Escolar Documentos

Profissional Documentos

Cultura Documentos

What Is Blown Film Extrusion

Enviado por

Jonas BonfimDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

What Is Blown Film Extrusion

Enviado por

Jonas BonfimDireitos autorais:

Formatos disponíveis

What

is

Blown

Film

Extrusion?

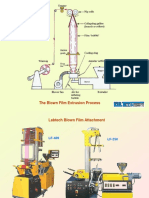

Blown Film Extrusion is one of the most common polymer conversion processes in the world Film is made by extruding molten plastic through a circular die, forming an inflated tubular bubble that moves through a cage as it cools, that is then collapsed and formed into rolls The typical film blowing process consists of a series of stages, including extrusion, blowing, collapsing, and winding

HIPF

Course

Course

Description

Objective

At the end of the course, the trainees will be able to:

Develop a working knowledge of and learn how to operate a Blown Film Extrusion machine Understand the basics of blown film technology, the common material used, and some common problem solving situations Analyze and solve practical blown film problems Develop a working knowledge on maintaining a blown film machine

Course Outline 1. Principles of Blown Film Extrusion

Definition and Principle; Product and Applications; Film Fabrication Process; Types of Blown Film Machines 2. Resin Materials for Blown Film

Raw Materials Use for Blown Film Extrusion; Three Common Polyethylene Grades Used for Blown Film; Suitable Grade index for Blown Film 3. Safety Education for Blown Film Operation

Safety Guideline and SOP; Personal Protective Equipment (PPE); Safety Devices; Warning Signs; Safety Rules for Operation; Safety Instructions on Operation 4. The Main Components of Blown Film Machine

The Extruder; The Die Head and Die; The Bubble Cooling System; Bubble Stabilizer; The TakeOff System/Pinch or Nip Rolls; The Wind-Up System; Corona Treatment 5. Die and Air Ring as Major Components for Blown Film

Kinds of Die for Blown Film; Details of Die and How It Works; Details of Air Ring and How It Works; Die and Air Ring Care and Maintenance 6. Introduction to the Blown Film Extrusion Machine

BFE Process Flow; Start-Up of Blown Film Line; Quality Control for Blown Film; Scheduled ShutDown of Blown Film Line; Emergency Shut-Down of Blown Film Line; Switching On After Emergency Stop 7. Operating Skills for Blown Film Extrusion Technology

Checking of Machine Conditions Before Operation; Winder Preparations; Film Guide Set-Up and Importance; Blown Film Run Preparations; Die Checking and Adjustments; Parameter SettingUp; Switching On After Emergency Stop; Changing Die; Changing Materials and Filling Procedures 8. Die Dismantling, Cleaning and Mounting

Die Dismantling Procedure; Die Cleaning and Care; Understand Die Assembly and Mounting 9. Blown Film Extrusion Troubleshooting

Types of Trouble of Blown Film Process; Unstable Bubble; Film Appearance; Machine Malfunction 10. Common Secondary Film Processing Methods

Printing; Bag Making Process; Scrap Recycling 11. Quality Control of Blown Film

Quality Check for Blown Film; Production Recording; How To Report the Result of Manufacturing 12. Practice Plant Operations

Você também pode gostar

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentNo EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentAinda não há avaliações

- View The Blown Film Extrusion Workbook - Higher Institute For ...Documento110 páginasView The Blown Film Extrusion Workbook - Higher Institute For ...Diana Mickute100% (2)

- Issue #9 Printing and Graphics Science Group NewsletterNo EverandIssue #9 Printing and Graphics Science Group NewsletterAinda não há avaliações

- Report BengkelDocumento11 páginasReport BengkelMuhammad Nasri Zainal AbidinAinda não há avaliações

- Adopting Best Practices in Blown Film ExtrusionDocumento16 páginasAdopting Best Practices in Blown Film ExtrusionHafiani HichamAinda não há avaliações

- Blown Film Extrusion ReportDocumento12 páginasBlown Film Extrusion ReportAbdul Razak RahmatAinda não há avaliações

- Blown Film ProblemsDocumento33 páginasBlown Film ProblemsNoel AndradeAinda não há avaliações

- 7 9layerblownfilmlinesDocumento6 páginas7 9layerblownfilmlinesductoan32Ainda não há avaliações

- Troubleshooting Guide For Film Blowing: Problem Possible Causes Possible SolutionsDocumento3 páginasTroubleshooting Guide For Film Blowing: Problem Possible Causes Possible SolutionsLaili Azkiyah100% (2)

- PFF of Blown Film Process FromDocumento32 páginasPFF of Blown Film Process FromMark SternAinda não há avaliações

- Blown Film CatalogueDocumento12 páginasBlown Film CatalogueMohammad-reza NabavinezhadAinda não há avaliações

- The Tubular Film Blowing ProcessDocumento9 páginasThe Tubular Film Blowing ProcessAlmir MachadoAinda não há avaliações

- FilmDocumento2 páginasFilmDhileepan KumarasamyAinda não há avaliações

- Blown FilmDocumento4 páginasBlown Filmwahyutrisutrisno91Ainda não há avaliações

- Film ExtrusionDocumento16 páginasFilm ExtrusionhatharasingheAinda não há avaliações

- Blown FilmDocumento11 páginasBlown FilmMarc Romero100% (1)

- Blown FilmDocumento18 páginasBlown Filmahsan888100% (2)

- Blown Film Additives 1Documento7 páginasBlown Film Additives 1mohammed100% (1)

- Film Extrusion PDFDocumento63 páginasFilm Extrusion PDFTrần Hữu Như100% (1)

- Blown Film ManualDocumento20 páginasBlown Film ManualJohn P. Bandoquillo100% (2)

- Stretch HoodDocumento1 páginaStretch HoodSelva RajanAinda não há avaliações

- Extrusion of Blown Film: Josip MauričDocumento47 páginasExtrusion of Blown Film: Josip MauričlinchonAinda não há avaliações

- Clase 7. Blown Film ExtrusionDocumento37 páginasClase 7. Blown Film ExtrusionJuan Carlos Amaro ReyesAinda não há avaliações

- Blown Film ExtrusionDocumento3 páginasBlown Film Extrusionchoirunissa setyaningrumAinda não há avaliações

- Types of Plastic ExtrudersDocumento7 páginasTypes of Plastic ExtrudershvadnalaAinda não há avaliações

- Presented By: Laminating Adhesives For Flexible PackagingDocumento14 páginasPresented By: Laminating Adhesives For Flexible PackagingKarim BoudaouchAinda não há avaliações

- LaminationDocumento18 páginasLaminationSiddharth SaxenaAinda não há avaliações

- Film Properties-Tests and DetailsDocumento40 páginasFilm Properties-Tests and DetailsShubham Kumar100% (2)

- Polymer Packaging and Food PPDocumento20 páginasPolymer Packaging and Food PPMaria Mendez100% (2)

- Castflex EngDocumento12 páginasCastflex EngJuanAinda não há avaliações

- Plastics Extrusion ProcessDocumento27 páginasPlastics Extrusion Processjaiprakash saini100% (5)

- Next Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical CompanyDocumento4 páginasNext Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical Companyductoan32Ainda não há avaliações

- Flexible Packaging PresentationDocumento58 páginasFlexible Packaging Presentationdickykucluk100% (2)

- Dry Film LaminationDocumento9 páginasDry Film LaminationDieselJakeAinda não há avaliações

- Pouch Case StudyDocumento4 páginasPouch Case StudyHamid HamidAinda não há avaliações

- Plastics Blown Film Extrusion: Manufacturing IntelligenceDocumento6 páginasPlastics Blown Film Extrusion: Manufacturing IntelligenceMark SternAinda não há avaliações

- RIL BoppDocumento14 páginasRIL BoppSaurabh PariharAinda não há avaliações

- .Extrusion - Single ScrewDocumento125 páginas.Extrusion - Single ScrewSUCHETHA N RAJU PST100% (2)

- Formula For Plastic ProductsDocumento6 páginasFormula For Plastic ProductsRRSAinda não há avaliações

- Plastic Moulding ProcessDocumento28 páginasPlastic Moulding ProcessQUAZI ADYAN AHMAD 160419736049Ainda não há avaliações

- Solventless Laminator Nordmeccanica SimplexDocumento9 páginasSolventless Laminator Nordmeccanica SimplexRishi SrivastavAinda não há avaliações

- Extrusion Troubleshooting PDFDocumento2 páginasExtrusion Troubleshooting PDFChivuAlexandruAinda não há avaliações

- ETSThermoplasticExtrsuionTrainingList PDFDocumento5 páginasETSThermoplasticExtrsuionTrainingList PDFFajr Al-FurqonAinda não há avaliações

- PP Cast FilmDocumento24 páginasPP Cast FilmTrung HoAinda não há avaliações

- Basic Laminating Technology 4Documento16 páginasBasic Laminating Technology 4Ronaldo latumanuwyAinda não há avaliações

- Guia Seleccion Productos AffinityDocumento4 páginasGuia Seleccion Productos AffinityFrank MariniAinda não há avaliações

- Antiskid Product Info PDFDocumento11 páginasAntiskid Product Info PDFSachin KothariAinda não há avaliações

- Extrusion of Blown Film: Josip MauričDocumento47 páginasExtrusion of Blown Film: Josip MauričnamAinda não há avaliações

- TPU Drying GuideDocumento16 páginasTPU Drying GuideBang QuachAinda não há avaliações

- Cleaning ScrewsDocumento6 páginasCleaning ScrewsRodolfoAntonioLeónCárdenasAinda não há avaliações

- Manufacturing Processes: International Islamic University IslamabadDocumento44 páginasManufacturing Processes: International Islamic University IslamabadMuhammad Qasim SajidAinda não há avaliações

- LDPE Shrink Film SpecificationsDocumento1 páginaLDPE Shrink Film SpecificationsSriniAinda não há avaliações

- Flexible Packaging: (Basic Films / Raw Materials For Converting)Documento10 páginasFlexible Packaging: (Basic Films / Raw Materials For Converting)pandu krAinda não há avaliações

- Flexible LaminatesDocumento13 páginasFlexible LaminatesHimanshu GuptaAinda não há avaliações

- Blow Moulding MachineDocumento114 páginasBlow Moulding MachineAbdelmoneim NoohAinda não há avaliações

- Curriculum Alignment - Machine Operator Blow Moulding - L4Documento5 páginasCurriculum Alignment - Machine Operator Blow Moulding - L4ZakAinda não há avaliações

- Blow Molding 1Documento21 páginasBlow Molding 1prashant_cool_4_u100% (1)

- AFI 90-901 Operational Risk ManagementDocumento7 páginasAFI 90-901 Operational Risk ManagementJohan Lai100% (1)

- 755th RSBDocumento32 páginas755th RSBNancy CunninghamAinda não há avaliações

- Manual StereoDocumento29 páginasManual StereoPeter Mac RedAinda não há avaliações

- Earnings Statement: Hilton Management Lane TN 38117 Lane TN 38117 LLC 755 Crossover MemphisDocumento2 páginasEarnings Statement: Hilton Management Lane TN 38117 Lane TN 38117 LLC 755 Crossover MemphisSelina González HerreraAinda não há avaliações

- ANTH 222 Syllabus 2012Documento6 páginasANTH 222 Syllabus 2012Maythe S. HanAinda não há avaliações

- Complete Cocker Spaniel Guide 009 PDFDocumento119 páginasComplete Cocker Spaniel Guide 009 PDFElmo RAinda não há avaliações

- Company Profile RadioDocumento8 páginasCompany Profile RadioselviAinda não há avaliações

- IKEA AyeshaDocumento41 páginasIKEA AyeshaAYESHAREHMAN100Ainda não há avaliações

- The Civil Mutinies of Romeo and Juliet: Glenn ClarkDocumento21 páginasThe Civil Mutinies of Romeo and Juliet: Glenn ClarkmilcahAinda não há avaliações

- Powerpoints 4 4up8Documento9 páginasPowerpoints 4 4up8Ali KalyarAinda não há avaliações

- ReportDocumento8 páginasReportTrust Asia Cargo in OfficeAinda não há avaliações

- Daftar PustakaDocumento6 páginasDaftar PustakaSeptian UtamaAinda não há avaliações

- Exam Questions AZ-304: Microsoft Azure Architect Design (Beta)Documento9 páginasExam Questions AZ-304: Microsoft Azure Architect Design (Beta)Deepa R NairAinda não há avaliações

- Ham (Son of Noah) - WikipediaDocumento3 páginasHam (Son of Noah) - Wikipediamike bAinda não há avaliações

- Harper 2001Documento6 páginasHarper 2001Elena GologanAinda não há avaliações

- Haryana at A Glance: Geographical AreaDocumento1 páginaHaryana at A Glance: Geographical AreasonuAinda não há avaliações

- Mae (256F) - HW3 PDFDocumento2 páginasMae (256F) - HW3 PDFClaireAinda não há avaliações

- Pesticides 2015 - Full BookDocumento297 páginasPesticides 2015 - Full BookTushar Savaliya100% (1)

- Bimetallic ZN and HF On Silica Catalysts For The Conversion of Ethanol To 1,3-ButadieneDocumento10 páginasBimetallic ZN and HF On Silica Catalysts For The Conversion of Ethanol To 1,3-ButadieneTalitha AdhyaksantiAinda não há avaliações

- Contoh Rancangan Pengajaran Harian (RPH)Documento7 páginasContoh Rancangan Pengajaran Harian (RPH)Farees Ashraf Bin ZahriAinda não há avaliações

- Sycip v. CA (Sufficient Funds With The Drawee Bank)Documento15 páginasSycip v. CA (Sufficient Funds With The Drawee Bank)Arnold BagalanteAinda não há avaliações

- Didhard Muduni Mparo and 8 Others Vs The GRN of Namibia and 6 OthersDocumento20 páginasDidhard Muduni Mparo and 8 Others Vs The GRN of Namibia and 6 OthersAndré Le RouxAinda não há avaliações

- Intimate TemporalitiesDocumento12 páginasIntimate TemporalitiesmittentenAinda não há avaliações

- Operations Management Final Exam Solutions CourseraDocumento2 páginasOperations Management Final Exam Solutions Courseratheswingineer0% (5)

- Thick Teak PVT LTD Aoa and MoaDocumento17 páginasThick Teak PVT LTD Aoa and MoaVj EnthiranAinda não há avaliações

- IN THE BEGINNING WAS AFFECT RolnikDocumento22 páginasIN THE BEGINNING WAS AFFECT RolnikFabiana PaulinoAinda não há avaliações

- Rotation and Revolution of EarthDocumento4 páginasRotation and Revolution of EarthRamu ArunachalamAinda não há avaliações

- Jesus Hold My Hand EbDocumento2 páginasJesus Hold My Hand EbGregg100% (3)

- Project CharterDocumento10 páginasProject CharterAdnan AhmedAinda não há avaliações

- 5.4 Marketing Arithmetic For Business AnalysisDocumento12 páginas5.4 Marketing Arithmetic For Business AnalysisashAinda não há avaliações