Escolar Documentos

Profissional Documentos

Cultura Documentos

Audit Checklist Template

Enviado por

Azizol WahabDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Audit Checklist Template

Enviado por

Azizol WahabDireitos autorais:

Formatos disponíveis

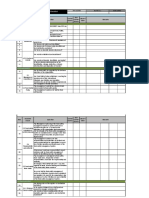

Audit checklist template

Company name: Date of audit: Auditor:

Table 1: Audit checklist Area Compliant? Crit Maj Min 1.0 1.1 Pre a!"it At start or before the audit, establish if there have been any changes to the existing scope, including: the Food safety plan personnel/shift patterns product types/variety extensions new equipment/changes to processes new raw material sources changed packaging. IMP CAR reference/Observations

f yes, note these details and then set up audit trails to review that these changes have been effectively implemented into the existing !A""# system when reviewing documents. Add these questions and audit trails into $ection %& of this checklist. #.0 2.1 $oo" safet% responsibilities an" reso!rces s there at least one person identified as accountable and responsible for development, implementation and ongoing maintenance of the

Food Safety Auditing Toolbox Audit checklist template

Food safety systems' ( n )ictoria * this is the Food safety supervisor+. #rovide the name of that person:

2.2

)erify that: the !A""# system (the Food safety plan+ is developed, reviewed and managed by a multi,disciplinary team key personnel identified as !A""# team members have adequate !A""# training and appropriate experience. -ecords sighted.

2.3

f the company does not have the appropriate expertise and has used external expertise to develop and review the !A""# system, it must: show the credentials of the external consultant re,confirm that day,to,day management remains the responsibility of the company.

&.0 3.1

$oo" safet% polic% Food safety policy requires that: company product safety policy is defined the policy shall refer to the company.s intentions to: , meet its obligations to produce safe and legal products , to comply with food safety regulations , meet its obligations to customers. company product safety policy is clearly communicated to employees and implemented.

3.2 3.3

/oes the company have a quality policy or mission statement' s there a documented 0uality system in place' /oes it include !A""# documentation'

3.4 3.5 3.6 3.7

s the 0uality system accredited and, if so, by whom' /o the !a1ard audit tables reflect the risks associated with the product' /oes the company have a documented "ustomer complaints handling procedure' /oes the company have a documented -ecall

Food Safety Auditing Toolbox Audit checklist template

procedure'

'.0 4.1

(ACCP met)o"olo*% an" "oc!mentation !as the Food safety plan been based on the Codex Alimentarius HACCP principles and is reference made to relevant legislation, codes of practice or guidelines' /oes the Food safety plan identify, monitor and manage physical, chemical or microbiological risks in products and processes' ()ictorian companies: does the company use an approved food safety plan template'+

4.2

/oes the Food safety plan describe what processes are covered within the context of the paddock to plate through chain process' !as a food safety plan been written to include all products and processes' 2otal number of Food safety plans within audit scope: /ate of the Food safety plan(s+:

4.3

4.4 4.5

/oes the Food safety plan include an appropriate flow diagram of the process' "heck that the company has used !A""# principles to: conduct a ha1ard analysis determine the "ritical control points (""#s+ by use of the Codex decision tree when determining ""#s establish critical limits establish a system to monitor control of the ""#s. s the established frequency for monitoring each ""# sufficient to control the ha1ard' establish the corrective action to be taken when monitoring indicates that a particular ""# is not under control establish procedures of validation and verification to confirm that the !A""# system is working effectively, including auditing of the !A""# system establish documentation concerning all procedures and records appropriate to these principles and their application establish the records required to show ongoing conformance to ""# requirements. Also, check that there are

Food Safety Auditing Toolbox Audit checklist template

records to show that effective corrective action occurred when there has been a non,conformance to these ""# requirements. 4.6 2he !A""# study shall be based on an assessment of risk. n conducting the ha1ard analysis, wherever possible, the following shall be included: the likely occurrence of ha1ards (physical, microbiological and chemical+ and the severity of their adverse health effects the qualitative and/or quantitative evaluation of the presence of ha1ards the survival and multiplication of micro, organisms of concern.

4.7

"heck that the company has included in its documentation some reference to its prerequisite programs which are there to support the !A""# system. For example, 3ood manufacturing practice (34#+, 0uality assurance, Allergen control, etc. ($ee also later sections in checklist+. Pro"!ct information/specifications /oes the Food safety plan reference a complete raw materials list' /oes each Food safety plan clearly describe the final product and its intended use' 2his can often be in the form of appropriate specifications: raw materials (including ingredients and packaging+ finished products intermediate/semi,processed products (where appropriate+ recipes/formulations/batch sheets (where appropriate+.

+.0 5.1

5.2 5.3

Are specifications regularly reviewed to ensure adequacy' Are characteristics of the product adequately defined' "onsider: product description raw materials and additives used description of traceability from raw materials to delivery general product characteristics

Food Safety Auditing Toolbox Audit checklist template

specific food safety characteristics (composition, chemical, microbiological and physical characteristics+ specific requirements (relevant legislation, customer demands+ storage conditions packaging shelf life * evidence to support claim.

5.4

Are characteristics for use adequately defined' "onsider: target groups that the product(s+ are intended for sale to (ie mmunodeficient populations, babies, preschoolers, pregnant women, patients, elderly people, diabetics, etc+ information on the label, including directions for use special legislation whether "ritical control points (""#s+ concerning the methods of storage and use have been checked known improper use.

,.0 6.1

Process information Flow diagrams Are these periodically validated to ensure they include: transfer and/or delay steps immediate storage steps subcontracted processes (on or off site+ rework loops reprocessing/recycling loops'

6.2

Layouts of the production process "heck these are documented to ensure consideration to: regulatory layout requirements the possibility of cross,contamination air currents in high,care areas pest control plans.

6.3

Critical control points (CCPs) For each process step defined as a ""#, check that the documents define:

Food Safety Auditing Toolbox Audit checklist template

6.4

responsibility for the monitoring of this ""# critical limit and what is its pass/fail criteria frequency of the monitoring check corrective action if outside of critical limit what will constitute the record of the ""# check responsibility, frequency and record of the verification check of the ""# record.

Corrective actions s there a documented procedure for recording food safety incidents and is it used to ensure appropriate correct action' Also, where applicable, does the procedure make provision for investigation and follow up to identify root causes to prevent likely recurrence' s there a customer complaint system which responds to and investigates the causes of non, conformance to prevent recurrence' s feedback provided to the customer' /oes it trigger any withdrawal or recall procedures that may be necessary'

6.5

Non-conforming product dentification and disposition of non,conforming product is undertaken in accordance with documented procedures and under the directive of an authorised person' For example, release, hold, rework and/or dump.

-.0 7.1

.erification "heck that a verification schedule exists, describing the range of verification activities. "heck also that the schedule describes the activity, responsibility, frequency and records. t should include some or all of the following: verification of cleaning and sanitation verification of ""# record compliance verification of 34# policy compliance verification of equipment accuracy.

7.2 7.3

s there sufficient evidence of the implementation of the )erification schedule' s there evidence of internal audits conducted by personnel independent of the area being audited'

Food Safety Auditing Toolbox Audit checklist template

7.4

s there evidence of management review processes to show periodic verification and analysis of at least: ""# records product non,conformities customer and consumer complaints.

5here deviations from any of the above requirements have occurred, review that corrective actions have been taken in a timely manner and closed off appropriately. 7.5 2here is a system for ensuring verification of the applicable regulations and/or food laws to ensure compliance to these obligations. .ali"ation 2he company has data to substantiate the claims related to food safety and/or regulatory compliance, for example: shelf life studies have been conducted to verify the product is safe according to its use,by date as claimed on the packaging special product claims. For example, fat free, gluten free, 6utritional information panel, etc special allergen statements (eg nut free+ preparation or storage instructions to customers for safe handling of the product. For example, heating instructions, statements like 7consume within four days of opening..

/.0 8.1

0.0 9.1

Traceabilit% s%stem /oes the traceability system enable identification of product lots and their batches of raw materials through to production and the distribution records' Are traceability records maintained for a defined and sufficient period of time' (two years+ s there a documented product withdrawal/recall procedure' s the system periodically tested by a mock recall at frequencies proscribed by customers or a company policy' (generally one to two times a year+ $et up a traceability exercise during the audit to verify its effectiveness. 2ime how long it takes. /oes the company have an approved supplier

9.2 9.3 9.4

9.5 9.6

Food Safety Auditing Toolbox Audit checklist template

program' Prere1!isite pro*rams 2PRPs3 $upport programs are established, implemented and maintained across the entire production system and are to a level as deemed appropriate by the !A""# team. #-#s are to assist in controlling: the likelihood of food safety ha1ards occurring contamination of products including cross,contamination maintaining food safety in product and process environment

2hey include but are not limited to the following: 10 10.1 4!ppl% c)ain mana*ement !as the Food safety plan identified which purchased and/or incoming materials could be a source of a significant food safety ha1ard' Note: incoming materials requirements include: ingredients, raw materials, processing aids, seedlings, food contact packaging, secondary packaging materials, agricultural chemicals, cleaning chemicals, ice, water, etc. 10.2 10.3 /oes the -aw material risk assessment drive the ncoming inspection and test plan' Are all goods received and inspected as prescribed by the nspection and test quality plan' s there a system for handling supplier related non,conformances' /o records show evidence of corrective actions when incidents occur' /o procedures exist for approval and removal of suppliers from the Approved supplier system' /oes it also include approval of emergency alternative suppliers' 11 11.1 Aller*en mana*ement Allergen identification and control includes: a current list of allergens present in all raw materials and finished product policy to prevent cross,contamination of non,allergenic product, including: scheduling, rework, production runs, separate processes, etc records kept for allergen use, type, product labelling.

10.4

10.5

11.2

5hat preventative measures are in place to provide allergen control between different product runs' Are any of the following products produced,

11.3

Food Safety Auditing Toolbox Audit checklist template

packaged or stored on the premises' #roducts containing gluten' For example, wheat starch, rye, barley or triticale' 8gg products, nuts and nut products, sesame products, milk and milk products, soybean products' 11.4 11.5 s testing carried out to detect residual allergens' Are dust collection units installed' s there regular pneumatic back flushing of these units' 1# 12.1 5esi*n of pro"!ction facilities Are there adequate standards maintained to safeguard the product' "onsider, as needed: 1& 13.1 product flow (eg for raw and cooked foods+ building interior (eg lighting, floors, employee facilities+ building exterior (eg location, waste management+ utilities (eg water, air+.

6mplo%ee )%*iene polic% Are there hygiene and security policies and procedures' /oes the company communicate the hygiene requirements to all employees, visitors and contractors' "heck that records are maintained for details of visitor.s entry and departure into process area, as appropriate.

13.2

Are the following prohibited in processing areas' watches 9ewellery * including earrings, bracelets and rings nail polish and false fingernails smoking eating and drinking.

Are personal items stored outside the process areas' f not, is this 9ustified on the basis of risk' 13.3 "heck there are processes to manage staff: washing hands policy, including the use of sanitiser and/or gloves

Food Safety Auditing Toolbox Audit checklist template

"

13.4

if they have an infectious diseases as prescribed by F$A6: F$$ &.%.%.

Are hand washing facilities located in toilets, amenities rooms and cleaning areas' n areas where employees handle food' $upplied with warm running water' Antibacterial soap, paper towel and bin supplied'

13.5

Are good hygiene practices observed to be followed by employees' Are hair covers provided and worn in processing and packaging areas'

13.6

Are employee uniforms supplied' Are employee uniforms laundered in house' s consideration given to temperature of laundering water' f employees supply their own clothing, is it clean and adequate for the tasks performed'

13.7

Are adequate, clean uniforms provided' (ie no top pockets, no buttons, uniforms not worn off site+ Are uniforms cleaned or laundered by an external laundry service'

13.8 13.9 13.10 13.11 1' 14.1

Are hands washed' Are gloves provided for operators and is there a procedure for the use and changing of the item' Are there in9ury procedures for protection of employee wounds' s personnel movement restricted from raw to processed food areas, where applicable' $actor% )%*iene polic%: 7al8 t)ro!*) 8xclusion of physical contaminant ha1ards in high,risk food processing areas. 5here they cannot be excluded, are there adequate control measures documented and implemented for:

14.2 14.3 14.4 14.5 14.6 14.7 14.8

glass metal bone wood rubber plastics (soft+ plastics (hard+

1#

Food Safety Auditing Toolbox Audit checklist template

14.9 14.10

other (eg insects+

/o customer complaint trends demonstrate that the ha1ards listed above are under sufficient control' f not, specify in what category it is not. All packaging material that comes into contact with food products is made of material that doesn.t contaminate food' #ackaging material specifications sighted stating packaging material is food grade. /uring the packing process, is product protected from damage, including contamination' Are packaging materials stored in appropriate conditions and clearly identified' s there in,line metal detection' 5hat checks are performed to ensure the detector is working properly' !ow often are checks performed'

14.11

14.12 14.13 14.14

14.15 14.16

s there any scalping in the process' Are checks carried out on weighing devices' 5hat is the frequency of the calibration'

14.17 14.18 14.19

5hat other processes are carried out during the packing process' 3arbage is stored appropriately and bins are provided' Are there devices to reduce contaminant ha1ards' !as there been consideration to use of magnets, sieves, screens, metal detectors, ;,ray machines and/or fine filters' 5here present, are devices positioned at appropriate locations to ensure maximum product protection' !ow often are checks carried out'

14.20

Dropped product policy Are there controls to ensure that product that is dropped on unsanitised or contaminated surface is discarded to eliminate contamination to product'

14.21 14.22

Are incoming goods deliveries checked' f so, what records are taken' Are raw materials stored so as to prevent contamination' Are food products arriving for repacking stored under appropriate conditions and clearly identified'

Food Safety Auditing Toolbox Audit checklist template

11

14.23

s the incoming goods receipt area maintained in a clean and hygienic manner' Are floors, walls and ceilings maintained in good condition'

14.24 14.25 14.26 14.27 14.28 14.29

s there adequate ventilation to remove fumes' )ents are not located directly near exposed packaging' s there adequate lighting' (refer to A$<=>? for recommendations+ Are premises maintained in a clean and hygienic manner' Are floors in good condition and clean' Are walls and ceilings sealed to prevent entry of dirt, dust and pests' Are they maintained in a clean condition' Are pipes that pass through external openings sealed to prevent the entry of pests' "an fittings and fixtures be easily cleaned' Are packaging lines designed so as to prevent cross,contamination' 5ood and glass, paper and plastic off cuts minimised in manufacturing areas' 6o potential to contaminate packaging' s there adequate product traceability, date coding on inner and outer cartons' /espatch area * is the final packed product stored and transported under appropriate conditions' s this area hygienic' 5hat end product testing is carried out' 4icrobiological' "hemical'

14.30 14.31 14.32 14.33

14.34 14.35 14.36 14.37

1+ 15.1 15.2 15.3

C)emical control !as the company conducted a food safety ha1ard assessment of the chemicals used' Are food,grade lubricants used on food contact equipment' Are non,food,grade chemicals stored and handled so as to minimise potential contamination' (eg paints, cleaners, detergents, diesel, battery fluids, ink9et thinners, etc'+ Pest control

1,

12

Food Safety Auditing Toolbox Audit checklist template

16.1

s there a program to minimise the entry of rodents, insects and birds in the manufacturing and warehousing areas' Are there storage bait station maps identifying their type and location' s one of the technicians a registered pest controller' s the contractor licensed for chemical applications where needed' -ecords sighted. 8lectronic pest devices to trap insects are located correctly and do not scatter dead insects onto food' Are the pest control chemicals approved for use in food plants' Are they stored correctly' Are there points of possible ingress of pests' For example, are doors in the processing storage area closed or are there holes in the walls' s there any evidence of infestation' s there regular removal of waste and rubbish to prevent harbourage' Cleanin* an" sanitation Are cleaning and sanitation requirements established, documented and implemented' 2his should include: responsibility, task to be performed, chemicals and equipment used. Are there records to prove compliance to the "leaning and sanitation schedule' 5ho is responsible for cleaning' Are cleaning chemicals fit for purpose and stored appropriately' 5hat types of chemicals are used' /etergent , $anitiser , 5hat is the name of the supplier'

16.2 16.3

16.4

16.5 16.6

16.7 117.1

17.2 17.3 17.4 17.5

17.6

s cleaning equipment stored in an hygienic manner' $eparate cleaning equipment used for amenities area'

17.7 17.8

Are there 4aterial safety data sheets (4$/$+ for all chemicals used on site' s there a system for verifying the effectiveness of the sanitation program' "onsider, where appropriate: preoperational inspections

Food Safety Auditing Toolbox Audit checklist template

13

environmental monitoring using rapid methods and/or microbiological swabbing allergen validation, if required.

Are records of results and corrective actions maintained' 17.9 s there evidence that corrective action occurs when incomplete or inadequate sanitation has been identified' 6o evidence of dirt or debris in production areas' Are walls, floors and ceilings clean' 61!ipment maintenance an" calibration /o records show activities by maintenance personnel have added to the customer complaints' For example, has foreign matter been found in product, etc' Are Food safety control points managed by breakdown maintenance' Are hygiene controls complied with when work occurs in high,risk hygiene areas' Are Food safety control points managed by preventative maintenance programs' f yes, have these been done at the prescribed frequencies' Are calibration procedures developed, documented and implemented to ensure that all parameters in the Food safety plan read accurately at the time of use' /o they refer to: frequency of calibration criteria for degree of accuracy methods for calibration checks and reference to recognised standards method of identifying equipment when it is found to be out of calibration when equipment is found to be out of calibration, the progress for assessment of impact on integrity records of all calibration checks, of authorised calibration personnel and corrective actions as required'

17.10 17.11 1/ 18.1

18.2

18.3

18.4

10 19.1

Trainin* !ave procedures been developed, documented and implemented to ensure activities, duties and functions that have an effect on the Food safety

14

Food Safety Auditing Toolbox Audit checklist template

plan are undertaken by a suitably trained person' 19.2 Are there suitable induction processes for visitors, contractors and casuals' /o records exist of these occurring' 19.3 #0 20.1 !ow is training provided' n house or third party' Are records kept' Transportation !ave procedures been developed and implemented to ensure activities related to storage and distribution of the food products are undertaken to a defined standard' Are any parts of the transportation loops undertaken by outside contractors' f yes, what controls exist to ensure standards are defined, understood and periodically verified' #1 21.1 5oc!ment control "heck that procedures exist for document control which ensure that systems are developed for: ## 22.1 approval and issuing of new documents identifying general changes and changes to the revision status of documents accessing documents at points of use identifying and controlling the distribution of documents preventing the use of obsolete documents.

20.2

Recor"s 2he company has a record filing system to ensure easy retrieval of the obligatory records and data. 2hese are: validation records to substantiate food safety characteristics of the product, including shelf life detailed records by the !A""# teams with respect to the -isk assessments and also the establishment of the "ritical control points (""#s+ records of any subsequent !A""# reviews or introduced changes to the !A""# plans expertise and training of employees involved in the !A""# team and ""# monitoring ""# monitoring and reports (dated and

22.2

22.3

22.4

22.5

22.6

Food Safety Auditing Toolbox Audit checklist template

15

signed+ 22.7 22.8 records of ""# deviations and corrective actions records of non,conformities and corrective actions including customer complaints, product withdrawals and recalls records of traceability for use from raw material up to and including the delivery of products audit reports and verification reports management reviews process and product evaluations and tests

22.9

22.10 22.11 22.12 #& 23.1

C)an*e control s there a system for identifying changed conditions to trigger a new review of !A""# systems' For example, new final products, new ingredients, changed suppliers and/or new equipment' Are these changes assessed for their impact on the Food safety plan and its prerequisite programs'

nd of chec!list

16

Food Safety Auditing Toolbox Audit checklist template

Você também pode gostar

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorDocumento16 páginasSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghAinda não há avaliações

- Guideline For The Validation of Food Safety Control MeasuresDocumento16 páginasGuideline For The Validation of Food Safety Control MeasuresKriston EdwardAinda não há avaliações

- Sample Audit Checklist For HACCPDocumento16 páginasSample Audit Checklist For HACCPAprilJoyBascosAinda não há avaliações

- HACCP Food Safety Audit Checklist PDFDocumento15 páginasHACCP Food Safety Audit Checklist PDFMuse ManiaAinda não há avaliações

- Audit Checklist TemplateDocumento19 páginasAudit Checklist TemplateAya_aoraAinda não há avaliações

- Checklist: Detailed Evaluation ReportDocumento46 páginasChecklist: Detailed Evaluation ReportAmira Smine100% (1)

- GMP Checklist For PremisesDocumento2 páginasGMP Checklist For PremisesEtta JeneeAinda não há avaliações

- CXG - 069e Guideline For The Validation of Food Safety Control MeasuresDocumento10 páginasCXG - 069e Guideline For The Validation of Food Safety Control MeasuresYêu Thời Trang SophieParisAinda não há avaliações

- ISO 22000 2015 Internal Audit Checklist PDFDocumento5 páginasISO 22000 2015 Internal Audit Checklist PDFMagesha kumarAinda não há avaliações

- Submitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyDocumento3 páginasSubmitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyJhon Rommel Dela Cruz-OdiamanAinda não há avaliações

- Haccp Audit ChecklistDocumento8 páginasHaccp Audit Checklistkarthikeyan G100% (1)

- HACCP Plan PDFDocumento13 páginasHACCP Plan PDFAnonymous qfCJwxib7Ainda não há avaliações

- Audit Report Template FSSC-22000 - 2018Documento21 páginasAudit Report Template FSSC-22000 - 2018Flavio Mondragón100% (1)

- FSMS-stage 02Documento15 páginasFSMS-stage 02Arpita TripathiAinda não há avaliações

- Food Safety - HACCP and CodexDocumento61 páginasFood Safety - HACCP and Codexnpsfpt335100% (4)

- Validation of Control Measures in A Food Chain Using The FSO ConceptDocumento7 páginasValidation of Control Measures in A Food Chain Using The FSO Conceptcaraquena123Ainda não há avaliações

- Hazard Analysis Critical Control PointDocumento9 páginasHazard Analysis Critical Control Pointjudeza100% (1)

- Weekly Food Safety AuditDocumento4 páginasWeekly Food Safety AuditNina YoungAinda não há avaliações

- ASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.Documento11 páginasASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.JHUPEL ABARIALAinda não há avaliações

- Internal Audit ChecklistDocumento16 páginasInternal Audit ChecklistShahrakeshc100% (1)

- FSSC 22000 Webinar - SlidesDocumento57 páginasFSSC 22000 Webinar - SlidesFurqon HidayatullohAinda não há avaliações

- Audit Test ShalgaltDocumento12 páginasAudit Test ShalgaltBgl TseAinda não há avaliações

- OPRP MeaningDocumento11 páginasOPRP MeaningSLQC KumaraAinda não há avaliações

- 17 - Procedure - Control of Records ProcessDocumento4 páginas17 - Procedure - Control of Records ProcessSaAhRaAinda não há avaliações

- Ingredient Vulnerability Assessment BRCDocumento3 páginasIngredient Vulnerability Assessment BRCSherylAinda não há avaliações

- ISO 22000 Gap Analysis Section 6Documento1 páginaISO 22000 Gap Analysis Section 6stevierayo100% (1)

- Good Hygiene Practices Check ListDocumento5 páginasGood Hygiene Practices Check ListMuhaiminulAinda não há avaliações

- GMP ChecklistDocumento12 páginasGMP ChecklistMikkaelaAinda não há avaliações

- C MR 01 02 Ims Check ListDocumento16 páginasC MR 01 02 Ims Check ListShaileshAinda não há avaliações

- GMP Checklist 2Documento13 páginasGMP Checklist 2kamal lochan paleiAinda não há avaliações

- Management Review MinsDocumento2 páginasManagement Review MinsIsmail SultanAinda não há avaliações

- Findings Comments/Remarks Food Safety Management System General RequirementsDocumento15 páginasFindings Comments/Remarks Food Safety Management System General RequirementsEssam El-DesokeyAinda não há avaliações

- Quality Assurance Manager JD 1Documento2 páginasQuality Assurance Manager JD 1Daniel Ratna RajuAinda não há avaliações

- Food Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryDocumento6 páginasFood Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryAdeniji Adeola StephenAinda não há avaliações

- ISO 22000 HACCP Implementation Steps-Sterling - Rev00-240914 PDFDocumento13 páginasISO 22000 HACCP Implementation Steps-Sterling - Rev00-240914 PDFAnkurAinda não há avaliações

- Supplier Audit ChecklistDocumento14 páginasSupplier Audit ChecklistMagesha kumar100% (1)

- Procurment in Emergency SituationsDocumento2 páginasProcurment in Emergency Situationspalani velanAinda não há avaliações

- Gfsi PDFDocumento41 páginasGfsi PDFPurnama HadiAinda não há avaliações

- ISO 22000 Gap Analysis: Text ChangeDocumento8 páginasISO 22000 Gap Analysis: Text ChangeSaulo JesusAinda não há avaliações

- Internal Audit ScheduleDocumento4 páginasInternal Audit ScheduleCQMS 5S DivisionAinda não há avaliações

- ValidationDocumento29 páginasValidationnilebhal100% (1)

- I. Food Defense Plan ManagementDocumento8 páginasI. Food Defense Plan ManagementSantiago GiraldoAinda não há avaliações

- Staff Training Slideshow 7-HACCPDocumento20 páginasStaff Training Slideshow 7-HACCPHemen Sharadkumar UpadhyayaAinda não há avaliações

- Food Safety Management System ManualDocumento45 páginasFood Safety Management System ManualKhalidAinda não há avaliações

- Roles Responsibility & Authority ProcedureDocumento2 páginasRoles Responsibility & Authority ProcedureAyobami Blessing100% (2)

- Checklist ISO 22000Documento21 páginasChecklist ISO 22000anggirasti100% (1)

- Protocol For Validation of FSMS - FinalVersionDocumento25 páginasProtocol For Validation of FSMS - FinalVersionChel Zalamea Domingo100% (1)

- OPRP 4 Management of Cleaning ValidationDocumento1 páginaOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.Ainda não há avaliações

- Farm Name - Doc 3.34 Supplier Approval QuestionnaireDocumento3 páginasFarm Name - Doc 3.34 Supplier Approval QuestionnaireVeronica SebaldAinda não há avaliações

- Internal Audit ISO 9001-2008 Checklist 1-20-12Documento43 páginasInternal Audit ISO 9001-2008 Checklist 1-20-12TravisAinda não há avaliações

- Sop Store Room SafetyDocumento4 páginasSop Store Room SafetyamirAinda não há avaliações

- Procedure For Emergency PreparenessDocumento4 páginasProcedure For Emergency PreparenessNaizil KareemAinda não há avaliações

- Audit Checklist TemplateDocumento16 páginasAudit Checklist TemplateAsif HabibAinda não há avaliações

- Audit Checklist TemplateDocumento18 páginasAudit Checklist TemplateDesi AgustiniAinda não há avaliações

- HACCP Food Safety Audit ChecklistDocumento15 páginasHACCP Food Safety Audit ChecklistTrương Liêm67% (6)

- Haccp & GMP ChecklistDocumento48 páginasHaccp & GMP ChecklistYasir Hussain100% (1)

- HACCP and GMP Self Assessment ChecklistDocumento48 páginasHACCP and GMP Self Assessment ChecklistMin ThuraAinda não há avaliações

- Hazard Analysis Critical Control PointDocumento37 páginasHazard Analysis Critical Control PointMark Nikko ManginsayAinda não há avaliações

- ISO 22000 Check ListDocumento10 páginasISO 22000 Check ListYasser Hassan100% (6)

- Hazard Analysis and Cri Hazard AnalysisDocumento11 páginasHazard Analysis and Cri Hazard Analysisanto132zokaAinda não há avaliações

- Gestetner 1502 - 1802 - 1802d Copy Ref Part 1Documento56 páginasGestetner 1502 - 1802 - 1802d Copy Ref Part 1Klema HanisAinda não há avaliações

- Green Building Index (Gbi)Documento22 páginasGreen Building Index (Gbi)Gholai KhocezkhoAinda não há avaliações

- ISO 14001 Ver 2015Documento12 páginasISO 14001 Ver 2015Resya Andita PutriAinda não há avaliações

- Global Marketing Managementt PDFDocumento277 páginasGlobal Marketing Managementt PDFKuthubudeen T MAinda não há avaliações

- Transfiguration of Recycling Spaces Towards Effective Space Utilization PDFDocumento74 páginasTransfiguration of Recycling Spaces Towards Effective Space Utilization PDFAnwar DuresoAinda não há avaliações

- Tenancy Fitout ManualDocumento99 páginasTenancy Fitout ManualRohan BagadiyaAinda não há avaliações

- FullPaper AllenH - Hu CarbonFootprintAssessmentofArtificialFluoritefromWasteCalciumFluorideCaF2Sludge... TaiwanR.O.CDocumento10 páginasFullPaper AllenH - Hu CarbonFootprintAssessmentofArtificialFluoritefromWasteCalciumFluorideCaF2Sludge... TaiwanR.O.CghanmiAinda não há avaliações

- Revised CSR Guidelines by DPE 10-05-13 PDFDocumento53 páginasRevised CSR Guidelines by DPE 10-05-13 PDFmehtakvijayAinda não há avaliações

- IWRG631Documento10 páginasIWRG631Tina YeganehAinda não há avaliações

- Geotechnical LabDocumento76 páginasGeotechnical LabJAZIRA BINTI JEFFRY -Ainda não há avaliações

- Republic Act 9003: (Salient Provisions)Documento55 páginasRepublic Act 9003: (Salient Provisions)Vivian Escoto de BelenAinda não há avaliações

- Solid and Liquid Waste ManagementDocumento13 páginasSolid and Liquid Waste Managementpunam sharmaAinda não há avaliações

- Aquaculture Wheaton PDFDocumento12 páginasAquaculture Wheaton PDFIsmael San Pablo GonzalezAinda não há avaliações

- Urbanization in IndiaDocumento16 páginasUrbanization in Indiauday88mba100% (1)

- Module 7 Handout - Watsan Logframe With BlanksDocumento4 páginasModule 7 Handout - Watsan Logframe With BlanksMakewaAinda não há avaliações

- Regular City Council Meeting - June 8, 2021Documento220 páginasRegular City Council Meeting - June 8, 2021Mike LynchAinda não há avaliações

- Final Project ProposalDocumento16 páginasFinal Project ProposalJerry'o Adewale OmonigbehinAinda não há avaliações

- A. Principle 1 - Nature Knows BestDocumento5 páginasA. Principle 1 - Nature Knows BestErika mae DPAinda não há avaliações

- Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDFDocumento391 páginasStabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes PDF김혜인Ainda não há avaliações

- 01 Amt Environmentally Friendly Technologies and Energy Efficiency enDocumento19 páginas01 Amt Environmentally Friendly Technologies and Energy Efficiency enVidyasenAinda não há avaliações

- Environmental Laws in IndiaDocumento16 páginasEnvironmental Laws in IndiaRaGa JoThi100% (1)

- Brief Profile of Claveria CagayanDocumento4 páginasBrief Profile of Claveria CagayanNathaniel Llido HamotAinda não há avaliações

- PpiDocumento73 páginasPpiKrushnasamy Suramaniyan100% (1)

- English 4 - ST2 - Q1Documento3 páginasEnglish 4 - ST2 - Q1Jimbert Hora TingcangAinda não há avaliações

- Cyclic On - Off Timer For Cooler PumpDocumento2 páginasCyclic On - Off Timer For Cooler PumpPrabhat SagarAinda não há avaliações

- Bai LuanDocumento25 páginasBai Luantrương nhẫn100% (1)

- All Guide 2007-2008 (En) MitsubishiDocumento91 páginasAll Guide 2007-2008 (En) MitsubishiAndreea JitarasuAinda não há avaliações

- Commercial Buidlings SWM Guideline Manual PDFDocumento163 páginasCommercial Buidlings SWM Guideline Manual PDFzaheeruddin_mohdAinda não há avaliações

- StatesMan Delhi 14 Oct 2023Documento13 páginasStatesMan Delhi 14 Oct 2023sasidkAinda não há avaliações

- (Board Resolution No. 201, Series of 2017) : PCAB Categorization - Classification TableDocumento2 páginas(Board Resolution No. 201, Series of 2017) : PCAB Categorization - Classification TableJennifer AlejoAinda não há avaliações