Escolar Documentos

Profissional Documentos

Cultura Documentos

Meyco Backfill

Enviado por

Amilton filhoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Meyco Backfill

Enviado por

Amilton filhoDireitos autorais:

Formatos disponíveis

Solutions for

Mine Backll

Expanding Horizons Underground

Technology Overview

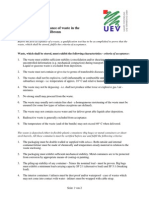

7 1

3 2

4 5 7 8 6

1 Pr Pre-Injection eInjection/Rock 2 Injection/Roc ck Bolting Sprayed Concrete/MEYCO Piccola 3 TSL/Dry Spra ayed Concr cola ete/MEYCO Picc Wet Sprayed Concrete/MEYCO Cobra 4 W et Mix Spra ayed Concr ete/MEYCO Cob bra

5 Mine Backll Wet 6 W et Mix Sprayed Concrete/MEYCO Concrete/M MEYCO Altera Admixture 7 Ad dmixture for Shaft Concrete Concrete e Admixture Concrete 8 Ad dmixture for Roadway Conc crete

Introduction

Chemical solution Chemical sol u t io n w with it h p otential cost c os t r ed uc t ions potential reductions

Back Backll, k ll, t the he p process rocess of of back back lling lling m material aterial i into nto t the he un underground derground v voids oids c created reated b y mining, mining, is e s s e n ti a l i nm any un de erground operations operations for for the the hol is stic extraction extraction by essential in many underground holistic p ro c e s s. B ack ll material material types types and and processes processes are are numerous numerous but but normally n o r m a ll y process. Backll u tilize a blend blend of of binders, binders, process process water water and and aggregates aggregates ranging ranging from from rock, ro ck , utilize c r u s he d a ggregates, g ravel a nd q ua r r ie d s a nds t ot ailings left lef t over over from from mineral min e r a l crushed aggregates, gravel and quarried sands to tailings p rocessing t op rovide t he required required restraint restraint to to enable enable massive massive strategic strategic support supp o r t processing to provide the o r the the h un derground extraction extraction sequence sequence of of the the ore. ore. Mine Mine ba ck ll is b ecoming or underground backll becoming m ore and and more more important impor tant because because of of the th e t re n d s i n m inin g t o: m in e d eeper, more trends in mining to: mine deeper, o ptimize o re r ecover y, o ptimize w ater r ecover y, i mprove t he m in e c ycle a nd optimize ore recovery, optimize water recovery, improve the mine cycle and o ptimize p roduction, decrease decrease environmental environmental impact impact and and reduce reduce overall overall cost. c o s t. optimize production, T he t ype o fb ack ll used used depends depends on on geotechnical geotechnical requirements, requirements, the the value value of of The type of backll t he ore, ore, conditions conditions in in the the mine, mine, b udget, lifetime lifetime of of the the project, p r oj e c t, e xperiences, and a nd the budget, experiences, a vailable e q u ip m e n t . T h e re i sam o re s cientic approach approach to to this this challenge challenge that th a t available equipment. There is more scientic c an help h lp m he ining c ompanies un derstand a nd r un backll back ll op e r a ti o n s a t lo wer r isks can mining companies understand and run operations at lower risks a nd lower lower costs. c o s t s. and A dvanced admixtures admixtures can can solve solve various various problems problems associated associated with with backll back ll Advanced p ro c e s s e s. T he se r a nge f ro m p aste e to c e m e nt a ggregate ( CAF ) t ype s o fb ack ll. processes. These range from paste cement aggregate (CAF) types of backll. C hemical solutions solutions are a re a vailable to to increase increase solid solid content, content, reduce reduce friction friction and a nd Chemical available s e g r e g a t i o n, m odif y rheology rheology and and ow, ow, and and reduce reduce binder binder content content as as well well as as segregation, modify c osts. We We push push back back t he physical physical limits limits with w i th o ur e x i s ti n g t echnologies such such as as costs. the our existing technologies r etarders, water water r educers, s uperplasticizers, vi s c osit y m odif ying admixtures admixtures retarders, reducers, superplasticizers, viscosity modifying ( VMAs ) etc. etc. a nd w ea re w o r k in g h a rd t og oe ven f u r th e r i na ll a re a s o fb a c k lli n g (VMAs) and we are working hard to go even further in all areas of backlling o perations. Depending Depending on on our our customers customers requirements, requirements, we we can can control control and a nd operations. a chieve : retardation, retardation, a cceleration, rheology rheology control, control, m odied v iscosity, reduce re du c e achieve: acceleration, modied viscosity, y ie ld s tre s s a nd p u m p in g p re s s u re s. F ur thermore, w ec an s tabilize nes nes in in the th e yield stress and pumping pressures. Furthermore, we can stabilize ll matrix matrix and and reduce reduce slime slime run run off, of f, segregation segregation and and porosity, porosity, and and also also enhance e nha nc e ll s trength development development and and optimize optimize binder binder content. content. strength B ASFs i n d u s tr y l e a din g t echnologies should should be be considered considered for for new new mining minin g BASFs industry leading technologies p r oj e c t s a sw e ll a se x i s ti n g o perations as as they they create create opportunities oppor tunities for for the the mine min e projects as well as existing operations o wne r t oo perate s ystems t hat are a re s afer, m o re e nvironmentally friendly friendly and and more m o re owner to operate systems that safer, more environmentally c ost effective. ef fective. cost

F low o ptimizatio on Flow optimization

Solutions

Performance P er formance r requirements equirements

T he c The criteria riteria a and nd r requirements e qui re m e nt s f for or b backlling ack lling can can vary var y substantially, substantially, depending d e p e n din g o n the the site site specic specic requirements. requirements. BASF BASF offers of fers an an extensive extensive range range of of customized customized on s olutions for for all all types types of of mine mine and and underground underground backll back ll operations, operations, all all of of which w hi c h solutions h ave been been developed developed with with a focus focus on: on : have �� P Placing the ll � l a c in g t he ll at at the the lowest lowest possible possible cost cost �� I Improving reliability � mproving r eliability of of ll ll delivery deliver y (ensuring ( ensuring reliable reliable and and adequate adequate delivery deliver y volumes) v olumes ) �� M Maximizing � a ximizing the the quality, quality, consistency, consistency, uniformity uniformity and and performances per formances of of the the ll ll �� P Providing cost-effective, sustainable backll � roviding a c ost-ef fective, efcient ef cient and a nd s u s t a in a b l e b ack ll solution solution as as a part pa r t of the total mining operation o ft he t ot a l m inin g o p e r a ti o n �� I Improving � mproving safety safety �� M Minimizing the risk of ll failure or liquefaction � i n i m iz i n g t he r isk o f ll f a il u r e o rl i q u e f a c ti o n �� E Ensuring adequate early � n s u r in g a dequate e arly strength s tr e n g th �� S Sustaining � ustaining long-term long-term strength s tr e n g th �� M Minimizing blockage risk � inimizing b lockage r isk �� A Achieving dimensional stability � chieving d im e n s i o n a l s tability after af ter placement p lac e m e nt �� Minim Minimizing � izing segregation segregation �� O Optimizing � ptimizing production production efciency ef ciency and and maintenance maintenance costs c osts �� R Reducing � educing build-up build-up in in the the pipe pipe lines li n e s BASFs extensive range backlling solutions have been developed to B ASFs e xtensive r ange of of mine mine b ack lling s olutions ha ve b een de veloped t o provide the p rovide t h optimum he optimum balance balance of of high high early early strength strength and and sustainable sustainable long long term term strength, s trength, ensuring ensuring dimensional dimensional stability stability after af ter placement placement by by meeting meeting (or ( or exceedexceeding) design performance i ng ) d esign ll ll p er formance requirements. re qui re m e nt s.

BASF and B ASF products p rod uc t s a nd support suppor t

BASF B ASF offers of fe ers chemical chemical admixtures admixtures that that aim aim to to make make the the ll ll less less costly costly and and more m o re reliable, the r eliable, and and reach reach or or exceed exceed t he design design performance. p e r f o r m a n c e. Divided into three distinct D ivi de d i nto t h re e d istinct product product categories, categories, BASFs BASFs range range of of backll back ll admixadmixtures includes specialized rheology modiers, hydration modiers and durability t u re s i ncludes s pecialized r heology m odiers, h ydration m odiers a nd d urability enhancers. e nhancers. All All products products are are supported suppor ted by by BASFs BASFs extensive extensive training training and and afteraf tersales s ales service. s e r v i c e.

Rheology mod Rheology modifying if ying a dmix tures admixtures

Paste Fill: Rheology Rheo ology modifying admixtures admixtures can n enhance the workability of most mo ost paste ll mixes in i the following ways: �� Reduced bind der usage for any given str ength hr equirement binder strength requirement �� Reduced pr es ssure losses (longer transportation improved ow) o ow) transportation distance and/or improved pressure � eline wear rate �� Reduced pipe pipeline � oved ll placement p (r educed beach angle) angle e) �� Impr Improved (reduced � oved consistency con nsistency of the ll mix and r educed segregation segregation �� Impr Improved reduced Hydraulic Fill: Rheology R admixtures s improve improve stability and transporttranspo ortmodifying admixtures ability of a hydr raulic ll at a constant solids density d a hydraulic or enhance owability and esulting in: transportability of the ll at higher density of th he hydraulic ll, r the resulting �� Reduced p pr es ssure losses (longer ( g transportation transportati p on distance and/or improved impr p oved ow) o ow) ) pressure �� Reducing bloc ckage risk blockage �� Reduced pipe eline and mixer wear rate pipeline � eased efc ciency and pr oductivity of back ll plant �� Incr Increased efciency productivity backll � eased en nergy consumption �� Decr Decreased energy � oved ll placement (more (more consistent and homogeneous properties properties of �� Impr Improved placed ll) �� Impr oved drai inage capabilities and signicantly signican ntly decreased decreased nes migration from from o Improved drainage the ll (slimes) ) �� Better water management m � der usage for any given str ength hr equirement �� Reduced bind binder strength requirement � oved consistency con nsistency of the ll mix and r educed segregation segregation �� Impr Improved reduced

Hydration H ydration controlling controlling a dmix tures admixtures

The use of selec cted hydration-contr olling admix xtures in cemented lls can: selected hydration-controlling admixtures � etard the strength strength gain in the placed p importa ant �� Accelerate or r retard ll. This can be an important issue dependi ing on the mining method and mining m schedule. depending � ol cement cemen nt hydration prior to ll placement. placeme ent. This can be very useful from from an �� Contr Control operational po oint of view because it r educes the t generation of waste and costly cos stly point reduces pipeline block kages. blockages. �� Give possibilit ties for the operator to manage the t process, process, as ll behavior is conco onpossibilities tr ollable by do osage rate. trollable dosage requirements and pr ojects, suc h as those r equiring the placement placeme ent For specic site requirements projects, such requiring of the ll into a stope with running water, water, BASF F provides provides solutions for improving improving the durability of the ll. BASFs BASFs specialized range ran nge of durability enhancing admixadm mixtur es can either be used alone or in a combination combina ation to improve improve ll durability: verv ver tures satile performan nces that can meet the needs of f even the most demanding project proje ect performances specications.

Durability enhancement D urabilit y e nhancement

Headquar ters Headquarters BASF Construction B ASF C onstruction Chemicals Chemicals Europe Europe AG AG MEYCO Construction M EYCO Global Global Underground Underground C onstruction Vulkanstrasse 110 V ulkanstrasse 1 10 8048 Zurich, Switzerland 8 048 Z urich, S witzerland Phone +41 58 958 22 11 P ho ne + 41 5 89 58 2 21 1 E-mail meyco.ugc@basf.com E - m ai l m eyco.ugc@basf.com

Australia Adelaide Adelaide Brisbane Brisbane Canberra Canberra Darwin Dar win Kalgoorlie Kalgoorlie Mackay Mackay Newcastle Newcastle Perth Per th Sydney Sydney Townsville Townsville

+61 +61 (08) (08) 8139 8139 7500 7500 (07) 3633 9900 ( 07) 3 633 9 900 (02) 6280 6010 (02) 6 280 6 010 (08) 8984 3269 ( 08) 898 43 269 (0408) ( 0408) 692 692 590 59 0 (0418) 991 567 ( 0418) 9 91 5 67 (02) 4961 3819 ( 02) 4 961 3 819 (08) 2600 (08) 9366 9366 2 600 (02) 8811 4200 (02) 8 811 4 20 0 (07) 4774 7344 ( 07) 4 774 7 344

Mexico M exico +52 81 8335 46 + 52 8 18 335 44 44 4 6 Bolivia Bol ivi a +54 911 6113 0759 + 54 9 11 6 113 0 759 Brazil B r a z il +55 11 2718 5503 + 55 1 12 718 5 503 Peru P e ru +51 995 713 991 + 51 1 9 95 7 13 9 91

Germany Germany +49 39266 98 311 + 49 3 9 26 6 9 83 11 Sweden Sweden +46 708 16 10 92 + 46 7 08 1 61 09 2 Kazakhstan Kazakhstan a +7 7272 790013 +7 7 272 7 90013

Melbourne (03) 9567 7300 Melbourne e ( 03) 9 5 67 7 300

Hong Kong H o ng K o ng +852 2408 4405 + 8 52 2 408 4 405 India India +91 9711 977 +91 9 711 200 20 0 9 77 New Zealand N ew Z e aland +64 414 7233 +6 4 9 4 14 7 23 3

Brochures Br rochur o res e on our un underground ndergr ro ound construction solutions ar are re available at www www.meyco.basf.com/mining: .meyco.basf.com/m mining:

and for Mineral Pr Processing: roc ocessing: www.basf.com/miningchemicals www.basf.com/m miningchemicals

The information given in this BASF publication pu ublication is based upon the present present state of our ou ur scientic and practical knowledge. As the information inf formation herein herein is of a generic nature, nature, no assumption assu umption can be made as to a pr oducts suitability for a particular use or application and no gua arantee or warranty as to it s accuracy , reliability reliability or completeness either expressed expressed or implied implie ed is given. products guarantee its accuracy,

MEYCO: 06/12/AB Cr Crea ea

www.meyco.basf.com

Você também pode gostar

- Mine Backfill - Optimisation OpportunityDocumento2 páginasMine Backfill - Optimisation OpportunityCarlos A. Espinoza MAinda não há avaliações

- Backfill System DesignDocumento17 páginasBackfill System Designkhuthadzo NgomaAinda não há avaliações

- AAA Characterisation of Tailings For Paste Backfill PDFDocumento234 páginasAAA Characterisation of Tailings For Paste Backfill PDFRicardo Salas IparraguirreAinda não há avaliações

- Topic11 Minewaste PDFDocumento59 páginasTopic11 Minewaste PDFhardajhbfAinda não há avaliações

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesAinda não há avaliações

- Basics of Paste Backfill SystemsDocumento5 páginasBasics of Paste Backfill Systemsalvaroaac4100% (1)

- Saw Et Al - AusIMM UOC 2017Documento16 páginasSaw Et Al - AusIMM UOC 2017sawhlaayeAinda não há avaliações

- Paste Back Filling PropertisDocumento14 páginasPaste Back Filling PropertisNina IdhiyanaAinda não há avaliações

- 2020 - ICMM - Tailings Governance Framework - Position StatementDocumento7 páginas2020 - ICMM - Tailings Governance Framework - Position StatementLiviaAinda não há avaliações

- Underhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFDocumento11 páginasUnderhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFwcamilo015Ainda não há avaliações

- BenchFill VillaescusaDocumento10 páginasBenchFill VillaescusaFredd_AlvaroAinda não há avaliações

- Centrifugal Sprayed Concrete For Lining Horizontal Pipes Culverts and Vertical ShaftsDocumento7 páginasCentrifugal Sprayed Concrete For Lining Horizontal Pipes Culverts and Vertical ShaftsFabiano MoraisAinda não há avaliações

- Burger 2005 Batu Hijau Mill Throughput ModelDocumento21 páginasBurger 2005 Batu Hijau Mill Throughput Modelboanerges wino pattyAinda não há avaliações

- PasteThickener TechnologyDocumento5 páginasPasteThickener TechnologyRodri GermánAinda não há avaliações

- Minefill 2020-21Documento450 páginasMinefill 2020-21ManuSachin100% (1)

- Flotation Advances PDFDocumento7 páginasFlotation Advances PDFvictrburgosAinda não há avaliações

- Hardrock Presentation v1.3Documento35 páginasHardrock Presentation v1.3Vian YoungAinda não há avaliações

- The Optimization of Mining Method and EquipmentDocumento6 páginasThe Optimization of Mining Method and EquipmentkullieAinda não há avaliações

- 004 Dam Cross Section Optimization Collahuasi Copper Project ChileDocumento10 páginas004 Dam Cross Section Optimization Collahuasi Copper Project ChileAfuye Oluyemi IbiyinkaAinda não há avaliações

- Curso POTVIN Graficos de EstabilidadDocumento74 páginasCurso POTVIN Graficos de EstabilidadJoseDarwinVegaGomezAinda não há avaliações

- Carter PaperDocumento13 páginasCarter Paperronan2000Ainda não há avaliações

- Ground Support in Mining and Underground Construction: Ernesto VillaescusaDocumento9 páginasGround Support in Mining and Underground Construction: Ernesto VillaescusaFrancoAinda não há avaliações

- TMW2016 ProceedingsDocumento966 páginasTMW2016 Proceedingsgushiken SantosAinda não há avaliações

- Strategies For Minimising Dilution in Narrow Vein Mine PDFDocumento12 páginasStrategies For Minimising Dilution in Narrow Vein Mine PDFRoy MaldonadoAinda não há avaliações

- Paste and Thickened Tailings A Guide Second Edition - TOCDocumento15 páginasPaste and Thickened Tailings A Guide Second Edition - TOCming changAinda não há avaliações

- Meyco Hard Rock Mining enDocumento12 páginasMeyco Hard Rock Mining enAlex SchoepfAinda não há avaliações

- Fragm: A Blasting Fragmentation Model of RocksDocumento183 páginasFragm: A Blasting Fragmentation Model of Rocksmeet1987Ainda não há avaliações

- Chapter 2: Literature ReviewDocumento14 páginasChapter 2: Literature ReviewShahadat HossainAinda não há avaliações

- Pebble Crusher Specific EnergyDocumento10 páginasPebble Crusher Specific Energy12milehillAinda não há avaliações

- Chapter 7 Sampling Methods 2013 Mineral ExplorationDocumento19 páginasChapter 7 Sampling Methods 2013 Mineral ExplorationCésarGeología100% (1)

- Examination of Copper Electrowinning Smoothing Agents. Part I: A ReviewDocumento7 páginasExamination of Copper Electrowinning Smoothing Agents. Part I: A ReviewHelen HuancaAinda não há avaliações

- Estimation of Fines Generated by Blasting - ApplicDocumento12 páginasEstimation of Fines Generated by Blasting - ApplicJennifer GordonAinda não há avaliações

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDocumento10 páginasFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravAinda não há avaliações

- Lecture5 Flotation Practice and MachinesDocumento31 páginasLecture5 Flotation Practice and Machinesvince coAinda não há avaliações

- Preconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsDocumento16 páginasPreconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsFernando RicardoAinda não há avaliações

- Optimum Ramp Design in Open Pit MinesDocumento9 páginasOptimum Ramp Design in Open Pit MinesFrancys CcoriAinda não há avaliações

- D55SP - D75KS Blasthole DrillDocumento4 páginasD55SP - D75KS Blasthole DrillIrvan Aryo Prakoso0% (1)

- A Simple and Accurate Method For Ore Reserve Estimation in SLC MinesDocumento15 páginasA Simple and Accurate Method For Ore Reserve Estimation in SLC MinesRalain NgatchaAinda não há avaliações

- 4.11.1 Literature Review Dense MediumDocumento20 páginas4.11.1 Literature Review Dense Mediumyansenbarus100% (1)

- 2.3.2.3 Avoca MethodDocumento67 páginas2.3.2.3 Avoca Methoddewin lizarazoAinda não há avaliações

- Thesis - Optimization of Level and Raising Spacing Range in Platinum MineDocumento228 páginasThesis - Optimization of Level and Raising Spacing Range in Platinum MineCarlos A. Espinoza MAinda não há avaliações

- Correlation Between The Top of Froth Grade and The Operational VariablesDocumento7 páginasCorrelation Between The Top of Froth Grade and The Operational VariablesRodolfo Mejías CáceresAinda não há avaliações

- Improved Cleaner Circut Performance at The Degrussa Copper Mine With An in Situ Column Sparging System PDFDocumento9 páginasImproved Cleaner Circut Performance at The Degrussa Copper Mine With An in Situ Column Sparging System PDFAllen GaoAinda não há avaliações

- Brochure Paste ThickenerDocumento8 páginasBrochure Paste ThickenerAndré BranchesAinda não há avaliações

- Stability of Tailing DamsDocumento1 páginaStability of Tailing DamsYogesh SharmaAinda não há avaliações

- Practical Application of Support Systems To Address Weak Rock Mass in Underground MinesDocumento29 páginasPractical Application of Support Systems To Address Weak Rock Mass in Underground MinesDrVikalp KumarAinda não há avaliações

- Raiseboring RSADocumento26 páginasRaiseboring RSAsijuaAinda não há avaliações

- Course Syllabi MinEDocumento113 páginasCourse Syllabi MinEabdullah.alananiAinda não há avaliações

- Grindex'S Great Pump Guide: Pump Features and BenefitsDocumento44 páginasGrindex'S Great Pump Guide: Pump Features and BenefitsCựu SV Bách KhoaAinda não há avaliações

- Potential Problems in Copper Dump LeachingDocumento10 páginasPotential Problems in Copper Dump LeachingLuis Lemus MondacaAinda não há avaliações

- Quellaveco Oct 2019 PDFDocumento23 páginasQuellaveco Oct 2019 PDFfrancisco saavedraAinda não há avaliações

- PIO Antamina PDFDocumento7 páginasPIO Antamina PDFJC AlemanAinda não há avaliações

- Block Cave Undecutting Aims Strategies Methods and ManagementDocumento7 páginasBlock Cave Undecutting Aims Strategies Methods and ManagementLucciano SalasAinda não há avaliações

- 3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)Documento22 páginas3rd International Geometallurgy Conference 2016 Paper Number (PDFDrive)W ZuoAinda não há avaliações

- Shaft SinkersDocumento4 páginasShaft SinkerstamanimoAinda não há avaliações

- PROCEEDINGS of The 4th International Conference On Heap Leach SolutionsDocumento455 páginasPROCEEDINGS of The 4th International Conference On Heap Leach SolutionsjoelAinda não há avaliações

- Rockfill Tailings DamDocumento12 páginasRockfill Tailings DamMOSHITOMOSHITAAinda não há avaliações

- Planning For Narrow Vein Mines: G GemellDocumento4 páginasPlanning For Narrow Vein Mines: G GemellBendigo BanksAinda não há avaliações

- Flow Assurance For Offshore Flow Assurance For Offshore Production - FAOP Production - FAOPDocumento2 páginasFlow Assurance For Offshore Flow Assurance For Offshore Production - FAOP Production - FAOPAhmed RamadanAinda não há avaliações

- OTC 18381 Flow-Assurance Field Solutions (Keynote) : Are We There Yet?Documento3 páginasOTC 18381 Flow-Assurance Field Solutions (Keynote) : Are We There Yet?lulalala8888Ainda não há avaliações

- Escavadeiras HidráulicasDocumento163 páginasEscavadeiras HidráulicasAmilton filho100% (1)

- Espace UndergroundDocumento24 páginasEspace UndergroundAmilton filhoAinda não há avaliações

- Backfill MiningDocumento6 páginasBackfill MiningAmilton filhoAinda não há avaliações

- TierDocumento4 páginasTierAmilton filhoAinda não há avaliações

- Automatic BenefitsDocumento6 páginasAutomatic BenefitsAmilton filhoAinda não há avaliações

- TratorDocumento19 páginasTratorAmilton filhoAinda não há avaliações

- Long WallDocumento19 páginasLong WallAmilton filhoAinda não há avaliações

- Unesco - Eolss Sample Chapters: Physical Properties of Food PowdersDocumento0 páginaUnesco - Eolss Sample Chapters: Physical Properties of Food PowdersAmilton filhoAinda não há avaliações

- Shuttle CarDocumento2 páginasShuttle CarAmilton filhoAinda não há avaliações

- Shuttle CarDocumento2 páginasShuttle CarAmilton filhoAinda não há avaliações

- Back FillDocumento11 páginasBack FillAmilton filhoAinda não há avaliações

- Vedação Closure MineDocumento10 páginasVedação Closure MineAmilton filhoAinda não há avaliações

- Backfill 2Documento190 páginasBackfill 2Amilton filhoAinda não há avaliações

- Fechamento de Mina IDocumento38 páginasFechamento de Mina IAmilton filhoAinda não há avaliações

- Fleet MineDocumento7 páginasFleet MineAmilton filhoAinda não há avaliações

- Conditions For Acceptance of Waste in The Untertagedeponie HeilbronnDocumento2 páginasConditions For Acceptance of Waste in The Untertagedeponie HeilbronnAmilton filhoAinda não há avaliações

- Caracterização GeomecânicaDocumento21 páginasCaracterização GeomecânicaAmilton filhoAinda não há avaliações

- Closure MineDocumento14 páginasClosure MineAmilton filhoAinda não há avaliações

- Rock BurstsDocumento18 páginasRock BurstsAmilton filhoAinda não há avaliações

- SeladorDocumento299 páginasSeladorAmilton filhoAinda não há avaliações

- Frequently Used Tunneling Terms PDFDocumento6 páginasFrequently Used Tunneling Terms PDFOrebic ViganjAinda não há avaliações

- Rheology FinalDocumento8 páginasRheology FinalAmilton filhoAinda não há avaliações

- Conveyor Belt Maintenance Manual 2010Documento46 páginasConveyor Belt Maintenance Manual 2010paul_lesberg100% (1)

- Fleet MineDocumento7 páginasFleet MineAmilton filhoAinda não há avaliações

- Acid Mine Drainage (AMD) Causes, Treatment and Case StudiesDocumento7 páginasAcid Mine Drainage (AMD) Causes, Treatment and Case StudiesAmilton filhoAinda não há avaliações

- Ventilação MinaDocumento8 páginasVentilação MinaAmilton filhoAinda não há avaliações

- Rock Excavation Machines - Surface Mining: Sr. Under Manager Singareni Collieries Company LTDDocumento50 páginasRock Excavation Machines - Surface Mining: Sr. Under Manager Singareni Collieries Company LTDjorgedavid31Ainda não há avaliações

- Aggregate ProductionDocumento39 páginasAggregate ProductionAshaprava MohantaAinda não há avaliações

- Tunnels 091214235809 Phpapp02Documento44 páginasTunnels 091214235809 Phpapp02andifachriAinda não há avaliações

- NAME Dendi Panji Nugraha: Career ExperiencesDocumento4 páginasNAME Dendi Panji Nugraha: Career ExperiencesAsep Ricky HerdiansyahAinda não há avaliações

- 002 Danfoss PICV Energy Valve Ver 090821 r0Documento2 páginas002 Danfoss PICV Energy Valve Ver 090821 r0Pattana MekkhumAinda não há avaliações

- 30 StabilizersDocumento29 páginas30 StabilizersnjileoAinda não há avaliações

- ASAP MethodologyDocumento14 páginasASAP MethodologyTiffany HughesAinda não há avaliações

- CrcwikiDocumento8 páginasCrcwikiPratik MahajanAinda não há avaliações

- SSH Client LogDocumento82 páginasSSH Client LogintorefAinda não há avaliações

- Quake Cheat CodesDocumento21 páginasQuake Cheat CodeshugtheslugAinda não há avaliações

- Legend: Add Subject Remove Subject: Student Number Name of StudentDocumento32 páginasLegend: Add Subject Remove Subject: Student Number Name of StudentJake ChesterphilAinda não há avaliações

- Optis - Ow - LM - Ug - 2014 SP1 PDFDocumento251 páginasOptis - Ow - LM - Ug - 2014 SP1 PDFRaghavAinda não há avaliações

- SEPG and Consulting ProcessDocumento20 páginasSEPG and Consulting ProcesszafzAinda não há avaliações

- S3F94xx BatteryCharger An REV000 060109-0Documento40 páginasS3F94xx BatteryCharger An REV000 060109-0Jack ChanAinda não há avaliações

- Pulveriser-Power PlantDocumento67 páginasPulveriser-Power PlantARUNGREESMAAinda não há avaliações

- Ce 506 Prestressed Concrete Design: M R M M MDocumento2 páginasCe 506 Prestressed Concrete Design: M R M M Mbadr amAinda não há avaliações

- MCQ Books List 1Documento1 páginaMCQ Books List 1BelagaviAinda não há avaliações

- 20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersDocumento2 páginas20e - cTI-60t - TI Pin Converter: Blackhawk™ Jtag Pin ConvertersvspuriAinda não há avaliações

- 5 Process SynchronizaionDocumento58 páginas5 Process SynchronizaionLokesh SainiAinda não há avaliações

- ACI 308R-16 - Guide o External Curing - PreviewDocumento6 páginasACI 308R-16 - Guide o External Curing - PreviewHaniAmin0% (4)

- BSS Steel Guide CataloguesDocumento52 páginasBSS Steel Guide Cataloguessaber66Ainda não há avaliações

- Internal Arc IEC 61641 - EN - V07Documento24 páginasInternal Arc IEC 61641 - EN - V07arkupi100% (1)

- Java ProgramsDocumento60 páginasJava ProgramsbagrechaamitAinda não há avaliações

- Windows 10 Volume Licensing GuideDocumento19 páginasWindows 10 Volume Licensing GuideVijayAinda não há avaliações

- Simple (Ideal) Vapor Compression Refrigeration Cycle ProblemsDocumento3 páginasSimple (Ideal) Vapor Compression Refrigeration Cycle Problemssajawal hassanAinda não há avaliações

- Removal of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingDocumento12 páginasRemoval of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingCaballero MarioAinda não há avaliações

- $MP 026 18Documento12 páginas$MP 026 18Safura BegumAinda não há avaliações

- PetroMod 1NEWDocumento20 páginasPetroMod 1NEWAbdalrhman MuhammadAinda não há avaliações

- TemperaturaDocumento2 páginasTemperaturakamalAinda não há avaliações

- ASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsDocumento35 páginasASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsPablo Antonio Valcárcel VargasAinda não há avaliações

- Cks 180 Ton MIGAS BaruDocumento46 páginasCks 180 Ton MIGAS BaruHario PramuditoAinda não há avaliações

- Gapura Company Profile - 17mar17Documento43 páginasGapura Company Profile - 17mar17als izmiAinda não há avaliações

- MK Conveyor Technology 5.0Documento484 páginasMK Conveyor Technology 5.0Samuel Getaneh TAinda não há avaliações