Escolar Documentos

Profissional Documentos

Cultura Documentos

Chute Calculation Example

Enviado por

René Mella CidDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chute Calculation Example

Enviado por

René Mella CidDireitos autorais:

Formatos disponíveis

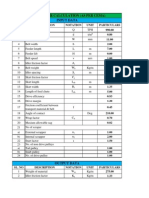

Chute Verification

CALCULATIONS INPUT Steel plate properties Chute steel plate yield stress Bending reduction factor Shear reduction factor for weld Weld nominal tensile stress (E48XX) Iron Ore properties Bulk ore unit weight Bulk ore internal friction angle Angle of wall friction Wall friction coefficient Chute properties P555 Head Chute weight P555 Transfer Chute weight P555 Head Chute blocked volume P555 Transfer Chute blocked volume Chute steel plate thickness Maximum steel plate unstiffened span Unsupported stiffener span Stiffener height Stiffener thickness Transfer chute half angle Fill height above max. unstiffened span Char. dimension of container cross-section Transition point depth below effective surface Maximum depth below transition point Support properties Number of collaborating supports Support depth Support thickness Plate-to-support fillet weld size

fy = b = s = fuw =

250 MPa 0,9 0,8 480 MPa

(ref. SPEC-007-M0004) (ref. AS 4100-1998 Table 3.4) (ref. AS 4100-1998 Table 3.4) (ref. AS 4100-1998 Table 9.7.3.10)

b = i = w = =

27 kN/m3 38 26 0,49

= TAN(w*/180)

(ref. FUSP-080-M-00004 Table 2.2.1) (ref. FUSP-080-M-00004) (ref. AS 3774-1996 Table 3.1) (ref. AS 3774-1996 Eq. 6.2.3.3)

Wch = Wtc = Vch = Vtc = t= Lus = Ls = hs = ts = = hf = r_c = z= zb =

9 3,5 2,8 0,9 10 1000 1140 85 10 17 2500 200 1600 1500

kN kN m3 m3 mm mm mm mm mm mm mm mm mm

(estimated from 087-M-12233) (estimated from 087-M-12234) (estimated from 087-M-12233) (estimated from 087-M-12234) (ref. 087-M-12233) (ref. 087-M-12234) (ref. 087-M-12234) (ref. 087-M-12234) (ref. 087-M-12234) (ref. 087-M-12234) (estimated from 087-M-12233) (ref. AS 3774-1996 Table 2.2) (estimated from 087-M-12233) (estimated from 087-M-12233)

ns = hb = tb = es =

4 235 mm 10 mm 6 mm

(estimated from 087-M-12233) (ref. 087-M-12233) (ref. 087-M-12233) Assume minimum fillet one side

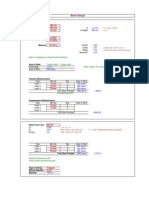

STEEL PLATE CALCULATIONS Initial normal pressure ratio Lateral pressure ratio Characteristic depth Initial normal pressure at transition level Maximum normal pressure Ultimate moment in steel plate Nominal steel plate moment capacity Steel plate bending check

kh = 0,39 k= 0,35 zo = 1172 pvi = 8246 pnh = 18782 Mup = 2817 Mnp = 6250 b*Mnp/Mup =

= TAN(*/180)/(TAN(*/180)+) mm Pa Pa N*m/m N*m/m 2,0 = r_c/(*k) = b*r_c*(1-EXP(-z/zo))/ = kh*(b*zb+pvi) = 1.2*pnh*(Lus*10^-3)^2/8 = t^2/4*fy > 1,0 OK

(ref. AS 3774-1996 Eq. 6.2.3.3) (ref. AS 3774-1996 Table 6.3) (ref. AS 3774-1996 Eq. 6.2.1.1) (ref. AS 3774-1996 Eq. 6.2.1.1) (ref. AS 3774-1996 Eq. 6.2.3.3) Calc'd as simple supported beam

STIFFENER CALCULATIONS Linear load on stiffener Ultimate moment in stiffener Stiffener slenderness Plasticity limit Yield limit Stiffener section elastic modulus Compact section eff. section modulus Striffener effective section modulus Stiffener nominal moment capacity Stiffener bending check SUPPORT CALCULATIONS Total weight Ultimate load per collaborating support Nominal weld capacity per support Support weld check

qs = 9391 Mus = 1831 s = 8,5 ep = 8 ey = 15 Zs = 12042 Zc = 18063 Ze = 17632 Mns = 4408 b*Mns/Mus =

N/m N*m

= pnh*Lus*10^-3/2 = 1.2*qs*(Ls*10^-3)^2/8 = hs/ts*SQRT(fy/250)

Assume uniforme pressure Calc'd as simple supported beam (ref. AS 4100-1998 Clause 5.2.2) (ref. AS 4100-1998 Table 5.2) (ref. AS 4100-1998 Table 5.2)

mm3 mm3 mm3 N*m 2,2

= hs^2*ts/6 = hs^2*ts/4 = Zs+((ey-s)/(ey-ep)*(Zc-Zs)) = fy*Ze*10^-3 > 1,0 OK

(ref. AS 4100-1998 Clause 5.2.4)

Wt = 112,4 Vub = 33,72 Vnb = 478,6 s*Vnb/Vub =

kN kN kN 11,4

= Wch+Wtc+b*(Vch+Vtc) = 1.2*Wt/ns = 0.6*fuw*tb/SQRT(2)*hb*10^-3 > 1,0 OK

(ref. AS 4100-1998 Clause 9.7.3.10)

Você também pode gostar

- Chute Calculation ExampleDocumento1 páginaChute Calculation ExampleBimal DeyAinda não há avaliações

- Chute Design Considerations For Feeding and TransferDocumento22 páginasChute Design Considerations For Feeding and TransferIsaac Kendall100% (2)

- BELT FEEDER Preliminary Dimension IngDocumento29 páginasBELT FEEDER Preliminary Dimension Ingshani5573100% (1)

- Helix Chute Design Sample Report 2Documento26 páginasHelix Chute Design Sample Report 2Sergio Diaz DuarteAinda não há avaliações

- Analisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIDocumento10 páginasAnalisis Drag Scrapper Chain Feeder (FB01 & FB02) EPIWaris La Joi WakatobiAinda não há avaliações

- ChuteDesignFormulas Paper43Documento11 páginasChuteDesignFormulas Paper43Martin LarochelleAinda não há avaliações

- Belt Conveyor PowerDocumento10 páginasBelt Conveyor PowerRyukiAinda não há avaliações

- MPE Chute DesignDocumento24 páginasMPE Chute DesignGareth Blakey100% (2)

- Sidewinder ManualDocumento162 páginasSidewinder Manualoscarjofk0% (1)

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocumento7 páginasProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- BELT CONVEYOR - Discharge TrajectoryDocumento1 páginaBELT CONVEYOR - Discharge TrajectoryEslam FaroukAinda não há avaliações

- Sidewinder ManualDocumento245 páginasSidewinder ManualkukstrongAinda não há avaliações

- Chapter 4 belt capacities and speedsDocumento1 páginaChapter 4 belt capacities and speedsachmatAinda não há avaliações

- Bucket Elevator Excel Calculations Bucket Elevator ApplicationsDocumento22 páginasBucket Elevator Excel Calculations Bucket Elevator ApplicationsThaigroup CementAinda não há avaliações

- Apron Feeder PDFDocumento3 páginasApron Feeder PDFabdulloh_99Ainda não há avaliações

- Chute Performance and Design For Rapid Flow ConditionsDocumento8 páginasChute Performance and Design For Rapid Flow Conditionsscrane@Ainda não há avaliações

- Apron Feeder Application Datasheet enDocumento1 páginaApron Feeder Application Datasheet enVaijayanti JoshiAinda não há avaliações

- FLSmidth - Apron FeedersDocumento2 páginasFLSmidth - Apron FeedersgomezjavieralexAinda não há avaliações

- Stuart-Dick&Royal-Design Principles For Chutes To Handle Bulk SolidsDocumento4 páginasStuart-Dick&Royal-Design Principles For Chutes To Handle Bulk SolidsJoaquín NarváezAinda não há avaliações

- Belt Feeder Calc. Pns Line 1Documento4 páginasBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Belt Feeder Calculation CEMADocumento7 páginasBelt Feeder Calculation CEMANAITIK100% (4)

- TYPICAL MANUAL CALCULATIONDocumento32 páginasTYPICAL MANUAL CALCULATIONSergio Diaz100% (1)

- Apron FeederDocumento2 páginasApron FeederRaji Suri100% (1)

- BELT CONVEYOR - Discharge TrajectoryDocumento3 páginasBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteAinda não há avaliações

- Silo Capacity CalculationDocumento1 páginaSilo Capacity Calculationlbc123Ainda não há avaliações

- Chute Diameter Calculation FormulaDocumento5 páginasChute Diameter Calculation FormulaManoj Thakur100% (1)

- Travelling Tripper CalculationDocumento5 páginasTravelling Tripper CalculationHarshGupta100% (1)

- Pipe ConveyorDocumento4 páginasPipe ConveyorDIBYENDU MONDALAinda não há avaliações

- Belt Conveyor CalcsDocumento3 páginasBelt Conveyor Calcsjnmanivannan100% (4)

- Sidewinder Manual (001-155)Documento150 páginasSidewinder Manual (001-155)NighWolfAinda não há avaliações

- Conveyor StringersDocumento9 páginasConveyor StringersAnup DoluiAinda não há avaliações

- Manual Helix Delta t6Documento309 páginasManual Helix Delta t6Ricardo Garay Reinoso100% (2)

- Transfer Chute Design ManualDocumento4 páginasTransfer Chute Design ManualluiasnadradeAinda não há avaliações

- Telescopic ChuteDocumento2 páginasTelescopic Chutebiswajit sabuiAinda não há avaliações

- Bulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoreDocumento56 páginasBulk Material Conveyor Design Guide - Belt Selection, Idlers, Pulleys, Curves & MoresigisyahAinda não há avaliações

- Conveyor Design-DraftDocumento42 páginasConveyor Design-Draftmkchy1295% (21)

- Belt Catalog #2 Bridge StoneDocumento55 páginasBelt Catalog #2 Bridge Stonetinyfalse100% (3)

- Slide Gates Eng Guide BrochureDocumento6 páginasSlide Gates Eng Guide Brochureraghunandanr1993Ainda não há avaliações

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocumento2 páginasCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Spile Bar DeflectionDocumento9 páginasSpile Bar DeflectionIsaac KendallAinda não há avaliações

- Conveyor Design Standards SimplifiedDocumento59 páginasConveyor Design Standards SimplifiedBapu612345Ainda não há avaliações

- Belt Conveyor Design - Apex FennerDocumento94 páginasBelt Conveyor Design - Apex Fennerdhangka100% (12)

- Concepts of Feeder Design and Performance in Relation to Loading Bulk Solids onto Conveyor BeltsDocumento24 páginasConcepts of Feeder Design and Performance in Relation to Loading Bulk Solids onto Conveyor BeltsSandi ApriandiAinda não há avaliações

- Belt Conveyor CalculationDocumento8 páginasBelt Conveyor CalculationFarrahxviiiAinda não há avaliações

- Belt Conveyor Belt Feeder Design ProgramDocumento147 páginasBelt Conveyor Belt Feeder Design Programmanoj983@gmail.com100% (1)

- Design Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherDocumento135 páginasDesign Calculation For Fly Ash Storage Silo Stage-II - Rev.2 - Z1660 TalcherSwapan Kumar BoseAinda não há avaliações

- Belt Curve ConveyorDocumento12 páginasBelt Curve ConveyorjayAinda não há avaliações

- Conveyor Belt CalculationDocumento14 páginasConveyor Belt CalculationIman SatriaAinda não há avaliações

- Design and Application of FeedersDocumento51 páginasDesign and Application of Feedersretrospect1000Ainda não há avaliações

- Yokohama Conveyor BeltsDocumento87 páginasYokohama Conveyor BeltsU Thaung Myint100% (12)

- Mechanical Design GuideDocumento51 páginasMechanical Design GuideRyanAinda não há avaliações

- Chute Design EssentialsDocumento29 páginasChute Design EssentialsJakes100% (3)

- Transfer Chute For Bulk MaterialDocumento131 páginasTransfer Chute For Bulk Materialmishra_1982100% (8)

- Design, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteDocumento132 páginasDesign, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteJakesAinda não há avaliações

- Combined Gusset Plate DesignDocumento3 páginasCombined Gusset Plate Designkalpanaadhi100% (3)

- RCC Design SheetsDocumento40 páginasRCC Design Sheetsashuswara84% (25)

- Column Base Plate (Fixed Type)Documento11 páginasColumn Base Plate (Fixed Type)Ernest Navarro100% (2)

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous 9iK0i8h0dPAinda não há avaliações

- RCC Design SheetsDocumento40 páginasRCC Design SheetsAnonymous nwByj9L100% (2)

- RCC Design SheetsDocumento40 páginasRCC Design SheetsIbrahim El SharAinda não há avaliações

- Story Shears - 30.04.2018Documento1 páginaStory Shears - 30.04.2018René Mella CidAinda não há avaliações

- Mat FDN Col - SupDocumento1 páginaMat FDN Col - SupRené Mella CidAinda não há avaliações

- Shear Lug Concrete CapacityDocumento2 páginasShear Lug Concrete CapacityRené Mella CidAinda não há avaliações

- Concrete Shear Verification ACI 318 App. D - ModifDocumento3 páginasConcrete Shear Verification ACI 318 App. D - ModifRené Mella CidAinda não há avaliações

- CV Trestle Uplift Calcs PDFDocumento1 páginaCV Trestle Uplift Calcs PDFRené Mella CidAinda não há avaliações

- Cálculo Enfierradura de MurosDocumento1 páginaCálculo Enfierradura de MurosRené Mella CidAinda não há avaliações

- Zap FDN Col - Losa Aprox EsteDocumento1 páginaZap FDN Col - Losa Aprox EsteRené Mella CidAinda não há avaliações

- CV Trestle Uplift CalcsDocumento1 páginaCV Trestle Uplift CalcsRené Mella CidAinda não há avaliações

- Fabricated Section PropertiesDocumento1 páginaFabricated Section PropertiesRené Mella CidAinda não há avaliações

- ConnectionsDocumento49 páginasConnectionsRené Mella CidAinda não há avaliações

- CV Trestle Uplift Calcs PDFDocumento1 páginaCV Trestle Uplift Calcs PDFRené Mella CidAinda não há avaliações

- Moment BP Design CasesDocumento1 páginaMoment BP Design CasesRené Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 08Documento2 páginasConveyor Truss Connections Calcs - 08René Mella CidAinda não há avaliações

- ConnectionsDocumento49 páginasConnectionsRené Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 12Documento1 páginaConveyor Truss Connections Calcs - 12René Mella CidAinda não há avaliações

- End Frame Moment Connection ForcesDocumento5 páginasEnd Frame Moment Connection ForcesRené Mella CidAinda não há avaliações

- Conveyor Truss Connections CalcsDocumento49 páginasConveyor Truss Connections CalcsRené Mella Cid100% (1)

- End Frame Moment Connection ForcesDocumento5 páginasEnd Frame Moment Connection ForcesRené Mella CidAinda não há avaliações

- Backstay connection design and analysisDocumento4 páginasBackstay connection design and analysisRené Mella CidAinda não há avaliações

- Backstay connection design and analysisDocumento4 páginasBackstay connection design and analysisRené Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 09Documento2 páginasConveyor Truss Connections Calcs - 09René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 08Documento2 páginasConveyor Truss Connections Calcs - 08René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 04Documento10 páginasConveyor Truss Connections Calcs - 04René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 06Documento3 páginasConveyor Truss Connections Calcs - 06René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 07Documento3 páginasConveyor Truss Connections Calcs - 07René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 03Documento5 páginasConveyor Truss Connections Calcs - 03René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 02Documento5 páginasConveyor Truss Connections Calcs - 02René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 05Documento4 páginasConveyor Truss Connections Calcs - 05René Mella CidAinda não há avaliações

- Conveyor Truss Connections Calcs - 01Documento5 páginasConveyor Truss Connections Calcs - 01René Mella CidAinda não há avaliações

- Anchor Rods in Shear and Tension (Interaction)Documento2 páginasAnchor Rods in Shear and Tension (Interaction)René Mella CidAinda não há avaliações

- Bed Making: Occupied Bed Unoccupied BedDocumento16 páginasBed Making: Occupied Bed Unoccupied BedHakdog ShermolangAinda não há avaliações

- Art Appreciation ReviewerDocumento14 páginasArt Appreciation ReviewerRon RealinAinda não há avaliações

- Arjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFDocumento328 páginasArjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFRondnelly Nunes100% (1)

- L-7 From Shelters To Village Settlements LPDocumento29 páginasL-7 From Shelters To Village Settlements LPAvril FernandesAinda não há avaliações

- OGP Life-Saving RulesDocumento24 páginasOGP Life-Saving RulesInternational Association of Oil and Gas Producers100% (3)

- 3-XLTC Manual 16-12-2019Documento24 páginas3-XLTC Manual 16-12-2019Paulo BeltranAinda não há avaliações

- 900209-3861 - Fifth WheelDocumento1 página900209-3861 - Fifth WheelCharaf EddineAinda não há avaliações

- As-Hort 121 PDFDocumento4 páginasAs-Hort 121 PDFTeam MrudgandhAinda não há avaliações

- Avp06sc ASC100CU1 2802353-XXXXXXX 120401 ENDocumento140 páginasAvp06sc ASC100CU1 2802353-XXXXXXX 120401 ENEffendiCibuburAinda não há avaliações

- CisplatinDocumento3 páginasCisplatinRicey MelegritoAinda não há avaliações

- PCR COVID Test ReportDocumento1 páginaPCR COVID Test ReportBilly Jean BanucaAinda não há avaliações

- PROII Data Transfer System User GuideDocumento86 páginasPROII Data Transfer System User GuideYves-donald MakoumbouAinda não há avaliações

- Calibration For 992 PDFDocumento6 páginasCalibration For 992 PDFMohammad MakhloufAinda não há avaliações

- G7 Group Presentation SlideDocumento16 páginasG7 Group Presentation SlideHtoo Myat AungAinda não há avaliações

- Week 5-6 Ucsp ExemplarDocumento5 páginasWeek 5-6 Ucsp ExemplarMaureen Latayan AgbingAinda não há avaliações

- MSDS N Acetyl D GlucosamineDocumento4 páginasMSDS N Acetyl D GlucosamineEdi SuryadiAinda não há avaliações

- Activity 1Documento13 páginasActivity 1Marving ZAinda não há avaliações

- Reg. No. IV SEMESTER B.TECH. (MECHATRONICS ENGINEERING) END SEMESTER EXAMINATIONS, JUNE 2018 DESIGN OF MACHINE LEMENTS MTE 2202Documento3 páginasReg. No. IV SEMESTER B.TECH. (MECHATRONICS ENGINEERING) END SEMESTER EXAMINATIONS, JUNE 2018 DESIGN OF MACHINE LEMENTS MTE 2202MeghaAinda não há avaliações

- English SHS Eappmodule3Documento25 páginasEnglish SHS Eappmodule3erraAinda não há avaliações

- MAZAYDEH V COMMISSIONER FOR SOCIAL HOUSING Residential Tenancies 2021 ACAT 115Documento33 páginasMAZAYDEH V COMMISSIONER FOR SOCIAL HOUSING Residential Tenancies 2021 ACAT 115Tacey MakoriAinda não há avaliações

- Unit Ii BVPDocumento24 páginasUnit Ii BVPCurious ManAinda não há avaliações

- Mechanical - PVLDocumento9 páginasMechanical - PVLrkssAinda não há avaliações

- TDS EU G-Energy X Hydro Bio EngDocumento2 páginasTDS EU G-Energy X Hydro Bio EngАлексей ДэконAinda não há avaliações

- 01 Total-Station GPS-1 PDFDocumento113 páginas01 Total-Station GPS-1 PDFAdam senoAinda não há avaliações

- Workshop ProceedingsDocumento71 páginasWorkshop ProceedingsAndualem TadesseAinda não há avaliações

- Bill of Lading PDFDocumento2 páginasBill of Lading PDFSushant Pai60% (5)

- APR7Documento213 páginasAPR7Rayge HarbskyAinda não há avaliações

- Codigos HondaDocumento25 páginasCodigos Hondamarquin84Ainda não há avaliações

- My Biology HomeworkDocumento7 páginasMy Biology HomeworkDumissa MelvilleAinda não há avaliações

- Upgrade As You Grow Aesthetic Platform: LuminaDocumento2 páginasUpgrade As You Grow Aesthetic Platform: Luminachash75Ainda não há avaliações