Escolar Documentos

Profissional Documentos

Cultura Documentos

Subcontractor and Supplier Management Program - Updated

Enviado por

sjmpakDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Subcontractor and Supplier Management Program - Updated

Enviado por

sjmpakDireitos autorais:

Formatos disponíveis

SUBCONTRACTOR and SUPPLIER MANAGEMENT

SUBCONTRACTOR and SUPPLIER MANAGEMENT PROGRAM The Company may assume different roles, depending on the specific project or contract they are working under. Generally the Company is retained to provide services by an Owner Company, who will remain as the Prime Contractor. In this situation the Company and any subcontractors work for the Prime, who retains responsibility for HSE matters at the worksite. You, the subcontractor, will not be considered the Prime Contractor for the purpose of this evaluation or services. In the event that the company is assigned and formally takes on the role of Prime Contractor, the Company is responsible for HSE matters at the worksite and will use Hodgso ns HSE Management System as the guiding documents. Prime Contractors (the Prime) are committed to hiring competent contractors and working together with those contractors to achieve the goal of an injury and accident free workplace. Effective communication is of utmost importance and is the equal responsibility of the contractor and Owner/Prime representatives. Contractors performing work for Owners who retain Prime Contractor responsibility are expected to perform activities in a safe and environmentally responsible manner, in accordance with industry and specific craftsman trade rules, regulations and operating procedures. CONTRACTOR AND SUPPLIER SELECTION It is important to give serious consideration to safety performance when selecting contractors or subcontractors. Generally the contractor/subcontractor with a better safety record, or one taking significant measures to improve its record should be awarded contract work. All bid documents and contracts should contain a section on safety, detailing the companys contractors and subcontractors safety specifications, requirements, and guidelines. Where contractors or subcontractors have met the requirements of IRP 9, Basic Program and/or have already received a Certificate of Recognition, the information required is reduced and the Simplified Safety Program Analysis can be used. For situations where a more comprehensive assessment of contractor safety is required, the questionnaire in this program can be utilized. Contractors are required to complete the selected questionnaire and submit it along with their other bid documents. In most cases the Company hiring contractors/subcontractors/suppliers will require them to sign an agreement which includes provision related to HSE Performance expectations.

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

CONTRACTOR ORIENTATIONS AND CONTROLS In the case where the Company is the designated Prime Contractor, they are responsible for providing leadership, ensuring that all parties involved are knowledgeable of potential hazards, and enforcing the Companys safety standards. This requires that adequate communication be established between Company and contractor/subcontractor personnel. All contractors/subcontractors must be provided an orientation, appropriate to the work, before they commence work at the worksite. The purpose of the orientation is to ensure that all contractors are familiar with the Companys requirements. On completion of the orientation, the contractor/subcontractor supervisor will sign the acknowledgement at the bottom of the form and turn it into the Company supervisor. The signed acknowledgement forms are maintained on site and returned to the Prime Contractors offices upon project completion. MONITORING AND FOLLOW-UP The Company worksite supervisor must periodically inspect the contractor/subcontractor work practices in order to verify that they are in compliance with the Companys HSE Management program and OH&S regulations. The supervisor with note any deficiencies and ensure that they are appropriately addressed. The Prime Contractor will perform all site inspections and audits as necessary to satisfy itself that health and safety requirements are being adhered. As a result of the inspections completed, the Company may request the immediate removal or repair of unsafe or defective equipment or the removal any personnel on site who do not comply with the worksite health and safety requirements. Upon the completion of a contract, safety considerations should be taken into account in the evaluation of the contractors overall performance. ASSIGNING PRIME CONTRACTOR RESPONSIBILITIES In accordance with applicable legislation, where two or more employers operate at the same site, a Prime Contractor must be designated, Where Prime Contractor responsibilities are being assigned to a contractor, a written agreement is required to transfer this responsibility. A Letter Agreement for formally assigning Prime Contractor is provided for reference. GUIDELINES FOR ASSIGNING PRIME CONTRACTOR Where Prime Contractor Responsibilities are being assigned to a contractor, a formal agreement transferring this responsibility is required. This checklist highlights the steps to be taken whenever Prime Contractor responsibilities are assigned.

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

1. Obtain and review the contractors safety program, answering the following questions: Does the contractor have an audited program, for example, a Partnership Program Certificate of Recognition? If an external audit has not been completed, an in-depth review should be considered. What standard(s) does the contractor set for the use of PPE, hazard identification, control and reporting, incident investigation, emergency response and general work practices? What type of standard is set for work site orientations to the contractors safety program for workers, contractors, sub-contractors and visitors? Is there a requirement to complete an orientation of all people entering the work site? How does the contractor identify and communicate the responsibilities of its workers on the work site and how are they responsible for their fellow workers, Company contractors, Company sub-contractors and Company visitors? How does the contractor communicate to work site personnel that they are the prime contractor on location and what their respective responsibilities associated with being the prime contractor? Do the standards overall as set out in the contractors safety program, meet IRP 9 Basic Safety Program elements and the Companys expectations? 2. Review the qualifications of at least the contractors supervisory staff that will be on the worksite: Has the Company shown due diligence in learning the qualifications of the personnel on location completing the contracted services Do you know if the workers are competent to perform the task(s)? 3. Review the contractors procedures for the task to be performed: Do they have a system in place to ensure any procedures developed are reviewed prior to the start of each job/shift? Do they have a system within their program to complete internal work site inspections? Do they have a system in place to correct any deficiencies noted in the inspections, including disciplinary actions? 4. Hold a meeting with senior personnel from the contractor to reinforce: The Companys expectations of the contractor in relation to prime contractor responsibilities. That the contractor is in control of the work site and that they are being hired, at least in part because of the quality of their safety program. They have to manage the worksite, at least for health and safety, to their standards, not Company standards. Even though they have been designated the prime contractor for that work site, the work clearance system is still in effect. Also reinforce how the work clearance is to be used and managed and that ALL people entering the work site have to abide by the policies and procedures.

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

5. Hold a Project / Agreement kick-off meeting with key players from the Company and contractor. 6. Review the scope of work as outlined in the Prime Contractor Agreement. 7. Sign the Prime Contractor Agreement 8. Develop a program / schedule to review contractor/subcontractor performance at the work site as it related to prime contractor responsibilities. The program should focus on ensuring the management of health and safety at the work sites. COMPANY CONTRACTOR QUALITY HEALTH, SAFETY AND ENVIROMENT (QHSE) SELECTION CRITERIA The Company will ensure that HSE is a priority when conducting work. Stringent HSE requirements are in place for conducting work and contractor/subcontractor selection will include verification and possible review of the contractor/subcontractor HSE Systems and/or Programs. Contractors/subcontractors hired by the Company will have, at a minimum, a basic HSE Program, including a drug and alcohol policy and program, Implemented throughout the company workforce for workers to have a full understanding of the contractor HSE requirements. HSE Systems and/or Programs will meet the intent of the Companys HSE Standards. The status and effectiveness of each contractors HSE system and /or Program will be evaluat ed. The following checklist must be completed and returned to the Company and will be utilized in the contractor selection process. Equipment or product suppliers are also required to fill out the Quality Systems portion of this checklist.

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

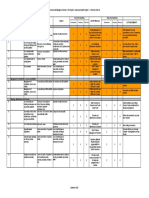

CONTRACTOR QHSE CHECKLIST

Please respond to the following questions. References to, or copies of, relevant documentation in support of your responses should be attached. Company Name/Site: Type of Services Offered:

Contractors WCB #: *Attach Clearance Letter

Account Number _____________________ Industry Code ___Click here to enter text.____________________

Contractor Insurance Agent: *Attach Proof of Insurance

(Minimum 2 Million Liability)

Name:_______________________ Number:__________________

1.0 POLICY STATEMENT Do you have a written statement of your HSE policy? (Please 1.1 provide a copy if "Yes") 1.2 Is the HSE policy communicated to all your personnel? 1.3 Do you enforce all aspects of your policy on all sub-contractors? Do you agree that all sub-contractors will adhere to our Company 1.4 policy? 2.0 HSE MANAGEMENT MANUAL 2.1 Does your Company have an HSE Management System? 2.2 Does your Company have an HSE Manual or Program? 2.3 Do all your sub-contractors have an HSE Management System or HSE Program, or do they use your HSE Systems and/or programs? 3.0 RISK MANAGEMENT 3.1 Do you have a method/process to identify risks to personnel, the environment or assets to mitigate or avoid these risks? Does your company use a behavior based safety observation 3.2 system?

YES NO N/A

YES NO N/A

YES NO N/A

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

4.0 BASIC SAFETY RULES Do you communicate work practices, safety instructions and 4.1 emergency response procedures to your personnel? Is the HSE Management System Manual or Program and 4.2 emergency response plan available to all your personnel? 4.3 Do you have a safety awareness program for your employee's? 5.0 EMERGENCY RESPONSE PLAN Does your Company have an emergency Response plan or 5.1 Program? 5.2 Are your managers trained and experienced in the use of ERP? 6.0 INCIDENT INVESTIGATION & REPORTING Does your company have an incident/accident reporting program for incidents that occur to company personnel or 6.1 property? Do incidents and near misses get reported to your Company's 6.2 management? Do you have a procedure for the investigation, reporting and follow-up of accidents, dangerous occurrences or occupational 6.3 illness? Do you communicate the results of accident investigations to 6.4 your personnel? Provide details of your annual safety record for the previous three years for all recordable incidents (including motor vehicle accidents, fatalities, lost time injuries, medical treatment cases, 6.5 first aid cases) 7.0 EMPLOYEE HSE ORIENTATION PROGRAM 7.1 Do you have a written HSE orientation program? Does your company conduct HSE orientation's of you sub7.2 contractor's personnel? 8.0 HSE MEETING PROGRAM 8.1 Do you hold regular in-house HSE meetings? Do you have an established system for communicating with 8.2 personnel on HSE matters? YES NO N/A

YES NO N/A

YES NO N/A

YES NO N/A

YES NO N/A

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

SUBCONTRACTOR and SUPPLIER MANAGEMENT

9.0 HSE TRAINING PROGRAM Have your personnel who will undertake the work for the Company received formal training in safe working practices and in the use of protective equipment relating to the potential hazards of 9.2 that work? Do you have a competency training scheme for your employees 9.3 and subcontractors? Does your Company conduct driver training for employees who 9.4 drive company vehicles? 10.0 OCCUPATIONAL HEALTH Does your company perform any employee pre-employment 10.1 medical evaluations? Does your Company perform any employee pre-employment Drug 10.2 Testing? Does your company have an Employee Assistance Program 10.3 (EAP)? 10.4 What is covered within the EAP? YES NO N/A

YES NO N/A

11.0 QUALITY SYSTEMS Does your Company have a quality management system (QMS) or 11.1 program in place for company goods or materials? 11.2 Does the QMS meet ISO 9001 Requirements? 11.3 Is your Company ISO 9001 certified or registered? 12.0 HSE INSPECTION/AUDIT PROGRAM 12.1 Does your Company have a planned inspection or audit Program? Has your Company conducted an audit of its HSE Program in the 12.2 last 3 years? 13.0 PROGESSIONAL SAFETY SUPPORT Does your Company have dedicated office and/or field HSE 13.1 supervisors?

Name: Click here to enter text. Signed: Click here to enter text. Position : Click here to enter text. Date : Click here to enter text.

YES NO N/A

YES NO N/A

YES NO N/A

Pipeworx Ltd. WHERE SAFETY & QUALITY ARE #1

Você também pode gostar

- Contractor Management ProcedureDocumento2 páginasContractor Management ProcedureShailendraAinda não há avaliações

- Contractor ManagementDocumento4 páginasContractor ManagementKhairul HazwanAinda não há avaliações

- Subcontractor Management PlanDocumento22 páginasSubcontractor Management Planthamimun100% (6)

- Subcontractor Management Plan (SMP) : PurposeDocumento9 páginasSubcontractor Management Plan (SMP) : Purposeamakiri Tamunoimama100% (3)

- Ppe ProcedureDocumento32 páginasPpe ProcedureIbrahim Umer100% (2)

- Contractor HSE Management ProcedureDocumento9 páginasContractor HSE Management ProcedureWinnie Eldama100% (1)

- Standard Operating Procedure For The Greenbelt Farms (LTD) WorkshopDocumento4 páginasStandard Operating Procedure For The Greenbelt Farms (LTD) WorkshopJames100% (1)

- Sub Contractor Management and Assessment ProceduresDocumento7 páginasSub Contractor Management and Assessment Proceduresloveson glariyansAinda não há avaliações

- Corporate Social Responsibility PolicyDocumento4 páginasCorporate Social Responsibility PolicyAbhishek MauryaAinda não há avaliações

- Incident Report Form (IRF)Documento2 páginasIncident Report Form (IRF)ashwin.devaliya6923Ainda não há avaliações

- Work Health and Safety Policy SamplesDocumento3 páginasWork Health and Safety Policy SamplesProf C.S.PurushothamanAinda não há avaliações

- Subcontractor ManagementDocumento10 páginasSubcontractor ManagementAjaz MalikAinda não há avaliações

- 10 Audit and Management Review Procedure FINALDocumento3 páginas10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanAinda não há avaliações

- Sample Health and Safety PolicyDocumento1 páginaSample Health and Safety PolicySaddem HadfiAinda não há avaliações

- Vehicle Use POlicyDocumento5 páginasVehicle Use POlicyAndrew James ParkerAinda não há avaliações

- Drug and Alcohol PolicyDocumento5 páginasDrug and Alcohol PolicyBonteanu CameliaAinda não há avaliações

- Policy and Strategic ObjectivesDocumento4 páginasPolicy and Strategic ObjectivesKhuda BukshAinda não há avaliações

- 04-Health, Safety & Environment PolicyDocumento56 páginas04-Health, Safety & Environment PolicyYacine BouAinda não há avaliações

- Quality PolicyDocumento1 páginaQuality PolicyAndre GonAinda não há avaliações

- 01 BSD - Site Boundary Access ControlDocumento5 páginas01 BSD - Site Boundary Access ControlPoduval AkpAinda não há avaliações

- Plant Equipment ProcedureDocumento7 páginasPlant Equipment Proceduresivaji8085Ainda não há avaliações

- Safety and Health OfficerDocumento2 páginasSafety and Health OfficermrsundeepsAinda não há avaliações

- Safety PolicyDocumento19 páginasSafety PolicyPaul Jolo100% (1)

- Construction Safety Policy GeneralDocumento57 páginasConstruction Safety Policy Generalayummy myra100% (3)

- Pre Mobilisation Checklist For Offshore TravellDocumento3 páginasPre Mobilisation Checklist For Offshore TravellUzair AhmedAinda não há avaliações

- Non Compliance Corrective Action ProcedureDocumento14 páginasNon Compliance Corrective Action Procedurerwillestone100% (5)

- Traffic Control PlanDocumento10 páginasTraffic Control PlanTimothy Ndeleva0% (1)

- Emergency Action Plan TemplateDocumento6 páginasEmergency Action Plan Templatearnel sungkipAinda não há avaliações

- Subcontract Management Procedure 1Documento4 páginasSubcontract Management Procedure 1Oladimeji Taiwo80% (5)

- QA and QC PlanDocumento84 páginasQA and QC PlanReehan Aslam100% (2)

- Generic Health and Safety Plan (EXAMPLE)Documento57 páginasGeneric Health and Safety Plan (EXAMPLE)Oliver Youens100% (2)

- Contractor Selection and Management-Example1Documento11 páginasContractor Selection and Management-Example1hazopman100% (1)

- PPE Program...Documento13 páginasPPE Program...Maryan Aybee Dabuet100% (1)

- 1.appointment LettersDocumento10 páginas1.appointment LettersWelma Johnson100% (1)

- 1910.147 Lockout-Tagout ProgramDocumento13 páginas1910.147 Lockout-Tagout Programquang06Ainda não há avaliações

- Safety OfficerDocumento5 páginasSafety OfficergunaefiAinda não há avaliações

- Permit To WorkDocumento11 páginasPermit To WorkKhuda BukshAinda não há avaliações

- REC107487 KPA Truck Loading and Unloading Operations V2 1 PDFDocumento11 páginasREC107487 KPA Truck Loading and Unloading Operations V2 1 PDFRoni EnjelaniAinda não há avaliações

- Quality Management Plan TemplateDocumento9 páginasQuality Management Plan TemplateMelford Bernard100% (2)

- Company Policy On InductionDocumento6 páginasCompany Policy On InductionTharanga KariyawasamAinda não há avaliações

- SHEQ01: Safety, Health, Environmental and Quality PolicyDocumento30 páginasSHEQ01: Safety, Health, Environmental and Quality PolicyASEPAinda não há avaliações

- Daily Inspection ChecklistsDocumento59 páginasDaily Inspection Checklistsibrahim100% (1)

- 2014 Contractor Safety Training - Contractor OrientationDocumento68 páginas2014 Contractor Safety Training - Contractor OrientationdethscrimAinda não há avaliações

- Corporate Social Responsibility Policy (CSR Policy)Documento7 páginasCorporate Social Responsibility Policy (CSR Policy)Ankit SinghAinda não há avaliações

- Safety Engineer PDFDocumento3 páginasSafety Engineer PDFخلف الله التوم0% (1)

- 32 - Safe WorkDocumento18 páginas32 - Safe WorkP Eng Suraj SinghAinda não há avaliações

- SHE Induction and Training Procedure PDFDocumento11 páginasSHE Induction and Training Procedure PDFAnonymous ocCa18RAinda não há avaliações

- HSE SOP-03 Incident & Accident Reporting, Investigation and AnalysisDocumento6 páginasHSE SOP-03 Incident & Accident Reporting, Investigation and AnalysisImad Chaudhary100% (3)

- HSE Procedures Incident & Accident Reporting, Investigation & AnalysisDocumento6 páginasHSE Procedures Incident & Accident Reporting, Investigation & AnalysisAli haider100% (1)

- Permit To Work Policy ProcedureDocumento7 páginasPermit To Work Policy ProcedureChristian Auditor RiveraAinda não há avaliações

- Safety ManualDocumento131 páginasSafety ManualAntonio NeiAinda não há avaliações

- Journey Management ReviewDocumento3 páginasJourney Management Reviewhamid123456789Ainda não há avaliações

- HSE Management SystemDocumento31 páginasHSE Management Systemtaufik100% (4)

- Contractor Safety ManualDocumento47 páginasContractor Safety ManualArshad Mahmood100% (4)

- Foreign Material ExclusionDocumento22 páginasForeign Material ExclusionBahim BahimanAinda não há avaliações

- Appendix E Fire & Emergency Response PlanDocumento11 páginasAppendix E Fire & Emergency Response PlanVenkadesh PeriathambiAinda não há avaliações

- Accident Investigation PolicyDocumento4 páginasAccident Investigation PolicyNorman AinomugishaAinda não há avaliações

- Driving Policy Signed ApprovedDocumento1 páginaDriving Policy Signed ApprovedSantos RexAinda não há avaliações

- 8 - Contractor & Subcontractor PolicyDocumento10 páginas8 - Contractor & Subcontractor PolicyNaveen ChaudharyAinda não há avaliações

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocumento5 páginasRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakAinda não há avaliações

- Diamond PDFDocumento61 páginasDiamond PDFsjmpakAinda não há avaliações

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocumento5 páginasRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakAinda não há avaliações

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocumento2 páginasRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakAinda não há avaliações

- Diamond Threat ModelingDocumento21 páginasDiamond Threat ModelingsjmpakAinda não há avaliações

- SBM - Screening Form (14412)Documento2 páginasSBM - Screening Form (14412)sjmpakAinda não há avaliações

- BRKCRS 3146Documento89 páginasBRKCRS 3146sjmpakAinda não há avaliações

- Business Plan Template: Executive SummaryDocumento2 páginasBusiness Plan Template: Executive SummarysjmpakAinda não há avaliações

- Safety GramDocumento4 páginasSafety GramsjmpakAinda não há avaliações

- Silkroad Ultimate Guide To PerformanceDocumento12 páginasSilkroad Ultimate Guide To PerformancesjmpakAinda não há avaliações

- PGS-WI-MC-02 Cranes Load Test ProcedureDocumento6 páginasPGS-WI-MC-02 Cranes Load Test ProceduresjmpakAinda não há avaliações

- Environemental Management System - Risk Register - Aspect and Impacts RegisterDocumento6 páginasEnvironemental Management System - Risk Register - Aspect and Impacts Registersjmpak100% (8)

- Guidance For OrganisationsDocumento24 páginasGuidance For OrganisationssjmpakAinda não há avaliações

- Guidance For StakeholdersDocumento25 páginasGuidance For StakeholderssjmpakAinda não há avaliações

- PGS-FM-MC-01 Measuring Tape Verification RecordDocumento1 páginaPGS-FM-MC-01 Measuring Tape Verification RecordsjmpakAinda não há avaliações

- Using DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryDocumento4 páginasUsing DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryzdnAinda não há avaliações

- Risk Based Thinking in ISO 9001 2015 PaperDocumento5 páginasRisk Based Thinking in ISO 9001 2015 PapersjmpakAinda não há avaliações

- Articulo de TQM e ISODocumento14 páginasArticulo de TQM e ISONelson GonzalezAinda não há avaliações

- Legal Register Evaluation Feb '20Documento61 páginasLegal Register Evaluation Feb '20Priyanka J100% (6)

- Hbo Report (Work and Work Attitude)Documento5 páginasHbo Report (Work and Work Attitude)Janh Kent Yeoj CruzAinda não há avaliações

- Labor Standards Finals Case DigestDocumento130 páginasLabor Standards Finals Case Digestchacile100% (10)

- Business IA Final Draft - MatthewDocumento21 páginasBusiness IA Final Draft - MatthewMatthew Christoviano KadangAinda não há avaliações

- The Rise and Fall of Neoliberal Capitalism (PDFDrive)Documento288 páginasThe Rise and Fall of Neoliberal Capitalism (PDFDrive)Zahra AdhaAinda não há avaliações

- United States Court of Appeals, Eleventh CircuitDocumento12 páginasUnited States Court of Appeals, Eleventh CircuitScribd Government DocsAinda não há avaliações

- Managing GoogleDocumento9 páginasManaging GoogleRose Andrea FerreiraAinda não há avaliações

- Mental Health and Stress in Emergency Medical ServicesDocumento17 páginasMental Health and Stress in Emergency Medical Servicesepraetorian100% (1)

- Gloria M Goytia - VP MarketingDocumento2 páginasGloria M Goytia - VP MarketinggmgoytiaAinda não há avaliações

- Catalog Top Angajatori Pentru Care Sa Lucrezi in 2023Documento148 páginasCatalog Top Angajatori Pentru Care Sa Lucrezi in 2023Marinel RaduAinda não há avaliações

- Unilever Hindustan Lever Limited India: Ramesh C. DattaDocumento36 páginasUnilever Hindustan Lever Limited India: Ramesh C. DattaRajen DhariniAinda não há avaliações

- WBPDCLadDocumento10 páginasWBPDCLadJeshiAinda não há avaliações

- Rules On Venue of Filing Labor Cases: Complainant /petitionerDocumento1 páginaRules On Venue of Filing Labor Cases: Complainant /petitionerLTB mtlawAinda não há avaliações

- ResumeDocumento3 páginasResumetinjorjAinda não há avaliações

- RetiremntDocumento3 páginasRetiremntDiane HigidaAinda não há avaliações

- Case Study - Risk Management in Health Care Construction Projects - Occupational Health & SafetyDocumento4 páginasCase Study - Risk Management in Health Care Construction Projects - Occupational Health & SafetyPuneet AroraAinda não há avaliações

- G.R. No. L-51182 July 5, 1983 Helmut DOSCH, Petitioner, National Labor Relations Commission and Northwest Airlines, Inc., FactsDocumento4 páginasG.R. No. L-51182 July 5, 1983 Helmut DOSCH, Petitioner, National Labor Relations Commission and Northwest Airlines, Inc., Factszyphora grace trillanesAinda não há avaliações

- Foreign Affairs - March - April 2016Documento224 páginasForeign Affairs - March - April 2016Talal AbdullahAinda não há avaliações

- CHP#2Documento2 páginasCHP#2H.H.A STATUSAinda não há avaliações

- Be Upper Intermediate PDFDocumento14 páginasBe Upper Intermediate PDFburubduk burundukAinda não há avaliações

- Chapter I Company ProfileDocumento62 páginasChapter I Company ProfileSherlin DisouzaAinda não há avaliações

- Role of Trade Unions in Government EnterprisesDocumento2 páginasRole of Trade Unions in Government Enterprisesrajiv_real100% (1)

- 2 The Scope and Potential of Services Trade in Developing CountriesDocumento1 página2 The Scope and Potential of Services Trade in Developing CountriesArun muraliAinda não há avaliações

- KRA PresentationDocumento23 páginasKRA PresentationSaju SaxenaAinda não há avaliações

- Job RotationDocumento46 páginasJob RotationAmit PasiAinda não há avaliações

- Government of Andhra Pradesh: Revenue DepartmentDocumento33 páginasGovernment of Andhra Pradesh: Revenue DepartmentRoja GuthiReddyAinda não há avaliações

- Affidavit of Support and GuaranteeDocumento1 páginaAffidavit of Support and Guaranteesaleem100% (1)

- Employer's Liability For Compensation Act, 1923Documento10 páginasEmployer's Liability For Compensation Act, 1923Shivam SinghAinda não há avaliações

- The Marble and The Sculptor Introduction Keith Lee PDFDocumento4 páginasThe Marble and The Sculptor Introduction Keith Lee PDFKeith LeeAinda não há avaliações

- DFCC Bank Application.Documento4 páginasDFCC Bank Application.Saint MotivesAinda não há avaliações

- Rules of Thumb for Maintenance and Reliability EngineersNo EverandRules of Thumb for Maintenance and Reliability EngineersNota: 4.5 de 5 estrelas4.5/5 (12)

- Fire Fighting Pumping Systems at Industrial FacilitiesNo EverandFire Fighting Pumping Systems at Industrial FacilitiesNota: 4.5 de 5 estrelas4.5/5 (3)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemAinda não há avaliações

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- A Complete Guide to Safety Officer Interview Questions and AnswersNo EverandA Complete Guide to Safety Officer Interview Questions and AnswersNota: 4 de 5 estrelas4/5 (1)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityNo EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityNota: 5 de 5 estrelas5/5 (2)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesAinda não há avaliações

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersNo EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersNota: 4 de 5 estrelas4/5 (32)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ENo EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ENota: 3 de 5 estrelas3/5 (6)

- Guidelines for Auditing Process Safety Management SystemsNo EverandGuidelines for Auditing Process Safety Management SystemsAinda não há avaliações

- Fundamentals of Risk Management for Process Industry EngineersNo EverandFundamentals of Risk Management for Process Industry EngineersAinda não há avaliações

- Culture, Health and Illness: An Introduction for Health ProfessionalsNo EverandCulture, Health and Illness: An Introduction for Health ProfessionalsAinda não há avaliações

- Epidemiology and Demography in Public HealthNo EverandEpidemiology and Demography in Public HealthJaphet KillewoNota: 5 de 5 estrelas5/5 (1)

- Handbook of Hazardous Chemical PropertiesNo EverandHandbook of Hazardous Chemical PropertiesNota: 5 de 5 estrelas5/5 (1)

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedNo EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedNota: 5 de 5 estrelas5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeNo EverandThe Invisible Rainbow: A History of Electricity and LifeNota: 4.5 de 5 estrelas4.5/5 (21)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeAinda não há avaliações

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaAinda não há avaliações

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsNo EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsNota: 4 de 5 estrelas4/5 (11)

- Workbook to Accompany Maintenance & Reliability Best PracticesNo EverandWorkbook to Accompany Maintenance & Reliability Best PracticesNota: 3.5 de 5 estrelas3.5/5 (3)