Escolar Documentos

Profissional Documentos

Cultura Documentos

Jac001im e

Enviado por

veerakumarsDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jac001im e

Enviado por

veerakumarsDireitos autorais:

Formatos disponíveis

JMAG Application Note

Analysis of a Three Phase Induction Motor

CONTENTS

Overview........................................................................................................................................ 2

Appendix........................................................................................................................................ 2

1 Analysis Scope........................................................................................................................... 3

2 Motor Specification..................................................................................................................... 3

3 Analysis Results ......................................................................................................................... 6

3.1 Current Density Distribution................................................................................................. 6

3.2 Speed-Torque Curve............................................................................................................ 7

4 Analysis Steps ............................................................................................................................ 8

5 FEM Model Creation .................................................................................................................. 9

5.1 Mesh Model ......................................................................................................................... 9

5.1.1 2D Model ...................................................................................................................... 9

5.1.2 Partial Model ................................................................................................................. 9

5.1.3 Air Region ..................................................................................................................... 9

5.1.4 Mesh Generation ........................................................................................................ 10

5.2 Material Properties ............................................................................................................ 10

5.3 Analysis Conditions ........................................................................................................... 11

5.3.1 Analysis Control .......................................................................................................... 11

5.3.2 Full Model Conversion................................................................................................ 11

5.3.3 Circuit Conversion ...................................................................................................... 11

5.3.4 Step............................................................................................................................. 12

5.3.5 Symmetry Boundary 2D.............................................................................................. 12

5.3.6 Periodic Boundary ...................................................................................................... 12

5.3.7 Motion ......................................................................................................................... 12

5.3.8 Electromagnetic Force and Torque Calculation.......................................................... 12

5.3.9 Slide............................................................................................................................ 12

5.3.10 FEM Coil ................................................................................................................... 13

5.3.11 Circuit ........................................................................................................................ 14

6 Results Display......................................................................................................................... 15

6.1 Current Density Distribution............................................................................................... 15

6.2 Speed-Torque Curve.......................................................................................................... 15

JMAG Application Note Analysis of a Three Phase Induction Motor -

2

JAC001an-06e

Overview

The purpose of this Application Note is to help JMAG users understand the steps and

settings used for a basic analysis of induction machines.

The model data from the JMAG Application Catalog can be downloaded to view the

analysis model, settings and results described in this Application Note.

The organization is as follows:

Section 1 Analysis Scope

Presents the scope of the analysis.

Section 2 Motor Specification

Specifies the motor used for the analysis, including the motor geometry, the coil

arrangement and the material properties.

Section 3 Analysis Results

Shows the speed-torque relationship and rotor-current distribution results obtained

from the analysis.

Section 4 Analysis Steps

Describes the analysis steps used to obtain the results presented in Section 3.

Section 5 FEM Model Creation

Describes the analysis settings, including the mesh model, the material properties

and the condition settings.

Section 6 Results Display

Describes how to display the analysis results, such as creating graphs and showing

contour plots.

Appendix

Shows the JMAG mesh model and lists the settings, including material properties and

analysis conditions. The analysis settings are identical to the settings used in the model files

available from our Website.

Magnetic Field Analysis Rotation speed 0 rpm

The JMAG module(s) and the version used for the analysis are:

Module DP

Version Studio 10.0, Designer 10.4

JMAG Application Note Analysis of a Three Phase Induction Motor -

3

JAC001an-06e

1 Analysis Scope

This note presents how the current density distribution and the Speed-Torque curve of a

three-phase induction motor can be obtained. The motor analyzed has 4 poles, one coil per

pole winding arrangement, and balanced three-phase currents are used in the stator coils.

This analysis inherently includes core saturation, space harmonics due to stator slots and

leakage paths. The rotor end-rings are approximated by adding an appropriate resistance to

each bar.

In the induction motor, current is induced in the rotor cage by the rotating magnetic field of

stator coils. Analyzing the current induced in the rotor bars is important since the induced

current essentially determines the performance of the induction motor.

2 Motor Specification

The specification of the induction motor used for the analysis is shown below.

Figure 2.1 Induction Motor

Coil

Rotor core

Stator core

Bolt hole

Bar

Shaft

JMAG Application Note Analysis of a Three Phase Induction Motor -

4

JAC001an-06e

Table 2.1 Specification

Number of poles 4

Number of stator slots 24

Number of rotor slots 34

Excitation Three-phase AC

Frequency 50 Hz Power supply

Current 4 A

Turns 66 turn/slot

Coil

Resistance 1.48 /phase

Coil winding 1 coil per pole, 1 coil-side per slot: see Figure 2.2

Stator core (outside dimension) L 108 W 108 thickness 42 mm

Rotor core (outside dimension) R 34.7 thickness 42 mm

End-ring cross-section 17.81 mm

2

Bar cross-section 13.34 mm

2

Table 2.2 Material Magnetic Properties

Part Property

Bar Non-magnetic material

Rotor core Isotropic magnetic material: see Figure 2.3 for BH curve

Bolt hole Air

Stator core Isotropic magnetic material: see Figure 2.3 for BH curve

Shaft Isotropic magnetic material: see Figure 2.3 for BH curve

Coil Non-magnetic material

JMAG Application Note Analysis of a Three Phase Induction Motor -

5

JAC001an-06e

Figure 2.2 Winding Pattern

0.0

0.5

1.0

1.5

2.0

2.5

0 10000 20000 30000 40000

Magnetic field, A/m

F

l

u

x

d

e

n

s

i

t

y

,

T

Figure 2.3 BH Curve (rotor core, stator core and shaft)

U-phase

V-phase

W-phase

JMAG Application Note Analysis of a Three Phase Induction Motor -

6

JAC001an-06e

3 Analysis Results

The current density distribution and the Speed-Torque curve can be obtained from analysis

of the induction motor described in Section 2.

3.1 Current Density Distribution

At each speed, the current density in the rotor bars is calculated for every motion step of

rotor position.

The current density distribution at 1050 rpm is shown in Figure 3.1 for two different instants

in time, i.e., two different positions.

Figure 3.1 Current Density Distribution of the Cage Conductor Bars (rotation speed: 1050 rpm)

(upper: 0.11 seconds, lower: 0.14 seconds)

(Unit: A/m

2

)

(Unit: A/m

2

)

JMAG Application Note Analysis of a Three Phase Induction Motor -

7

JAC001an-06e

3.2 Speed-Torque Curve

Figure 3.2 shows the Speed-Torque curve obtained for this induction motor model. The

maximum torque is found to be near 1000rpm. In the range labeled b in Figure 3.2, the speed

change is only about 5%, with a 100% change in the torque, therefore the motor is considered

to be essentially a constant speed machine with a fixed frequency power supply.

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

0 150 300 450 600 750 900 1050 1200 1350 1500

Rotation speed, rpm

T

o

r

q

u

e

,

N

m

Figure 3.2 Speed versus Torque

a b

JMAG Application Note Analysis of a Three Phase Induction Motor -

8

JAC001an-06e

4 Analysis Steps

A number of transient response magnetic field analyses are required to obtain the

Speed-Torque curve. The average torque is calculated at each speed, including the effects of

the slip, and then the data is exported to a spreadsheet to create the Speed-Torque graph.

The current density can be viewed and evaluated inside JMAG with PLOT files that contain

the analysis results.

The steps to calculate the current density distribution are:

STEP 1: Create the FEM model

STEP 2: Run the analysis for each load point

The steps to obtain the Speed-Torque curve of the induction motor are:

STEPS 1 & 2: Same as above

STEP 3: Calculate the average torque at the specified speed

STEP 4: Repeat STEPS through 1 to 3 at different speeds

STEP 5: Evaluate the results using a spreadsheet

JMAG Application Note Analysis of a Three Phase Induction Motor -

9

JAC001an-06e

5 FEM Model Creation

The FEM model, required to run the magnetic field analysis, is composed of a mesh model,

the material properties, and the analysis conditions.

5.1 Mesh Model

Some notes on the creation of the mesh model are provided below.

5.1.1 2D Model

The 2D analysis of JMAG's DP solver module is a good starting point for induction machine

analysis because it is easier and faster than 3D, yet gives sufficiently accurate results. 2D

analysis can be used when the stack length of the rotor and the stator are the same and the

two cores are aligned axially.

In this analysis, the magnetic flux in the axial direction, such as fringing at the ends of the

stack, is ignored.

5.1.2 Partial Model

A half model can be used when the geometry and the magnetic field of the motor have a

periodicity of 180 degrees. The analysis runs faster with a partial model because it reduces

the time for data creation and calculation, as well as the CPU load of the computer.

A partial model requires periodic boundary condition settings, which are done during a later

step. For details, see 5.3.6 Periodic Boundary.

5.1.3 Air Region

The air region is required even if the magnetic circuit is closed within the motor, because of

some flux leakage, usually caused by saturation. An adequate size of the air region is 1.05 to

2.5 times the outer radius of the stator core, and the optimum value varies with the severity of

the saturation.

In this analysis, the mesh model of the air region is set to 1.25 times the radius of the motor.

A symmetry boundary condition specifies the outer circumference of the mesh model. See

5.3.5 Symmetry Boundary.

JMAG Application Note Analysis of a Three Phase Induction Motor -

10

JAC001an-06e

5.1.4 Mesh Generation

Since the rotor has the rotational motion, the cylindrical slide mesh option can be used to

efficiently generate the mesh in the gap between the stator and the rotor for each increment of

rotation.

The number of divisions is set so there are at least 8 divisions in one period of the torque.

Generally, the divisions needed for accurate calculation vary with motor geometry. For this

analysis, one division has about 10 divisions in the circumferential direction. The number of

divisions in the radial direction is set to 5 because the flux in the gap of the induction motor

changes significantly as the stator current changes and as the rotor moves.

.

5.2 Material Properties

The material properties of the parts are specified with reference to the motor specification

list. See Figure 2.1 and Table 2.1.

In this analysis, the electric conductivity of the bar (3.010

7

S/m) is corrected to include the

effect of the current flowing in the end rings. Values used for the calculation are listed in Table

5.1. The resistance R

2

of the corrected bar is calculated using the equation (1.1) and (1.2).

The inductance of the end rings is ignored in this method; however, there is no problem to

evaluate the Speed-Torque curve.

b

b

b

S

l

R

1

(1.1)

r

r

r

S

l

R

1

2 (1.2)

2

2

2

P

N

R R R

r b

(1.3)

JMAG Application Note Analysis of a Three Phase Induction Motor -

11

JAC001an-06e

Table 5.1 Values Used for Calculating Correction Values of Electric Conductivity

Parameter Value

b

R : Resistance of the bar Calculated using the

equation 1.1

r

R : Resistance of the end ring Calculated using the

equation 1.2

2

R : Corrected resistance of the bar Calculated using the

equation 1.3

2

N : Number of rotor slots 34

P : Number of poles 4

b

l : Length of bar 42 mm

b

S : Cross-section of the bar 13.34 mm

2

r

l : Length of the end ring circumference 188.5 mm

r

S : Cross-section of the end ring 17.81mm

2

: Conductivity of the conductor 3.010

7

S/m

5.3 Analysis Conditions

Some note about the analysis conditions are provided below.

5.3.1 Analysis Control

Transient response analysis is selected since the induced magnetomotive force and the

rotation motion of the rotor are time-varying phenomena, and the effects of eddy current need

to be included.

When a half (180 degrees) model is used for the analysis, the conversion factor for both the

FEM model and the circuit is 2.

Since the torque is constant at each rpm in the calculation of the Speed-Torque curve, the

dummy stationary analysis option may be used to shorten the initial transient state.

5.3.2 Full Model Conversion

The conversion factor is set to 2 because a half model is used for this analysis.

5.3.3 Circuit Conversion

The conversion factor is set to 2 because a half model is used for this analysis.

JMAG Application Note Analysis of a Three Phase Induction Motor -

12

JAC001an-06e

5.3.4 Step

The rotor is set to rotate 1 degree per step in this analysis. The time interval is used to

specify the speed for each point on the Speed-Torque curve. When the analysis needs to run

for a mechanical angle, such as 720 degrees, the number of steps would be set to 721 to

include the initial starting position.

5.3.5 Symmetry Boundary 2D

The symmetry boundary sets the outer boundary of the entire mesh model, assuming all

magnetic flux stays inside this boundary.

5.3.6 Periodic Boundary

The periodic boundary needs to be specified when a half model is used. In this example,

both the model geometry and the direction of the magnetic field have a periodicity of 180

degrees in the circumferential direction. The model is 2D and the center is the origin, so the

point on the rotation axis is set to (0,0,0) and the direction of the rotation axis is set to

(X,Y,Z)=(0,0,1).

5.3.7 Motion

The motion condition is set on the rotating parts including the shaft, rotor core and rotor

bars. The center of the rotation is the origin and the rotation axis is Z-axis, sothe point on the

rotation axis is set to (0,0,0) and the direction of the rotation axis is set to (X,Y,Z)=(0,0,1).

To obtain the Speed-Torque curve, a number of analyses at different speeds will need to be

specified.

5.3.8 Electromagnetic Force and Torque Calculation

For this analysis, this condition is set on the shaft, rotor core, and the bars to calculate the

torque generated in the rotating parts. The nodal force method is used when the condition is

set on magnetic materials.

5.3.9 Slide

The cylindrical slide mesh option is used in this case to efficiently generate the mesh in the

air gap. With this option, the slide condition will be set automatically during the mesh

generation.

JMAG Application Note Analysis of a Three Phase Induction Motor -

13

JAC001an-06e

5.3.10 FEM Coil

An FEM coil condition needs to be assigned to each phase. The coil regions for each phase

are connected in series, so only a single condition needs to be set to each phase.

The directions of the current flow in the coil region are indicated in Figure 5.1.

Figure 5.1 Current Flow Directions Set by the FEM Coil Conditions (+ is upward, - is downward)

-V

-V

+U

+U

-W

-W

+W

+W

-U

-U

+V

+V

JMAG Application Note Analysis of a Three Phase Induction Motor -

14

JAC001an-06e

5.3.11 Circuit

In this basic induction motor model, the currents in the stator coil are user-specified as input

values.

The settings for the three-phase current sources and the FEM coil components will specify

the typical balanced three-phase operation of the motor.

For this analysis, amplitude is set to 4 A, frequency to 50 Hz, number of turns to 66 turns,

and resistance to 1.48 ohm as shown in the specification, Table 2-1. The U-phase current is

set to 0 degrees, the V-phase is set to +120 degrees (theta+120) and the W-phase is set to

-120 degrees (theta-120).

In JMAG, one FEM coil condition in the FEM model corresponds to one FEM coil

component in the circuit. The conditions defined in the circuit are run simultaneously with

magnetic field analysis.

Figure 5.2 Circuit Diagram (left: whole circuit, right: internal circuit of star connection block)

U-phase

V-phase

W-phase

JMAG Application Note Analysis of a Three Phase Induction Motor -

15

JAC001an-06e

6 Results Display

After the analysis is complete, a results file is created, which is opened in a new window

with one click. Many parameters can be displayed, each with choices such as line plots or

color contours. The display of the current density and the Speed-Torque curve is described

below.

6.1 Current Density Distribution

A contour plot of the current density distribution in the stator coils and the rotor bars of the

induction motor can be viewed.

6.2 Speed-Torque Curve

The Speed-Torque curve is displayed in a graph using the average torque at each rotation

speed in spreadsheet software. The electromagnetic force of the torque is exported from the

analysis results for each rotation speed to graph the Speed-Torque curve. The average torque

can be calculated by averaging one period of the torque in the steady state. The

Speed-Torque curve shown in Figure 3.2 was created by setting the average torque on the

vertical axis, and the speed on the horizontal axis.

JMAG Application Note Analysis of a Three Phase Induction Motor -

16

JAC001an-06e

URL http://www.jmag-international.com/catalog/

Technical Support

JSOL Corporation

Engineering Technology Division, JMAG Support Team

jmag-support@sci.jsol.co.jp

or

A distributor in your country

JMAG Application Note

Copyright(C) 2006-2011 JSOL Corporation All Rights Reserved.

Você também pode gostar

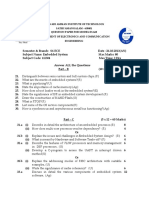

- Bannari Amman Institute of Technology (Bit)Documento3 páginasBannari Amman Institute of Technology (Bit)veerakumarsAinda não há avaliações

- 11L504 Es Unit 1Documento6 páginas11L504 Es Unit 1veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology Sathyamangalam - 638401 Department of Electronics and Communication Engineering Question Paper For Model ExamDocumento3 páginasBannari Amman Institute of Technology Sathyamangalam - 638401 Department of Electronics and Communication Engineering Question Paper For Model ExamveerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology (Bit)Documento3 páginasBannari Amman Institute of Technology (Bit)veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology (Bit)Documento3 páginasBannari Amman Institute of Technology (Bit)veerakumarsAinda não há avaliações

- 11L504 EMBEDDED SYSTEMS SyllabusDocumento2 páginas11L504 EMBEDDED SYSTEMS SyllabusveerakumarsAinda não há avaliações

- Question Paper For Model Exam Department of Computer Science EngineeringDocumento2 páginasQuestion Paper For Model Exam Department of Computer Science EngineeringveerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Claa141wb05a ChunghwapicturetubesDocumento25 páginasClaa141wb05a ChunghwapicturetubesveerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology Sathyamangalam - 638401 Question Paper For Model Exam Department of Electronics and Communication EngineeringDocumento3 páginasBannari Amman Institute of Technology Sathyamangalam - 638401 Question Paper For Model Exam Department of Electronics and Communication EngineeringveerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- ARM Class 1Documento19 páginasARM Class 1veerakumarsAinda não há avaliações

- Arduino: Open Sourcing ImaginationDocumento60 páginasArduino: Open Sourcing ImaginationveerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- Bannari Amman Institute of Technology: Regulation: 2018Documento2 páginasBannari Amman Institute of Technology: Regulation: 2018veerakumarsAinda não há avaliações

- GSM Motor Control V2.0 - 2019: Master Number OnlyDocumento2 páginasGSM Motor Control V2.0 - 2019: Master Number Onlyveerakumars100% (1)

- INTERFACING OF 16x2 LCD WITH ARM LPC2148Documento4 páginasINTERFACING OF 16x2 LCD WITH ARM LPC2148veerakumarsAinda não há avaliações

- Electrical Product Development Lab: 4/15/2020 Special Lab Bannari Amman Institute of Technology Monthly ReviewDocumento15 páginasElectrical Product Development Lab: 4/15/2020 Special Lab Bannari Amman Institute of Technology Monthly ReviewveerakumarsAinda não há avaliações

- Tamil Cover Letter For CollegeDocumento1 páginaTamil Cover Letter For CollegeveerakumarsAinda não há avaliações

- Akka BHARATHIAR UNIVERSITYDocumento3 páginasAkka BHARATHIAR UNIVERSITYveerakumarsAinda não há avaliações

- Flashing LEDDocumento3 páginasFlashing LEDveerakumarsAinda não há avaliações

- TAMILNADUDocumento118 páginasTAMILNADUveerakumarsAinda não há avaliações

- Karuvalvadi Pudur, Iyyan Thottam, Athani (Po), Bhavani (TK), Erode (DT)Documento3 páginasKaruvalvadi Pudur, Iyyan Thottam, Athani (Po), Bhavani (TK), Erode (DT)veerakumarsAinda não há avaliações

- TAMILNAD1Documento4 páginasTAMILNAD1veerakumarsAinda não há avaliações

- 230V, 50Hz AC Supply 6.8Kv, DC Supply, 2ma Current +: C1 C3 C5 C7 R1 R2 FuseDocumento1 página230V, 50Hz AC Supply 6.8Kv, DC Supply, 2ma Current +: C1 C3 C5 C7 R1 R2 FuseveerakumarsAinda não há avaliações

- Different Types of Operators in CDocumento3 páginasDifferent Types of Operators in CveerakumarsAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Lecture 2 Revision MOSFET Operation and ModellingDocumento35 páginasLecture 2 Revision MOSFET Operation and ModellingDominiqueAinda não há avaliações

- Amateur Radio Site - StoomDocumento6 páginasAmateur Radio Site - StoomK. RAJA SEKARAinda não há avaliações

- Eee3352 L3Documento34 páginasEee3352 L3Desmond CheweAinda não há avaliações

- Mirt BuildDocumento5 páginasMirt BuildKomishinAinda não há avaliações

- Turnstile Fractal Patch Antenna ReportDocumento61 páginasTurnstile Fractal Patch Antenna ReportShailesh PatelAinda não há avaliações

- Tower Cell Site EngineeringDocumento280 páginasTower Cell Site EngineeringSanjeev GoelAinda não há avaliações

- Speed Control of DC Motor Using PID Algorithm (STM32F4) : InstructablesDocumento10 páginasSpeed Control of DC Motor Using PID Algorithm (STM32F4) : InstructablespedroAinda não há avaliações

- Asco Series 551 553 Direct Mount Inline Spool CatalogDocumento4 páginasAsco Series 551 553 Direct Mount Inline Spool CatalogNaseer HydenAinda não há avaliações

- Gek 36378D PDFDocumento14 páginasGek 36378D PDFoso0214Ainda não há avaliações

- Certificate of SuitabilityDocumento1 páginaCertificate of SuitabilityEvans OrlandoAinda não há avaliações

- Non Destructive Testing and Evaluation (Ultrasonic-Testing-Level-2 (Set-3) ) Solved MCQsDocumento8 páginasNon Destructive Testing and Evaluation (Ultrasonic-Testing-Level-2 (Set-3) ) Solved MCQspandab BkAinda não há avaliações

- Focusmart25.6-100 SpecificationDocumento6 páginasFocusmart25.6-100 Specificationmna478Ainda não há avaliações

- Modulos de EntradaDocumento4 páginasModulos de EntradaYury AlejandraAinda não há avaliações

- C60N-H Breaker Disjoncteur SchneiderDocumento2 páginasC60N-H Breaker Disjoncteur SchneiderAgus H TulasnoAinda não há avaliações

- VSD ManualDocumento317 páginasVSD Manualfernando Hurtado100% (1)

- STP80NF70: N-Channel 68 V, 0.0082, 98 A, TO-220 Stripfet™ Ii Power MosfetDocumento13 páginasSTP80NF70: N-Channel 68 V, 0.0082, 98 A, TO-220 Stripfet™ Ii Power MosfetAsif IqbalAinda não há avaliações

- Silergy Corp SY8213FCC - C178246Documento9 páginasSilergy Corp SY8213FCC - C178246Thai LamAinda não há avaliações

- Wiring Diagrams of PLC and DCS Systems - DI, DO, AI, AODocumento1 páginaWiring Diagrams of PLC and DCS Systems - DI, DO, AI, AODani FayçalAinda não há avaliações

- Approved Make of Equipment & Materials To Be Used in The Sub-Station and Transmission LinesDocumento6 páginasApproved Make of Equipment & Materials To Be Used in The Sub-Station and Transmission LinesRAKESH CHANDRA PATRAAinda não há avaliações

- Solar System: PV1800 HM SeriesDocumento1 páginaSolar System: PV1800 HM SeriesHanibal АтанасовAinda não há avaliações

- Ee6503 - Power Electronics MCQDocumento10 páginasEe6503 - Power Electronics MCQKarthikeyan100% (2)

- Furnace Transformer: Benefits Hyundai Furance TransfomersDocumento2 páginasFurnace Transformer: Benefits Hyundai Furance TransfomersjuliancansenAinda não há avaliações

- B-64483EN 01 120229 FANUC Connection Manual HWDocumento553 páginasB-64483EN 01 120229 FANUC Connection Manual HWRaj kumar B BRJAinda não há avaliações

- Modeling and Control of A Brushless DC MotorDocumento66 páginasModeling and Control of A Brushless DC MotorBalajiKRamAinda não há avaliações

- PFC Boost DesignDocumento13 páginasPFC Boost DesignAnonymous 4intki5Ainda não há avaliações

- Daewoo CM-405F DTH-2930SSFVDocumento54 páginasDaewoo CM-405F DTH-2930SSFVMarco Antonio100% (3)

- Lsa 50.2Documento12 páginasLsa 50.2KarlaAinda não há avaliações

- Patriarch Service Manual WebDocumento60 páginasPatriarch Service Manual WebD Abdos D AbdosAinda não há avaliações

- Bewley 1934Documento9 páginasBewley 1934brunoscarpaAinda não há avaliações

- Epoch-Modeling and Simulation of An AllDocumento40 páginasEpoch-Modeling and Simulation of An Allraducu2009Ainda não há avaliações