Escolar Documentos

Profissional Documentos

Cultura Documentos

Error Code Ir3300

Enviado por

Nadeesha NishaniDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Error Code Ir3300

Enviado por

Nadeesha NishaniDireitos autorais:

Formatos disponíveis

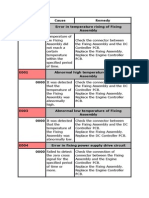

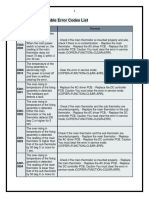

Code Subcode Description E000 0000 The reading of the main thermistor does not reach 30oC 1 sec

aft er the main power switch is turned on. Or, it does not reach 70oC 2 sec thereaft er E001 0000 The main thermistor detects 250oC or higher 0001 The main thermistor or the sub thermistor detects overheating (hardware circuit detection) 0002 The sub thermistor detects about 295oC or higher E002 0000 The temperature of the fixing film is as follows: has exceeded 100oC, but does not reach 115oC within 1 sec thereafter. has exceeded 140oC, but does not reach 150oC within 1 sec thereafter. has exceeded 160oC, but does not reach 165oC within 1 sec thereafter E003 0000 The main thermistor reading is lower than 140oC when paper is mo ved 0001 Low fixing temperature detection after standby (by sub thermistor) E007 0000 An error in the rotation of the fixing film is detected. The reading of the main thermistor is 100oC or higher and, in addition, the fixi ng film sensor does not detect the rotation of the film for 6 sec or more while the fixing motor is driven E010 0000 After the main motor drive signal is generated, the clock signal does to arrive within 1.3 sec E014 000 After the fixing motor drive signal is generated, the clock sign al does not arrive within 1.3 sec E019 0000 The waste toner case is full of waste toner E032 0001 The DA unit connection is disconnected (after connection). E051 0000 At start-up, home position is not detected when the horizontal r egistration assembly is moved 100 mm in the direction of home position E064 0000 The presence of a high-voltage error is communicated by the comp osite power supply PCB (The output for primary charging, developing, or transfer has deviated from a specific level of voltage) E100 0001 The BD signal is not detected 10 times or more within 10 msec in 5 msec after the generation of the laser drive signal 0001 The BD signal is not detected 10 times or more within 10 msec in 5 msec after the generation of the laser drive signal 0002 While the laser is ON, the BD signal cycle is outside a specific range 2 0 times or more continuously 0003 While the laser is ON, the horizontal sync signal cycle is outside a spe cific range 20 times or more E110 0000 The motor ready signal does not arrive within 15 sec after the l aser scanner motor drive signal is generated E202 0001 The scanner home position sensor does not go OFF when the scanne r is moved forward by 40 mm 0002 The scanner home position sensor does not go ON when the scanner is move d reverse 450 mm E204 0001 While an original is being read, the image leading edge signal d oes not arrive from the ADF E220 0001 A fault is detected on the inverter PCB for the scanning lamp E225 0000 A specific level cannot be attained for the signal during CCD ga in correction at power-on 0002 The edge gain correction level is different from the correction level fo r the preceding sheet by a specific level or more E240 0000 A fault occurs in communication between the CPU of the main cont roller PCB and the CPU of the DC controller PCB E243 0000 A fault occurs in the communication between the CPU of the contr ol panel PCB and the CPU of the main controller PCB E248 0001 A difference is discovered between the ID in EEPROM read when th e main power switch is turned on and the ID in ROM upon comparison 0002 The data read does not match the data written to EEPROM 0003 A difference is discovered between the ID of EEPROM and the ID of ROM up on comparison while writing data

E261 0000 The intervals of zero-cross signals deviate from the tolerance r ange while the fixing heater is supplied with power E302 0001 During shading, the shading processing does not end on the reade r controller PCB after 1 sec 0002 During stream reading, the edge white addition processing does not end o n the rear controller PCB after 10 sec E315 - Any of the following is true in the image processing by the main contr oller: The image data has a fault The encoding/decoding operation for image data has a fault The image processing element of the main controller PCB has a fault E601 0000 When an image is transferred between the main controller PCB and the HDD, the main controller PCB detects a fault in control information 0001 When an image is transferred between the main controller PCB and the DC controller PCB, the DC controller PCB detects a fault in the control information E602 0001 A mounting fault of the HDD is detected when the HDD is started up from the BOOT ROM 0002 A data read fault of the HDD is detected when the HDD is started up from the BOOT ROM E604 0000 A fault is detected in the image memory E605 0001 A fault is detected in the battery for the image memory E606 0001 A mounting fault of the HDD is detected when the HDD is started up from the BOOT ROM E674 0000 A faulty occurs in the communication between the fax PCB and the main controller PCB E677 0001 A fault occurs it the combination between any of the printer boa rds (accessories) and the main controller PCB E710 0001 When the main power is turned on, the communication IC (IPC) on the reader controller PCB cannot be initialized 0002 When the main power is turned on, the communication IC (IPC) on the DC c ontroller PCB cannot be initialized 0003 When the main power is trend on, the communication IC (IPC) on the main controller PCB cannot be initialized E711 0001 Data is written to the error register of the communication IC (I PC) on the reader controller PCB four times or more within 1.5 sec 0002 Data is written to the error register of the communication IC (IPC) on t he DC controller PCB four times or more within 2 sec 0003 Data is written to the error register of the communication IC (IPC) on t he main controller PCB four times or more within 2 sec E712 0001 The communication is not resumed 3 sec or more after data has be en written to the error register of the communication IC (IPC) on the ADF contro ller PCB 0002 The transmission bit is not enabled 10 sec or more in the sync register of the communication IC (IPC) on e reader controller PCB E713 0000 The communication with the finisher is not resumed 3 sec or more after it is disrupted E716 0000 The ID signal is not detected within a specific period of time a fter the presence of a pedestal is detected E719 0000 Erroneous communication with card reader (serial communication) 0002 Erroneous communication with coin vender (serial communication) E717 0001 The communication with the DA unit is not resumed 3 sec or more after it is disrupted E719 0001 The communication between the Card Reader-C1 or the coin vendor and the main controller PCB is disrupted E732 0001 A fault is detected by the main controller PCB in the communicat ion between reader controller PCB and the main controller PCB E733 0001 A fault is detected by the main controller PCB in the communicat ion between the DC controller PCB and the main controller PCB E737 0000 During self diagnosis at power-on, the DRAM check finds a fault in the main controller PCB

E740 0001 At power-on, the LAN card has a fault 0002 The MAC address has a fault 0003 The LAN card cannot be read E741 0000 The PCI bus has a fault E743 0000 The reader controller PCB detects a fault in the communication b etween the main controller PCB and the reader controller PCB E744 0000 The BootROM on the main controller PCB and the system software a re for different models or are of different types E803 0000 The 24V output from the composite main power supply PCB is absen t for 1 sec or more E805 The clock signal is absent for 5 sec or more after the fan drive signal has been generated. The detail codes of the fans in question are as foll ows: 0001 developing fan (FM1) 0002 fixing fan (FM2) 0003 curl reducing fan (FM4) 0004 curl reducing fan (FM5) 0005 electrical unit fan (FM3) E901 0000 The motor ready signal does not arrive within 1.3 sec after the pedestal main motor drive signal is generated ADF Error Codes E420 0001 When the power switch of the host machine is turned on, the back -up data from the EEPROM cannot be read or the data that has been read has a fau lt E421 0001 The back-up data cannot be written to the EEPROM, or the data th at has been written has a fault E422 0001 While the ADF is in standby, the communication with its host mac hine is disrupted for 5 sec or more; or, while the ADF is in operation, the comm unication with its host machine is disrupted for 0.5 sec or more Saddle Finisher-G1 Error Codes E501 0001 The communication between the finisher controller PCB and the pu ncher drive PCB is disrupted E505 0001 When the main power is turned on, the checksum of the finisher c ontroller PCB has a fault 0002 When the main power is turned on, the checksum of the puncher driverPCB has a fault E510 0001 The feeding roller does not leave home position when the feed mo tor is driven for 2 sec 0002 The feeding roller does not return to home position when the feed motor is driven for 2 sec E514 0001 The delivery belt does not leave home position when the stack de livery motor is driven for 3 sec 0002 The delivery belt does not return to home position when the stack delive ry motor is driven for 3 sec E530 0001 The aligning plate (rear) does not leave home position when the alignment motor (rear) is driven for 3 sec 0002 The aligning plate (rear) does not return to home position when the alig nment motor (rear) is driven for 3 sec E531 0001 The stapler does no leave home position when the stapler/folder motor is driven for 1.5 sec 0002 The stapler does not return to home position when the stapler/folder mot or is driven for 1.5 sec 0003 The clock signal is disrupted for 1 sec or more while the stapler/folder motor is driven E532 0001 The stapler unit does not leave home position when the stapler s lide motor is driven for 4.5 sec 0002 The stapler unit does not return to home position when the stapler slide motor is driven for 4.5 sec E537 0001 The aligning plate (front) does not leave home position when the alignment motor (front) is driven for 3 sec

0002 The aligning plate (front) does not return to home potion when the align ment motor (front) is driven for 3 sec E540 0001 The paper surface sensor remains unchanged 10 sec after the tray ascent/ descent motor is driven 0002 The tray upper sensor goes ON while the tray is moving up. 0003 The clock for the clock sensor is disrupted for 10 sec or more while the tray ascent/descent motor is driven E577 0001 The paddle does not leave home position when the paddle motor is driven for 2 sec or more 0002 The paddle does not return to home position when the paddle motor is dri ven for 2 sec or more 0003 The stack ascent/descent guide does not leave home position when the pad dle motor is driven for 2 sec or more 0004 The stack ascent/descent guide does not return to home position when the paddle motor is driven for 2 sec or more E590 0001 The puncher does not return to home position when the puncher mo tor is driven for 250 msec 0002 The clock from the puncher motor clock sensor is disrupted for 60 msec o r more when the puncher motor is driven E592 In the course of sensor output automatic adjustment, the light-r eceiving voltage is 2.5 V or less even when the light-emitting voltage is set to 4.4 V. In the course of output automatic adjustment, the light-receiving voltage is 2.5 V or more even when the light-emi tting voltage is set to 0 V. In the course of sensor output automatic adjustment , the light-emitting voltage is set to 4.4 V or more 0001 to 0005 Horizontal registration sensor 0006 Puncher waste full sensor E593 0001 The puncher not leave home position when the puncher shift motor is driven for 1 sec 0002 The puncher does not return to home position when the puncher shift moto r is driven for 1 sec E5F1 0001 The folding roller does not leave home position when the stapler /folder motor is driven for 1.5 sec 0002 The folding roller does to return to home position when the stapler/fold er motor is driven for 3.5 sec or more 0003 The clock is disrupted for 1 sec or more while the stapler/folder motor is driven Finisher-J1 Error Codes E500 0000 The communication between the copier and the finisher is disrupt ed and is not corrected for 5 sec or less E514 0000 At the start of the motor CW operation, the stack handling motor (M2) may be driven for a specific number of rotations; however, the stack deliv ery lever home position sensor (S8) does not go ON E530 0000 The alignment motor (M4) is driven for a specific number of rota tions, but the aligning plate home position sensor (S7) does not go ON. The alig nment motor (M4) is driven for a specific number of rotations, but the aligning plate home position sensor (S7) does not go OFF E531 0000 The stapling home position sensor (S16) does not go off 0.5 sec after the stapler motor is rotated CW. The stapling home position sensor (S16) d os not go ON with 0.5 sec after the stapler motor is rotated CW and, thereafter, the sensor does not go ON within 0.5 sec after the motor is rotated in reverse E537 0000 The aligning plate home position sensor (S6) does not go ON when the front alignment motor (M3) is driven for a specific number of rotations. Th e aligning plate home position sensor (S6) does not go OFF when the front alignm ent motor (M3) is driven for a specific number of rotations E577 0000 The return roller does not reach home position when the delivery motor (Ml) has been driven as much as will move it to the return roller home po sition sensor (S3) E580 0000 The delivery tray upper limit sensor (S13) goes ON while the del ivery tray ascent/descent motor (M5) is in operation.

The clock signal of the delivery tray ascent/descent motor clock sensor (S9) is not detected 15 times or more within 0.8 sec while the delivery tray ascent/ des cent motor (M5) is in operation. The delivery tray paper height sensor (S10) does not go ON 4 sec after the deliv ery tray ascent/descent motor (M5) starts to move up. The delivery tray paper height sensor (S10) does not go OFF 4 sec after the deli very tray ascent/descent motor (M5) starts to move down E585 0000 At the start of the motor CCW operation, the stack handling moto r (M2) may be driven for a specific number of rotations; however, the stack deli very lever home position sensor (S8) does not go ON

Você também pode gostar

- Exploring Arduino: Tools and Techniques for Engineering WizardryNo EverandExploring Arduino: Tools and Techniques for Engineering WizardryNota: 4.5 de 5 estrelas4.5/5 (5)

- CSMC25M-Canon Ir2200 2800 3300 Service ManualDocumento768 páginasCSMC25M-Canon Ir2200 2800 3300 Service ManualELIAS100100% (2)

- Project Varibles: FPC-500 Battery CalculatorDocumento14 páginasProject Varibles: FPC-500 Battery CalculatorLe Quang AnAinda não há avaliações

- Canon IR2200 Trouble Error CodesDocumento29 páginasCanon IR2200 Trouble Error CodesnafeesAinda não há avaliações

- Division of Mzone Financial Services PVT LTDDocumento19 páginasDivision of Mzone Financial Services PVT LTDMzone SalesAinda não há avaliações

- Canon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesDocumento37 páginasCanon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesTariq MajeedAinda não há avaliações

- Design & Analysis of Mono Composite Leaf SpringDocumento5 páginasDesign & Analysis of Mono Composite Leaf Springijsret100% (1)

- Canon Copier Error CodesDocumento9 páginasCanon Copier Error CodesHaftamu100% (1)

- Ralph M. McInerny - Aquinas and Analogy (1996, Catholic University of America Press)Documento182 páginasRalph M. McInerny - Aquinas and Analogy (1996, Catholic University of America Press)cuba esquivel amadeoAinda não há avaliações

- CH 02Documento20 páginasCH 02Pauline Nguyen100% (1)

- Ir 3300 Code ListDocumento44 páginasIr 3300 Code ListAashish Chaudhari84% (44)

- DLL CSS Week 5Documento3 páginasDLL CSS Week 5Juanits BugayAinda não há avaliações

- SaaS Marketing Automation Playbook TeaserDocumento19 páginasSaaS Marketing Automation Playbook TeaserValery FenskeAinda não há avaliações

- Chapter 1 - PolymersDocumento94 páginasChapter 1 - Polymersa2hasijaAinda não há avaliações

- Error Codes Canon Ir3300Documento5 páginasError Codes Canon Ir3300Ashraf Ali82% (11)

- Fixing Assembly Temperature Errors and SolutionsDocumento7 páginasFixing Assembly Temperature Errors and SolutionsAnonymous 2WKRBqFlfAinda não há avaliações

- Error Codes 7095Documento70 páginasError Codes 7095Gerald Aguero PorrasAinda não há avaliações

- Error Code Details for Canon ImageRunner CopiersDocumento70 páginasError Code Details for Canon ImageRunner CopiersPadiparn Sae HouseAinda não há avaliações

- ERRor Code IR3245Documento7 páginasERRor Code IR3245JatmokoAinda não há avaliações

- Codigos de Error CanonDocumento7 páginasCodigos de Error CanonHenryAinda não há avaliações

- Ir7095 Error CodesDocumento15 páginasIr7095 Error Codesnag85100% (5)

- Canon IR2530 Error CodesDocumento10 páginasCanon IR2530 Error CodesnafeesAinda não há avaliações

- Canon IR Advance 500 Trouble Error CodesDocumento30 páginasCanon IR Advance 500 Trouble Error CodesnafeesAinda não há avaliações

- Canon IR2535 Trouble Error CodesDocumento36 páginasCanon IR2535 Trouble Error Codesnafees100% (4)

- Canon Ir8070 Error Codes List PDFDocumento18 páginasCanon Ir8070 Error Codes List PDFGirish KumarAinda não há avaliações

- Canon IR2022 Error CodesDocumento7 páginasCanon IR2022 Error CodesnafeesAinda não há avaliações

- Canon iR8070 Error Codes ListDocumento18 páginasCanon iR8070 Error Codes ListGirish Kumar100% (1)

- FOR Approval Specification: 42.0" Wuxga TFT LCD TitleDocumento35 páginasFOR Approval Specification: 42.0" Wuxga TFT LCD TitleWalter Petracca100% (1)

- Canon IR2016 Error CodesDocumento7 páginasCanon IR2016 Error CodesnafeesAinda não há avaliações

- User Manual SRT1CDocumento578 páginasUser Manual SRT1Cgbaeta0% (1)

- Canon IR105 Trouble Error CodesDocumento32 páginasCanon IR105 Trouble Error Codesnafees0% (2)

- Canon IR2020 Trouble Error CodesDocumento6 páginasCanon IR2020 Trouble Error Codesnafees100% (1)

- IR Remote Control TesterDocumento4 páginasIR Remote Control TesterNahitha100% (1)

- Fixing, Transfer, Developing Errors in Copier CodesDocumento9 páginasFixing, Transfer, Developing Errors in Copier CodesJozef0% (1)

- Canon Error CodesDocumento10 páginasCanon Error CodesEumir Garcia TrejoAinda não há avaliações

- SU KAM Cosmic 800 1400VA Manual PDFDocumento13 páginasSU KAM Cosmic 800 1400VA Manual PDFaliyu zaharaddeen0% (1)

- 171 CatalogDocumento156 páginas171 Catalogchente_b100% (1)

- Error Code Ir3245 - Series-SmDocumento22 páginasError Code Ir3245 - Series-SmvikramAinda não há avaliações

- SK350 / SK200 Software Manual: 1 How To Upload New Software For The SK350 / SK200Documento8 páginasSK350 / SK200 Software Manual: 1 How To Upload New Software For The SK350 / SK200Ray PutraAinda não há avaliações

- Attuatori Multigiro-AumaDocumento72 páginasAttuatori Multigiro-AumaAnonymous fbeCwgBFY50% (2)

- SMD FusesDocumento5 páginasSMD FusesatentinAinda não há avaliações

- Intro To MiRModbusTCPDocumento9 páginasIntro To MiRModbusTCPOliver Ochoa GarciaAinda não há avaliações

- Xerox Error CodesDocumento6 páginasXerox Error Codessaito36Ainda não há avaliações

- Danfoss VLT Micro Drive Fc51 Quick GuideDocumento20 páginasDanfoss VLT Micro Drive Fc51 Quick Guidewilly190486Ainda não há avaliações

- Service Manual: Induction Plate HD4918Documento2 páginasService Manual: Induction Plate HD4918Arumugam Rajendran100% (2)

- CITECT-1hr Quick Start Tutorial2Documento53 páginasCITECT-1hr Quick Start Tutorial2Stoica GeorgeAinda não há avaliações

- Samsung LN40D630M3FXZA Fast Track Guide (SM)Documento4 páginasSamsung LN40D630M3FXZA Fast Track Guide (SM)Carlos OdilonAinda não há avaliações

- Program Reset Ink Level Epson l100 l200 l800 - TeamtechDocumento8 páginasProgram Reset Ink Level Epson l100 l200 l800 - Teamtechvinujohnpanicker50% (2)

- Canon Error CodeDocumento13 páginasCanon Error CoderichardpalilinganAinda não há avaliações

- Konica Minolta C220/C280/C380 Malfunction CodeDocumento2 páginasKonica Minolta C220/C280/C380 Malfunction CodegrzegorzAinda não há avaliações

- Manual D2008fa G C PDFDocumento38 páginasManual D2008fa G C PDFAk100% (1)

- Canon IR7095 Error CodesDocumento21 páginasCanon IR7095 Error CodesnafeesAinda não há avaliações

- Mini Statement 1Documento2 páginasMini Statement 1Aashish ChaudhariAinda não há avaliações

- HG8245W5 Quick Start For QR Code 04 PDFDocumento15 páginasHG8245W5 Quick Start For QR Code 04 PDFhhhAinda não há avaliações

- iPR C270C265 - SM - 3Documento2.130 páginasiPR C270C265 - SM - 3stefanspa2Ainda não há avaliações

- LCD Display Troubleshooting ManualDocumento54 páginasLCD Display Troubleshooting Manualjl1225Ainda não há avaliações

- Daftar Kode Kesalahan Canon IR5000 IR6000Documento14 páginasDaftar Kode Kesalahan Canon IR5000 IR6000M MiftakhAinda não há avaliações

- Daftar Kode Kesalahan Canon IR5000 IR6000Documento26 páginasDaftar Kode Kesalahan Canon IR5000 IR6000desy zulfiarniAinda não há avaliações

- Canon Ir3225 Error Codes: Code DescriptionDocumento46 páginasCanon Ir3225 Error Codes: Code DescriptionnishaAinda não há avaliações

- Task Alfa Errors CodeDocumento47 páginasTask Alfa Errors CodeSuraj GavaliAinda não há avaliações

- Error Code 3030 CanonDocumento9 páginasError Code 3030 CanonsubramaniansonyAinda não há avaliações

- Fax and printer error codes guideDocumento39 páginasFax and printer error codes guideLuis Romero MartinezAinda não há avaliações

- Canon Ir1600 Error CodesDocumento11 páginasCanon Ir1600 Error Codesshelar_s4649100% (1)

- Codigos Error Canon 1019Documento3 páginasCodigos Error Canon 1019Mariangela PintoAinda não há avaliações

- Ir 6000 Code ListDocumento21 páginasIr 6000 Code ListAashish Chaudhari83% (12)

- KOg; gjpg;GupikAilaJDocumento2 páginasKOg; gjpg;GupikAilaJNadeesha NishaniAinda não há avaliações

- Grade 9 - Study Pack-Third Term PDFDocumento30 páginasGrade 9 - Study Pack-Third Term PDFNadeesha Nishani100% (2)

- 2019 3rdterm Dancing Answers G7 SM PDFDocumento2 páginas2019 3rdterm Dancing Answers G7 SM PDFNadeesha NishaniAinda não há avaliações

- "Way Forward" Study Pack - English Grade Ten Third Term-2021Documento26 páginas"Way Forward" Study Pack - English Grade Ten Third Term-2021Vindya Oshani100% (1)

- FTK(X)N-N, FTK(X)-N Series Inverter Pair Service ManualDocumento133 páginasFTK(X)N-N, FTK(X)-N Series Inverter Pair Service ManualKevin AryaAinda não há avaliações

- Es 2303 Installation Guide enDocumento2 páginasEs 2303 Installation Guide enNadeesha NishaniAinda não há avaliações

- KZ30 enDocumento82 páginasKZ30 enNadeesha NishaniAinda não há avaliações

- Es 2303 Installation Guide enDocumento32 páginasEs 2303 Installation Guide enNadeesha NishaniAinda não há avaliações

- R 03Documento21 páginasR 03Nadeesha NishaniAinda não há avaliações

- Safety Information enDocumento24 páginasSafety Information enNadeesha NishaniAinda não há avaliações

- TopAccess Guide enDocumento94 páginasTopAccess Guide enNadeesha NishaniAinda não há avaliações

- DP-1800 Om en 0000Documento172 páginasDP-1800 Om en 0000Nadeesha NishaniAinda não há avaliações

- Toshiba e Studio Installation Guide EnglishDocumento32 páginasToshiba e Studio Installation Guide EnglishNadeesha NishaniAinda não há avaliações

- Toshiba - DP-4500 Service HandbookDocumento257 páginasToshiba - DP-4500 Service HandbookBitelec EspinalAinda não há avaliações

- Es 255 All Error CodesDocumento10 páginasEs 255 All Error CodesNadeesha NishaniAinda não há avaliações

- Software Installation Guide: Multifunctional Digital SystemsDocumento0 páginaSoftware Installation Guide: Multifunctional Digital SystemsNadeesha NishaniAinda não há avaliações

- Es 167mr 2017Documento90 páginasEs 167mr 2017Nadeesha NishaniAinda não há avaliações

- DP 2006 2007 Part Numbers ManualDocumento1 páginaDP 2006 2007 Part Numbers ManualNadeesha NishaniAinda não há avaliações

- 4570 error code troubleshooting guideDocumento3 páginas4570 error code troubleshooting guideNadeesha NishaniAinda não há avaliações

- 5330 Error CodeDocumento2 páginas5330 Error CodeNadeesha NishaniAinda não há avaliações

- ContentsDocumento1 páginaContentsNadeesha NishaniAinda não há avaliações

- Quick Guide enDocumento0 páginaQuick Guide enNadeesha NishaniAinda não há avaliações

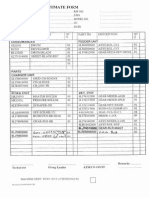

- RISO KZ30 Estimate FormDocumento2 páginasRISO KZ30 Estimate FormNadeesha Nishani100% (3)

- ContentsDocumento1 páginaContentsNadeesha NishaniAinda não há avaliações

- Safety Information enDocumento0 páginaSafety Information enNadeesha NishaniAinda não há avaliações

- Viewer 2 EngDocumento56 páginasViewer 2 EngNadeesha NishaniAinda não há avaliações

- New Temxt DocumentDocumento1 páginaNew Temxt DocumentNadeesha NishaniAinda não há avaliações

- R IntroDocumento103 páginasR Introtajjj9Ainda não há avaliações

- Alzheimers and DementiaDocumento4 páginasAlzheimers and DementiaNidhi ManojAinda não há avaliações

- ETHOSUXIMIDEDocumento14 páginasETHOSUXIMIDEAfrizal MahadiAinda não há avaliações

- Numark Orbit - VirtualDJ 8 Operation GuideDocumento13 páginasNumark Orbit - VirtualDJ 8 Operation GuideCasiLokoAinda não há avaliações

- FY2010 DSM-IV-TR Summary: Division of Juvenile Justice State of Alaska, DHSSDocumento15 páginasFY2010 DSM-IV-TR Summary: Division of Juvenile Justice State of Alaska, DHSSGnostic43Ainda não há avaliações

- Seance 1 Introduction To DystopiaDocumento32 páginasSeance 1 Introduction To DystopiaHanane AmadouAinda não há avaliações

- GyratoryDocumento4 páginasGyratoryFrancisco M. RamosAinda não há avaliações

- Oil Based Mud ThinnerDocumento2 páginasOil Based Mud ThinnerjangriAinda não há avaliações

- NetAct Plan Editor 4.9-4 CNDocumento4 páginasNetAct Plan Editor 4.9-4 CNAshraf JarjeesAinda não há avaliações

- Effect Design On Store ImageDocumento13 páginasEffect Design On Store Imagebermand75Ainda não há avaliações

- My Journey in PharmacologyDocumento30 páginasMy Journey in PharmacologysureshAinda não há avaliações

- FTT - en 45545 EU Railway Industry 2015 - CompressedDocumento24 páginasFTT - en 45545 EU Railway Industry 2015 - Compresseddody andiAinda não há avaliações

- Bhaskar Agarwal CVDocumento1 páginaBhaskar Agarwal CVbhaskaraglAinda não há avaliações

- Applying HACCP PrinciplesDocumento88 páginasApplying HACCP Principlesbbeard90% (1)

- Android Caputre CameraDocumento7 páginasAndroid Caputre CameraSagarraj WangdareAinda não há avaliações

- TANCET Model Question Paper For Me EEE PDFDocumento51 páginasTANCET Model Question Paper For Me EEE PDFsree ramAinda não há avaliações

- Chapter 10Documento30 páginasChapter 10Fernando Alcala Dela CruzAinda não há avaliações

- Itp 8Documento5 páginasItp 8Arung IdAinda não há avaliações

- Quarter 1 Revision SheetsDocumento7 páginasQuarter 1 Revision Sheetsghada kamalAinda não há avaliações

- CFO To Chief Future OfficerDocumento24 páginasCFO To Chief Future OfficerSuccessful ChicAinda não há avaliações

- Cascade Approach of DWT-SVD Digital Image WatermarkingDocumento5 páginasCascade Approach of DWT-SVD Digital Image WatermarkingPrashant SangulagiAinda não há avaliações

- Rupali Bank Final 2003Documento29 páginasRupali Bank Final 2003Rupz D TrackerAinda não há avaliações

- BachelorprojektDocumento29 páginasBachelorprojektKaroline SternAinda não há avaliações

- Resume SasDocumento3 páginasResume Saslubasoft0% (1)

- The Modern World SystemDocumento30 páginasThe Modern World SystemDey afAinda não há avaliações