point of view it results in uncertainty about

what may be required and acts as a deterrent to taking

an alternative design approach.

1. Review of steel properties

It should be noted that the chemical composition of "old"

steel is very similar irrespective of its origin.

CAN/CSA-S16-01 (5.2) considers steel suitable for

building construction only if its properties can be identi-

fied by a mill or producer certificate or a colour marking

which is defined in all the structural steel standards

above. The two main alternatives which are open to the

designer who wants to reuse steel components without

documentation are to approve steel and use the

prescribed properties (yield strength of 210 N/mm and

ultimate strength of 380 N/mm ) or to have a testing

agency carry out tests to determine the mechanical and

chemical properties and thus identify the steel. Once

the steel type is identified, the minimum values of yield

and ultimate strength given in the product specifications

for that type of steel (not actual tested values) must be

used. It should be noted that the determination of

2

3

2

2

2

introduced carbon content (previously ladle analysis

done by the manufacturer checked the carbon content),

while phosphorus and sulphur remained unchanged,

and further introduced limits on manganese and silicon.

The maximum carbon content decreases with the

increased steel strength. The next major revision of

CSA-G40.21 was in 1973. The metric version was pub-

lished in 1981. This revision covered a wide range of

steel strengths and the types described above. The

2004 version of CSA-G40.21 is similar to the 1981

version in terms of strengths but the general construc-

tion steel type was eliminated and corrosion resistant

weldable and notch-tough steel, and quenched and

tempered low alloy notch-tough steel types were add-

edIt should be noted that all standards dealt with steel

marking using colour codes to identify different steels.

This is important for mills but through the fabrication

process the marking gets lost.

It should be noted that the Canadian Highway Bridge

Code CAN/CSA-S6-00, Section 14.6 may be used as

guidance. Besides identification of steel using project

documentation including the mill certificates, the Code

offers alternative approaches, namely: testing of

samples to identify steel and use the minimum product

specifications; selecting yield and ultimate strength from

a given table based on the year of construction; or more

rigorous testing described in that standard which

includes the procedure for the evaluation of test result

and strength determination. Table 2 gives the estimation

of properties of structural steel by the age of construction

which are recommended by S6 in the absence of more

specific information.

chemical composition to determine its weldability may

be more important than its strength. A third alternative is

an affidavit from the fabricator stating that the fabricated

material conforms to material specifications.

Table 1 Properties of steel in Canadian history

From CAN/CSA-S6-00.

Table 2 Properties of steel by the age of construction

2)

2)

1)

From CAN/CSA-S6-00, Canadian Highway Bridge Code

Recommendations

The most significant changes are related to modifica-

tions in seismic loads and snow loads. The major impact

on the adaptive reuse of buildings designed before 1985

are the seismic loads. The previous code (NBC 1980)

was based on peak horizontal acceleration and seismic

contour map from 1970 with probability on 0.01 per

annum. The 1985 NBC included a new zoning map,

including both, peak accelerations and peak velocities

and increased probability of 10% in 50 years. Other

changes included the treatment of seismic load by limit

state design approach. The load factor for seismic load

since 1990 equals to 1.0. What this means for adaptive

reuse is that all buildings designed prior to adoption on

the 1980 NBC will require seismic retrofit and buildings

designed prior to 1970 in some locations were not

Steel components have great potential for reuse. The

knowledge of steel history is important for the designer

if reuse of components is to be adopted. The first Cana-

dian steel code for buildings (C.E.S.A. S16) dates from

1935 and remained in place until 1948. The steel which

is described in that code is mild and medium steel

(governed by C.E.S.A.-S40). This latter standard after

1950 became the CSA - G40.x series. Carbon steel for

plates and silicon steel appeared after the Second

World War in addition to the original mild and medium

steel which was used until 1964 (see Table 1). The

injection of preheated oxygen rather than air into the

modified Bessemer furnace and electric arc steel-

making processes, led to better quality and the emer-

gence of higher strength steels. Several types have

appeared: general construction steel, weldable steels

(regular and low temperature), corrosion resistant steels

(regular and with improved low temperature properties),

and quenched and tempered low alloy plates. The

chemical analysis in CSA-G40.21 1964 for the first time

The 1990 NBC introduced the rain components of snow

load and the ground snow load was changed (generally

for most areas ground snow load decreased) as well as

the default snow density was increased from 2.4 kN/m

to 3.0 kN/m3. This had a minor impact on the magnitude

and the extent of snow accumulation on lower roofs

adjacent to higher buildings. Since 1995, the snow

accumulation was typically decreased in recognition of

the fact that the amount of snow on upper is limited by

the size of the upper roof and there is often not enough

snow to fill the step. The extent of the lower roof zone

impacted by snow accumulation increased. Generally,

there should not be a problem resulting from snow load-

ing if a component or building remains in the same geo-

graphical location.

designed for seismic load at all or much smaller load.

Post 1990 buildings comply with current code seismic

provisions. When comparing the current maximum seis-

mic shear to the 1985 NBC, for ductile design, the

design shears are almost identical, however for nominal

ductility or non-ductile detailing, the 1990 and subse-

quent NBC result in greater loads, 40% and 36%

respectively.

If the components are older than 70 years (prior to

1935), there are potentially other materials than steel

available, such as cast and wrought iron, and it is more

difficult to assess the properties. The following refer-

ences are recommended:

ASTM Standards A7 and A9.

The publication "Appraisal of existing iron and

steel structures" by The Steel Construction Insti-

tute of the United Kingdom [Bussell, 1997].

CAN/CSA-S6-00 (Canadian Highway Bridge

Code).

FACILITATING GREATER REUSE AND RECYCLING OF STRUCTURAL STEEL IN THE CONSTRUCTION AND DEMOLITION PROCESS

Action Plan 2000

on Climate Change

www.reuse-steel.org

This information paper was prepared by Vera Straka at the Department of ArchitecturaI Science, Ryerson

University, with support from the Enhanced Recycling component of the Government of Canada Action Plan 2000

on Climate Change, Minerals and Metals Program and by the Canadian Institute for Steel Construction (CISC).

Period

Pre - 1905

1)

1905 - 1935

1)

1935 - 1964

1964

- 1973

1973 - 1981

From 1981

Yield Strength

N/mm

2

180

210

186

227

303

230

480

260

480

Tensile Strength

N/mm

2

360

360

344 - 427

413 - 497

427

380

- 500

590 - 790

410 - 590

590

- 790

Date of bridge construction

Specified

Fy, MPa

Specified

Fu, MPa

Before 1905

1905 - 1932

1933 - 1975

After 1975

180

210

230

250

360

420

420

420

As described above there are recommended values for

steel strength which can be used in absence of more

detailed information available. The summary of chrono-

logical research summarized above clearly supports the

default value selection. The default value of steel

strength is yield strength of 210 N/mm and ultimate

strength of 380 N/mm . If the welded connections are to

be used, it is important to carry out chemical analysis of

steel to determine its weldability. Caution should be

exercised when the unidentified steel is to be used on a

project for rigid and braced frames member in seismic

zones. When the frame is designed for seismic load with

reduction factor R of 2 or greater, the accurate determi-

nation of yield strength is very important as it control

structural behaviour of a frame.

Codes and Standards

Although, the codes and standards are focusing on

new materials and new construction, their scope

accommodates reused material and adaptive building

reuse. They may not be as specific as designers would

like, but they give a sufficient framework which can be

followed. The codes and standards should not be seen

as an obstacle to material reuse and adaptive building

reuse. Certainly, with the emergence of new set of

objective based codes, it will be easier in the future to

develop innovative solutions.

ConcIusion

Over the period of last 35 years there have been signifi-

cant changes in loading. Very important was the emer-

gence of the limit state approach to design in 1980?s in

the NBC. New material standards since then started to

adopt the limit states approach leading to full adoption of

this design philosophy. Typically, the working stress

steel design underestimates the capacity of the section

by around 10% when compared with the ultimate design

strength for the same grade of steel. As deflection crite-

ria often govern the selection of sections for non-

composite steel construction, both approaches yield the

same section. Therefore, there should not be a problem

when checking a steel section today which was

designed to working stress design provided there were

no changes to design loads.

The first NBC was issued in 1941 which in many

instances provided only guidance to load determination.

The occupancy loads provided for in this code are quite

similar to the current practice. One wind pressure is

given for all locations. Its value is significantly greater for

low rise buildings but generally satisfactory for most of

the locations. The seismic provisions on the NBC 1941

are very general and generally inadeq uate. Between

1941 and 1970, the code has been republished four

times with snow, wind and earthquake loads being more

defined as well as climatic data building more readily

available (shift from contour maps to tables). The load

due to snow is generally greater than today's standards.

Wind loads continue to be overestimated for low rise

buildings.

1. General requirements

Steel-Reuse Information Paper No.4

www.reuse-steel.org

The Ontario Building Code (OBC) 1997 has additional

provisions which deal with existing buildings. Part 10 of

the OBC deals with performance requirements related

to change in use. Part 11 deals with Renovation. This

part considers extensively the issue of fire safety result-

ing from change in use and increase in occupant load.

It does not require a change in performance level in the

case of alteration or repair which is consistent with the

original design intention and use. However when the

occupancy load is increased, this code requires reme-

dial action to support the extra loads, although it

accepts postings of restricted loading requirements for

a portion of a floor.

The NBC 2005 has adopted a different, objective based

approach. It specifies the objectives which the code

aspires to achieve and in a separate division it describes

how these can be met. There are no longer firm require-

ments which designers have to comply with. This

approach will result in a significant change in the build-

ing approval process and the mind set of the building

officials. There is no longer the norm and prescriptive

solution but the designer has the freedom to address the

objectives of the code and provide relevant documenta-

tion. This should make the approval process for innova-

tive or non-standard construction far more readily

achievable.

CSA, (1960), CSA G40.8, Structural Steels with Improved Resistance to Brittle Fracture. Canadian Standards

Association, Canada.

CSA, (1959), CSA G40.7, Steel Sheet Piling. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966.), CSA G40-6, Structural Silicon Steel. Canadian Standards Association,

Canada.

Further Information

CSA, (1950, 1959, 1963, 1966), CSA G40-5, Carbon steel plates of structural quality, Plates 2" and under in

thickness. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-4, Medium Structural Steel. Canadian Standards Association,

Canada.

CSA, (1959, 1963, 1966.), CSA G40-3, Structural steel for locomotives and cars. Canadian Standards Associa-

tion, Canada.

CSA, (1950), CSA G40-3, Mild Structural Steel. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-2. Structural Steel Rivets. Canadian Standards Association, Canada.

CSA, (1950, 1959, 1963, 1966), CSA G40-1 to G40-6, General requirements for delivery of rolled steel plates,

shapes and bars for structural use. Canadian Standards Association, Canada.

CSA, (2000), CAN/CSA-S6-00. 2000. Canadian Highway Bridge Code. CSA, Ca.

CSA, (2001,2003), CAN/CSA-S16-01. - Limit States Design of Steel Structures. Canadian Standards Associa-

tion, Canada.

CSA, (1964), CSA G40.12, General Purpose Steel. Canadian Standards Association, Canada.

CSA, (1971, 1973, 1976, 1978, M1978, M81, 87, 98, 04), CSA G40.20/G40.21. General Requirements for

Rolled or Welded Structural Quality Steel/ Structural Quality Steel. Canadian Standards Association, Canada.

NRC. (1953,1960, 1965, 1970, 1975, 1977, 1980, 1985, 1990, 1995, 2005). The National Building Code of

Canada. NRC, Ottawa, Canada.

NRC. (1996). User's Guide - NBC 1995: Structural Commentaries (Part4). NRC, Ottawa, Canada.

Bussell, M. (1997). Appraisal of Existing Iron and Steel Structures. SCI 138. The Steel Construction Institute,

Silwwod Park, Berkshire, UK.

CISC, 2004. Handbook of Steel Construction. Eighth edition. CISC & Quadratone Graphics Ltd, Toronto,

Canada.

2. Loading

The NationaI BuiIding Code

History of steeI

as refIected in standards

The reason for this research work arose as a result of

interviews and surveys of the professionals associated

with steel industry which suggested that there is a concern

that the main difficulty when reusing steel is the problem

of identification of steel and its structural properties.

Another issue which was brought up was related to the

approval by building officials. It was decided that the

investigation will be done to look into the national codes

and steel standards to trace the evolution and identify

potential problems, and ways to establish the characteris-

tics of old steel.

Although national standards and codes encourage new

construction and use of new materials, the National Build-

ing Codes (NBC) definition of the scope includes "altera-

tion, reconstruction, demolition, removal, relocation and

occupancy of existing buildings". Not only does the scope

reiterate the application to old construction and new /

different materials, but it has contained the following

clause since 1985 - "Unless otherwise specified, used

materials, appliances and equipment are permitted to be

reused where they meet the requirements of this Code for

new materials and are satisfactory for the intended use". It

should be noted that equivalence is defined for materials

and components failing to comply with Part 4 and past

performance, tests (for structure a full-scale test) or model

analogue are accepted.

The third revision of the 1990 NBC included for the first

time the relationship between NBC and other standards,

testing and certification organizations, defining for design-

ers authorities which can assist them to determine equiva-

lencies. The 1995 Code was accompanied by the Struc-

tural Commentaries on the National Building Code of

Canada 1995 which for the first time included a section

entitled "Application of NBC Part 4 for the Structural

evaluation and Upgrading of Existing Buildings", assisting

designers to deal with issues related to buildings designed

to previous codes in the context of Part 4. This document

is very important as it recognizes the shortcomings of Part

4 of the NBC with its focus on new construction (new or

addition) and the lack of its application to existing build-

ings which may contain a structural system or materials

no longer in use.

Used materials and systems are permitted if they

comply with the NBC requirements for new construction.

There is reasonable freedom given to designers to

prove equivalency but the problem is that it is a depar-

ture from the prescriptive, requirement based process.

The non-prescriptive approach challenges building

department officials leading to inconsistent interpreta-

tion and varying attitudes and requirements. From the

designer's point of view it results in uncertainty about

what may be required and acts as a deterrent to taking

an alternative design approach.

1. Review of steel properties

It should be noted that the chemical composition of "old"

steel is very similar irrespective of its origin.

CAN/CSA-S16-01 (5.2) considers steel suitable for

building construction only if its properties can be identi-

fied by a mill or producer certificate or a colour marking

which is defined in all the structural steel standards

above. The two main alternatives which are open to the

designer who wants to reuse steel components without

documentation are to approve steel and use the

prescribed properties (yield strength of 210 N/mm and

ultimate strength of 380 N/mm ) or to have a testing

agency carry out tests to determine the mechanical and

chemical properties and thus identify the steel. Once

the steel type is identified, the minimum values of yield

and ultimate strength given in the product specifications

for that type of steel (not actual tested values) must be

used. It should be noted that the determination of

2

3

2

2

2

introduced carbon content (previously ladle analysis

done by the manufacturer checked the carbon content),

while phosphorus and sulphur remained unchanged,

and further introduced limits on manganese and silicon.

The maximum carbon content decreases with the

increased steel strength. The next major revision of

CSA-G40.21 was in 1973. The metric version was pub-

lished in 1981. This revision covered a wide range of

steel strengths and the types described above. The

2004 version of CSA-G40.21 is similar to the 1981

version in terms of strengths but the general construc-

tion steel type was eliminated and corrosion resistant

weldable and notch-tough steel, and quenched and

tempered low alloy notch-tough steel types were add-

edIt should be noted that all standards dealt with steel

marking using colour codes to identify different steels.

This is important for mills but through the fabrication

process the marking gets lost.

It should be noted that the Canadian Highway Bridge

Code CAN/CSA-S6-00, Section 14.6 may be used as

guidance. Besides identification of steel using project

documentation including the mill certificates, the Code

offers alternative approaches, namely: testing of

samples to identify steel and use the minimum product

specifications; selecting yield and ultimate strength from

a given table based on the year of construction; or more

rigorous testing described in that standard which

includes the procedure for the evaluation of test result

and strength determination. Table 2 gives the estimation

of properties of structural steel by the age of construction

which are recommended by S6 in the absence of more

specific information.

chemical composition to determine its weldability may

be more important than its strength. A third alternative is

an affidavit from the fabricator stating that the fabricated

material conforms to material specifications.

Table 1 Properties of steel in Canadian history

From CAN/CSA-S6-00.

Table 2 Properties of steel by the age of construction

2)

2)

1)

From CAN/CSA-S6-00, Canadian Highway Bridge Code

Recommendations

The most significant changes are related to modifica-

tions in seismic loads and snow loads. The major impact

on the adaptive reuse of buildings designed before 1985

are the seismic loads. The previous code (NBC 1980)

was based on peak horizontal acceleration and seismic

contour map from 1970 with probability on 0.01 per

annum. The 1985 NBC included a new zoning map,

including both, peak accelerations and peak velocities

and increased probability of 10% in 50 years. Other

changes included the treatment of seismic load by limit

state design approach. The load factor for seismic load

since 1990 equals to 1.0. What this means for adaptive

reuse is that all buildings designed prior to adoption on

the 1980 NBC will require seismic retrofit and buildings

designed prior to 1970 in some locations were not

Steel components have great potential for reuse. The

knowledge of steel history is important for the designer

if reuse of components is to be adopted. The first Cana-

dian steel code for buildings (C.E.S.A. S16) dates from

1935 and remained in place until 1948. The steel which

is described in that code is mild and medium steel

(governed by C.E.S.A.-S40). This latter standard after

1950 became the CSA - G40.x series. Carbon steel for

plates and silicon steel appeared after the Second

World War in addition to the original mild and medium

steel which was used until 1964 (see Table 1). The

injection of preheated oxygen rather than air into the

modified Bessemer furnace and electric arc steel-

making processes, led to better quality and the emer-

gence of higher strength steels. Several types have

appeared: general construction steel, weldable steels

(regular and low temperature), corrosion resistant steels

(regular and with improved low temperature properties),

and quenched and tempered low alloy plates. The

chemical analysis in CSA-G40.21 1964 for the first time

The 1990 NBC introduced the rain components of snow

load and the ground snow load was changed (generally

for most areas ground snow load decreased) as well as

the default snow density was increased from 2.4 kN/m

to 3.0 kN/m3. This had a minor impact on the magnitude

and the extent of snow accumulation on lower roofs

adjacent to higher buildings. Since 1995, the snow

accumulation was typically decreased in recognition of

the fact that the amount of snow on upper is limited by

the size of the upper roof and there is often not enough

snow to fill the step. The extent of the lower roof zone

impacted by snow accumulation increased. Generally,

there should not be a problem resulting from snow load-

ing if a component or building remains in the same geo-

graphical location.

designed for seismic load at all or much smaller load.

Post 1990 buildings comply with current code seismic

provisions. When comparing the current maximum seis-

mic shear to the 1985 NBC, for ductile design, the

design shears are almost identical, however for nominal

ductility or non-ductile detailing, the 1990 and subse-

quent NBC result in greater loads, 40% and 36%

respectively.

If the components are older than 70 years (prior to

1935), there are potentially other materials than steel

available, such as cast and wrought iron, and it is more

difficult to assess the properties. The following refer-

ences are recommended:

ASTM Standards A7 and A9.

The publication "Appraisal of existing iron and

steel structures" by The Steel Construction Insti-

tute of the United Kingdom [Bussell, 1997].

CAN/CSA-S6-00 (Canadian Highway Bridge

Code).

FACILITATING GREATER REUSE AND RECYCLING OF STRUCTURAL STEEL IN THE CONSTRUCTION AND DEMOLITION PROCESS

Action Plan 2000

on Climate Change

www.reuse-steel.org

This information paper was prepared by Vera Straka at the Department of ArchitecturaI Science, Ryerson

University, with support from the Enhanced Recycling component of the Government of Canada Action Plan 2000

on Climate Change, Minerals and Metals Program and by the Canadian Institute for Steel Construction (CISC).

Period

Pre - 1905

1)

1905 - 1935

1)

1935 - 1964

1964

- 1973

1973 - 1981

From 1981

Yield Strength

N/mm

2

180

210

186

227

303

230

480

260

480

Tensile Strength

N/mm

2

360

360

344 - 427

413 - 497

427

380

- 500

590 - 790

410 - 590

590

- 790

Date of bridge construction

Specified

Fy, MPa

Specified

Fu, MPa

Before 1905

1905 - 1932

1933 - 1975

After 1975

180

210

230

250

360

420

420

420

APPENDIX: Research notes

Structural steel standards

C.E.S.A. S16-1935 Steel Structures for Buildings until 1948

Composite construction allowed Type-A and Type-B

C.E.S.A.-S39: Mild structural steel

C.E.S.A.-S40: Medium structural steel

Table 3 Steel Properties. (fromC.E.S.A. S16 1935)

Elongation Steel type Chemical

Analysis

Yield stress

(psi)

Tensile

strength

(psi)

8 gauge (%) 2 gauge (%)

Mild

P acid 0.06

P basic 0.04

S 0.05

Medium

Cu 0.20

33,000

min 0.5 of

tensile strength

60,000

72,000

1.5E6/(tensile

strength)

22

Standards Material Properties after 1950:

CSA-G 40-1: General requirements for delivery of rolled steel plates, shapes and bars for structural use

CSA-G 40-2: Structural steel rivets

CSA-G 40-3: Mild structural steel

CSA-G 40-4: Medium structural steel

CSA-G 40-5: Carbon steel plates of structural quality, plates 2 and under in thickness

CSA-G 40-6: Structural silicon steel

General notes:

All revised and reissued in 1959; G40-1 reissued in 1959 and last revised in 1963

G40-1 1959 has section headings

Ladle analysis of molten steel from each heat of open-hearth or electric furnace is required by the

Manufacturer to determine the percentage of carbon, manganese, phosphorous (P) and sulphur

(S); of copper when copper (Cu) steel specifies; any other elements specified or restricted by the

applicable specifications.

Check analysis by the purchaser

Manufacturing process: open hearth or electric furnace; basic oxygen process added in 1959

Marking of steel required, typically of each piece but how to be done is vague (die stamp is referred

to for plates).

Tensile test and bend test (cold steel bent through 180without cracking on outside; ratio of inside

diameter to thickness specified) are prescribed; two of each per each heat. Speed of loading for

loads over one half of the yield is defined. The test specimen is either flat bar 9 long (8 gauge

length) of actual material thickness or greater thickness than 1.5 when thickness can be used

or 2.5 long (2 gauge length) rod test can be done.

G40.3-1959: Structural Steel for Locomotives and Cars change from mild steel previously used.

G40.7-1959: Steel Sheet Piling introduced.

Table 4 Steel Properties. (fromG40 series 1959)