Escolar Documentos

Profissional Documentos

Cultura Documentos

Tricking Out HF 9x20 Lathe

Enviado por

Cliff MillerDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tricking Out HF 9x20 Lathe

Enviado por

Cliff MillerDireitos autorais:

Formatos disponíveis

!

!

!

"#$%#&' )*!

"

"

#

#

$

$

%

%

#

#

&

&

'

'

)

)

*

*

!

!

!"# %&'%( )*+, -%!"#

!

!

"

"

#

#

%

%

&

&

'

'

%

%

(

(

)

)

*

*

+

+

,

,

-

-

%

%

!

!

"

"

#

#

bv. Cletus L. Berkelev

! !" "# #$ $% %& &# #' ' ) )* *+ +* *, ,- -- -. . / / 0 0' '- -1 1 2 23 3

!

#

#

$

$

$

%&#

#

#

'

'

'

(%

)

*)*+,

,

,

&$

$

$

!

!

# %

%

&

&

(

(

%

%

)

)

-

-

-

*

*

)

)

*

*

+

+

&

&

,

,

,

& .%

/)0'

'

'

'

'

'

1& '

'

'

)2(

1$

$

$

%& %0

34

5&$

$

$

'

'

'

)+(

)62%$

$

$

(

&

&

#

#

#

.

.

%

%

/

/

)

)

0

0

-

-

-

1

1

&

&

#

#

#

)

)

2

2

(

(

1

1

%

%

&

&

#

#

#

%

%

0

0

3

3

4

4

5

5

&

&

)

)

+

+

(

(

)

)

6

6

2

2

%

%

(

(

This is a non-profit document produced by and for the members of

http://groups.yahoo.com/group/9x20Lathe/

The information contained herein is presented for intellectual enrichment only and may

not change hands for monetary gain. The Author, Researchers, Contributors, Manufacturers,

Suppliers and Members assume no liability whatsoever from the use of information

contained herein.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 2

Contents

Topic Page

Foreword ............... 3

1. 4-Bolt Compound Clamp .......... 4

2. Rigid Toolpost Mount .......... 8

3. QCTP .................. 9

4. Reverse Tumbler ............ 11

5. DRO ................. 16

6. DC Motor Variable Speed ........ 18

7. Saddle Lock .............. 25

8. Ball Turning Toolpost ............ 27

9. Manual Spindle Crank ........... 39

10. Digital Spindle Tachometer ......... 42

11. Emergency STOP ............. 45

12. Easy Toolpost Grinder ........... 47

13. Links & Recommended Reading ...... 48

14. Acknowledgements ........... 49

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 3

Foreword

It`s well established that the Asian 920 Lathe oIIers an inexpensive solution Ior persons wanting a

capable machine and with some clever modiIications and tweaking these machines can and have been

developed into Machining Centers rivaling equipment costing many times the what was paid Ior these

mechanical marvels.

This manual attempts to show some oI the many useIul modiIications that are possible and popular

among owners oI these excellent lathes.

A wealth oI detailed inIormation is contained in the archives oI the Iollowing:

http://groups.yahoo.com/group/9x20Lathe/

http://groups.yahoo.com/group/9x20Lathe2/

A word of Caution

Please be aware, that many of these modifications and ~tweaks call for varying component

dimensions, metal removal and/or otherwise changing the mechanical and/or electrical

configuration of these machines, in a manner that in all probability, voids your manufacturer`s

warranty.

Further, these modifications may constitute the use of accessories considered not-recommended

and/or may be construed as unsafe by the manufacturer and as such, any claims for in-warranty

service may therefore be denied.

Now that you understand all oI this, its time to get those tools out and let`s start building a 'Super 920

Lathe.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 4

4-BoIt 4-BoIt

Compound CIamp Compound CIamp

By: Steve Bedair By: Steve Bedair

This is one oI the Iirst improvements needed on the 9

x 20 lathes. I have included photos Irom start to Iinish

to build your own clamp. I have also included

measurements but please note that these are the

measurements that worked Ior my HF 9 x 20 lathe.

All the 9 x 20's are basically the same but exact

measurements may diIIer.

This is one oI the Iirst improvements needed on the 9

x 20 lathes. I have included photos Irom start to Iinish

to build your own clamp. I have also included

measurements but please note that these are the

measurements that worked Ior my HF 9 x 20 lathe.

All the 9 x 20's are basically the same but exact

measurements may diIIer.

Please also note that the construction oI a new

compound clamp plate needs to be a minimum oI 1/2"

thick steel ( 5/8" thick would be even better) This is

to ensure that there is enough material to provide a

snug Iit to the existing neck oI the compound to the

new hole in the clamping plate. This extra material at the neck is what provides the support, not just the

4 attaching bolts.

Please also note that the construction oI a new

compound clamp plate needs to be a minimum oI 1/2"

thick steel ( 5/8" thick would be even better) This is

to ensure that there is enough material to provide a

snug Iit to the existing neck oI the compound to the

new hole in the clamping plate. This extra material at the neck is what provides the support, not just the

4 attaching bolts.

I started with a piece oI 1/2" thick steel plate ( 5/8"

would even be better). I cut this to size with my

metal cutting bandsaw. I next drilled a 3/8" hole in the

center oI the plate. ( Note: Some have went with a

larger 4" x 4" clamp dimension )

I started with a piece oI 1/2" thick steel plate ( 5/8"

would even be better). I cut this to size with my

metal cutting bandsaw. I next drilled a 3/8" hole in the

center oI the plate. ( Note: Some have went with a

larger 4" x 4" clamp dimension )

A 3/8" x 3" long bolt can be tightened in the chuck with the head oI the 3/8" bolt pulled against the rear

jaws oI the chuck. This allows a nut to be tightened "tight" without the bolt moving / slipping.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 5

With the 1/2" steel plate attached to the

3/8" bolt I create a shoulder as shown

above.

This will be the top oI the clamp. The

shoulder will allow the steel plate to be

held

in the chuck to complete the bottom side

oI the clamp.

With the 1/2" steel plate attached to the

3/8" bolt I create a shoulder as shown

above.

This will be the top oI the clamp. The

shoulder will allow the steel plate to be

held

in the chuck to complete the bottom side

oI the clamp.

Once the shoulder is completed the steel plate is removed Irom the chuck and turned around.

You will have to change out the chuck jaws and use the shoulder to grip the steel plate as shown.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 6

BeIore starting on the bottom side oI the clamp

here is the Iinished pic along with

measurements. You can click on the pic Ior a

larger version. This will give you a better idea

oI the process.

The Iirst step is to bore the ID to 2.01".I use a large drill

bit setup in the tailstock to remove as much metal as

possible ( 5/8"-3/4") Next I use a lathe bit and stop short oI

the 2.01" I Iinish up with a boring bar. The 2.01" ID will

be through the Iull thickness oI the steel plate. Still using

the boring bar cut the outer shoulder to an OD oI 2.57" and

a depth oI .185"

Once the

bottom cuts

are completed

I turn the clamp over and make a Iinishing cut across the

raised shoulder on the top side.

Please also note that the construction oI a new compound

clamp plate needs to be a minimum oI 1/2" thick steel (

5/8" thick would be even better) This is to ensure that there

is enough material to provide a snug Iit to the existing neck

oI the compound to the new hole in the clamping plate.

This extra material at the neck is what provides the support,

not just the 4 attaching bolts.

For the Iour mounting holes I lay the clamp on the topslide and mark with a straight edge. I drill the Iour

mounting holes to 17/64" (slightly larger than 1/4") For attaching screws 1/4" carriage bolts with the

sides oI the heads ground to Iit the T slots works well.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 7

II you want to go an extra step you can add a

notch that allows you to see the degree wheel. I

did use the mini mill Ior this although a Iile

would work.

II you want to go an extra step you can add a

notch that allows you to see the degree wheel. I

did use the mini mill Ior this although a Iile

would work.

Completed clamp

Please note that these are the measurements that worked Ior my HF 9 x 20 lathe.

All the 9 x 20's are basically the same but exact measurements may diIIer.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 8

Rigid Rigid

TooIpost Mount TooIpost Mount

By: Cletus Berkeley By: Cletus Berkeley

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 9

Quick-Change Quick-Change

TooIpost (QCTP) TooIpost (QCTP)

By: Cletus Berkeley By: Cletus Berkeley

The Iirst thing you need to do is take oII the stock toolpost, remove the compound Irom your lathe and

take the compound apart. Turn the handwheel counterclockwise until the slide comes oII. Remove the

gib and set aside. Remove the two bolts securing the leadscrew bearing plate/handwheel assembly. You

should at this point realize that the original toolpost stud is press Iitted Irom the bottom oI the slide.

Some blunt Iorce trauma to the stud Irom a brass hammer dislodges it quickly. A Mini-mill or similar is

needed Ior the Iollowing operations:

The Iirst thing you need to do is take oII the stock toolpost, remove the compound Irom your lathe and

take the compound apart. Turn the handwheel counterclockwise until the slide comes oII. Remove the

gib and set aside. Remove the two bolts securing the leadscrew bearing plate/handwheel assembly. You

should at this point realize that the original toolpost stud is press Iitted Irom the bottom oI the slide.

Some blunt Iorce trauma to the stud Irom a brass hammer dislodges it quickly. A Mini-mill or similar is

needed Ior the Iollowing operations:

1) Setup the slide on the milling table ensuring that the top oI the slide (plinth) is perpendicular to

the mill`s quill.

1) Setup the slide on the milling table ensuring that the top oI the slide (plinth) is perpendicular to

the mill`s quill.

2) Bore the toolpost hole to appropriate size and thread to accommodate the new stud that came

with the QCTP. It is important that the hole be bored and threaded perpendicular to the top

surIace oI the plinth.

2) Bore the toolpost hole to appropriate size and thread to accommodate the new stud that came

with the QCTP. It is important that the hole be bored and threaded perpendicular to the top

surIace oI the plinth.

3) Using an endmill, remove 0.125 Irom the periphery oI the plinth to a depth oI 0.125. This

creates a recess that allows the QCTP to be lowered. Doing this permits a Iull range oI vertical

adjustment Ior tooling Irom 0.25 through 0.5 to be used in the toolholders..

3) Using an endmill, remove 0.125 Irom the periphery oI the plinth to a depth oI 0.125. This

creates a recess that allows the QCTP to be lowered. Doing this permits a Iull range oI vertical

adjustment Ior tooling Irom 0.25 through 0.5 to be used in the toolholders..

4) Clean the parts thoroughly, use some locktite and install the new stud. Reassemble the compound

applying lube as necessary and readjust the gib iI needed.

4) Clean the parts thoroughly, use some locktite and install the new stud. Reassemble the compound

applying lube as necessary and readjust the gib iI needed.

5) Install the QCTP and you`re done. 5) Install the QCTP and you`re done.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 10

Once you use a Quick Change Toolpost (QCTP), you will not want to go back to the stock toolpost.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 11

Reverse TumbIer Reverse TumbIer

By: A. Kelemen (design & illustration), Cletus Berkeley (editorial) By: A. Kelemen (design & illustration), Cletus Berkeley (editorial)

The stock 920 lathe comes with an electrical motor reverse integral to the power switch. This switch

eIIectively reverses the spindle rotation and leadscrew rotation together, since the spindle and leadscrew

are mechanically coupled by the geartrain.

The stock 920 lathe comes with an electrical motor reverse integral to the power switch. This switch

eIIectively reverses the spindle rotation and leadscrew rotation together, since the spindle and leadscrew

are mechanically coupled by the geartrain.

In other words, the leadscrew rotation cannot be reversed with respect to spindle rotation, making the

cutting oI leIt handed threads impossible.

In other words, the leadscrew rotation cannot be reversed with respect to spindle rotation, making the

cutting oI leIt handed threads impossible.

In order to accomplish reversal oI the leadscrew independent oI spindle rotation another gear needs to be

introduced into the geartrain.

In order to accomplish reversal oI the leadscrew independent oI spindle rotation another gear needs to be

introduced into the geartrain.

This becomes most convenient iI this reversing gear

can be readily inserted and retracted by means oI a

selector lever or 'Reverse Tumbler. Fortunately

the design oI the 920 is as such to readily lend itselI

to this type oI modiIication. Another and not readily

apparent use oI the 'Reverse Tumbler is the ability

to neutralize the geartrain. In doing so, the geartrain

may be isolated Irom the spindle rotation Ior

general turning operations when automatic carriage

movement is unnecessary. The machine runs much

quieter, there is less wear and tear on the machine

and more power can be made available at the

spindle. The Iollowing is probably one oI the best

tumbler reverse designs that I`ve seen to date. Its

easy to build and implement.

This becomes most convenient iI this reversing gear

can be readily inserted and retracted by means oI a

selector lever or 'Reverse Tumbler. Fortunately

the design oI the 920 is as such to readily lend itselI

to this type oI modiIication. Another and not readily

apparent use oI the 'Reverse Tumbler is the ability

to neutralize the geartrain. In doing so, the geartrain

may be isolated Irom the spindle rotation Ior

general turning operations when automatic carriage

movement is unnecessary. The machine runs much

quieter, there is less wear and tear on the machine

and more power can be made available at the

spindle. The Iollowing is probably one oI the best

tumbler reverse designs that I`ve seen to date. Its

easy to build and implement.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 12

!

! !

"

" "

#

# #

$

$ $

%

% %

#

# #

&

& &

'

' '

)

) )

*

* *

!

! !

!

! !

"

" "

#

# #

%

% %

&

& &

'

' '

%

% %

(

( (

)

) )

*

* *

+

+ +

,

, ,

-

- -

%

% %

!

! !

"

" "

#

# #

P

a

g

e

1

3

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 14

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 15

4&5&67 89 :8";&8&<%$%:=< => %?& @&A&57& BC8D;&5 =< %?& E5:FF;9 E)---'

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 16

DigitaI Readout (DRO) DigitaI Readout (DRO)

By: Cletus Berkeley By: Cletus Berkeley

One oI the leading DRO systems Ior Lathes and Mills is the CBX Digital Display, manuIactured in

Canada by Shooting Star Technology.

One oI the leading DRO systems Ior Lathes and Mills is the CBX Digital Display, manuIactured in

Canada by Shooting Star Technology.

The CBX works by counting the revolutions oI a precision pinion on a rack with an optical encoder.

There is NO backlash with the CBX rack and pinion. The gear is mounted on a small leaI spring, and it

is constantly in mesh with the rack. The spring that presses the gear into the teeth oI the rack is applying

a very slight pressure, not enough to amount to any wear. The rack can easily be cut with a hacksaw to

Iit your machine.

The CBX works by counting the revolutions oI a precision pinion on a rack with an optical encoder.

There is NO backlash with the CBX rack and pinion. The gear is mounted on a small leaI spring, and it

is constantly in mesh with the rack. The spring that presses the gear into the teeth oI the rack is applying

a very slight pressure, not enough to amount to any wear. The rack can easily be cut with a hacksaw to

Iit your machine.

The CBX comes with 1/2" wire loom (black, plastic tubing) over the racks. It is also suggested you

shield it with angle aluminum, or iron, etc. This will protect the scale Irom any damage Irom dropping

something heavy on it.

The CBX comes with 1/2" wire loom (black, plastic tubing) over the racks. It is also suggested you

shield it with angle aluminum, or iron, etc. This will protect the scale Irom any damage Irom dropping

something heavy on it.

The accuracy oI the CBX is 0.002 / Ioot. (Worst case scenario), The resolution is 0.0005. (1/2 thou) and

a repeatability oI 0.0005. (1/2 thou).

The CBX Digital Display unit includes a comprehensive manual with mounting hardware, and

diagrams. It also shows you step by step how to use all oI the Ieatures oI the unit.

!

!

"

"

#

#

$

$

%

%

#

#

&

&

'

'

)

)

*

*

!

!

!"# %&'%( )*+, -%!"

!"#$%#&' )*! !

!

"

"

#

#

%

%

&

&

'

'

%

%

(

(

)

)

*

*

+

+

,

,

-

-

%

%

!

!

"

"

#

#

#

Page 17

X-Y Encoder Mounting

Both encoder heads mounted to a common

aluminum plate bolted to the rear oI the saddle,

using the original three bolts holding the apron

tension bar to the saddle. Makes Ior a very simple,

stable installation. The Y-Axis Encoder is visible

the X-Axis encoder is mounted on the same plate,

but below.

The basic dimensions Ior the two brackets are

shown below. The dimensions are reIerence only as

the dimensions Ioe mounting on your lathe may

diIIer.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 18

DC Motor DC Motor

VariabIe Speed Modification VariabIe Speed Modification

By: Cletus Berkeley By: Cletus Berkeley

WARNING

YOU CAN BE KILLED

These instructions encompass working with LINE VOLTAGE. If you are

unqualified or uncomfortable working with electricity:

SEEK PROFESSIONAL ASSISTANCE

This document is issued for INFORMATION PURPOSES ONLY. The author

and/or Manufacturers mentioned herein assume no liability for damages,

injury and/or loss of life from performing the procedures mentioned herein.

The Asian 920 Lathes readily lend themselves to a variety oI useIul modiIications one oI which is

variable speed.

The Asian 920 Lathes readily lend themselves to a variety oI useIul modiIications one oI which is

variable speed.

There are a number oI ways in which variable speed may be accomplished and this article Iocuses on an

inexpensive approach (US$140.00) using readily available surplus components to accomplish the goal.

There are a number oI ways in which variable speed may be accomplished and this article Iocuses on an

inexpensive approach (US$140.00) using readily available surplus components to accomplish the goal.

The modiIication suggested herein utilizes a surplus 2HP Permanent Magnet DC Treadmill Motor and a

Regenerative Electronic Drive Circuit Board. Few additional parts and minor modiIications are required

to complete the project.

The modiIication suggested herein utilizes a surplus 2HP Permanent Magnet DC Treadmill Motor and a

Regenerative Electronic Drive Circuit Board. Few additional parts and minor modiIications are required

to complete the project.

This document suggests utilizing such components to achieve simple, reliable and saIe Spindle Speed

Control. Further research into the design oI the Drive Electronics would reveal that a more advanced

control system may be implemented by those wishing to do so.

This document suggests utilizing such components to achieve simple, reliable and saIe Spindle Speed

Control. Further research into the design oI the Drive Electronics would reveal that a more advanced

control system may be implemented by those wishing to do so.

Once you`ve experienced a Variable Speed Lathe. you`ll wonder how you survived without it! Once you`ve experienced a Variable Speed Lathe. you`ll wonder how you survived without it!

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 19

Components Components

Here`s the stuII you will need to acquire: Here`s the stuII you will need to acquire:

TIP: Lots of stuff mav alreadv be in vour funkbox

1. 1 ea DC Motor

http://www.surpluscenter.com/item.asp?UID2005012618452113&item10-

1906&catnameelectric

2. 1 ea DC Speed Control Board

http://www.surpluscenter.com/item.asp?UID2005012618452113&item11-

2434&catnameelectric

3. 1 ea 10K Potentiometer (Speed Control)

http://www.surpluscenter.com/item.asp?UID2005021309260284&catnameelectric&item11-

2432

4. 1 ea Enclosure

5. 1 ea Knob

6. 1 ea Fan 12VDC

7. 1 ea TransIormer 12V 500mA

8. 1 ea Diode 1A 50V

9. 1 ea Capacitor 250uI 50V

10. 1 ea LED (a color oI your Iancy)

11. 1 ea Resistor 1K .25W

12. 1 ea DPDT Switch 10A 125VAC

13. 2 ea SPST Toggle Switch

14. 1 ea SPST Momentary Pushbutton (NC) 0.5A 125VAC

15. Power Cord With Plug

16. Fuseholder

17. 20A Fuse

18. Enclosure and hardware to make it all nice and neat

789:;<=7;>89

(A) The Iirst order oI business is to mill a 0.125 keyway in the shaIt (it all Iits in the Mini-Mill). The

motor does not have to be taken apart to do this, but be sure to encase the motor in a plastic bag or you

will get all the crud pulled into the works by the magnetic Iield.

TIP: You can use a 12JDC supplv to safelv test run

(no load ) the motor on the bench (I was able to run

mine with a bench power supplv with as little as

5JDC 500mA) .

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 20

(B) Keeping the crud out oI the motor is paramount to system longevity. There are three entry points

(Iront, rear and side vents). You will want to use some type oI mesh to keep the crud out and allow the

passage oI cooling air, such as Screen-Door mesh. I chose to use a combination oI Screen-Mesh and 3M

pot scrubbers stuck on with a Glue-Gun. the pot scrubbers Iorm a Iine Iilter and helps keep smaller

chips out yet allows air into the motor.

(B) Keeping the crud out oI the motor is paramount to system longevity. There are three entry points

(Iront, rear and side vents). You will want to use some type oI mesh to keep the crud out and allow the

passage oI cooling air, such as Screen-Door mesh. I chose to use a combination oI Screen-Mesh and 3M

pot scrubbers stuck on with a Glue-Gun. the pot scrubbers Iorm a Iine Iilter and helps keep smaller

chips out yet allows air into the motor.

REAR FILTER FRONT FILTER

(C) The DC Drive we are using is a proprietary derivative oI Model NRG10-115AC-2Q manuIactured

by Minarik Automation and Control. This regenerative DC Drive was intended Ior use on Treadmills

and a number oI adjustment controls have been omitted Irom the board. These adjustments have been

preset by the addition oI discrete components. The board in its preset condition perIorms perIectly well

Ior our intended purpose including its acceleration and deceleration timing. However, the electronics

enthusiast may opt to upgrade the board with the necessary controls and Iurther 'Iine-tune the

system. but that is beyond the scope oI this document.

TIP: Whistles and bells. Feel free to carefullv remove the PCB LEDs and remount them to vour front panel if vou desire

(not necessarv)

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 21

TIP: I chose to mount the Speed Control Pot, Run Switch and Jog Pushbutton on a sub-panel on the front of the lathe. If vou

chose to do so, use shielded cable leading to S1,S2, S3.

Adjustments

There are only two electronic adjustments that need to be set, these are the Minimum and Maximum

Speed trimpot adjustments. These two adjustments interact with each other so you need to go back and

Iorth a couple oI times to get it right. Here`s what we`re trying to achieve:

1) We need the spindle to respond Irom standstill to a RUN or JOG command with little or no delay.

This is achieved with the Minimum Speed Trimpot.

2) We need the spindle to respond Irom rotating to deceleration with little or no delay when the toggle

switch is reset Irom run to jog or the jog button is released. This is achieved with the Maximum Speed

Trimpot.

1. Set the Toggle to JOG, SPEED control to zero, Minimum trimpot adj to Iull CCW, Maximum

adj trimpot to Iull CW.

2. MINIMUM ADJUST - Toggle to RUN and adjust the Minimum adj trimpot to just start the

motor rotating and back oII the adjustment to where it just stops the rotation.

3. MAXIMUM ADJUST With the toggle still at RUN, advance the SPEED control Irom zero to

Iull, the motor should accelerate smoothly Irom zero to Iull speed. Once at Iull speed, reduce the

Maximum adj trimpot Irom Iull CW to a point just beIore the motor starts to decelerate.

4. At this point, iI you return the SPEED control to zero, you will probably Iind that you have lost

the 'zero setting. II so repeat steps two and three.

Here`s the link to the DC Controller Manual:

http://www.minarikcorp.com/PDFs/250-0246.pdI

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 22

SPEED CHART

Belt/Pulley RPM RPM

Configuration Range Stock Speed

BC1 5-300 130

BC2 10-720 300

AC1 10-860 400

BC3 40-1380 600

AC2 60-2300 1000

AC3 100-4100 2000

FormuIa RPM SFPM * (12 / ) / d

SFPM SurIace Feet Per Minute

d Job Diameter

TIP: The above formula should be considered a starting point and is based on HSS tooling.

For Carbide tooling, multiplv the speeds twofold. Remember this is merelv a starting point guide, vou now have variable

speed and lots of power to back it, experiment and applv common sense liberallv, varv the speed, vou will soon find a speed

that matches the fob, tooling and machine. But dont over do it'

Here are some pictures of a GrizzIy G4000 modification:

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 23

FWD/REV

Switch

Close-up of Control

Panel (made on a CNC

Engraver/Router)

A view inside the DC Drive Box

DC Drive Box tucked away under the bench.

(note the Spindle Reverse Switch mounted on the box)

Lathe-Mounted Control Panel

TIP. With this Motor/Drive combination theres more torque available at the motor than can be delivered to the spindle due

to Belt Slippage. Belt Slippage is a good thing, as it prevents things from otherwise breaking. Keeping the Belts and Pullevs

clean and free from oil,( wiping with Isopropvl or Rubbing Alcohol) will allow more efficient torque transfer to the spindle.

Let common sense prevail'

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 24

The motor is mounted (note filter) The pulley arrangement (note filter)

The tach says 480 RPM .and 480 RPM it is 4 dia CRS in the chuck and the motor runs cool

Observations

!" $%& '(' ) *+,-.(%, &(./%+. 012(1345 6755'8

9" :+-/ (;72%05' 6+2*1-5 *(,(6/ &(./ ./5 <= :%.%2"

>" =1, -/1,?5 6755'6 1. &(44@ ,(-5 &/5, '%(,? *1-(,?6"

A" =1, ?5. 2514 64%&@ ,(-5 *%2 ./251'(,? 1,' &(,'(,? -%(46"

B" C%? 3+..%, (6 +65*+4 &/5, 65..(,? +7 ./5 D%3"

E" F% ,55' .% D%-G5H ./5 354. .5,6(%, 45052 %, 6.12.+7 &/5, ) /105 1 /510H D%3 (, ./5

-/+-G %2 &/5, ) 1; +6(,? ;H ;166(05 AID1&" J/5 1--54521.(%,K'5-54521.(%,

.(;(,? .1G56 -125 %* (."

L" M%.6 %* .%2N+5 *2%; 1 ;+-/ ;%25 7%&52*+4 ;%.%2"

O" F% ;%'6 .% ./5 41./5" ) -1, 25052. .% ./5 6.%-G ;%.%2 (, 9PI;(,+.56"

Q" $105 ;1-/(,5' 6%;5 AR '(1 =ST *%2 13%+. .&% /%+26 1,' ./5 ;%.%2 /16 %,4H

31254H ?%..5, &12;""

J/5 6755' -/1,?56 1,' 21;7(,? 125 052H 6;%%./ 1,' 1--54521.(%,K'5-54521.(%, .(;5 (6

1772%U OI65-%,'6" J/525 (6 0(2.+144H ,% 2567%,65 '541H *2%; 6.1,'6.(44 .% 6.12. %* 2%.1.(%,

1,' 61;5 *2%; 2%.1.(%, .% 6.12. %* '5-54521.(%," J/(6 <= ;%.%2 72%'+-56 4%.6 ;%25

.%2N+5 %052 ./5 6.%-G ;%.%2 1,' (6 052H 6(45,. 1712. *2%; ./5 -/121-.52(6.(- &/(,5 %* 1 <=

:%.%2 1. *+44 SV:"

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 25

SaddIe Lock

By: Steve Bedair

The 9 x 20's normally have a recessed allen

head screw here Ior the saddle lock. I

originally added just the ball handle and this

worked well. On two occasions while

threading with the tumbler reverse

(threading Irom leIt to right ) the handle ran

into the tailstock. To Iix this I added a spring

indent that keeps the handle at one oI two

positions. Works very well & keeps the

handle out oI way.

I milled a recess and drilled a hole that a 3/16" ball

bearing sits in. The ball bearing sits in a 3/16" hole. The

hole to the leIt is a threaded hole to attach the spring

cover.

The spring cover is made Irom a piece oI

5/16" square key stock. The hard part is

Iinding a spring small enough to Iit.

I also built a new 1/4"-20 attaching bolt. This has the indention's Ior

the spring loaded ball. The clamp is copied Irom the original clamp

and is threaded to accept the 1/4-20 bolt. ( I didn't have a metric tap

or I would have used the original clamp ) indention's Ior the ball

bearing.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 26

Close up oI the holes drilled in the saddle.

Close up oI the holes drilled in the saddle.

Position 1 unlocked Position 2 unlocked

Position 3 Locked.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 27

BaII-Turning BaII-Turning

TooIpost TooIpost

By: Steve Bedair By: Steve Bedair

Here's a ball cutter I came up with Ior my 9 x 20 lathe. It can turn balls up to 1 7/8" OD and it can also

do concave cuts. The cutter uses a replaceable carbide insert so the tool bit height is "Iixed". Three set

screws on the Iront allow the tool bit to be adjusted leIt and right. The cutter really works great , no

chatter, very rigid & super smooth cutting action. I have included pictures & building details below.

Here's a ball cutter I came up with Ior my 9 x 20 lathe. It can turn balls up to 1 7/8" OD and it can also

do concave cuts. The cutter uses a replaceable carbide insert so the tool bit height is "Iixed". Three set

screws on the Iront allow the tool bit to be adjusted leIt and right. The cutter really works great , no

chatter, very rigid & super smooth cutting action. I have included pictures & building details below.

Turning a 1" steel ball Yeah , It works !!

Everywhere I look needs a ball

!

!

"

"

#

#

$

$

%

%

#

#

&

&

'

'

)

)

*

*

!

!

!

!

"

"

#

#

%

%

&

&'

!"#$%#&' )*! !"# %&

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 28

The ball turning toolpost consist oI three main components: base section , body and the tool holder.

For the base I ended up using 1/2" aluminum plate 4" x 4" ( didn't have any 1/2" steel plate on hand )

The body is built Irom a piece oI 2.5" OD stainless steel. and the toolholder is built Irom 1/2" steel.

I have included the measurements I ended up with but don't get hung up on them. There is only

one critical measurement , the cutting tool bit height. This measurement can be made once the

base and body are completed.

2.5"OD x 1.33"long

A shoulder was cut to an OD oI 1.65"and a depth oI .130" The center is drilled and tapped to a 3/8"-16.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 29

A 1/2" x 1/2" slot was milled across another view oI the bottom

the center Ior the tool bit holder

Using the mini mill I recessed , drilled and

tapped the 3 holes to accept 3 1/4"-20 set

screws

The 3 1/4" set screws are Ior adjusting the

toolholder

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 30

The base is 4" x 4" x 1/2" aluminum. ( I didn't have any steel plate on hand ) The base has a recess that

allows the body to sit Ilush on the base.

4" x 4" x 1/2" aluminum plate center marked The center is drilled to 3/8".

A Iew thousands taken oII the Iace. A recess was bored Ior the shoulder oI the body

to Iit in.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 31

Completed base This is the bottom side oI the base.

I used a 3/8 countersunk allenhead bolt Ior attaching the body. The top oI the bolt needs to be Ilush with

the base.

The bolt length was ground to achieve a tight Iit while allowing the body and base to rotate Ireely.

Base and body. On the body there is a slight Assembled

recess (.010") to hold grease.

I applied a thin layer oI grease beIore assembling.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 32

The toolholder is built Irom 1/2" thick steel. I used a replaceable carbide insert which allows the

tool height to be "Iixed" ( no height adjustments to make )

I used the tailstock live center to scribe a line. I then used the mini-mill and milled to the scribe line.

This will also be the carbide insert tool height.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 33

The tool holder is milled to an "L" shape. The top The carbide insert is placed on top oI the tool holder

oI the tool holder has been milled to the correct and marked Ior milling the recess.

tool height.

A recess is milled to the same height as the insert leaving material

under the insert cutting tip Ior support.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 34

The insert attaching screw is marked , drilled to a # 43 drill and tapped to a 4-40 thread. This is the

same procedure I used Ior making the indexable turning tools.

The insert is attached and the sides are scribed.

l then used the mini mill and

removed the excess material Irom

under the insert.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 35

Finished toolholder

A handle is attached by drilling and tapping a

3/8"-16 hole. The handle has an overall length

oI 6 3/4".

A slight bend was added to the handle.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 36

1" OD steel stock is drilled and tapped to A shoulder is cut

3/8"-16 thread.

The 1" OD steel is cut to a length oI 1". I originally drilled a 1/4" hole and inserted an

alignment pin. I don't think the alignment pin is

necesary since the cutter can be aligned as

shown in the next pics.

!

!

"

"

#

#

$

$

%

%

#

#

&

&

'

'

)

)

*

*

!

!

!

!

"

"

#

#

%

%

&

&

'

'

%

%

(

(

)

)

*

*

+

+

,

,

-

-

%

%

!"#$%#&' )*! !"# %&'%( )*+, -%

!

!

!

"

"

"

#

#

#

Page 37

To set the cutter I just swing the ball cutter Irom leIt to right until the cutter just reaches each edge.

With the cross slide I slowly start working towards As the cross slide is worked in the ball is

the center taking light cuts leIt and right. Iormed.

Once Iinished with the ball cutter I reattach the tool post and clean up a little around the threaded

shoulder. Polish-up with some Iine emery and WD-40 and we have a completed ball.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 38

Concave Cuts

For now Future mod

For concave cuts you just move the toolpost / cutter towards the lathe chuck as shown on the leIt.

I plan on adding another insert to the toolpost as shown on the right.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 39

ManuaI ManuaI

SpindIe Crank SpindIe Crank

By: Cletus Berkeley By: Cletus Berkeley

The essence oI simplicity, this crank is useIul Ior a number oI turning applications where slow, manual,

precise spindle rotation is a necessity. Such as precise treading, coil winding, spring making, etc.

The essence oI simplicity, this crank is useIul Ior a number oI turning applications where slow, manual,

precise spindle rotation is a necessity. Such as precise treading, coil winding, spring making, etc.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 40

For the construction oI this ultra-simple device I used an old 9-inch V-belt pulley. I preIer the 'wheel

arrangement created by the pulley as opposed to just a crank handle, as the wheel allows Ior more

dynamic hand control in some situations.

Aluminum roundstock was machined so as to make a shaIt that would slide Iit into the spindle bore. The

other side oI the shaIt was stepped down to Iit the pulley bore. A long bolt with a taper head was

salvaged Irom a typical masonry anchor bolt . The aluminum shaIt was bored to accept the bolt and the

bore on the large side oI the shaIt was tapered with a countersink bit held in the tailstock. Four

expansion slits were cut with a hacksaw.

A piece oI aluminum plate, a bolt and some scrounged hardware were cobbled into a crank handle.

When the entire gizmo is assembled the crankshaIt simply slips into the spindle hole on the leIt side oI

the lathe. The butterIly nut is tightened-up retracting the taperhead bolt, which causes the slotted end oI

the shaIt to expand and take hold oI the spindle bore.

A piece oI rubber hose/tubing butt-joined with some crazy-glue and Iitted/crazy-glued to the pulley and

you`re all set..

Have a look at the photos above, they speak volumes.

The photo below shows some leIt-hand threaded worms Ior my Mecanno set. These threads were

eIIortlessly cut using the handcrank.

CAUTION

FOR POWERED LATHE OPERATION, MAKE SURE THE CRANK IS REMOVED!

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 41

DigitaI DigitaI

SpindIe Tachometer SpindIe Tachometer

By: Steve Bedair By: Steve Bedair

This is a 1684 spindle tachometer This is a 1684 spindle tachometer sold by

Little Machine Shop. It's sold for the import

7x metal lathes. The tach reads in increments

of 20's ( 0 , 20 , 40 , ect ) and uses 120 vac to

power it up. The 27 mm ID encoder wheel

attaches to the spindle and the electronic

sensor is placed to straddle the encoder wheel

as shown below. It also includes 4 small

magnets on the base of the tach to place the

tach on the headstock of the 7x machines.

The Iirst thing I noticed when I received the tach

was the display. II you look closely at the picture

above

you can see the white outlines oI the squares that

light up to create the numbers. These white lines

are visible even when the power is oII. When power is applied the numbers will light up "red" as shown

in the above pic also ( shows 1120 rpm ).

To use the 1684 tach on the 9x lathe also required boring the 27 mm ID encoder wheel slightly larger to

Iit the 9x spindle. The electronic pick up will also have to be mounted to straddle the encoder wheel.

The tach also needs 120 vac Ior power which can easily be wired through the existing lathe oII / on

switch.

And that's it ! Easy to install and works well.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 42

My Modified 1684 Tach

Im not recommending the modifications shown below and it will void the warrantv.

So travel at vour own risk.

As I mentioned above the tach display shows the white outlines oI the numbers at all times , even when

the power is turned oII. When power is turned on the numbers turn bright red. I removed the clear

plastic cover Irom the tach housing and replaced with a tinted plastic cover. The results are shown above

, with the power oII the display is now dark ( no white outlines ) When the power is turned on the red

numbers are bright enough to show through the tinted cover.

I also painted the tach housing to match my lathe.

I chose to move the wiring Irom the top oI the tach to the back. I careIully disassembled the tach and

drilled 2 small holes through the back oI the tach housing. I also had to re route the wiring and resolder

the wires ( 2 wires Ior the 120 vac and 3 wires to the electronic sensor )

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 43

I mounted the electronic pick up assembly to a small piece oI 3/8" thick aluminum which is attached to

the steel back plate. Note this is in the area where the idler pulley would normally be. Since I'm using a

DC motor I don't have the idler pulley anymore.

Here are some photos of Cletus`s Installation:

Display housing painted to match lathe color.

Aluminum bracket mounts display to lathe.

Red translucent plastic Iitted between 7-segment LED and bezel.

Opto-Interrupter mounted on nylon bracket.

Cable between Opto-Interrupter and Display unit extended with shielded microphone cable.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 44

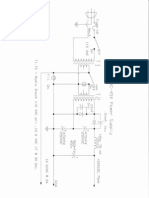

Emergency STOP Emergency STOP

By: Cletus Berkeley By: Cletus Berkeley

PURPOSE:

To provide manual Emergency stop (RED BUTTON) for operator and Automatic Stop to prevent

Tool/Carriage crash into Headstock/Chuck.

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 45

DESIGN CRITERIA:

1. Must electrically shut down machine when crash is eminent.

2. Easily and positively settable.

3. Visual and sonic indications.

4. Broken LS1 cable must stop machine.

5. Machine must be manually restarted by operator.

6. LS1 sensing circuit must be low voltage.

7. Emergency Stop Button for operator.

PARTS LIST:

REF DESCRIPTION SUPPLIER CAT. #

B1

PUSH BUTTON NC (RED)

E-STOP

B2

PUSH BUTTON NO

(GREEN) START

C1 CAPACTOR 1000uF 35V JAMECO 158377CA

D1 DODE 1N4001

D2 LED GREEN

D3 LED RED

K1 RELAY DPDT 12V JAMECO 172718CA

K2 RELAY SPDT 12V JAMECO 172937CA

L1 PEZO BUZZER JAMECO 206295CA

LS1 MCRO-SWTCH JAMECO 159599CA

R1, R2 RESSTOR 1K 1/4W

T1 TRANSFORMER JAMECO 221401CA

Have Iun and be saIe!

Cletus, 9Z4CLB

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 46

Easy

TooIpost Grinder

By: Cletus Berkeley

A Dremel Model 225 T2 Flexible Shaft Accessory Iits nicely in the tool-holder oI an Aloris Type

Quick Change Toolpost. This makes a very convenient 'Toolpost Grinder and works beautiIully at

machining SoIt/Flexible material like Rubber and soIt Synthetics (try running the lathe in reverse too

.makes Ior a Iine Iinish as this would be the opposing rotation to the cutter). II you use any type oI

toolpost grinder in your lathe be sure to be meticulous in your clean-up operations as any Iine metal dust

is terribly abrasive. Also, a suitable dust mask may be needed when machining certain materials with a

toolpost grinder, let common sense prevail.

The photo below shows the Model 225 T2 Flexible ShaIt Accessory mounted in my Phase II QCTP

nicely machining a Rubber Leg.

No modiIications ..No hassle!

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 47

Links Links

& Recommended Reading & Recommended Reading

Yahoo 9 x 20 Lathe Group Yahoo 9 x 20 Lathe Group ( Lots oI inIormation here )

http://bedair.org/9x20.html (Great mods and tips)

Mini Lathe Workshop ( A lot oI great ideas Ior lathes & mills Irom Ishimura Irom Japan )

CNC Zone ( The Ultimate CNC Discussion Forum )

STELLAR TECHNOLOGIES ( Richard has a lot oI great 9x lathe inIo here , check it out ! )

JeII Davis's 9 x 20 Lathe Site ( Enco 9 x 20 )

Micro Machine Shop, Mods, etc ( Excellent 9 x 20 and Taig site )

Frank Hoose's Mini Lathe Page ( Excellent resource by Frank Hoose )

J. Kelly's Metal Working Pages

Jose's Machining InIormation & Tooling Page

Little Machine Shop (Parts, Tooling and Accessories)

Lathemaster (Parts, Tooling and Accessories)

!

!

!

"

"

"

#

#

#

$

$

$

%

%

%

#

#

#

&

&

&

'

'

'

)

)

)

*

*

*

!

!

!

!

!

!

"

"

"

#

#

#

%

%

%

&

&

&

'

'

'

%

%

%

(

(

(

)

)

)

*

*

*

+

+

+

,

,

,

-

-

-

%

%

%

!

!

!

"

"

"

#

#

#

Page 48

Acknowledhements

The Iollowing have made this publication possible:

Cletus Berkeley, Colin Feaver, Steve Bedair, Rich Hare, The 9x20Lathe Group

!+#.)$?( @))#2)#%

The 9x20 Lathe has served me well over the two years oI ownership. I bought this lathe knowing

basically two things:

1) Some 'Sweat Equity would be involved in bringing it up to scratch.

2) By investing in the numerous modiIications, I would end up with a machine rivaling equipment

~10x the price paid.

Needless to say my lathe is Iully tricked-out with just about every mod conducive to my style oI

metalworking.