Escolar Documentos

Profissional Documentos

Cultura Documentos

Pengerang - Inquiry Specification FG Supply System

Enviado por

SIVADescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pengerang - Inquiry Specification FG Supply System

Enviado por

SIVADireitos autorais:

Formatos disponíveis

Fuel Gas Supply System

1. General Plant name Country/ Town Plant type Revision Site Conditions Temperature (Min./ Max.) Rel. Air Humidity (Min./ Max.) Atmosphere st 1 Storey Level Earthquake zone Electrical Supply Low voltage / frequency (< 185 kW) Medium voltave/frequency (>185 kW) Mechanical Design [ x ] ASME [ x ] IEC [ ] .. Electrical Design [x] [x] [ ] IEC ISO CENELEC C % RH m : : : : : : : 20 / 34 / 40 60 / 85 / 95 Tropical, Coastal + 8.5 Seismic zone 1 (UBC 1997) 400 / 230 V, 3 phase / 50 Hz 11 kV, 3 phase / 50 Hz : : : : Pengerang Cogen Johor, Malaysia 1 x KA26 - 6 26-7-2013

V / Hz V / Hz

Identification System [x] KKS

QA Standard [] [x] [] Manufacturer standard ISO 9000 ..

Special requirements [ ] Duty Natural gas equipments. Natural gas scrubbing and filtering.

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 1 / 6

Fuel Gas Supply System

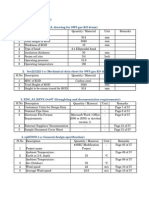

2. Performance Data All data are given at skid limit 2.1 ESD valve Quantity duty Total fuel flow (min. / design ) Duty per train Fuel gas inlet pressure (min. / max.) Fuel gas inlet temperature (min. / max.) Pressure drop 2.2 Scrubbing and Filter Liquid/dust separator Quantity duty Total fuel flow (min. / design / max.) Duty per train Fuel gas inlet pressure (min. / max.) Fuel gas inlet temperature (min. / max.) Fuel gas outlet pressure (min. / max) Pressure drop Condensate tank size : : : : : : : : 3 50% 16.1 / 119 59.5 38.5 / 49.3 14.7 / 40 37.7 / 48.5 0.8 2 : : : : : : 3 50% 16.1 / 119 59.5 38.6 / 49.4 14.8 / 40 < 0.1

kg/s kg/s bar (a) C bar

kg/s kg/s bar (a) C bar (a) bar m3

2.7 Pressure Reducing Station (only for HRSG) Quantity duty Total fuel flow (min. / design ) Duty per train Fuel gas inlet pressure (min. / max.) Fuel gas outlet pressure (set point) Fuel gas inlet temperature (min. / max.) Connection (inlet / outlet) Flange rating Pressure drop : : : : : : : : : 2 100% 3.7 / 22.4 22.4 35.9 / 46.6 9.0 28.7 / 34.1 < 1.5 at full aperture

kg/s kg/s bar (a) bar (a) C bar

3. Scope of Supply 3.1 Emergency Shut Down valve equipment [ x ] 3 50 % Fast acting Emergency Shut Down valve spring loaded incl. instrumentation and equalizing line, skid mounted [ x ] Internal piping including double isolation valve on drains and vents [ x ] Internal power and signal cabling [ x ] First filling of consumables [ x ] Name plates [ x ] Special tools - if required [ x ] Recommended spare parts for commissioning **

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 2 / 6

Fuel Gas Supply System

[x] [x]

Spare and wear parts for 2 years ** rd th Recommended spare part for 3 & 4 year (optional) **

3.2 Liquid/dust Separator equipments [] [x] [x] [x] [] [] 2 100 % Cyclone separator station incl. instrumentation 3 50 % Liquid/dust separator station incl. instrumentation Automatic condensate discharge system for separator station Drain tank incl. instrumentation Drain tank discharge No. (2 100 %) Cartridge filter station(s) (one per GT), each consisting of: [] [] [x] [x] [x] [x] [x] [x] [x] [x] [x] Cartridge filter section Internal piping, valves and instrumentation

Local motor control center - if applicable Local control cubicle - if applicable Internal power and signal cabling First filling of consumables Name plates Special tools - if required Recommended spare parts for commissioning ** Spare and wear parts for 2 years ** rd th Recommended spare part for 3 & 4 year (optional) **

3.3 Pressure Reducing Station equipments [x] 2 No. 1 100 % Pressure reducing station(s), each consisting of: [x] [] [x] [] [] [x] [ x] [x] [x] [x] [x] [x] [x] [x] [x] Pressure reducing valve Slam shut valve(s) Pressure relief valve Noise reduction package Check valve at gas outlet Unit internal piping, valves and instrumentation

Local motor control center - if applicable Local control cubicle Internal power and signal cabling First filling of consumables Name plates Special tools - if required Recommended spare parts for commissioning Spare and wear parts for 2 years rd th Recommended spare part for 3 & 4 year (optional) **

** Please provide cost breakdown for easy accessment 3.5 Services [x] [x] [x] [x] Equipment design Manufacturing and manufacture supervision Shop assembly Inspections, examinations and tests

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 3 / 6

Fuel Gas Supply System

[x] [x] [x] [] [] [] []

Cleaning, painting and coating Documentation Protection and packing for shipment Erection Erection supervision only Commissioning Commissioning supervision only

3.3 Exclusions [x] [] Civil works ..

4. Design Features Location Equipment Design Pressure Equipemnt Design Temperature Separation Efficiency Liquid/Dust Separator Noise Requirements Sound pressure level at 1 m distance 5. Transport Information Weight Dimensions (L W H) kg m : : vendor to advise vendor to advise : 99.99 % of particles 5 m 85 : : : shelter 65 bar 70 deg C

dB (A)

6. Erection / Commissioning Information n.a.

7. Time Schedule Estimated order date: : March 2014

8. Commercial 8.1 Delivery Conditions [x] [x] EXW Packing

seaworthy

8.2 Pricing [x] Firm price

8.3 Warranty / Guarantee

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 4 / 6

Fuel Gas Supply System

[x]

Duration of material warranty after successful commissioning

24 months (Mandatory) + 10 months extension (optional)

[x]

Performance guarantee

9. Documents to be submitted with the Proposal [x] [x] [ ] [x] [x] Price Technical data and descriptions Tender documents Outline drawing Schedules and comments (Please advise the delivery schedule)

10. Submittal Dates [x] Entire proposal : 7 Aug 2013

th

11. Enclosures [x] [x] [ ] [x] [ ] [ ] [ ] [ x] Flow sheet Medium analysis Principle arrangement Data sheet to be filled in Clients schedules Clients specification Project time Schedule Sub-vendor list (Please provide equipment according to vendor list)

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 5 / 6

Fuel Gas Supply System

Pengerang

Based on: 53840s01.doc - Rev. 2 - 2000-07-04

Page 6 / 6

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Schedule BDocumento122 páginasSchedule BSIVA100% (6)

- Aux Mach ReviewerDocumento11 páginasAux Mach ReviewerpatricklarinAinda não há avaliações

- Fire Fight TACDocumento92 páginasFire Fight TACSIVAAinda não há avaliações

- Good MannersDocumento4 páginasGood MannersSIVAAinda não há avaliações

- Sivakumar KomarasamyDocumento6 páginasSivakumar KomarasamySIVAAinda não há avaliações

- Operation Mode: Central Monitoring BasinDocumento1 páginaOperation Mode: Central Monitoring BasinSIVAAinda não há avaliações

- Renewal Premium Acknowledgement: Collecting Branch: E-Mail: Phone: Transaction No.: Date (Time) : Servicing BranchDocumento1 páginaRenewal Premium Acknowledgement: Collecting Branch: E-Mail: Phone: Transaction No.: Date (Time) : Servicing BranchSIVAAinda não há avaliações

- A00 A Doc Ve 722722 - 0001Documento25 páginasA00 A Doc Ve 722722 - 0001SIVA0% (1)

- A43 A Doc Ve 728823 - 0001Documento14 páginasA43 A Doc Ve 728823 - 0001SIVA100% (1)

- Schedule Q - Attachment VIDocumento8 páginasSchedule Q - Attachment VISIVAAinda não há avaliações

- Goat Farm AddressDocumento3 páginasGoat Farm AddressSIVAAinda não há avaliações

- TOC DISK - User GuideDocumento13 páginasTOC DISK - User GuideSIVAAinda não há avaliações

- Filter TOCDocumento38 páginasFilter TOCSIVAAinda não há avaliações

- Printer Friendly TOCDocumento19 páginasPrinter Friendly TOCSIVAAinda não há avaliações

- Schedule DDocumento17 páginasSchedule DSIVA100% (4)

- S.No Scope of Work Manhour Estimate For IGCC Sulfur Recovery Unit GeneralDocumento4 páginasS.No Scope of Work Manhour Estimate For IGCC Sulfur Recovery Unit GeneralSIVAAinda não há avaliações

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocumento1 páginaTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVAAinda não há avaliações

- Inputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)Documento3 páginasInputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)SIVAAinda não há avaliações

- Tubular Heat Exchanger Rating Sheet: Start 2 o 2 oDocumento1 páginaTubular Heat Exchanger Rating Sheet: Start 2 o 2 oSIVAAinda não há avaliações

- Technical Aspects of Desalination PlantDocumento0 páginaTechnical Aspects of Desalination PlantSIVAAinda não há avaliações

- S.O.W Between Sdi, Msog & AcidchemDocumento4 páginasS.O.W Between Sdi, Msog & AcidchemSIVAAinda não há avaliações

- Flowmeter Piping RequirementsDocumento11 páginasFlowmeter Piping RequirementskarthipetroAinda não há avaliações

- S.No Scope of Work Feed Water Pumping Skid Manhour Estimate For Prebid Engineering of Fuel Gas SystemDocumento2 páginasS.No Scope of Work Feed Water Pumping Skid Manhour Estimate For Prebid Engineering of Fuel Gas SystemSIVAAinda não há avaliações

- Byt BZB 1 8 Tsfi EngDocumento51 páginasByt BZB 1 8 Tsfi EngΤασος ΑΜ100% (3)

- Natural Gas Processing Principles and Technology Part-II - DR YoungerDocumento448 páginasNatural Gas Processing Principles and Technology Part-II - DR YoungerBakhtiyar Suleimenov100% (2)

- Equipment in The Oil & Gas IndustryDocumento294 páginasEquipment in The Oil & Gas IndustryRaycharlesAinda não há avaliações

- Hoffmann Crump HocottDocumento10 páginasHoffmann Crump HocottAzliyama Md ZainuddinAinda não há avaliações

- Alfa OliverDocumento4 páginasAlfa OliverJulio GarcíaAinda não há avaliações

- Mother Dairy Fruit and Vegetable PVTDocumento49 páginasMother Dairy Fruit and Vegetable PVTAadietya SinhaAinda não há avaliações

- Lecture 6Documento18 páginasLecture 6Tural EmirliAinda não há avaliações

- The Language of DrillingDocumento3 páginasThe Language of DrillingAntonio Jose da CostaAinda não há avaliações

- Resume Himanshu MishraDocumento3 páginasResume Himanshu MishraAnkush SehgalAinda não há avaliações

- PETE 216: Reservoir Rock and Fluid Properties Fall 2006-2007 Dr. Mahmut ParlaktunaDocumento25 páginasPETE 216: Reservoir Rock and Fluid Properties Fall 2006-2007 Dr. Mahmut ParlaktunaAli ShahAinda não há avaliações

- Slop Tank Design For Improved Load-On-TopDocumento6 páginasSlop Tank Design For Improved Load-On-Topscm_2628Ainda não há avaliações

- Circulation Rates in Thermosiphon ReboilerDocumento7 páginasCirculation Rates in Thermosiphon ReboilersAinda não há avaliações

- Chapter 3 SteamGeneratorsDocumento156 páginasChapter 3 SteamGeneratorssam afiAinda não há avaliações

- Alfa Laval CentrifugaDocumento40 páginasAlfa Laval CentrifugaClodoaldo BiassioAinda não há avaliações

- ALTOSONIC IV - Technical Datasheet - 20FT - 001 - Test SeparatorDocumento4 páginasALTOSONIC IV - Technical Datasheet - 20FT - 001 - Test SeparatorKUSNOAinda não há avaliações

- Rig 370 HPDocumento15 páginasRig 370 HPAbdul Sani YatimAinda não há avaliações

- Desuperheater Online Program Sizing GuidanceDocumento12 páginasDesuperheater Online Program Sizing GuidancebadesharamkAinda não há avaliações

- Compressor Suction Drums PDFDocumento6 páginasCompressor Suction Drums PDFrossifrancesco100% (1)

- P and H Chapter 3Documento42 páginasP and H Chapter 3Noor UL AaienAinda não há avaliações

- SOP - 05 - Rig Up and Rig Down Procedure - Rev04Documento36 páginasSOP - 05 - Rig Up and Rig Down Procedure - Rev04HasnainAinda não há avaliações

- DURI-GENF14GN000-MEC-LST-PHR-2003-00 Rev.0A Mechanical Equip List (List)Documento3 páginasDURI-GENF14GN000-MEC-LST-PHR-2003-00 Rev.0A Mechanical Equip List (List)Budi KamilAinda não há avaliações

- SeparatoareDocumento252 páginasSeparatoareIancu Mihai100% (2)

- Project Report RajkishanDocumento58 páginasProject Report RajkishanRajkishan GuptaAinda não há avaliações

- PP Aaa PP1 136Documento37 páginasPP Aaa PP1 136Rabah AmidiAinda não há avaliações

- Kaeser Compressor and Valve (Of) - 11Documento30 páginasKaeser Compressor and Valve (Of) - 11Muhammad Sajid67% (3)

- Emulsion Treatment and Dehydration of Crude OilDocumento6 páginasEmulsion Treatment and Dehydration of Crude Oilmohammed naeemAinda não há avaliações

- 2E-3 Gas Cleaning in Flue Gas From Combustion of BiomassDocumento32 páginas2E-3 Gas Cleaning in Flue Gas From Combustion of BiomassAisha Nabeel100% (1)

- UBDDocumento566 páginasUBDHamza Lahbiben100% (1)

- Multiphase Pumps & SystemsDocumento20 páginasMultiphase Pumps & SystemsGianni Martoccia100% (1)