Escolar Documentos

Profissional Documentos

Cultura Documentos

Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part15

Enviado por

linghuchongDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part15

Enviado por

linghuchongDireitos autorais:

Formatos disponíveis

Track Design Handbook for Light Rail Transit, Second Edition

traffic even if the track itself is capable of higher speeds. The civil design speed should also be coordinated with the operating speeds used in any train performance simulation program speeddistance profiles as well as with the train control system design. Where the LRT system includes at-grade segments where light rail vehicles will operate in surface streets in mixed traffic with rubber-tired vehicles, the applicable geometric design criteria for such streets will need to be met in the design of the track alignment. Where the LRT system includes areas where light rail vehicles will operate in joint usage with railroad freight traffic, the applicable minimum geometric design criteria for each type of rail system needs to be considered. The more restrictive criteria will then govern the design of the track alignment and clearances. In addition to the recommendations presented in the following articles, it should be noted that combinations of minimum horizontal radius, maximum grade, and maximum unbalanced superelevation are to be avoided in the geometric design. The geometric guidelines discussed in this chapter consider both the limitations of horizontal, vertical, and transitional track geometry for cost-effective designs and the ride comfort requirements for the LRT passenger. 3.1.3 Minimum and Maximum Criteria Limits In determining track alignment, several levels of criteria may be considered.[4] Note that an individual criteria limit could be either a minimum or a maximum. In the case of a curve radius, a minimum value would be the controlling limit. In the case of track gradient, there may both a maximum and a minimumthe maximum being controlled by the vehicles capabilities and the minimum defining the minimum slope necessary to achieve storm water drainage. However, three conditions should be considered: the desirable condition, the acceptable condition, and the absolute condition, each as defined below. Desired Minimum or MaximumThis criterion is based on an evaluation of maximum passenger comfort, initial construction cost, and maintenance considerations on ballasted, embedded, and direct fixation track. It is used where no physical restrictions or significant construction cost differences are encountered. An optional preferred limit may also be indicated to define the most conservative possible future case; i.e., maximum future operating speed for given conditions within the alignment corridor. Acceptable Minimum or MaximumThis threshold defines a level that, while less than ideal, is considered to be good enough to meet the operating objectives without either compromising ride quality or taxing the mechanical limits of the vehicle. The use of acceptable criteria limits typically does not require the designer to produce detailed explanations of why it wasnt possible to do better. Determination of the limits for acceptable criteria is usually project-specific and driven by an interest in maintaining a specific level of service to the maximum degree possible at reasonable cost. As such, the limits of acceptable criteria may be established by qualitative methods rather than a rigorous quantitative analysis.

3-2

Light Rail Transit Track Geometry

Absolute Minimum or MaximumWhere physical restrictions prevent the use of both the desired and acceptable criteria, an absolute criterion is often specified. This criterion is determined primarily by the vehicle design, with passenger comfort a secondary consideration. The use of an absolute minimum or maximum criterion should be a last resort. The need for doing so should be thoroughly documented in the projects basis-ofdesign report and accepted by the project owner.

In addition to the above, lower thresholds of criteria are often stipulated for conditions where ordinary operating speeds are much lower than the desired figures noted above and/or site constraints are extraordinary. These include Main Line Embedded TrackWhere the LRT is operated on embedded track in city streets, with or without shared automotive traffic, there generally are multiple physical site restrictions. Overcoming these requires a special set of geometric criteria that accommodates existing roadway profiles, street intersections, and narrow horizontal alignment corridors that are typical of urban construction and also recognizes the municipal or state design criteria for the roadway surface. Yard and Non-Revenue TrackThese criteria are generally less stringent than main line track, due to the low speeds and low traffic volumes of most non-revenue tracks. The minimum criteria are determined primarily by the vehicle design, with little or no consideration of passenger comfort.

Some yard and non-revenue track criteria may not be valid for frequently used tracks such as when the yards main entrance leads to and from the revenue service line. For all types of track, the criteria should consider that work train equipment will occasionally use the tracks. The use of absolute minimum and absolute maximum geometric criteria, particularly for horizontal alignment, has several potential impacts in terms of increased annual maintenance, noise, and vehicle wheel wear, and shorter track component life. The use of any absolute criterion should therefore be done only with extreme caution. One or two isolated locations of high track maintenance may be tolerated and included in a programmed maintenance schedule, but extensive use of absolute minimum design criteria can result in revenue service degradation and unacceptable maintenance costs, in both the near term and far term. Designers should therefore attempt to either meet or do better than the desired criteria limits whenever it is feasible to do so. 3.2 LRT TRACK HORIZONTAL ALIGNMENT The horizontal alignment of track consists of a series of tangents joined to circular curves, preferably with spiral transition curves. Track superelevation in curves is used to maximize vehicle operating speeds wherever practicable. An LRT alignment is often constrained by both physical restrictions and minimum operating performance requirements. This generally results in the effects on the LRT horizontal alignment and track superelevation designs discussed below. All other things being equal, larger radii are always preferable to tighter turns. In addition to wear and noise, small radius curves limit choices on the vehicle fleet both now and in the future. The

3-3

Track Design Handbook for Light Rail Transit, Second Edition

minimum main line horizontal curve radius on most new LRT systems is usually 82 feet [25 meters], a value that is negotiable by virtually every available vehicle. Some modern LRVs and streetcars can negotiate curves as tight as 59 feet [18 meters], and a few can negotiate much smaller radii. Vintage streetcars, including both heritage equipment and modern replicas, can usually negotiate curves as tight as 35 feet [10.7 meters]. Superelevation unbalance (also variously known as underbalance, cant deficiency, or simply unbalance) can range from 3 to 9 inches [75 to 225 mm] depending on vehicle design and passenger comfort tolerance.[3] Vehicle designs that can handle higher superelevation unbalance can operate at higher speeds through a given curve radius and actual superelevation combination. LRT design criteria for maximum superelevation unbalance vary appreciably from as low as 3 inches [75 mm] on some projects to as high as 4 inches [115 mm] on others. The latter value is consistent with a lateral acceleration of 0.1 g, a common, albeit conservative, metric also cited in most design criteria manuals. See Article 3.2.4 for additional discussion on this topic. LRT spiral transition lengths and superelevation runoff rates are generally shorter than corresponding freight/commuter railway criteria. The recommended horizontal alignment criteria herein are based on the LRT vehicle design and performance characteristics described in Chapter 2. The limiting factors associated with alignment design can be classified as shown in Table 3.2.1. 3.2.1 Minimum Tangent Length between Curves The discussion of minimum tangent track length is related to circular curves (see Article 3.2.3). The complete criteria for minimum tangent length will be developed here and referenced from other applicable sections. The development of this criterion usually considers the requirements of the AREMA Manual for Railway Engineering, Chapter 5, which specifies that the minimum length of tangent between curves is equal to the longest car that will traverse the system.[5] This usually translates into a desired minimum criterion of 100 feet [30 meters]. However, that limitation generally addresses operation of freight equipment at low speeds, such as in a classification yard. For passenger operation, ride comfort criteria must be considered. Considering the ability of passengers to adjust for changes of direction, the minimum length of tangent between curves is usually given as LT = 3V where LT = minimum tangent length in feet [meters] V = operating speed in mph [km/h] This formula is based on vehicle travel of at least 2 seconds on tangent track between two curves. This same criterion also applies to the lengths of circular curves, as indicated below. This criterion has been used for various transit designs in the United States since BART in the [LT = 0.57V]

3-4

Light Rail Transit Track Geometry early 1960s.[6] The desired minimum length between curves is thus usually expressed as an approximate car length or in accordance with the formula above, whichever is larger. Table 3.2.1 Alignment design limiting factors Alignment Component Minimum Length between Curves Major Limiting Factors Passenger comfort Vehicle truck/wheel forces Vehicle twist Trackwork maintenance Vehicle truck/wheel forces Noise and vibration issues Passenger comfort Vehicle frame forces Passenger comfort Vehicle twist limitations Track alignment maintenance Passenger comfort Vehicle stability Passenger comfort Passenger comfort Vehicle frame forces Passenger comfort Trackwork maintenance Noise and vibration issues Vehicle twist (especially at jump frogs) Vehicle clearances ADAAG platform gap requirements Trackwork maintenance Railroad alignment criteria Compatibility of LRT and freight vehicle truck/wheels Special trackwork components and geometry

Circular Curves (Minimum Radius)

Compound and Reverse Circular Curves Spiral Transition Curve Length

Superelevation Vertical Tangent between Vertical Curves Vertical Curve/Grade (Maximum Rate of Change) Special Trackwork

Station Platforms Joint LRT/Freight RR Usage

Main line absolute minimum tangent length depends on the vehicle and degree of passenger ride quality degradation that can be tolerated. One criterion is the maximum truck center distance plus axle spacing, i.e., the distance from the vehicles front axle to the rear axle of its second truck. In other criteria, the truck center distance alone is sometimes used. When spiral curves are used, the difference between these two criteria is not significant. An additional consideration for ballasted trackwork is the minimum tangent length for mechanized lining equipment, which is commonly based on multiples of 31-foot [10-meter] chords. Very short

3-5

Track Design Handbook for Light Rail Transit, Second Edition

curve lengths have been noted to cause significant alignment throw errors by automatic track lining machines during surfacing operations. The 31-foot [10-meter] length can thus be considered an absolute floor on the minimum tangent distance for ballasted main line track in lieu of other criteria. The preceding discussion is based on reverse curves. For curves in the same direction, it is preferable to have a compound curve, with or without a spiral transition curve, than to have a short length of tangent between the curves. The latter condition, known as a broken back curve, does not affect safety or operating speeds, but it does create substandard ride quality. As a guideline, curves in the same direction should preferably have no tangent between curves or, if that is not possible, the same minimum tangent distance as is applicable to reverse curves. In embedded trackwork on city streets and in other congested areas, it may not be feasible to provide minimum tangent distances between reverse curves. Unless the maximum vehicle coupler angle is exceeded, one practical solution to this problem is to waive the tangent track requirements between curves if operating speeds are below about 20 mph [30 km/h] and no track superelevation is used on either curve.[4] However, the designer must carefully consider unavoidable cross slope that is placed in the street pavement to facilitate drainage and whether light rail vehicle twist limitations might be exceeded. Pavement cross slope can have a direct effect on actual superelevation (Ea) and unbalanced superelevation (Eu) and must be considered when computing minimum spiral lengths. See Article 3.2.9 for additional discussion on this topic. For yards and in special trackwork, it is very often not practicable to achieve the desired minimum tangent lengths. AREMA Manual for Railway Engineering, Chapter 5, provides a series of minimum tangent distances based on long freight car configurations and worst-case coupler angles. It is also noted in the AREMA Manual for Railway Engineering that turnouts to parallel sidings can also create unavoidable short tangents between reverse curves. The use of the AREMA table would be conservative for an LRT vehicle, which has much shorter truck centers and axle spacings than a typical freight railroad car. As speeds in yards are restricted by operating rules and superelevation is generally not used, very minimal tangent lengths can be employed between curves. However, because yards typically lack a train control system that would monitor and limit speed, train velocities appreciably higher than those authorized can occur. For this reason alone, compromising on criteria is discouraged. Existing LRT criteria do not normally address minimum tangent lengths at yard tracks, but leave this issue to the discretion of the trackwork designer and/or the individual transit agency. To permit the use of work trains and similar rail-mounted equipment that are designed around standards for railroad rolling stock, it is prudent to utilize the AREMA minimum tangent distances between reverse curves in yard tracks. Extremely small radius reverse curves, such as those common for streetcar operations, have an additional consideration. Whenever one light rail vehicle is pushing or towing another, such as commonly occurs around a yard and shop, the angle that the couplers assume to the long axis of both cars must not exceed the vehicles design limits. A maximum angle of 30 degrees is acceptable, but less would be desired. An angle of 45 degrees to the vehicle should be considered an absolute maximum since, beyond that threshold, the force component tending to push or pull the dead car along the track will be less than the force component that acts to push or pull the vehicle

3-6

Light Rail Transit Track Geometry

laterally and hence off the track. One project included an alignment where, during pre-revenue service testing, it was discovered that the tow bar between the streetcar being pushed and the streetcar doing the pushing was at an angle of nearly 90 degrees, at which point all forward motion obviously ceased. The alignment needed to be reconstructed to achieve a smaller angle. Curves with no intervening tangent are discouraged but can be employed under strict circumstances as described in Article 3.2.7 of this chapter. Considering the various criteria discussed above for tangents between reverse curves, the following is a summary guideline criteria for light rail transit. Main Line Desired Minimum The greater of either LT = 200 feet [60 meters] or LT = 3V [LT = 0.57V] where LT = minimum tangent length in feet [meters] V = maximum operating speed in mph [km/h] Main Line Acceptable Minimum The greater of either LT = length of LRT vehicle over couplers in feet [meters] or LT = 3V [LT = 0.57V] where LT = minimum tangent length in feet [meters] V = maximum operating speed in mph [km/h] Note: So as to not limit future vehicle purchases, the vehicle length is often rounded up for purposes of the equation above. If the actual vehicle is about 90 feet [27 meters] long, the value used in the equation might be 100 feet [30 meters].

Main Line Absolute Minimum The greater of either LT = 31 feet [9.5 meters] or LT = (Vehicle Truck Center Distance) + (Axle Spacing) where the maximum speed is restricted as follows: VMAX = LT / 3 or LT = zero [VMAX = LT / 0.57]

3-7

Você também pode gostar

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7Documento6 páginasTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part7linghuchongAinda não há avaliações

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part21Documento6 páginasTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part21linghuchongAinda não há avaliações

- Attachment A Speed AREMA MRE 2011 Volume 3 Chapter 13 - 3.2.4 SPEEDS (2008)Documento1 páginaAttachment A Speed AREMA MRE 2011 Volume 3 Chapter 13 - 3.2.4 SPEEDS (2008)mekkawi6650Ainda não há avaliações

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part14Documento6 páginasTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part14linghuchongAinda não há avaliações

- Geometric Design Note Plus ProblemsDocumento48 páginasGeometric Design Note Plus ProblemsAndenet Ashagrie50% (2)

- Module 2 - Highway ReviewerDocumento10 páginasModule 2 - Highway ReviewerAlvanna ParondaAinda não há avaliações

- Calibrated ModelDocumento8 páginasCalibrated ModelCarlo M. FloresAinda não há avaliações

- Part 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDocumento45 páginasPart 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDylkanWingsAinda não há avaliações

- Design Ntersections, Ramps & Exit-Enterance SectionsDocumento31 páginasDesign Ntersections, Ramps & Exit-Enterance Sectionsعصام ايادAinda não há avaliações

- Highway Capacity Analysis2 9Documento89 páginasHighway Capacity Analysis2 9LilyAinda não há avaliações

- Policy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009Documento13 páginasPolicy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009sage.electconAinda não há avaliações

- Vertical Curve Part IDocumento36 páginasVertical Curve Part IALIAinda não há avaliações

- TCRP Track ClearanceDocumento13 páginasTCRP Track ClearanceSamuel Carlos Sanjuán Torres100% (1)

- 5 - Superelevation & Transition CurvesDocumento20 páginas5 - Superelevation & Transition Curvesmochan31100% (3)

- 05 Allignment Super Elevation AttainmentDocumento20 páginas05 Allignment Super Elevation AttainmentFrank Omune Eshiwani100% (1)

- 13 - Chapter-13Documento6 páginas13 - Chapter-13mubareklibenAinda não há avaliações

- CE414 02 Design FactorsDocumento7 páginasCE414 02 Design FactorsMohamed Imbarek EsekbiAinda não há avaliações

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part19Documento6 páginasTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part19linghuchongAinda não há avaliações

- Mobil TRR 2007Documento9 páginasMobil TRR 2007Laura ČupićAinda não há avaliações

- Length of Spiral Length of Spiral. Generally, The Euler Spiral, Which Is Also Known As The Clothoid, Is Used inDocumento3 páginasLength of Spiral Length of Spiral. Generally, The Euler Spiral, Which Is Also Known As The Clothoid, Is Used inTraore AristideAinda não há avaliações

- ConvEx Paper - The Design of High Speed Belt ConveyorsDocumento11 páginasConvEx Paper - The Design of High Speed Belt Conveyorsgego2Ainda não há avaliações

- Process To Develop Design Standards Using AASHTO ManualDocumento6 páginasProcess To Develop Design Standards Using AASHTO Manualrodzz_03813207Ainda não há avaliações

- Chapter 3 - Intersections PublicationDocumento16 páginasChapter 3 - Intersections PublicationHisham Abou HalimaAinda não há avaliações

- TD rw11 PDFDocumento5 páginasTD rw11 PDFMin Chan MoonAinda não há avaliações

- Freeway Weaving Segments: US HCM 2010 - Chapter 12Documento38 páginasFreeway Weaving Segments: US HCM 2010 - Chapter 12Febriasty TanjungAinda não há avaliações

- Traffic Term PaperDocumento36 páginasTraffic Term Papershivam yadavAinda não há avaliações

- Road DesignDocumento75 páginasRoad DesignSoni Mishra Tiwari100% (3)

- Intersections, Interchanges and OverpassDocumento7 páginasIntersections, Interchanges and OverpassMahipal Singh RaoAinda não há avaliações

- Development of Semi-Active Road-Friendly Truck SuspensionsDocumento10 páginasDevelopment of Semi-Active Road-Friendly Truck SuspensionsLe ThanhAinda não há avaliações

- Integrated Longitudinal and Lateral Networked ContDocumento25 páginasIntegrated Longitudinal and Lateral Networked ContJasAinda não há avaliações

- Selecting and Using Appropriate Truck Data in Design GuidelinesDocumento3 páginasSelecting and Using Appropriate Truck Data in Design GuidelinesAlioune PAYEAinda não há avaliações

- Highway Geometric Alignment and Design LectureDocumento98 páginasHighway Geometric Alignment and Design LectureMatthew MazivanhangaAinda não há avaliações

- Designing A Final Drive For A Tracked VehicleDocumento9 páginasDesigning A Final Drive For A Tracked VehicleIroshana Thushara KiriwattuduwaAinda não há avaliações

- Construction and Maintenance of Underground Railway Tracks To Safety Standard of SANS: 0339Documento6 páginasConstruction and Maintenance of Underground Railway Tracks To Safety Standard of SANS: 0339mavessAinda não há avaliações

- Vertical Alignment: State Highway Geometric Design Manual Section 5: Vertical Alignment 5 - 1Documento16 páginasVertical Alignment: State Highway Geometric Design Manual Section 5: Vertical Alignment 5 - 1Chandrasiri de SilvaAinda não há avaliações

- Basic Design PoliciesDocumento44 páginasBasic Design PoliciesByram J100% (1)

- Load Rating Bridge Structures - Vicroads Practice: Vincenzo ColosimoDocumento14 páginasLoad Rating Bridge Structures - Vicroads Practice: Vincenzo ColosimoMuhammad AbdullahAinda não há avaliações

- Hre Group 2Documento46 páginasHre Group 2Michael Dominique Granada IIAinda não há avaliações

- Capacity and Level of ServiceDocumento16 páginasCapacity and Level of ServiceBismilAinda não há avaliações

- JUNE, 2000 Road Design Manual (English) 5-0 (1) At-Grade IntersectionsDocumento49 páginasJUNE, 2000 Road Design Manual (English) 5-0 (1) At-Grade IntersectionsVladimir MalinaAinda não há avaliações

- Câmbio CVT Explicação Força Centrífuga Molas ExcelenteDocumento23 páginasCâmbio CVT Explicação Força Centrífuga Molas ExcelenteGardenia AndradeAinda não há avaliações

- Vol3 Chapter7Documento14 páginasVol3 Chapter7Rizzal LiaAinda não há avaliações

- No. 47 Crane Rail InspectionDocumento3 páginasNo. 47 Crane Rail InspectionDaniel ConwayAinda não há avaliações

- PlanningDocumento29 páginasPlanningEnachi DragosAinda não há avaliações

- Chapter 2 - Design Elements and Design ControlsDocumento50 páginasChapter 2 - Design Elements and Design ControlsMaria MarqueAinda não há avaliações

- 12 - WP3-RICAM-2016-Chapter FinalDocumento39 páginas12 - WP3-RICAM-2016-Chapter Finalfood diariesssAinda não há avaliações

- Chapter 3: Geometric Design of Highways: D Ep Artm Ent of Civil Engineering, Ambo UniversityDocumento27 páginasChapter 3: Geometric Design of Highways: D Ep Artm Ent of Civil Engineering, Ambo UniversityTarmok Hirpo100% (1)

- Lec 06 Highway Engineering - Vertical AlignmentDocumento20 páginasLec 06 Highway Engineering - Vertical AlignmentDr Firas Asad100% (3)

- Road DesignDocumento75 páginasRoad Designjansen100% (1)

- Track Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part12Documento6 páginasTrack Design Handbook TCRP - RPT - 155 2nd Ed. (2012) - Part12linghuchongAinda não há avaliações

- Pantograph Acceptance Requirements and Methodology in Great BritainDocumento44 páginasPantograph Acceptance Requirements and Methodology in Great Britaintaarak143Ainda não há avaliações

- © 2011 by The American Association of State Highway and Transportation Officials. All Rights Reserved. Duplication Is A Violation of Applicable LawDocumento1 página© 2011 by The American Association of State Highway and Transportation Officials. All Rights Reserved. Duplication Is A Violation of Applicable LawSabina ShresthaAinda não há avaliações

- Chapter 3Documento12 páginasChapter 3masroorAinda não há avaliações

- Lane-Changing Model in SUMODocumento13 páginasLane-Changing Model in SUMOAnatta OngAinda não há avaliações

- Mining Haul Roads by Abhishek MishraDocumento19 páginasMining Haul Roads by Abhishek MishraAbhishek Mishra100% (1)

- Sensors 23 01417 v3Documento18 páginasSensors 23 01417 v3sajad soleymanzadeAinda não há avaliações

- Metro EngineeringDocumento11 páginasMetro EngineeringAnil Chhotu JhaAinda não há avaliações

- Travel Speed. A Traffic Stream Measure Based On Travel Time Observed OnDocumento10 páginasTravel Speed. A Traffic Stream Measure Based On Travel Time Observed OnLady ParedesAinda não há avaliações

- 356 Topic 1Documento16 páginas356 Topic 1Victor KemeiAinda não há avaliações

- Dynamic Analysis of High-Speed Railway Alignment: Theory and PracticeNo EverandDynamic Analysis of High-Speed Railway Alignment: Theory and PracticeNota: 4 de 5 estrelas4/5 (2)

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16linghuchongAinda não há avaliações

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4linghuchongAinda não há avaliações

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67linghuchongAinda não há avaliações

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65linghuchongAinda não há avaliações

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part57Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part57linghuchongAinda não há avaliações

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part52Documento4 páginasProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part52linghuchongAinda não há avaliações

- Procedure For Safety Certification and Technical Clearance of Metro Systems (With CS No Upto 3) PDFDocumento58 páginasProcedure For Safety Certification and Technical Clearance of Metro Systems (With CS No Upto 3) PDFMayank SharmaAinda não há avaliações

- PiyushDocumento65 páginasPiyushGovind MeenaAinda não há avaliações

- Civil 4 1 Te2 PDFDocumento19 páginasCivil 4 1 Te2 PDFci_balaAinda não há avaliações

- UGC06 - Part2 - Section VII - (ODS) - R2 - 20141127Documento408 páginasUGC06 - Part2 - Section VII - (ODS) - R2 - 20141127pradeeepgargAinda não há avaliações

- DPR - Volume II - Main Report - Part B (Version 2.1)Documento607 páginasDPR - Volume II - Main Report - Part B (Version 2.1)Jobins JamesAinda não há avaliações

- BS en 13803 2017Documento102 páginasBS en 13803 2017TC Ercan Asude AlpAinda não há avaliações

- Railway Track GeometryDocumento88 páginasRailway Track Geometryarpit089Ainda não há avaliações

- Unit18 RailwaytrackDocumento12 páginasUnit18 Railwaytrackupadhyay kulbhushanAinda não há avaliações

- BA 5857 Engl GesamtDocumento391 páginasBA 5857 Engl GesamtAlan100% (2)

- Geometric Design of Railways TracksDocumento21 páginasGeometric Design of Railways TracksJACOB CHIMIDZIAinda não há avaliações

- Etd 02 01Documento7 páginasEtd 02 01mkashkooli_scribdAinda não há avaliações

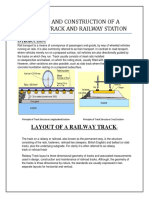

- Layout and Construction of A Railway Track and Railway StationDocumento12 páginasLayout and Construction of A Railway Track and Railway StationAli Hassan LatkiAinda não há avaliações

- Amberg Rail 2.0 - More Efficient. MoreDocumento21 páginasAmberg Rail 2.0 - More Efficient. Morebdaniel4008Ainda não há avaliações

- Curvature LubricationDocumento56 páginasCurvature LubricationSuciu FlorinAinda não há avaliações

- Vortok Balise Mounts Technical PackDocumento27 páginasVortok Balise Mounts Technical PackDragan GligorovAinda não há avaliações

- Chennai Metro Rail Ltd. +: Horizontal and Vertical Alignment Drawing (Up Line) Sheet 01 of 16Documento1 páginaChennai Metro Rail Ltd. +: Horizontal and Vertical Alignment Drawing (Up Line) Sheet 01 of 16vetrismanikkamAinda não há avaliações

- PrEN 13848-2 TrackDocumento44 páginasPrEN 13848-2 TrackDragana TranavacAinda não há avaliações

- Curved Track and Realignment of CurvesDocumento13 páginasCurved Track and Realignment of CurvesBRIDGE DESIGNCELLAinda não há avaliações

- 2.1 Specifiche Tecniche D'Interoperabilita: Gaetano ImperatoDocumento40 páginas2.1 Specifiche Tecniche D'Interoperabilita: Gaetano ImperatoDiego García VaqueroAinda não há avaliações

- UIC 518 2.desbloqueadoDocumento78 páginasUIC 518 2.desbloqueadoDustin RodriguezAinda não há avaliações

- BS en 13231-1-2013Documento34 páginasBS en 13231-1-2013TAHER AMMAR100% (3)

- CCE-TMS-340 Horizontal Curvature Design (NNTR)Documento16 páginasCCE-TMS-340 Horizontal Curvature Design (NNTR)Samuel Carlos Sanjuán TorresAinda não há avaliações

- Sist en 13231 1 2013Documento12 páginasSist en 13231 1 2013Apura TintaAinda não há avaliações

- Uic 518-2Documento78 páginasUic 518-2steeven7783% (6)

- Highspeed020609 PDFDocumento213 páginasHighspeed020609 PDFKailash Chandra PradhanAinda não há avaliações

- SW Railway MapDocumento1 páginaSW Railway MapKrishnaMohanAinda não há avaliações

- 3 Curve - Surveying2Documento25 páginas3 Curve - Surveying2Nø Wømen Nø CryAinda não há avaliações

- Curve NoteDocumento13 páginasCurve NotePuneet AggarwalAinda não há avaliações

- Rbe MicroprojectDocumento8 páginasRbe MicroprojectTushar Patil100% (3)

- Assessment of Crude by Rail (CBR) Safety Issues in Commonwealth of PennsylvaniaDocumento84 páginasAssessment of Crude by Rail (CBR) Safety Issues in Commonwealth of PennsylvaniaGovernor Tom Wolf100% (1)