Escolar Documentos

Profissional Documentos

Cultura Documentos

Hendrik Cosemans Nynas

Enviado por

prevrtljivacDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hendrik Cosemans Nynas

Enviado por

prevrtljivacDireitos autorais:

Formatos disponíveis

Properties behind eective Transformer Oil Cooling Hendrik Cosemans, General Manager Nynas Dubai

As a Belgian national, where 3 ocial languages are part of the national structure, Hendrik is adding English and Spanish to his language portfolio. And very basics of Arabic, but he would like to improve these skills. Trained as a Business Engineer he has travelled the world, both in his studies and work experience. Barcelona, Belfast and Dubai have little secrets for him. He moved from Linde Gas to Nynas in 2007. Being active in the eld of sales or purchasing, the commercial surroundings are where he thrives best. The international business scene was swapped for Dubais iconic landscape since 2011, together with his family. As General Manager of Nynas Dubai, a further growth of the 15 countries under his responsibility has been achieved. Transformer oils remain the main focus of the Naphthenic oils that are being produced by Nynas, next to process-oils, oil for lubes & greases and tyre-oils. Setting up good cooperation and local partnerships, lobbying for quality prescriptions and passing the knowledge via conferences and seminars, whilst travelling actively to meet the customers, contractors and utilities are the main activities, next to ensuring that the Dubai oce keeps delivering its excellent performance in order handling and customer satisfaction.

S11

Properties behind eective Transformer Oil Cooling

Heat transfer in transformers

Nynas AB

Cooling properties of insulating liquid

ELI Technical Presentation

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Cooling

! Heat generation in transformers ! Viscosity ! Heat transfer coefficient

Heat transfer in transformers

29.09.13

Heat generation in transformers

! No load losses: Independent of load of transformer ! Comes from magnetic losses and hysteresis in the iron core ! Load losses = Copper electrical resistance loss + Stray losses ! Copper electrical resistance loss: QR I*R2 = =Electric Current * Resistance2 ! Stray losses: Leakage of electric flux and eddy losses to tank and other metal parts ! Copper electrical resistance loss: R(T)=R0 + *T ! (Where T= Temperature, with constants R0 and )

There are two main types of losses of power in transformers: No load losses and Load losses

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Example of heat generation in a transformer

! TRAFO: 630 kVA (15kV/0.42 kV), with 3 MT of TRO ! Losses (Q) in TRAFO ! QCore= 600 W and QLoad= 4600 W ! Reference: EFACEC 2012 ! To keep temperature steady in the transformer the cooler needs to remove 5200 W from the oil! ! If no cooler is installed, the oil temperature will rise 3C in 1 hour! ! Cellulose degrades faster at higher temperature!

Heat transfer in transformers

29.09.13

Convective and conductive heat transfer

Convective heat transfer is the cooling from the cold wind (flowing air), and is the chilling effect on your bare skin and through your clothes. Conductive heat transfer is the cooling through the clothes (in stagnant air) and no wind all.

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Heat transfer overview

Heat transfer in transformers

29.09.13

Specific heat capacity, cp

! Specifies the amount of heat required to change the temperature of an object or solid/liquid/gas by a given amount. ! Example: In order to increase the temperature 1 K of 1 kg naphthenic transformer oil at 40C : 1875 J/(kg*K). This means that 1875 J is needed to be transfered to 1 kg of oil to increase the temperature to 41C. ! The specific heat capacity is changing over increasing temperatures as shown below

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Thermal conductivity

! Thermal conductivity, k ! Specifies how a material conduct heat flux from a point to another. The heat conductivity is measured in stagnant fluid at a certain temperature. ! In order to transport heat flux through a layer of naphthenic transformer oil at 40C; k=0,310 W/(m*K) ! Thermal conductivity is important part of total heat transfer in the boundary layer at laminar flow (high viscosity and/or low flow velocity)

Heat transfer in transformers

29.09.13

Density and itsrole in heat transfer

! Density ; Describes how many kilograms 1 m3 of fluid weight at a certain temperature. ! Density is changing over temperature due to volume expansion at higher temperature ! Natural convection is heat transfer where the density gradient drives the circulation: warm fluid rises (stable) and cold fluid sinks (unstable)

10

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

ONAN cooling of transformer

! The warmer oil rises to the top and cools down and flows to the bottom in the tubes mounted in the mantle. For transformers below 25kVA is ONAN common.

11

Heat transfer in transformers

29.09.13

ONAF cooling of transformer

! The oil is cooled by a fan (forced air flow) in the heat transfer zone

12

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

OFAF cooling of transformer

! The oil is (forced or) pumped to the heat transfer zone where the air is forced by a fan. OF cooling is the common choice for transformer above 60MVA. ! OEMs recommends a maximum flow velocity of 1 m/s for the insulation oil . ! In practice the velocity is around 0.5 m/s and up to 1 m/s. ! Above 1 m/s there is risk for static electricity charges build up, or ECT

13

Heat transfer in transformers

29.09.13

OFWF

! Water cooling is more effiecient than air cooling. Corrosion and leakage might be an issue when used in transformers. Cp and k is much higher for water than for air.

14

Heat transfer in transformers

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Viscosity

! Lowest possible viscosity is the best way to obtain rapid and efficient cooling in a transformer

Heat transfer in transformers

Virtual Oil Wheel

T

2

P

T

1

w

w f n p = = = =

Calculation of the natural oil circulation speed on basis of the Laws of Bernoulli, Newton, Reynolds and Prandtl.

p

w

=

f

Oil flow speed Calculation factor Kin. viscosity at operation temperature force from buoyancy

29.09.13

S11

Properties behind eective Transformer Oil Cooling

Influence of Viscosity to Heat Dissipation

T [C]

63

62

60

58

T=3C

kin. Viscosity [mm/s] 5

Operation temperature

of cooling system

depends on viscosity

of insulating oil

1 mm/s higher

working-

viscosity leads to 3C

higher operation-

temperature

4800

5000

5200

Loss Heat [W/h]

29.09.13

Viscosity index

! Oil with lower viscosity index have better cooling properties ! Naphthenic oil have lower viscosity index

18

Subjectmatter, Name, Division

29.09.13

10

S11

Properties behind eective Transformer Oil Cooling

Transformer Operating Temperature for two oils with the same viscosity at 40 C

T [C] 70

T=2.7C

Oil Viscosity [mm2/s] 2.8 2

Operating temperature of transformer cooling system is dependent on transformer oil viscosity

40

Index:

5400 5600 Dissipation Heat [W/h]

1 mm/s higher operating viscosity is leading to approximately 3C higher operating temperature

19

Jayme Nunes

Nynas AB

29.09.13

Hanging Paper Wetting

! Level of oil wetting checked over 72 h ! Two oils compared ! Paraffinic Visc. 40 C 10.6 cSt Visc. 20 C 22.5 cSt ! Naphthenic Visc. 40 C 9.1 Visc. 20 C 19.5

29.09.13

11

S11

Properties behind eective Transformer Oil Cooling

Results over time

Naphthenic Paraffinic

29.09.13

Reynolds number

! Reynolds number: Re= ! u = Flow velocity of the oil in [] ! D= Characteristic lenght, which is for a pipe the diameter in [m] ! = Kinematic viscosity in [2/] ! In pipes: At Re 2300 the flow will change from laminar to turbulent and over 5000 fully turbulent is developed

!

! When the inertial forces dominates over the viscous forces, small turbulent eddys increases mixing between warmer oil and cooler oil during the flow and enhances heat and mass transfer

22

Heat transfer in transformers

29.09.13

12

S11

Properties behind eective Transformer Oil Cooling

Flowing fluid and heat transfer in pipes

! At higher flow velocity the fluid will develop turbulence and this will be beneficial for the heat transfer. ! A lower viscosity increases heat transfer and turbulence ! At higher flow rate the fluid

Turbulent flow

Laminar flow

23

Heat transfer in transformers

29.09.13

Viscosity and VI

This temperature zone is interesting for investigating cooling properties of oils

Heat transfer in transformers

13

S11

Properties behind eective Transformer Oil Cooling

Heat transfer coefficient of three different types of transformer fluids

Cooler data: Pipe : 10 cm Velocity: 0.5 m/s

25

Heat transfer in transformers

29.09.13

Conclusions

! The viscosity is the dominant physical property for the heat transfer coefficient ! A lower viscosity increases heat transfer ! Oil with lower viscosity have much better cooling properties ! Oil with lower viscoisty can impregnate insulating paper much faster ! Forced convection is the best way to increase cooling rate on a surface ! A better cooling capacity in a transformer fluid lowers the overall temperatures in the unit and potentially extends cellose life time

26

Heat transfer in transformers

29.09.13

14

S11

Properties behind eective Transformer Oil Cooling

Thank you! Any questions?

27

Heat transfer in transformers

29.09.13

15

S11

Você também pode gostar

- H W5Documento1 páginaH W5Bahadır KayaAinda não há avaliações

- Very GOOD Condition Monitoring TransformersDocumento67 páginasVery GOOD Condition Monitoring Transformersmartinez_josel100% (1)

- Determination of OD Cooling System Parameters Based On Thermal Modeling of Power Transformer WindingDocumento12 páginasDetermination of OD Cooling System Parameters Based On Thermal Modeling of Power Transformer Windingmpu682Ainda não há avaliações

- R14 - Steam Power Cycles PDFDocumento10 páginasR14 - Steam Power Cycles PDFnotoriousneal12Ainda não há avaliações

- Use of Ammonia in Comfort Cooling and Heat Pump ApplicationsDocumento10 páginasUse of Ammonia in Comfort Cooling and Heat Pump ApplicationsOmran Al-SatariAinda não há avaliações

- Cooling System: Engine - 2Tr-Fe Engine EG-18Documento2 páginasCooling System: Engine - 2Tr-Fe Engine EG-18Maxi SardiAinda não há avaliações

- Official US-Chemtrail Patent From 1990Documento7 páginasOfficial US-Chemtrail Patent From 1990bitbunker7929100% (2)

- 2019dec - MEC551Documento9 páginas2019dec - MEC551Aina Najwa Binti ShamsuddinAinda não há avaliações

- Mcqs Part 11-mDocumento15 páginasMcqs Part 11-msiraj udinAinda não há avaliações

- Turbine PerformancesDocumento28 páginasTurbine PerformancesBryan Scofield100% (1)

- Vapor Power Cycles Lecture 1Documento23 páginasVapor Power Cycles Lecture 1Albert Shesman100% (1)

- Comparison of Liquid Chillers With Screw Compressor For Air-Conditioning Applications With Ammonia and R134aDocumento6 páginasComparison of Liquid Chillers With Screw Compressor For Air-Conditioning Applications With Ammonia and R134ahjduarteAinda não há avaliações

- Thermal Design Parameters Radiator & Oil CoolersDocumento9 páginasThermal Design Parameters Radiator & Oil CoolersManikanta SwamyAinda não há avaliações

- L2 Power TransformerDocumento97 páginasL2 Power TransformerHarmandeep AhluwaliaAinda não há avaliações

- Mahek PresentationDocumento13 páginasMahek PresentationAmit GangulyAinda não há avaliações

- Short Time Over Load of Transformer PDFDocumento107 páginasShort Time Over Load of Transformer PDFIrfan AliAinda não há avaliações

- Important Points 1-50Documento3 páginasImportant Points 1-50akarshansoodAinda não há avaliações

- Techno Economic Report of Oil TreatmentDocumento5 páginasTechno Economic Report of Oil TreatmentZain Ul AbedinAinda não há avaliações

- Mee 181 - L7Documento9 páginasMee 181 - L7Tawsiful AlamAinda não há avaliações

- Question & AnswerDocumento41 páginasQuestion & AnswerKapil Dev Mandal100% (1)

- Generator Hydrogen CoolingDocumento4 páginasGenerator Hydrogen CoolingBanamali MohantaAinda não há avaliações

- Van NessDocumento50 páginasVan NessBianca SpotifyAinda não há avaliações

- Thermo 2Documento23 páginasThermo 2SHek Hxni100% (1)

- Design and Thermal Analysis of Hydraulic Oil Cooler by Using Computational Fluid Dynamics (CFD)Documento8 páginasDesign and Thermal Analysis of Hydraulic Oil Cooler by Using Computational Fluid Dynamics (CFD)Anonymous kw8Yrp0R5rAinda não há avaliações

- Dry Type TransformersDocumento12 páginasDry Type Transformersraul_bsuAinda não há avaliações

- Compact Power Transformers For Substation in Urban Areas Using Hybrid Insulation SystemDocumento8 páginasCompact Power Transformers For Substation in Urban Areas Using Hybrid Insulation SystemR0B0T2013Ainda não há avaliações

- The Meaning of LIFEDocumento77 páginasThe Meaning of LIFEjokanovAinda não há avaliações

- Transformer Heating and CoolingDocumento11 páginasTransformer Heating and CoolingAli FarooqAinda não há avaliações

- Transformer Cooling Methods HTTPDocumento6 páginasTransformer Cooling Methods HTTPa7med_26Ainda não há avaliações

- Centrifugal Chiller - Fundamentals - Energy-ModelsDocumento30 páginasCentrifugal Chiller - Fundamentals - Energy-ModelsPrashant100% (1)

- Refrigeration and LiquefactionDocumento51 páginasRefrigeration and LiquefactionAlbert ShesmanAinda não há avaliações

- Carnot Cycle For I.C Engine and Its LimitationsDocumento27 páginasCarnot Cycle For I.C Engine and Its Limitationsmsshahenter0% (1)

- Transformer OilDocumento19 páginasTransformer Oilinetbrosingcentre100% (1)

- 8carnot CycleDocumento24 páginas8carnot CycleMuhammad Randy AkbarAinda não há avaliações

- Refrigeration and Heat PumpsDocumento8 páginasRefrigeration and Heat PumpsFarouk BassaAinda não há avaliações

- Reverse Cornot, Vapor Compression Cycles Part IDocumento14 páginasReverse Cornot, Vapor Compression Cycles Part ISumran ShahidAinda não há avaliações

- Vapor Power Cycles Lecture 1Documento55 páginasVapor Power Cycles Lecture 1mjunaidAinda não há avaliações

- Oesse HY Catalog enDocumento104 páginasOesse HY Catalog enAlejandroCalleRuizAinda não há avaliações

- Power Production & RefrigerationDocumento30 páginasPower Production & RefrigerationVina Dwita100% (1)

- Heat Trasnfer in EnginesDocumento29 páginasHeat Trasnfer in Enginesmohan ladiAinda não há avaliações

- Lab Heat PumpDocumento9 páginasLab Heat PumpShahran IezzatAinda não há avaliações

- Production of Power From Heat & RefrigerationDocumento32 páginasProduction of Power From Heat & Refrigerationadith aninditoAinda não há avaliações

- Refrigeration and Air Conditioning: Lecture # 3Documento38 páginasRefrigeration and Air Conditioning: Lecture # 3Owais AzharAinda não há avaliações

- ITK-233-6 - Power Production & RefrigerationDocumento30 páginasITK-233-6 - Power Production & RefrigerationAndy Noven KrisdiantoAinda não há avaliações

- TEWI AnalysisDocumento63 páginasTEWI Analysismirali74Ainda não há avaliações

- Ohrid 2013 IntroductionDocumento8 páginasOhrid 2013 IntroductionforuzzAinda não há avaliações

- Gen-Seal&cool-New - 500 MWDocumento98 páginasGen-Seal&cool-New - 500 MWharisankar100% (2)

- Refrigeration CyclesDocumento10 páginasRefrigeration Cyclesaravoof84Ainda não há avaliações

- Compressors IntroductionDocumento12 páginasCompressors Introductionhiyeon100% (1)

- Thermodynamics - Lesson 5Documento13 páginasThermodynamics - Lesson 5Raymond AbesamisAinda não há avaliações

- Transformers: Electrical Engineering I Module 7.1 Course NotesDocumento25 páginasTransformers: Electrical Engineering I Module 7.1 Course NotesAmirul AmranAinda não há avaliações

- The LINE No. 11 Distribution Transformer Article June 2005Documento2 páginasThe LINE No. 11 Distribution Transformer Article June 2005Lilanka UdawattaAinda não há avaliações

- Working Principle of A TransformerDocumento67 páginasWorking Principle of A TransformerkrishnandrkAinda não há avaliações

- RevisionDocumento19 páginasRevisionmenemAinda não há avaliações

- Heat Transfer in RadiatorsDocumento20 páginasHeat Transfer in RadiatorsJignesh Gandhi100% (2)

- Thermodynamics - Lesson 6Documento13 páginasThermodynamics - Lesson 6Raymond AbesamisAinda não há avaliações

- Lecture 5Documento16 páginasLecture 5Nely JayAinda não há avaliações

- 5 Second Law of ThermodynamicsDocumento14 páginas5 Second Law of ThermodynamicsThulasi RamAinda não há avaliações

- Unit 2Documento31 páginasUnit 2ashwinharry69Ainda não há avaliações

- Choice of MV - LV Transformer - Electrical Installation GuideDocumento5 páginasChoice of MV - LV Transformer - Electrical Installation Guidehmha83Ainda não há avaliações

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- PR 859991559370 enDocumento2 páginasPR 859991559370 enprevrtljivacAinda não há avaliações

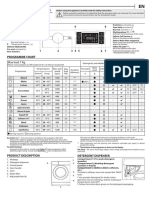

- WWW - Whirlpool.eu/register: User ManualDocumento14 páginasWWW - Whirlpool.eu/register: User ManualprevrtljivacAinda não há avaliações

- 198 199Documento2 páginas198 199prevrtljivacAinda não há avaliações

- Users Guide 48601Documento4 páginasUsers Guide 48601prevrtljivacAinda não há avaliações

- Press Brake BendingDocumento6 páginasPress Brake Bendingkumarjs19Ainda não há avaliações

- Voe Main2Documento4 páginasVoe Main2prevrtljivacAinda não há avaliações

- DC or AC DrivesDocumento12 páginasDC or AC DrivesNeelima MishraAinda não há avaliações

- Technical Specification of Asta Cooling Duct CTCDocumento2 páginasTechnical Specification of Asta Cooling Duct CTCprevrtljivacAinda não há avaliações

- Today:: Internal Effects in Beams Continued - Deformation Signs Continued - FramesDocumento28 páginasToday:: Internal Effects in Beams Continued - Deformation Signs Continued - FramesprevrtljivacAinda não há avaliações

- Hany Et AlDocumento13 páginasHany Et AlprevrtljivacAinda não há avaliações

- Complex Theory2Documento8 páginasComplex Theory2prevrtljivacAinda não há avaliações

- 7.5 The form: r (cos θ + j sin θ)Documento2 páginas7.5 The form: r (cos θ + j sin θ)prevrtljivacAinda não há avaliações

- 7.3 The Argand Diagram: Imaginary AxisDocumento1 página7.3 The Argand Diagram: Imaginary AxisprevrtljivacAinda não há avaliações

- 7.4 The Polar Form: B Z A + BJ (A, B) RDocumento2 páginas7.4 The Polar Form: B Z A + BJ (A, B) RprevrtljivacAinda não há avaliações

- 7.2 Complex Arithmetic: C Pearson Education LTD 2000Documento2 páginas7.2 Complex Arithmetic: C Pearson Education LTD 2000prevrtljivacAinda não há avaliações

- Proselecta ManualDocumento1 páginaProselecta ManualvjAinda não há avaliações

- Designing A BEM Heat ExchangerRev1Documento22 páginasDesigning A BEM Heat ExchangerRev1Steve WanAinda não há avaliações

- Experiments in Transport Phenomena PDFDocumento162 páginasExperiments in Transport Phenomena PDFRebeca Albino100% (1)

- Heat Conduction Through Composite WallsDocumento6 páginasHeat Conduction Through Composite WallsGael MendozaAinda não há avaliações

- To Verify NewtonDocumento26 páginasTo Verify NewtonRoshan AdhikariAinda não há avaliações

- Cold Storage Warehouse Design FactorsDocumento22 páginasCold Storage Warehouse Design FactorsLhexter Mhervin CoAinda não há avaliações

- 6023Documento6 páginas6023SHAFEEK A RAinda não há avaliações

- Building Physics: EditionDocumento28 páginasBuilding Physics: EditionAnnisa FajrianiAinda não há avaliações

- Cm2-Interactions - Detection - Dosimetry ÇaouiDocumento84 páginasCm2-Interactions - Detection - Dosimetry ÇaouiDouaa lkAinda não há avaliações

- LAM 24 - Natural Convection Heat Transfer - Informal Report - Benita - COMMENTEDDocumento14 páginasLAM 24 - Natural Convection Heat Transfer - Informal Report - Benita - COMMENTEDdannie3Ainda não há avaliações

- Ejercicios Propuestos Temas Hasta Primer PrevioDocumento2 páginasEjercicios Propuestos Temas Hasta Primer PrevioJuan De DiosAinda não há avaliações

- Thermodynamics Lecture 6Documento1 páginaThermodynamics Lecture 6Mariah NicolAinda não há avaliações

- Heat Traps in Installations 20120508Documento4 páginasHeat Traps in Installations 20120508Mike ArqAinda não há avaliações

- Uts Be3002Documento2 páginasUts Be3002malya corryAinda não há avaliações

- Heat Transfer: Kotiba Hamad - Sungkyunkwan UniversityDocumento31 páginasHeat Transfer: Kotiba Hamad - Sungkyunkwan UniversityAlex choquehuanca VilcaAinda não há avaliações

- Transport: Engineering To Engine HeatDocumento13 páginasTransport: Engineering To Engine HeatPankaj Kumar SainiAinda não há avaliações

- Paper 2 Theoretical Parametric Study of Wrap-Around Heat Pipe (WAHP) in Air PDFDocumento19 páginasPaper 2 Theoretical Parametric Study of Wrap-Around Heat Pipe (WAHP) in Air PDFAnonymous 7pJU2NFhAAinda não há avaliações

- Experiment EME4016 - 2015 - 2016 Sem 1Documento9 páginasExperiment EME4016 - 2015 - 2016 Sem 1Joshua ChongAinda não há avaliações

- Melting and Solidification of A Pure Metal On A Vertical WallDocumento8 páginasMelting and Solidification of A Pure Metal On A Vertical WallMuhammad AkbarAinda não há avaliações

- Terminology of HVAC TermsDocumento2 páginasTerminology of HVAC TermsNaresh SewdinAinda não há avaliações

- HVAC SyllabusDocumento8 páginasHVAC SyllabusbalajivangaruAinda não há avaliações

- 10 Comparisons Between Hydronics and VRFDocumento8 páginas10 Comparisons Between Hydronics and VRFBinu BhadranAinda não há avaliações

- Heat Transfer Through Composite Wall: Iii Sem/Basic Mechanical Engineering/Dr.R.Sudhakaran 1/3Documento32 páginasHeat Transfer Through Composite Wall: Iii Sem/Basic Mechanical Engineering/Dr.R.Sudhakaran 1/3Narayanan SubramanianAinda não há avaliações

- AaaaDocumento10 páginasAaaashintaAinda não há avaliações

- Heat and Mass Transfer in A Clay-Pot Refrigerator: Analysis RevisitedDocumento15 páginasHeat and Mass Transfer in A Clay-Pot Refrigerator: Analysis RevisitedSanaan AhmadiAinda não há avaliações

- Importance of Transport Phenomena? AnsDocumento3 páginasImportance of Transport Phenomena? AnsRohit Bansode100% (1)