Escolar Documentos

Profissional Documentos

Cultura Documentos

Update ERCA Safety Warning 1 2011 WireRopeTerminations

Enviado por

peachykrista0 notas0% acharam este documento útil (0 voto)

66 visualizações0 páginaUpdate ERCA Safety Warning 1 2011 WireRopeTerminations

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoUpdate ERCA Safety Warning 1 2011 WireRopeTerminations

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

66 visualizações0 páginaUpdate ERCA Safety Warning 1 2011 WireRopeTerminations

Enviado por

peachykristaUpdate ERCA Safety Warning 1 2011 WireRopeTerminations

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 0

Safety Warning 1/2011: Wire Rope Terminations

ERCA Safety Commission

2011 European Ropes Course Association

http://www.erca.cc

Issued on 2011-08-29 Page 1 of 4

Correction & ammendment to ERCA safety warning 1 / 2011: Wire Rope Terminations

Please note: ERCA safety warning 1 / 2011 has been corrected (see note B.2 below) and ammended (see B.3

below) on 2011-08-29. Please have a look on page 3 where the corrections were inserted. Henceforth, only this

corrected version will describe the process correctly . This document replaces the former document published on

2011-01-23.

We have noticed that there was conflicting advice in our Safety Warning 1/2011 that relate to

torque settings and the positioning of wire rope grips. We have investigated the reasons for

the discrepancies and can report as follows:

A) The version of EN13411-5 revised in 2003 and 2008 may have been inconsistently or

incompletely incorporated into the installation manual of manufacturers.

B) An old recommendation of the Technical Committee for Metal and Surface Treatment on

the use of wire rope grips with spiral ropes still exists, even though this recommendation was

rendered invalid by the new version of EN13411-5 several years ago.

B.1 Current status

We can confirm that only EN13411-5 in the latest 2009-02 version is the directive for the

application of wire rope grips. The installation manuals of manufacturers should be based on

this version. If you notice a significant discrepancy between the data in the standard and the

manufacturer's instructions, you should ask your manufacturer / supplier whether the

statements are consistent with the latest version.

B.2 Corrections

a) Torque (please see page 3 as well)

We need to revise the sample specification made in our ERCA Warning 1/2011

relating to the torque setting for a 10-mm diameter wire rope (type: 6x19+1SE). The

correct torque setting (for grips compliant with EN13411-5, Appendix A) that is

required within EN13411-5 is 9 Nm and not the erroneously printed value of 9.9 Nm.

For all data relating to the correct application of wire rope grips please refer to the

standard or the installation manual of the manufacturer. This data varies with the

cable diameter.

b) Grip spacing (please see page 3 as well)

The spacing "e" between the wire rope grips should now be at least 1.5 t and not

more than 3 t, where t is the width of the clamping jaw.

B.3 Ammendment: Exclusion of spiral ropes

The use of U-bolt wire rope grips with spiral ropes (for rope types & rope classes, see

EN12385-2 :2008-06, section 3.6 et seq) was prohibited (see EN13411-5:2003-05, page 4).

The name of the rope class of spiral ropes is usually indicated as "1x ...", e.g. "1x19", "1x37",

etc.

Safety Warning 1/2011: Wire Rope Terminations

ERCA Safety Commission

2011 European Ropes Course Association

http://www.erca.cc

Correction issued on 2011-08-29 Page 2 of 4

ERCA Safety Commission Safety Warning 1/2011

Corrected version: 2011-08-29. Changes marked in red color.

The aim of this safety warning from the ERCA is to prevent accidents and it will be sent to all

members in the near future. We have endeavoured to provide an objective portrayal of the

events and causes of the incident without a detailed inquiry being carried out.

Please send relevant comments and questions to: sicherheit@erca.cc

1/2011: Ropes courses closed ever more frequently due to construction faults

Certification criteria not met in accordance with EN 15567-1 and ERCA inspection standards

From reports by inspection bodies and inquiries by operators, we can deduce that the ropes

course construction varies widely in terms of quality. One ropes course which did not meet

basic requirements of EN 15567-1 or ERCA standards had safety faults that resulted in it

being shut down.

In the interest of accident prevention and better orientation for operators of ropes courses, we

would like to describe here some of the most basic safety requirements. Even though this

collection is incomplete, it may help to better assess the design of ropes courses.

Rope end connections and fastening methods

a. Wire rope terminations

As already described in our alert of 1/2006 and referred to in the norms and

standards only certain terminations of wire ropes is permitted.

Wire rope (safety) clamps:

Rope end terminations using wire rope clamps must be made in accordance

with EN 13411-5 (cf. Ropes Course Standard EN 15567-1 (paragraph 2.

Normative References) as well as ERCA Standards -V- C.5.4).

EN 13411-5 (formerly DIN 1142) describes precisely the production process,

materials and surface treatment as well as how to use the clamps. The approved

rope diameter and the manufacturer ID are provided on the clamping jaw of

these clamps (e.g. XB). Both the clamping bracket and the nuts of these clamps

have to be yellow chromated, and the clamping jaw has to be electrogalvanised

and chromated.

These features differ sharply from other types of rope clamps, and anyone can

verify them with a visual check.

Other wire rope clamps, such as the type in DIN 741 were withdrawn from the

market years ago, are specifically not safety clamps and should therefore only

be used in non critical applications (e.g. bracing garden fences and

suspending office lamps).

Wire rope clamp terminations which have a critical application, should be

consistent with the requirements of EN 13411-5.

Safety Warning 1/2011: Wire Rope Terminations

ERCA Safety Commission

2011 European Ropes Course Association

http://www.erca.cc

Correction issued on 2011-08-29 Page 3 of 4

The number of clamps to be used, and the torque of the screw fastening, will

depend on the rope diameter. A 10-mm steel rope of the 6x19+1SE design, for

example, requires at least four rope clamps in accordance with EN 13411-5.

According to the standards table, the nuts must be tightened with a torque of

9 Nm9.9 Nm. This standard stipulates other requirements for how to use and

inspect rope clamps, which is why installation should only be performed by

competent, skilled personnel.

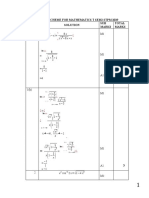

The following diagram illustrates, for example, the positioning of such wire

rope clamps, using as an example a 10-mm thick wire rope of the 6x19+1SE

design:

Schematic sketch

1

: How to use wire rope clamps (following EN 13411-5)

Sketch coorected on 2011-08-29

Additionally, it has proved worthwhile to retighten the nuts at regular test

intervals, to make visual inspections and to check the clamps for any corrosion

damage. Examination is important in particular:

About 12 to 24 hours after the initial installation and before any loading

about one week after the initial installation, when several rounds with

stressing have taken place

about one month after the initial installation, when further rounds and

stressing have taken place

whenever some external manipulation cannot be ruled out

for connections subjected to great loading (i.e. for bottom elements in ropes

courses)

where there are effects from severe weather conditions (e.g. temperature

etc)

Ferrule secured terminations

Similar rules and inspection methods apply to ferrule secured terminations, the

scope of which does not allow these to be presented in detail here. It is

important to mention that these terminations have to be made in accordance

with 13411-3. These standards also require that a manufacturer ID be included

on the ferrule.

Ferrule connections are being made more and more often by construction firms

on site, using small mobile compression tools. This is permissible if a licensed

testing institute has issued a test certificate for such tools.

The certificate for proper compression is part of the documentation which

construction firms must provide to customers.

1

This sketch only serves as an example illustration. The number of clamps and the torque of the nuts must be

adjusted depending on the diameter and type of the wire rope (cf. top of page 3).

Safety Warning 1/2011: Wire Rope Terminations

ERCA Safety Commission

2011 European Ropes Course Association

http://www.erca.cc

Correction issued on 2011-08-29 Page 4 of 4

42 Grad

b. Fastening methods and connecting ropes

Steel ropes are susceptible to bending and creasing stresses and must only be

executed with appropriate fastening methods. When eyes are made, thimbles

must be used, to keep the rope in a sufficiently large radius, thereby preventing

kinking. Avoid wire ropes from moving (unfixed) over one other, rubbing

together or creasing.

Schematic sketch

2

: following EN 15567-1:2007 (D)

When fastening by wrapping around a mast or tree, ensure the wire rope runs

in a large radius around the attachment point and that the rope enters the clamp

connection at as acute an angle as practicably possible.

Schematic sketch: ERCA

2

This sketch only serves as an example illustration. The number of clamps and the torque of the nuts must be

adjusted depending on the diameter and type of the wire rope (cf. top of page 3).

Editors Note: Image annotation below translated from EN 15567-1:2007 (D)

a) Correct arrangement of rope clamps when connecting parallel rope ends

b) Connection with double rope loop

c) Incorrect arrangement of rope clamps when connecting parallel rope ends

Editors Note: Image annotation below translated from EN 15567-1:2007 (D)

With wire rope terminations that run around trees or poles, the effects of the angle on the loop

have to be taken into account. An angle of a=60 is recommended (see Figure 3). In case of an

angle >60 (e.g. using big trees) please see recommendations at EN 15567-1 (chapter 4.2.4).

Você também pode gostar

- Cat Truck Engine Serial Number Prefix ChartDocumento2 páginasCat Truck Engine Serial Number Prefix Chartangelobor100% (7)

- Ansi z5354pdfDocumento52 páginasAnsi z5354pdfBaraa AtwanAinda não há avaliações

- BS en Iso 3166-1-2020Documento40 páginasBS en Iso 3166-1-2020LUZ MERYAinda não há avaliações

- Impacto Charpy - Iso - 9016Documento12 páginasImpacto Charpy - Iso - 9016Lucas MlbAinda não há avaliações

- Plant and Equipment Risk Assessment Checklist1Documento9 páginasPlant and Equipment Risk Assessment Checklist1peachykrista100% (1)

- Transformer and Electronic Controllers For HVAC: WWW - Breve.plDocumento9 páginasTransformer and Electronic Controllers For HVAC: WWW - Breve.plpeachykristaAinda não há avaliações

- Basic Rigging Training ManualDocumento70 páginasBasic Rigging Training ManualsteelageAinda não há avaliações

- Etsy Business TemplateDocumento28 páginasEtsy Business TemplatepeachykristaAinda não há avaliações

- Soil Mechanics PowerpointDocumento239 páginasSoil Mechanics PowerpointEdcel Angelo TomasAinda não há avaliações

- Publicly Available Specification: IEC PAS 62400Documento70 páginasPublicly Available Specification: IEC PAS 62400Nalex GeeAinda não há avaliações

- Atest TipBDocumento250 páginasAtest TipBpeachykristaAinda não há avaliações

- BS4678 Class 3 TrunkingDocumento3 páginasBS4678 Class 3 TrunkingKy ChauAinda não há avaliações

- Bearing Reliability Improvement-SKFDocumento55 páginasBearing Reliability Improvement-SKFAbdulrahman AlkhowaiterAinda não há avaliações

- Na VI GrammarDocumento65 páginasNa VI GrammarDaniel RăzvanAinda não há avaliações

- Connection TypeDocumento9 páginasConnection Typesmelihates100% (1)

- LEVAC Slings Instruction Manual ENGLISHDocumento20 páginasLEVAC Slings Instruction Manual ENGLISHpeachykristaAinda não há avaliações

- Generic Safety Manual v2Documento266 páginasGeneric Safety Manual v2Gnalagnas KarlengianAinda não há avaliações

- BS en 355 2002Documento14 páginasBS en 355 2002Carolina TelesAinda não há avaliações

- Programming Real-Time Systems With C/C++ and POSIX: Michael González HarbourDocumento9 páginasProgramming Real-Time Systems With C/C++ and POSIX: Michael González HarbourGaetan LAinda não há avaliações

- Volume 3 Highway Construction Details Highway Construction DetailsDocumento47 páginasVolume 3 Highway Construction Details Highway Construction Detailsalejandraoy9Ainda não há avaliações

- Installation Manual: DPS 232 Differential Positioning SystemDocumento154 páginasInstallation Manual: DPS 232 Differential Positioning SystemVladimirs Arzeninovs100% (3)

- 13480-5 - 2017 - EN-Inspection and TestingDocumento34 páginas13480-5 - 2017 - EN-Inspection and TestingPaulo VidasinhaAinda não há avaliações

- Iso 4628 4 2003 FR en PDFDocumento8 páginasIso 4628 4 2003 FR en PDFJairo AguilarAinda não há avaliações

- En 12517Documento15 páginasEn 12517Nguyen Huu TriAinda não há avaliações

- OWI 1000 DrawworksDocumento54 páginasOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- BS 7036Documento2 páginasBS 7036Uzi DaganAinda não há avaliações

- Armaseam Technical BrochureDocumento24 páginasArmaseam Technical BrochureMuraleedharanAinda não há avaliações

- UL Standardes Seguridad MaquinasDocumento19 páginasUL Standardes Seguridad MaquinasSergioAinda não há avaliações

- BS Iso 04190-1-2010 (2011)Documento40 páginasBS Iso 04190-1-2010 (2011)coolkaisyAinda não há avaliações

- Iso 4757 1983Documento9 páginasIso 4757 1983GorkaAinda não há avaliações

- Belaac Guidnace For Certification ISO 17024Documento35 páginasBelaac Guidnace For Certification ISO 17024sheref_hamadyAinda não há avaliações

- Iso 691 2005 ToleranciasDocumento9 páginasIso 691 2005 ToleranciasFer JAinda não há avaliações

- Handrail Design Standard PDFDocumento6 páginasHandrail Design Standard PDFereresrdfAinda não há avaliações

- Latest Date For Receipt of Comments: 31 July 2013: Form 36Documento15 páginasLatest Date For Receipt of Comments: 31 July 2013: Form 36Popeye William CapthandsomeAinda não há avaliações

- IS 13834 Part 5Documento6 páginasIS 13834 Part 5SourabhAdikeAinda não há avaliações

- PASMA Toolbox TalksDocumento5 páginasPASMA Toolbox TalksUlviyye Cavid-Umid Elesgerova100% (1)

- Iso 945 4 2019 en PDFDocumento11 páginasIso 945 4 2019 en PDFAriyan AriyanAinda não há avaliações

- IEC - 61892 6 2019 en FR stGnH9WUUvDocumento101 páginasIEC - 61892 6 2019 en FR stGnH9WUUvElia MadyAinda não há avaliações

- BS en 927-3-2012 PDFDocumento30 páginasBS en 927-3-2012 PDFjohnAinda não há avaliações

- BS en 1335-3-2009Documento30 páginasBS en 1335-3-2009Adel A. Abdelaziz100% (1)

- Iso 10110 12 2019Documento12 páginasIso 10110 12 2019dave judayaAinda não há avaliações

- Green Walls in High-Rise Buildings: September 2014Documento23 páginasGreen Walls in High-Rise Buildings: September 2014Nafis Abrar 1631155610Ainda não há avaliações

- Standards Regulations Approvals - Technical Performance and Principles of System Design - The White Book - Third EditionDocumento5 páginasStandards Regulations Approvals - Technical Performance and Principles of System Design - The White Book - Third EditionHuỳnh Ngọc HiệpAinda não há avaliações

- Platbulb (Holland-Profiel of HP) (B 150 MM) : Stafstaal StripstaalDocumento1 páginaPlatbulb (Holland-Profiel of HP) (B 150 MM) : Stafstaal StripstaalArun PrasadAinda não há avaliações

- Keyence AS - 81944 - KV-7000 - KV-5000 - 3000 - CV-X - OM - WW - GB - 1066 - 1Documento20 páginasKeyence AS - 81944 - KV-7000 - KV-5000 - 3000 - CV-X - OM - WW - GB - 1066 - 1Gabriel Martinez MessnerAinda não há avaliações

- NEK 606offshore Cables CatalogDocumento214 páginasNEK 606offshore Cables CatalogJose Luius100% (1)

- Chapter 3 - Shackles and Rigging ScrewsDocumento12 páginasChapter 3 - Shackles and Rigging ScrewsAthox QhurienAinda não há avaliações

- Mrhkli: Beam Pro Training and ExaminationDocumento68 páginasMrhkli: Beam Pro Training and ExaminationSimon LawAinda não há avaliações

- TRD Construction Safety Manual Issue March 2017 No 4Documento76 páginasTRD Construction Safety Manual Issue March 2017 No 4Ran WangAinda não há avaliações

- Ul-Eu Certificate: Chris MilesDocumento6 páginasUl-Eu Certificate: Chris Milescity chemAinda não há avaliações

- Bs+en+12517-2-2008 NDT PDFDocumento16 páginasBs+en+12517-2-2008 NDT PDFPham CongAinda não há avaliações

- YoungMan EN131 GUIDEDocumento16 páginasYoungMan EN131 GUIDErcpawar100% (1)

- En 15804-2012-A1-2013Documento17 páginasEn 15804-2012-A1-2013Boran YelkenciogluAinda não há avaliações

- SWG To MM Chart PDFDocumento1 páginaSWG To MM Chart PDFSundara Moorthy100% (1)

- Iso 15257Documento34 páginasIso 15257Danilo AmendolaAinda não há avaliações

- OGUK Cumulative Risk Guidelines Issue 1Documento34 páginasOGUK Cumulative Risk Guidelines Issue 1nsikakabasi Okon100% (1)

- Directive Low VoltageDocumento137 páginasDirective Low Voltageximeres0% (1)

- 141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFDocumento12 páginas141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFmarigusatuAinda não há avaliações

- BS 5728-2-1980 Cold Potable WaterDocumento9 páginasBS 5728-2-1980 Cold Potable WaterPD AWSSIESPAinda não há avaliações

- AS1101 and AS2101 SummaryDocumento2 páginasAS1101 and AS2101 SummaryAliya James100% (1)

- BS en 10108-2004Documento14 páginasBS en 10108-2004Martijn GrootAinda não há avaliações

- Plain Washers - Extra Large Series - Product Grade C: Technical Corrigendum 1Documento1 páginaPlain Washers - Extra Large Series - Product Grade C: Technical Corrigendum 1Anonymous DTzckOAinda não há avaliações

- HSE - Simple Guide To The Provision & Use of Work Equipment Regulations 1998Documento5 páginasHSE - Simple Guide To The Provision & Use of Work Equipment Regulations 1998helleneaAinda não há avaliações

- BS en 1932-2014Documento50 páginasBS en 1932-2014desenvolvimentoAinda não há avaliações

- BS en 16297-3-2012Documento12 páginasBS en 16297-3-2012Tasawwur Tahir100% (1)

- Iso 9624 2019Documento11 páginasIso 9624 2019Mayuresh GawadeAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento21 páginasDisclosure To Promote The Right To InformationBrijeshAinda não há avaliações

- Access Forklifts Forklifts 2 3TDocumento5 páginasAccess Forklifts Forklifts 2 3TNii AshiiiAinda não há avaliações

- Barefoot Slip Resistance DIN 51097Documento1 páginaBarefoot Slip Resistance DIN 51097stellatsiAinda não há avaliações

- BS en Iso 22600-3-2014Documento80 páginasBS en Iso 22600-3-2014Tiger CageAinda não há avaliações

- 0.6. TR-18 Stockbridge Type Vibration DampersDocumento10 páginas0.6. TR-18 Stockbridge Type Vibration Dampersgiorgis072Ainda não há avaliações

- PL WB e 21032013Documento7 páginasPL WB e 21032013peachykristaAinda não há avaliações

- Catalogo TycoDocumento51 páginasCatalogo TycoCésar CutruneoAinda não há avaliações

- Busatec Application TableDocumento1 páginaBusatec Application TablepeachykristaAinda não há avaliações

- Straaltechniek 98CE 2000 50CE enDocumento2 páginasStraaltechniek 98CE 2000 50CE enpeachykristaAinda não há avaliações

- Comunication DataDocumento104 páginasComunication DatapeachykristaAinda não há avaliações

- En PDF PDF p31378 enDocumento3 páginasEn PDF PDF p31378 enpeachykristaAinda não há avaliações

- UC400 S23 Cat.6: U/FTP Installation CableDocumento3 páginasUC400 S23 Cat.6: U/FTP Installation CablepeachykristaAinda não há avaliações

- S3i Lifting Shackles Technical InformationDocumento4 páginasS3i Lifting Shackles Technical InformationpeachykristaAinda não há avaliações

- Catalog Incubator2013 IPEEDocumento16 páginasCatalog Incubator2013 IPEEolunguAinda não há avaliações

- Cust SpeDocumento9 páginasCust SpepeachykristaAinda não há avaliações

- Risk Analysis MatrixDocumento1 páginaRisk Analysis MatrixpeachykristaAinda não há avaliações

- S VarcoDocumento2 páginasS VarcopeachykristaAinda não há avaliações

- Microstructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsDocumento6 páginasMicrostructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsReza nugrahaAinda não há avaliações

- Trigonometric Substitution: Jzfa20Documento12 páginasTrigonometric Substitution: Jzfa20Samuel SmallmanAinda não há avaliações

- Kluang (A) S2 STPM 2019Documento9 páginasKluang (A) S2 STPM 2019Rex KalAinda não há avaliações

- 4333105.56 Ledenvo Led ST 60w 757 Vs1 Osram-TrfDocumento12 páginas4333105.56 Ledenvo Led ST 60w 757 Vs1 Osram-TrfFathulAinda não há avaliações

- Optimizing Valve Actuator Parameters To Enhance Control Valve PerformanceDocumento7 páginasOptimizing Valve Actuator Parameters To Enhance Control Valve PerformanceRomanStrikerAinda não há avaliações

- Delamination With AbaqusDocumento13 páginasDelamination With AbaqusSchmetterling TraurigAinda não há avaliações

- Gantry Crane DesignDocumento2 páginasGantry Crane DesignSophia PoBari-Soter (MenaXrux)Ainda não há avaliações

- Lazauskas 2013Documento15 páginasLazauskas 2013Youcef FermiAinda não há avaliações

- L071ME4182DFADocumento81 páginasL071ME4182DFAmegamech23Ainda não há avaliações

- Atmel 0038Documento1 páginaAtmel 0038namerAinda não há avaliações

- Essilor MR - Blue - 20-1Documento132 páginasEssilor MR - Blue - 20-1Primoz DolinsekAinda não há avaliações

- Alcatel 4029 EngDocumento31 páginasAlcatel 4029 Engafsanto2000Ainda não há avaliações

- Practical 1 PacingDocumento13 páginasPractical 1 PacingFiaz Hussain0% (1)

- Practical Exercise 2 - SolutionDocumento5 páginasPractical Exercise 2 - SolutionmidoriAinda não há avaliações

- Zalzalah Cesar Thesis 2016Documento72 páginasZalzalah Cesar Thesis 2016feezy11Ainda não há avaliações

- LAN Cabling: Straight ThroughDocumento3 páginasLAN Cabling: Straight ThroughGemma Quiocho-CardenasAinda não há avaliações

- Low Reynolds NumberDocumento10 páginasLow Reynolds NumberMOHAMMEDAinda não há avaliações

- Scopus Crystal NeedleDocumento256 páginasScopus Crystal NeedleDr. Ramchandra Gosavi PatilAinda não há avaliações

- Roasting Matte To Nickel Oxide and MetalDocumento7 páginasRoasting Matte To Nickel Oxide and MetalDavid SanchezAinda não há avaliações

- Physics Oly Practice Test 01Documento7 páginasPhysics Oly Practice Test 01Nguyễn Trần Minh TríAinda não há avaliações

- OPTICast BrochureDocumento2 páginasOPTICast BrochureIndra Pratap SengarAinda não há avaliações

- Tractor Engine and Drawbar PerformanceDocumento3 páginasTractor Engine and Drawbar PerformancemaureenAinda não há avaliações

- A Simulation of Attempts To Influence Crowd Dynamics'Documento6 páginasA Simulation of Attempts To Influence Crowd Dynamics'KhairulAinda não há avaliações

- Electronic Temperature Switch ETS 1700: User ManualDocumento15 páginasElectronic Temperature Switch ETS 1700: User ManualНикита ЛесюкAinda não há avaliações