Escolar Documentos

Profissional Documentos

Cultura Documentos

2008 09FoamSystem

Enviado por

api_fabianDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2008 09FoamSystem

Enviado por

api_fabianDireitos autorais:

Formatos disponíveis

SprinklerAge

Vol 27 / 1

January 2008

An American Fire Sprinkler

Association Publication

SprinklerAge

Vol 27 / 09

September 2008

An American Fire Sprinkler

Association Publication

Reliables

Reliables

NewEvolution of

NewEvolution of

RFC49

RFC49 F1 RES 76

F1 RES 76

Residential Flat Plate Concealed sprinkler

K Factor of 4.9

Combines attractive appearance with (13mm)

of cover adjustment for ease of installation

Refer to Technical Bulletin 006

Largest K Factor on the market today

K Factor of 7.6

For design densities of .05 and .10

Available as pendent, recessed pendent and CCP

Refer to Technical Bulletins 135 and 176

1.800.431.1588

www.reliablesprinkler.com

The Reliable Automatic Sprinkler Co., Inc.

Manufacturer & Distributor of Fire Protection Equipment

RELIABLE ONE SOURCE

For all your fire protection needs.

Residential

Residential

Sprinklers

Sprinklers

Weve expanded our Residential product line

with TWONEWSPRINKLERS!

Sprinkler Spacing

ft. (m)

Minimum Required Sprinkler

Discharge

Flow

gpm (Lpm)

Press.

psi (bar)

12 x 12 (3.6x3.6)

14 x 14 (4.3x4.3)

16 x 16 (4.9x4.9)

18 x 18 (5.5x5.5)

20 x 20 (6.0x6.0)

13 (49)

13 (49)

13 (49)

17 (64.3)

20 (75.7)

7.0 (0.48)

7.0 (0.48)

7.0 (0.48)

12.0 (0.83)

16.7 (1.14)

With these two new sprinklers,

Reliable continues to have the

best combinations of K Factors

for NFPA-13, 13R & 13D

Residential Applications

Reliables

Reliables

NewEvolution of

NewEvolution of

RFC49

RFC49 F1 RES 76

F1 RES 76

Residential Flat Plate Concealed sprinkler

K Factor of 4.9

Combines attractive appearance with (13mm)

of cover adjustment for ease of installation

Refer to Technical Bulletin 006

Largest K Factor on the market today

K Factor of 7.6

For design densities of .05 and .10

Available as pendent, recessed pendent and CCP

Refer to Technical Bulletins 135 and 176

1.800.431.1588

www.reliablesprinkler.com

The Reliable Automatic Sprinkler Co., Inc.

Manufacturer & Distributor of Fire Protection Equipment

RELIABLE ONE SOURCE

For all your fire protection needs.

Residential

Residential

Sprinklers

Sprinklers

Weve expanded our Residential product line

with TWONEWSPRINKLERS!

Sprinkler Spacing

ft. (m)

Minimum Required Sprinkler

Discharge

Flow

gpm (Lpm)

Press.

psi (bar)

12 x 12 (3.6x3.6)

14 x 14 (4.3x4.3)

16 x 16 (4.9x4.9)

18 x 18 (5.5x5.5)

20 x 20 (6.0x6.0)

13 (49)

13 (49)

13 (49)

17 (64.3)

20 (75.7)

7.0 (0.48)

7.0 (0.48)

7.0 (0.48)

12.0 (0.83)

16.7 (1.14)

With these two new sprinklers,

Reliable continues to have the

best combinations of K Factors

for NFPA-13, 13R & 13D

Residential Applications

5 Sprinkler Age | September 2008

SprinklerAge

Vol 27 / 9

September 2008

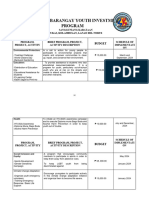

ON THE COVER

High-expansion foam systems are

installed in many different hazards.

The equipment is specialized and the

protection schemes are different from

standard sprinkler protection.

Features

8 | High-Expansion Foam Systems

Be Aware of Differences Before Installing

12 | Foam Systems

Least Remote Calculations

14 | Special Hazard Situation?

Informal Interpretations Can Help

18 | Dont Miss This Capitol Experience

AFSAs 27th Annual Convention & Exhibition Opens Soon

19 | Online Courses Bridge Language Barrier

NCCER Partners With cNI

20 | Victaulic Vortex is First Hybrid Water-Based

Inert Gas System

New Fire Suppression System Unveiled

23 | Sprinklers Squelch School Fire

Success Story From Nampa, Idaho

26 | A Step-by-Step Approach to Seismic Bracing

Dont Miss October 30 Virtual Seminar

27 | President Signs Campus Fire Safety

Right-to-Know Act

Colleges and Universities Required to Provide Fire Safety Information to Students

28 | Carolinas Chapter Donates Trailer to Local College

Students Will Receive Hands-On Training This Fall

30 | Pipe Clamps Are Not Sway Brace Components

Read and Follow Listings Very Carefully

6 CHAIRMANS MESSAGE

32 AHJ PERSPECTIVE

36 CHAPTER NEWS

36 ASSOCIATION NEWS

37 AFSA NEWS

37 CALENDAR OF EVENTS

38 NEW MEMBERS

39 U.S. CONSTRUCTION

39 CANADA CONSTRUCTION

40 PEOPLE IN THE NEWS

42 PRODUCT NEWS

44 INDUSTRY NEWS

46 INDEX OF ADVERTISERS

6 Sprinkler Age | September 2008

EDITORIAL : 214 349 5965

JANET REID KNOWLES, Publisher, ext. 117

jknowles@firesprinkler.org

DARCY GRAHAM MONTALVO, Editor, ext. 115

dmontalvo@firesprinkler.org

NICOLE DUVALL, Communications Coordinator, ext. 126

nduvall@firesprinkler.org

ADVERTISING : 214 349 5965

NICOLE DUVALL, Communications Coordinator, ext. 126

nduvall@firesprinkler.org

CIRCULATION : 214 349 5965

AMY SWEENEY, Asst. to Membership Director, ext. 119

asweeney@firesprinkler.org

AFSA BOARD OF DIRECTORS

LAWRENCE J. THIBODEAU, CHAIRMAN

603-432-8221

R. DONALD KAUFMAN, FIRST VICE CHAIRMAN

505-884-2447

DWIGHT E. BATEMAN, SECOND VICE CHAIRMAN

713-910-3242

DONALD J. ECKERT, TREASURER

513-948-1030

JOSEPH A. HEINRICH, SECRETARY

785-825-7710

MANNING J. STRICKLAND, IMMEDIATE PAST CHAIRMAN

301-474-1136

DONALD G. ALBARES, 504-837-0572

LINDA M. BIERNACKI, 318-688-8800

MARTIN L. GILES, 804-550-9600

PAUL E. HENSLEY, 864-834-5188

THOMAS J. MCKINNON, 925-417-5550

WILLIAM J. RHODES, 860-627-6490

WAYNE WEISZ, 209-334-9119

AFSA MANAGEMENT : 214 349 5965

STEVE A. MUNCY, CAE, President

PHILLIP A. BROWN, SET, CFPS

Director of Technical Program Development & Codes, ext. 123

MARLENE M. GARRETT, CMP

Director of Education Services & Meetings, ext. 118

ROLAND J. HUGGINS, PE, Vice President of

Engineering & Technical Services, ext. 121

LLOYD M. IVY, Director of Membership, ext. 120

JANET R. KNOWLES, Executive Vice President,

Vice President of Marketing & Communications, ext. 117

TAMMY L. TAYLOR, Director of Administrative

Services, ext. 112

SPRINKLER AGE, (ISSN 0896-2685) is published

monthly for $33.95 per year by the American

Fire Sprinkler Association, Inc., 12750 Merit

Drive, Suite 350, Dallas, Texas 75251. Peri-

odicals postage paid at Dallas, Texas and ad-

ditional mailing offices.

POSTMASTER: Send address changes to

SPRINKLER AGE, 12750 Merit Drive, Suite

350, Dallas, Texas 75251.

Sprinkler Age is devoted to the professional development

of the Fire Sprinkler Industry. Deadline is 5th of the month,

two months preceding month of publication.

Call (214) 349-5965, FAX (214) 343-8898, or

E-Mail sprinklerage@firesprinkler.org for information.

Copyright American Fire Sprinkler Association, Inc. All

rights reserved. PRINTED IN USA. Unless expressly stated

otherwise, all editorial and advertising material published

is the opinion of the respective authors and/or companies

involved and should not be construed as official action by

or approved by Publisher or the Association.

Sprinkler Age is a membership benefit, provided free of

charge to AFSA members. For information on non-mem-

ber and/or foreign subscription rates, call (214) 349-5965.

ABOUT AFSA MEMBERSHIP

AFSA annual membership dues are a sliding scale for

Contractors and Associates and a flat fee for Authorities

Having Jurisdiction. (Members receive a free subscrip-

tion to Sprinkler Age.) Write or call AFSA for membership

information. See AFSAs website at: www.firesprinkler.org

By the time you get to read this article, summer will be almost over. For most of us

that signals the arrival of winter in a few short months. I trust most of you had a

great summer with the opportunity to take some well deserved time of.

Now I guess I am going to date myself with this next question, Do you remember

the good old days in the fre sprinkler industry? As contractors, all we had to worry

about was whether we would install a spray upright sprinkler, a spray pendent

sprinkler, or a spray sidewall sprinkler, and, in cold areas of the country, a dry

sprinkler all with the correct temperature 165, 212, or 286 degree sprinklers.

Should we use Schedule 40 steel pipe or Schedule 40 steel pipe? Tere were no other

choices to pick from. Will it be screwed, big and heavy? Yes.

Te reason I call those days the good old days is life in the sprinkler industry was

much simpler. I am not saying that in a malicious way, because our industry has

come a very long way in making life much safer for the public. As contractors, we

have had to adapt to the ever-changing technology of the sprinkler business. Te

grooved coupling came along and we were all amazed as to how many feet of main

we could hang in a day, no more chain tongs with cheater bars. Ten came light-

wall pipe, grooved fttings and hydraulic calculations. We thought we died and

went to heaven. Smaller diameter pipe, lighter pipe could it get any better? For

years we watched plumbers hang PVC piping with a can of cleaner and a can of

glue. Who would have ever thought we would be installing sprinklers with piping

that was not steel?

We have had polybutelene piping, with heat-fused fttings, which was taken of the

market for health reasons. When this came out, everyone said, Wow, I dont even

have to go in a straight line to get from point A to point B. Now we cant even get

it for repairs. We now have other products such as CPVC and PEX piping. Tis

certainly has made our lives much easier but now we have to be aware of non-compa-

tability issues.

Te sprinkler device manufacturers have also done their part in improving the

technology of our industry. As I mentioned before, we basically had three types of

heads. We now, I would dare to say, have hundreds. Tere are certainly too many for

me to list in this article. In the advent of some of this new technology we, as contrac-

tors, have had our share of challenges. We have had to deal with the CPSC head

recall, 3mm bulb issues, and the dry pendent sprinkler recall to name a few. Tese are

issues that come along with new technology.

New and improved technology is good for all of us in the sprinkler industry and we

need to continue to look for more and better ways to Save Lives and Property. But

as I look back at the good old days, the life of a sprinkler contractor and an old

ftter was not so bad with less liability. n

CHAIRMANS MESSAGE

BY LAWRENCE J. THIBODEAU

AFSA Chairman of the Board

FlexHead commercial

fire sprinkler connections:

Whats your application?

More productive installers with lower installation costs.

Perfect center-of-tile eliminating virtually all punch list items.

Highest quality available featuring all stainless steel construction.

Meets all code requirements including NFPA 13 and IBC.

Fast-Track construction with simplified project management.

Seismically qualified without the need for an over-sized ring.

Meets USGBC objectives for green building design & construction.

The best idea in sprinkler systems since water

800-829-6975 www.flexhead.com

U.S. and international patents pending: #6,123,154, #6,119,784, #6,752,218,

#7,032,680, #6,488,097.

Prescribed by leading hospitals

A smart choice for schools

Welcomed in the finest hotels

A bargain for retail buildings

4405 FH ADS 2008 combo What Ap Master 060908 6/9/08 2:45 PM Page 1

FlexHead commercial

fire sprinkler connections:

Whats your application?

More productive installers with lower installation costs.

Perfect center-of-tile eliminating virtually all punch list items.

Highest quality available featuring all stainless steel construction.

Meets all code requirements including NFPA 13 and IBC.

Fast-Track construction with simplified project management.

Seismically qualified without the need for an over-sized ring.

Meets USGBC objectives for green building design & construction.

The best idea in sprinkler systems since water

800-829-6975 www.flexhead.com

U.S. and international patents pending: #6,123,154, #6,119,784, #6,752,218,

#7,032,680, #6,488,097.

Prescribed by leading hospitals

A smart choice for schools

Welcomed in the finest hotels

A bargain for retail buildings

4405 FH ADS 2008 combo What Ap Master 060908 6/9/08 2:45 PM Page 1

8 Sprinkler Age | September 2008

Introduction High-expansion foam systems are installed in

many diferent hazards: high-piled storage, liquefed natural

gas, dike or bund protection, aircraft hangars, etc. What is a

high-expansion foam system? A high-expansion foam system

is a foam deluge system that delivers the foam solution,

(foam concentrate and water mixture), to a discharge device

known as a high-expansion foam generator.

Most commercially available foam generators are water-

powered fans that force or blow the foam solution

against a screen, which results in a finished foam blanket

that expands into a large fluffy cloud of foam bubbles. If

you ever blew bubbles as a child, you submerged the

circular ring dipping wand into a soapy solution, as you

blew air through the circular end of the wand where the

soapy film clung to, large bubbles would result on the

discharge side of the dipping wand. High-expansion foam

generators work in essentially the same way, with the

obvious exception being that the quantity of the soapy

solution is greater, more air is provided, and the screen

has thousands of more holes than the dipping wand.

High-expansion foam generators are open discharge

devices, meaning there is not a fusible link, like in an

automatic sprinkler. The piping supplying the foam

generator is empty, until a deluge valve is activated. When

the deluge valve is activated, water passes through the

riser past a proportioning device, which is located in line

with the sprinkler piping. The proportioning device is

where the foam concentrate is introduced into the water

stream to form a foam solution. Foam solution leaves the

proportioning device and travels down the empty piping

until it enters the foam generator. Think of the foam

generator as a water motor alarm. The foam solution

pushes the fan in a circular motion, the foam solution

discharges through a nozzle or series of nozzles, (depend-

ing upon the manufacturer), and the air current provided

by the fan pushes or forces the foam solution against a

screen, which in turn creates the large bubbles. I made the

comparison to the water motor alarm, as they operate in a

High-Expansion

Foam Systems

Be Aware of Differences Before Installing

MARTIN WORKMAN | The Viking Corporation

Figure 1. Foam Deluge Riser. (Photo courtesy of S&L Mechanical.)

9 Sprinkler Age | September 2008

similar fashion and they both need to have strainers

installed on the supply piping prior to connecting to the

devices. Some manufacturers include this strainer, others

do not, but in all cases, consult the manufacturer for the

correct strainer, as the strainer mesh will vary depending

upon the integral discharge nozzle(s) orifices of the foam

generator.

System Design We normally think of sprinkler systems

in two-dimensional terms, we look down from the ceiling

on our drawings in the plan view, our system design water

flow rate is generally referred to in terms of density, which

is gallons per minute per square foot.

High-expansion foam system design is a three-dimensional

thought process. NFPA utilizes a foam submergence

volume as a rate of application. Most designs are based

upon three cubic feet per square foot per minute. High-

expansion foam fills a space with a puffy foam blanket.

Care should be taken to note where wall openings may

occur. If doors are present, they must be self closing doors

as the effectiveness of the high-expansion foam is based on

the foam blanket staying in the hazard. If wall openings

are present and unavoidable, additional high-expansion

foam must be provided to account for the leakage of the

medium from the hazard area.

A handful of NFPA standards discuss the use of high-ex-

pansion foam as a protection option. Chapter 6 of NFPA

11, Standard for Low, Medium, and High-Expansion Foam

lays out the basic guidelines for the installation of a

high-expansion foam system. Early in the chapter it

explains what hazards it can be used for and what hazards

it cannot be used for. High-expansion foam can be used

for ordinary combustibles (Class A Fires), Flammable and

Combustible Liquids (Class B Fires), and a mixture of

Class A materials and Class B materials, and liquefied

natural gas. Caution should be exercised when protecting

combustible and flammable liquids, if the liquid is

miscible (a miscible compound is one that readily mixes

with water, such as alcohol), contact the high-expansion

foam manufacturer to determine if their high-expansion

foam is suitable for the miscible liquid. High-expansion

foam shouldnt be used where there are water reactive

materials or metals, chemicals that release sufficient

oxygen to sustain combustion, or liquefied flammable gas.

NFPA 11 also discusses personnel safety in the use of

high-expansion foam. Once the system activates, the area

flls with a foam blanket, if personnel are located in the

hazard at the time, they are essentially blinded by the foam

blanket. Adequate pre-operation alarms must be present to

prevent someone from being trapped in the hazard area. If

you are to enter a space where a high-expansion foam

discharge has occurred, you are to use a hose stream to

break down the foam or to cut your way through the foam.

Generally a fre hose with a fog nozzle will do the job. One

should never enter a high-expansion foam blanket without

some sort of life line and a breathing apparatus, the best

way to enter a high-expansion discharge is cutting your way

through it with a hose stream.

NFPA also provides guidance regarding how deep the

high-expansion foam has to build to. The depth require-

ment is as follows: 1.1 times higher than the highest

hazard but in no case less than two feet over the hazard. A

general question of how fast does the high-expansion foam

have to fill the space depends upon if the hazard has a

sprinkler system or not and how the building is construct-

ed. As an example, rubber tires have a maximum submer-

gence rate of seven minutes in a sprinklered building of

light or unprotected steel construction. The same hazard

in a sprinklered building with heavy or fire resistive

construction has a maximum submergence of eight

minutes. If the same hazards are not sprinklered, the foam

has to fill approximately 30 percent faster.

NFPA 11 makes an allowance for the submergence time to

be timed 30 seconds after the automatic detection has

activated the system, meaning high-expansion foam must

be discharging from the generators within 30 seconds of

system activation. If a delay longer than 30 seconds occurs,

some sort of system design change must occur. Te most

likely cause of foam not discharging from the high-expan-

sion foam generators in 30 seconds is transit time from the

deluge valve to the generator or that adequately propor-

10 Sprinkler Age | September 2008

tioned foam solution is not provided to the generator. In

the case of transit time being too great, you try to shorten

your distance to the generators, which may mean changing

the supply piping to the generators. In the case of the

proportioning not being correct for the foam solution,

there are a variety of cause and efects, such as the wrong

proportioning method chosen, foam concentrate not being

present at the proportioning device at the same time the

water is passing through it, foam concentrate supply piping

has excess fttings, not enough straight piping on the supply

or discharge of the proportioning device.

System Commissioning A high-expansion foam

commissioning test is an event. The only way to prove

that the system is designed and installed correctly is to

activate the system. In the past seven years, high-expan-

sion foam has grown in the protection of aircraft hangars.

The largest single reason is that it will generally have a

lower water requirement over other protection methods.

For an example, well use a 50,000 ft

2

Group 1 hangar

that will not house aircraft with wing projections over

3,000 ft

2

. You have three (3) protection options:

1. Low expansion foam deluge systems at the ceiling.

2. Low expansion foam system at the floor and overhead

sprinklers.

3. High-expansion foam system covering the floor and

overhead sprinklers.

Option 1 will require a .16 gpm per square foot of

low-expansion foam designed over the entire ceiling,

having a minimum demand of 8,000 gpm. Option 2 will

require a .10 gpm per square foot of low-expansion foam

over the floor area and a design of .17 gpm per square foot

over 15,000 ft

2

for water sprinklers at the ceiling, requir-

ing a minimum water flow demand of 7,550 gpm. Option

3 will require a design of three cubic feet per square ft

over the hangar floor and a design of .17 gpm per square

foot over 15,000 ft

2

for water sprinklers at the ceiling, for

a minimum water flow requirement of 5,550 gpm.

When you discharge a high-expansion foam system in a

hangar, you will generally operate the system for four (4)

minutes, the frst minute is to ensure that you cover the

foor and the additional three (3) minutes are generally

needed to ensure you have submergence. Once you have

the hangar full of soapy bubbles, what do you do with it?

One thing you dont want to do is just open the doors,

otherwise youll have big clouds of soapy bubbles blowing

across the airport and disrupting take-of and landings.

Prior to activating the system, ensure that you have some

hose lines with fog nozzles to spray down the foam to break

it down. Once you hit high-expansion foam with water

spray it readily breaks down and will go down the drain.

Conclusion High-expansion foam systems have been in

use for many years and are gaining popularity for a variety

of protection schemes. The equipment is specialized and

the protection schemes are different than standard sprin-

kler protection. Before quoting, designing, or installing a

high-expansion foam system, one should consult the

NFPA standard that governs the design and installation

for the hazard and probably speak with a manufacturer/

provider of the equipment for further guidance. Each

manufacturer has specific high-expansion foam concen-

trate that is tied to their high-expansion foam generators

performance, and the manufacturer will generally lead a

contractor through the steps required to install their

equipment correctly. n

ABOUT THE AUTHOR: Martin Workman has been involved in

the fire sprinkler industry for more than 20 years. He joined

the Viking Corporation in 1997 as product manager, spe-

cial hazards. Workman is a principal member of the NFPA

30 committee. He is NICET certified and is a member of

AFSA, ASPE, NFPA and the Society of Military Engineers.

Figure 3. High Expansion Foam Discharge. (Photo courtesy of Chemguard.)

Figure 2. High Expansion Foam Generators. (Photo courtesy of Chemguard.)

TOLCO brings you a superior seismic bracing system that is

FM approved as well as:

Expertise you can count on

Innovative designs that promote labor savings

Technology that exceeds the industrys highest standards

Discover the benets of advanced seismic protection when

you use TOLCO.

TOLCO

SUPPORTING THE FLOW

800.786.5266 www.tolco.com

FM approved it.

TOLCO makes it.

California OSHPD Approved

TOLCO brings you a superior seismic bracing system that is

FM approved as well as:

Expertise you can count on

Innovative designs that promote labor savings

Technology that exceeds the industrys highest standards

Discover the benets of advanced seismic protection when

you use TOLCO.

TOLCO

SUPPORTING THE FLOW

800.786.5266 www.tolco.com

FM approved it.

TOLCO makes it.

California OSHPD Approved

12 Sprinkler Age | September 2008

800-PUMP 13D

The D System

A complete pre-wired factory

assembled unit

Installs in 3 easy steps

Meets NFPA quality standards

Components UL approved

The D Cono Line

New super affordable systems

Tanks available to fit

through 29 doorway

Your Best Value In Residential

Water Delivery Systems

D System Patent #4366865

800. 786. 7133

800-PUMP 13D

www. t hedsyst em. com

HF_AD 12/15/05 1:07 PM Page 1

Reed Manufacturing Company

1425 West 8th Street, Erie, PA 16502 USA

Telephone: 800-666-3691 or 814-452-3691

Fax: 800-456-1697 or 814-455-1697

www.reedmfgco.com

Pipe Tools & Vises

Since 1896

Cutters & Cutter Wheels

Groovers, Power Drives, Threaders & Dies

Vises

Clean Room Tools

Water Services Tools & Machines

Plastic Pipe Tools

Large Diameter Pipe Tools

Wrenches

General Pipe Working Tools

C

h

e

c

k

o

u

t

R

e

e

d

's

N

e

w

5

3

0

1

P

D

P

o

w

e

r

D

r

iv

e

!

An often forgotten and overlooked

design requirement for foam systems

is the requirement of the least

remote calculation. The 2007

edition of NFPA 16, Standard for the

Installation of Foam-Water Sprinkler

and Foam-Water Spray Systems;

7.4.2.2 requires that two sets of

hydraulic calculations be provided;

(1) a most remote hydraulic calcula-

tion and (2) a least remote hydraulic

calculation (both balanced to the

available water supply). In the design

of all fire sprinkler system, we utilize

the most remote calculation to

examine pressure losses and deter-

mine pipe sizes.

In the event of a fire in the most

remote area of a foam system, you

would have adequate pressure and

foam to achieve the design criteria,

but what if there was a fire much

closer to the water source? You would

certainly expect to have enough

pressure, but will you have enough

foam to last for the required duration

of the fire?

Tis scenario underlines the importance

of the least remote calculation, which is

the proper way to determine the actual

amount of foam required for the system.

Since the least remote calculation may

discharge more than the most remote

calculation, you may run out of foam

before the desired duration (20 minutes

in our example) if you used the most

remote area to determine the amount of

foam for the system.

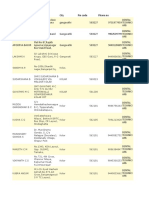

The following example shows a

standard tree system with 6-in. cross

Foam Systems

Least Remote Calculations

RANDY NELSON | VFS Fire & Security Services

13 Sprinkler Age | September 2008

Figure 1. A standard tree system with 6-in. cross mains and 2-in. branch lines with heads spaced at 80 ft

2

throughout the system.

mains and 2-in. branch lines with

heads spaced at 80 ft

2

throughout the

system. (See Figure 1 above.) Using

the criteria in Figure 2 (below), we

can see that the total discharge for

the most remote area is 1,975 gpm

which would require 1,185 gallons of

foam (three percent concentration) to

satisfy a duration of 20 minutes,

however the total discharge for the

least remote area is 2,150 gallons

which would require 1,290 gallons of

foam (three percent concentration)

for the same duration.

This example shows that if you used

only the most remote area to dictate

the amount of foam for the system

you would be short 105 gallons of

foam or about nine percent.

Therefore, considering the valuable

assets that are typically protected by

foam systems, it doesnt make sense

to take on any additional risk or

liability because you are short one

more calculation and you didnt

supply a few more gallons of foam. n

ABOUT THE AUTHOR: Randy Nelson is

president of VFS Fire & Security Ser-

vices in Anaheim, Calif. He is a princi-

pal member of the NFPA 16 Technical

Committee for Foam-Water Sprinkler

and Foam-Water Spray Systems.

Figure 2. Foam systems comparative calculation at base of riser.

RESIDENTIAL FIRE SPRINKLER SYSTEM

INSTALLATION GUIDE RELEASED!

If you are thinking about getting into the residential

sprinkler market - or you already are but want to

become more effective, AFSA has a new fre sprinkler

ftter correspondence training program for you and your

employees Residential Fire Sprinkler System Installation.

Member price: $250

Non-Member price: $500

(Price includes online testing. Add $50 for paper testing option)

For more information, call (214) 349-5965 or

to order, visit AFSA online at www.fresprinkler.org

14 Sprinkler Age | September 2008

Complete fabricating services, including threading, grooving, welding, and end of pipe preparation for black or galvanized material.

Available with Viking SupplyNets complete line of fire protection products for a complete, single-source solution for any project.

Accurate, on-time delivery to virtually any location through Viking SupplyNets fleet of delivery vehicles.

Fabricated pipe is clearly and systematically marked, then bundled for easy installation at the job site.

From the smallest project to the largest endeavor,

its the one contact that gets the job done.

Nine Locations Serving the United States

East

147 Lincoln Drive

Hometown, PA 18252

Phone: (570) 668-4686

Fax: (570) 668-4688

vfshometown@supplynet.com

4593 Carolina Avenue

Richmond, VA 23222

Phone: (804) 228-1107

Fax: (804) 228-1556

vfsrichmond@supplynet.com

South

100 Piedmont Court, Suite A

Doraville, GA 30340

Phone: (770) 446-3068

Fax: (770) 446-3713

vfsatlanta@supplynet.com

West

6480 Box Springs Boulevard

Riverside, CA 92507

Phone: (951) 656-3111

Fax: (951) 656-2606

vfsriverside@supplynet.com

625 E. Watkins Street

Phoenix, AZ 85004

Phone: (602) 252-0400

Fax: (602) 252-2134

vfsphoenix@supplynet.com

12360 E. 46th Avenue #400

Denver, CO 80239

Phone: (303) 576-0665

Fax: (303) 576-0611

vfsdenver@supplynet.com

5081 Kelton Way, Suite 100

Sacramento, CA 95838

Phone: (916) 923-1080

Fax: (916) 923-1748

vfssacramento@supplynet.com

Midwest

640 Center Avenue

Carol Stream, IL 60188

Phone: (630) 462-5860

Fax: (630) 871-1898

vfschicago@supplynet.com

2353 International Street

Columbus, OH 43228

Phone: (614) 527-5800

Fax: (614) 527-5818

vfschicago@supplynet.com

Viking Fabrication Services

www.vikinggroupinc.com

Trusted above all.

TM

AFSAs informal interpretations are provided by AFSA Vice

President of Engineering & Technical Services Roland

Huggins, a P.E. registered in fre protection engineering; Phill

Brown, a NICET IV certifed automatic sprinkler technician

and NFPA Certifed Fire Protection Specialist (CFPS); and

Tom Wellen, a degreed fre protection engineering technolo-

gist. Tese opinions are provided for the beneft of the

requesting party, and are provided with the understanding

that AFSA assumes no liability for the opinions or actions

taken on them.

Subject: Water Velocity in Water Spray Systems

QUESTION: Even though NFPA has no specifc require-

ments for maximum water velocity in fre sprinkler systems,

some AHJs impose seemingly arbitrary maximum water

velocity limits, sometimes as low as 15 feet per second. What is

the impact of water velocity on sprinkler systems?

ANSWER: We have reviewed the 2007 editions of NFPA 13 and

NFPA 15 as the applicable standards. Our informal interpretation is

that except for water-spray systems, NFPA standards do not restrict

the water velocity for sprinklers and the impact of velocity does not

warrant any restriction. Tere are two aspects of hydraulics afected

by water velocity; one is the accuracy of the Hazen-Williams

equation for hydraulic calculations and the other is the impact on

water fow from a sprinkler (or branch line). Te accuracy of

Hazen-Williams was thought to break down at high-water velocities

(such as 32 ft/s). Te Hazen-Williams and Darcy-Weisbach formula

calculations were compared and the fndings were presented in an

article in Sprinkler Age, Pressure Velocity Part I: Defnition

Special Hazard

Situation?

Informal Interpretations Can Help

Complete fabricating services, including threading, grooving, welding, and end of pipe preparation for black or galvanized material.

Available with Viking SupplyNets complete line of fire protection products for a complete, single-source solution for any project.

Accurate, on-time delivery to virtually any location through Viking SupplyNets fleet of delivery vehicles.

Fabricated pipe is clearly and systematically marked, then bundled for easy installation at the job site.

From the smallest project to the largest endeavor,

its the one contact that gets the job done.

Nine Locations Serving the United States

East

147 Lincoln Drive

Hometown, PA 18252

Phone: (570) 668-4686

Fax: (570) 668-4688

vfshometown@supplynet.com

4593 Carolina Avenue

Richmond, VA 23222

Phone: (804) 228-1107

Fax: (804) 228-1556

vfsrichmond@supplynet.com

South

100 Piedmont Court, Suite A

Doraville, GA 30340

Phone: (770) 446-3068

Fax: (770) 446-3713

vfsatlanta@supplynet.com

West

6480 Box Springs Boulevard

Riverside, CA 92507

Phone: (951) 656-3111

Fax: (951) 656-2606

vfsriverside@supplynet.com

625 E. Watkins Street

Phoenix, AZ 85004

Phone: (602) 252-0400

Fax: (602) 252-2134

vfsphoenix@supplynet.com

12360 E. 46th Avenue #400

Denver, CO 80239

Phone: (303) 576-0665

Fax: (303) 576-0611

vfsdenver@supplynet.com

5081 Kelton Way, Suite 100

Sacramento, CA 95838

Phone: (916) 923-1080

Fax: (916) 923-1748

vfssacramento@supplynet.com

Midwest

640 Center Avenue

Carol Stream, IL 60188

Phone: (630) 462-5860

Fax: (630) 871-1898

vfschicago@supplynet.com

2353 International Street

Columbus, OH 43228

Phone: (614) 527-5800

Fax: (614) 527-5818

vfschicago@supplynet.com

Viking Fabrication Services

www.vikinggroupinc.com

Trusted above all.

TM

16 Sprinkler Age | September 2008

A 2250 gallon tank will t through a standard doorway

and assemble to full size capacity inside.

More information on all products is available

on our newly designed website: www.rewatersystemsinc.com

INDOOR & OUTDOOR MODULAR & STANDARD FIBERGLASS WATER TANKS

Phone: 800-381-0801 Fax: 717-234-3474

Complete systems of pumps, tanks and components available separately

Tanks come in all different congurations and are rated for potable water

Call for more information on our complete line of site water systems

Lowest Prices in the Industry

All individual pump components are listed and/or approved

Modular Tanks to Fit Through Small Spaces

Aboveground tanks : 108 to 12,000 gallons

Underground tanks: 900 to 24,000 gallons

Hydraulic Calculations for NFPA 15, Water Spray Fixed Systems

by Roland J. Huggins, P.E., November 1996. In summary, the

results varied signifcantly by pipe size and material, so no pattern

was detected. Te largest deviation took place with 1-in. Schedule

40 steel pipes, which had a 22 percent variance at 40 ft/s, but in real

numbers presented a diference of only 0.6 psi. In comparison,

4-inch schedule 40 varied only 0.08 psi at 40 ft/s. Te most

important aspect about this is that a fow of 108 gpm is required to

obtain 40 ft/s in 1-in. pipe. Tis is an immense amount of water for

such small pipe, resulting in a friction loss of 2.2 psi/ft. Very few

water supplies can tolerate a 22 psi friction loss in only 10 ft of pipe.

Te bottom line is that in regards to the accuracy of hydraulic

calculations, friction loss alone provides sufcient control on water

velocity. Te second aspect is the impact of velocity on fow from a

sprinkler. Typically, hydraulic calculations use total pressure (P

t

) for

determining fow from a sprinkler. Technically, the fow is a result of

normal pressure (P

n

) that is the total pressure minus velocity

pressure (P

v

). Recently, NFPA 15 changed such that hydraulic

calculations for water spray systems must account for velocity

pressure. Tere is an exception to this requirement; if P

v

does not

exceed fve percent of P

t

, it can be ignored. Te concern is if P

v

is

high, the actual fow from the sprinkler may be inadequate. Tere

have been cases, in water spray systems, where sprinklers near the

riser had virtually no fow. Tis is an issue for some water spray

systems because diferent nozzles and/or orifce sizes are allowed

across a system to balance the fow. Since this practice is not allowed

in NFPA 13 systems, the impact of water velocity is greatly reduced.

It comes down to a balancing act between friction loss (F

L

) and

velocity pressure. Its not uncommon, though, for P

v

to slightly

exceed F

L

for the second head up from the end of a branch line. At

frst glance, this could be perceived as a problem, but it is ofset by

the fact that the overall system demand (for both pressure and fow

rate) based on the P

t

method is higher than that for the P

v

method.

For example, I ran the calculations using both methods for the same

system and found the demands to be: P

t

- 283.8 gpm at 51.0 psi P

v

- 267.5 gpm at 48.2 psi. Te higher overall demand of the P

t

method is generally sufcient to cause the sprinklers identifed as

defcient by the P

v

method to actually exceed the minimum

required density. In closing, there is not a technical reason for

imposing a restriction on velocity so NFPA 13 does not restrict

water velocity.

Subject: Differing Orice Sizes on a Water-Spray

System

QUESTION: Te installation plans were rejected since K-4.2

orifce heads were used along with K-5.6 orifce heads. Is it the

intent to have all the fre sprinkler orifces the same size for a

open head foam system?

ANSWER: In response to your question, we have reviewed the 2007

edition of NFPA 16, Standard for the Installation of Foam-Water

Sprinkler and Foam-Water Spray Systems, as the applicable standard.

Our informal interpretation is that not all sprinkler orifce sizes have

to be constant for this application. Te hydraulic design for

foam-water deluge system refers to NFPA 15, Standard for Water

Spray Fixed Systems for Fire Protection. Section 8.1.1 states Hydrau-

lic calculations shall be conducted as part of the design of the piping

system to determine that the required pressure and fow is available

at each nozzle. Since this application is an open head foam-water

deluge system, all the sprinklers operate. Te system has to be

designed to provide a reasonably uniform foam and water distribu-

tion over the coverage area. When water fows through a piping

network, pressure changes result throughout the system due to

friction, turbulence, and elevation changes. Terefore, the pressures

acting at each sprinkler in the design area can vary, resulting in

diferent fows at each sprinkler. Te uniform foam application is

accomplished by sizing pipes and sprinkler orifces to accomplish

the hydraulic design. Te comment concerning the difering orifce

sizes may have originated from NFPA 13 that generally prohibits

the use of fre sprinklers with difering orifce sizes. Te concern was

that if sprinklers with various orifce sizes are used and if some of

those sprinklers have to be replaced at a future date, a sprinkler with

a difering orifce size might be installed. An example where

difering orifces can be used is if a room is protected with extended

coverage sprinklers that have a nominal K-factor of 8.0. However,

the space under a 3-ft wide soft also needs to be protected. Because

the areas under the softs are so small, the use of a smaller orifce

sprinkler can be used. In summary, the design of the system should

be according to NFPA 16 and 15 standards that permit the use of

difering orifce sizes. n

EDITORS NOTE: As noted in at the beginning of this article, these

interpretations were prepared by AFSAs Technical Services De-

partment in answer to specific questions from contractors and/

or AHJs. These opinions are provided for the benefit of the request-

ing party, and are provided with the understanding that AFSA as-

sumes no liability for the opinions or actions taken on them.

This program is available in all states, except Delaware. Some restrictive

coverage and limits may apply in certain states for residential exposures.

2005 Copyright Construction Insurance Solutions. All Rights Reserved

Are you having difficulty insuring your residential or

commercial operations? Facing coverage reductions?

At RISC, Inc. we have the tools of the trade to protect

your business. Backed by an insurance carrier with

excellent financial strength, we can cover your general

liability and umbrella needs providing you with the

peace of mind you deserve. This program is available

through your local agent we can even contact them

on your behalf. You get a comprehensive national

program with the convenience of local service.

For more information

call RISC, Inc. at 1-800-725-7472

or visit our Web site at www.gorisc.com

We have answers.

Have Questions?

Have Concerns?

We have solutions.

Endorsed By

TM

18 Sprinkler Age | September 2008

Te 27th Annual Convention & Exhibi-

tion of the American Fire Sprinkler

Association (AFSA), AFSA in D.C.: A

Capitol Experience, is almost upon us! Tis

years event will be held October 15-19,

2008, at the Marriott Wardman Park Hotel

in Washington, D.C. Tis annual trade-

show boasts the worlds largest gathering of

fre sprinkler professionals, drawing some

1,400 participants from around the globe.

Tis years event features over 30

diferent sessions and countless network

opportunities including an exclusive

private event at the renowned Smithso-

nian Air and Space Museum. Its not too

late to attend North Americas largest

industry show exclusively tailored to the

needs of fre sprinkler contractors of

every size. Registration for the conven-

tion will be available onsite.

D.C. is a vibrant, accessible and world-

class city with everything from inspiring

monuments to monumental arts and

culture, and together with AFSAs

industry-leading show, it promises to be

one trip you wont want to miss! For

details, visit www.fresprinkler.org or call

(214) 349-5965. n

Dont Miss This

Capitol Experience

AFSAs 27th Annual Convention & Exhibition

Opens Soon

Always a great show, this years exhibition is bigger than ever, with a sold-out hall featuring 165 booths.

19 Sprinkler Age | September 2008

NCCER has partnered with construct-

Net International (cNI), Phoenix, Ariz.,

to provide online instructional language

resources for the construction industry

to help bridge the language barrier

between employers and employees.

Te frst series titled, Construction

English for the Spanish Speaker, contains

fve courses. Tese courses will cover

basic terminology related to employ-

ment, employability skills, construction,

and safety. Te frst course in this series,

Introduction to Construction English I,

will be available in September. Other

courses in this series are Introduction to

Construction English II, Intermediate

Construction English I and II, and

Advanced Construction English. Tese

courses are expected to be released

throughout 2008 and 2009.

Tis program is designed to improve

communication at work sites between

Spanish-speaking and English-speaking

employees. Whether asking for tools or

clarifying instructions, employees will learn

key phrases and increase vocabulary in an

easy-to-learn online format. Participants can

log in anytime and anywhere there is access

to a computer and the Internet. An

orientation on how to use the computer

and the Internet is also included.

A second series titled, Construction Spanish

for the English Speaker, consists of one

course aimed at foremen, supervisors, crew

leaders, and administration and is

estimated to be available in fall 2008. Te

primary purpose of this course is to ensure

clear communication between all parties

involved to ensure safety at the job site.

Safety and productivity are a priority for

contractors, and the language barrier is a

large factor contributing to construction-

related injuries and

fatalities, says Don

Whyte, NCCER presi-

dent. With the increas-

ing number of Hispanics

entering the industry, we

must do everything we

can to create a safe

working environment on

our job sites.

NCCER has also devel-

oped other Spanish-based

curricula and assessment

resources. Visit www.

nccer.org. n

Online Courses Bridge

Language Barrier

NCCER Partners With cNI

A screenshot from NCCER/cNIs online Construction English for the Spanish

Speaker series.

20 Sprinkler Age | September 2008

Tere are a variety of fre protection

systems available today, from traditional

sprinkler and high-pressure water mist

systems to chemical and inert gas clean

agent systems. Inherent in these systems

are particular advantages and limita-

tions, depending upon the hazard

application.

In June of this year, Victaulic launched

the worlds frst hybrid water-based inert

gas system: the Victaulic Vortex Fire

Suppression System. Trough a propri-

etary patented technology, this total

fooding solution combines nitrogen gas

and water to extinguish fres without

damaging property or using toxic agents.

Applications for the system include data

centers, automotive manufacturing,

industrial and power generation facilities.

Less Water, Smaller Droplets Te

engineering team at Victaulic spent

more than four years creating a product

that would conquer the limitations of

fre suppression systems currently on

the market. One objective was to

reduce the required water volume,

while simultaneously maximizing heat

absorption efciency. To achieve this

objective, a new high-velocity atomiza-

tion method was developed, producing

a homogeneous mixture of miniscule

water droplets and nitrogen gas,

propelled with enough energy to

overcome the drag efect which limits

the efectiveness of traditional water

mist systems. Te hybrid water and

nitrogen gas mixture travels at high

velocity to reach the fuel source and

overcome any fre plume resistance.

Figure 1. Victaulic Vortex emitter piping for water and nitrogen.

Victaulic Vortex is First Hybrid

Water-Based Inert Gas System

New Fire Suppression System Unveiled

ANTHONY GEE | Victaulic

21 Sprinkler Age | September 2008

Te small droplet size, velocity of the

hybrid mixture and minimal amount of

water dispersed diferentiate the Victau-

lic Vortex system from other technolo-

gies. Traditional sprinklers typically

release greater than 25 gallons of water

per minute per sprinkler, depending on

system design, with droplets generally

greater than 1,000 microns in size.

Te average Victaulic Vortex droplet size

is dramatically smaller at around 10

microns and the amount of water

released per emitter is also much less: as

little as one gallon per minute. Tis

virtually eliminates noticeable wetting of

the protected space, a critical beneft to

minimize property damage.

Supersonic Aerodynamics For the

Victaulic Vortex system piping, the

delivery of water and nitrogen requires

minimal pressure at the Victaulic Vortex

patented emitter. Te emitter has been

developed based upon the aerodynamics

of supersonic aircraft wing design.

Within the emitter, supersonic nitrogen

fow is transformed to subsonic velocity.

Tis produces a series of shock waves which

atomize water injected through the emitter.

Once the water is atomized in the nitrogen

stream, the blended (homogeneous)

mixture is projected from the emitter at

high velocity and at great distances. Each

emitter can cover 2,500ft

3

/70m

3

.

Te nitrogen and water mist function as

complementary extinguishing agents. Te

nitrogen serves as the primary extinguish-

ing agent in small, smoldering fres by

reducing the oxygen level in the enclosure

to where the air remains breathable but

combustion cannot be sustained. In larger

fres, the water mist is more efective as the

extinguishing media, cooling the fre by

Figure 2.Typical single-zone system design. Fully compatible with building detection and security systems.

Figure 3. Typical multi-zone system design. System scalability provides design flexibility and accommodates

changes in hazard protection needs.

What is YOUR Business

Doing To Be As Competitive

As It Can Be?

Fire protection contractors

may not realize the impact that

changes in regulations and

technology have on

their bottomline.

INCREASE REVENUE

Contractors who have trained

their employees on the latest

technology can often leverage

that skill to be more competitive

in the bid process.

DECREASE COSTS

Those contractors often see a

jump in accurate designed and

quality of work, resulting in

fewer change orders or rework.

Tyco now offers 2 & 3 day fire

protection training seminars

with CEU credit in Cranston, RI.

TRAINING

TRAINING

www.tyco-fire.com

401-781-8220 ext. 500

Training@TycoFP.com

TOPICS INCLUDE:

Changes in Technology

Hands On Experience

Live Demos

Industry Direction

22 Sprinkler Age | September 2008

heat absorption and reducing available

oxygen at the fre by generating steam as

the droplets evaporate.

Agency fre testing was conducted in large

rooms (up to 125,000 ft

3

) with 8 ft x 8 ft

doors open allowing airfow and leakage of

agent from the room. Te results demon-

strated successful fre extinguishment

scalability to enclosures larger than any tests

previously conducted at Factory Mutual.

Additionally, the Victaulic Vortex Fire

Suppression System has demonstrated

the capability of extinguishing all fre

scenarios of NFPA 750 and NFPA 2001

even though this hybrid fre suppression

system is neither a pure water mist

system nor a clean agent system.

Sustainable and 90 Times More

Effective Since the Victaulic Vortex

system only deploys water and non-toxic

Nitrogen, system activation is immediate

upon detection of a fre hazard without

concern for exposing human occupants of

the space to any health danger from the

fre suppression system. Te system is

designed to make sure there is always

sufcient breathable oxygen in the

protected space while reducing it to a level

where the fre will extinguish. Addition-

ally, the large number of small droplets

produced by the Victaulic Vortex system

creates a heat-absorbing water droplet

surface area 90 times that of a standard

sprinkler system, providing signifcantly

higher heat absorption efciency.

Te Victaulic Vortex system has been

recognized by the EPA as a non-toxic

replacement for Halon 1301 in total

fooding applications.

Simple Design and Maintenance

Victaulic Vortex system design is modular

and straight-forward, based upon the

calculation of cubic feet/cubic meters per

hazard. Actual placement of emitters and

piping is fexible and single or multi-zone

layouts are possible.

Te system operates on a potable or

distilled water supply, as well as local

sources of Nitrogen. In environments

where electrical hazards are present,

de-ionized water may be used. System

maintenance is less than other technologies

currently available as the system can be

tested without water discharge, minimizing

the disturbance of the protected environ-

ment. Savings is also seen in the rapid reset

of the system after discharge, minimizing

facility downtime. Te low impact of

installation and system features make the

Victaulic Vortex an extremely cost-efective

fre suppression system option for new

construction and retroftting.

Minimal Wetting, Reduced Water

Damage Minimal wetting of the

protected space is an important beneft,

particularly in spaces housing electronic

equipment, such as data centers or

irreplaceable works like museums or

libraries. After system discharge, residual

moisture is barely detectible. Te reduced

amount of water discharged in such fne

particles creates a dew-like residue, as

compared to the hundreds of gallons of

water typically dispersed by sprinklers or

high-pressure mist systems.

Scalability Te Victaulic Vortex system

ofers scalable design, allowing for single or

multiple zones of hazard coverage and

integration with other facility systems such

as hazard detection and security. Tis

minimizes retroft impact and allows the

system to adapt to changes in space layout

and coverage requirements.

Te Victaulic Vortex Fire Suppression

System, built upon more than 80 years of

Victaulic innovation and product

development, provides the best capabili-

ties of both water mist and inert gas

systems. Te ease of design, minimal

wetting, and fre suppression features give

the Victaulic Vortex system numerous

advantages over existing systems. Visit

www.victaulicvortex.com. n

ABOUT THE AUTHOR: Anthony Gee is product

manager, Vortex for Victaulic. He has 24 years

experience in special hazards fire protection

system design, engineering, project manage-

ment, business development and marketing.

Gee has a Bachelors degree in mechanical en-

gineering. He has a diverse project background

in various vertical markets, including projects

such as the Canadian Hibernia Production

Platform, European Eurotunnel Channel Tunnel

Shuttle Trains and Locomotive Fire & Gas De-

tection and Suppression Systems, and the U.S.

Navy Arleighe Burke Guided Missile Destroyer

Program Fire Alarm Systems.

Wheeler Manufacturing

Division of Rex International U.S.A., Inc.

US Toll Free: 800-321-7950 Fax: 440-992-2925

e-mail: wheeler@wheelerrex.com www.wheelerrex.com

Grooves 1" 6" pipe

Mounts fast, no need to remove carriage

Short lengths stay on pipe without help

Fast, easy T-handle feed

Fits Wheeler-Rex models 6090, 7090 & 6790

Fits Ridgid

300 & 300 compact

The Ridge Tool Company

Now, you can turn a pipe threader

into a roll groover in just seconds.

WHE-447 RGDrop_B&W_SA_R3 11/11/05 11:01 AM Page 1

23 Sprinkler Age | September 2008

Save Time & Labor !

GECCO, INC.

866-432-2600

dropmasterfiresprinkler.com

Innovative solutions for the fire

protection system industry.

Maintain 10 Hg regulated vac-

uum while removing and replacing

sprinkler heads in minutes

t Save over 50% in labor costs

t Water & odor removal

t No water spills in

occupied spaces

t Reduce operating down-time

t Fits all sizes of FPS

Dropmaster Custom Accessories:

Truck Attachable Carrier

Rigid 620 PDK Custom Cart

Luckily, only a damp closet is all that

remains from a fre that spontaneously

combusted inside Nampa Christian

High Schools brand-new gymnasium

Saturday, August 2. Te fre sprinklers

that Greg Patricks company, AFSA

contractor member Treasure Valley Fire

Protection, Inc., installed in the building

activated, extinguishing the fre, in

efect, saving the schoolhouse.

Te good news and the blessing was the

sprinkler system caught it as it was

supposed to, Principal Kevin Rex told

Boise, Idaho television station KIVI.

Te small fre that started in the new

schools unfnished gymnasium at 4:09

p.m., investigators believe, was caused by

the spontaneous combustion of leftover

nitro work gloves and mineral spirits

stored in a plastic bag inside a closet at

the far end of the gym.

With the nitro gloves and the mineral

spirits being the main culprit, they reacted

together and started the bag of debris on

fre, which smoldered for some time,

Nampa, Idaho Battalion Chief Larry

Richardson told the Idaho Press-Tribune.

A crew fnishing the gym foor uninten-

tionally left behind the bag flled with

chemicals. Tose chemicals reacted and

ignited some sawdust, triggering an

automatic alarm. Te sawdust in the

bag was likely smoldering for some time

before it developed enough heat to

provoke the sprinkler system, said

Richardson in an interview with

Channel 6 News. Te damage is pretty

limited fre-wise.

Te Nampa Fire Department respond-

ed to an automatic alarm about 4:10

p.m. and arrived on the scene within

minutes. By the time they went inside,

the sprinkler system had already doused

the fames, leaving the crews to merely

open doors to rid the gym and hallways

of smoke.

Rex told reporters the fre would not

afect classes when students return to

school. He credits that to the sprinklers

that reacted when no one was around.

Rex told KIVI, We learned a lot from

the Middleton fre, in terms of how to

prepare and have the building ready. I

dont think well miss a beat. Well hop

back on it.

Damages should be less than $20,000

from water under the gym foor and

some smoke that flled the building,

according to Rex.

[Te fre service] also did an excellent

job of making sure that the news

media reported the story correctly,

Patrick said, promptly adding, Its

another overwhelming fre sprinkler

success story. n

EDITOR'S NOTE: Thanks to Greg Patrick for

sending us this success story. Sprinkler Age

welcomes any submissions for publication

consideration. Stories may be emailed to Edi-

tor DArcy Montalvo at dmontalvo@firesprin-

kler.org, faxed to (214) 343-8898 or mailed

to Sprinkler Age Magazine, AFSA, 12750

Merit Drive, Suite 350, Dallas, Texas 75251.

Sprinklers Squelch

School Fire

Success Story From Nampa, Idaho

2007

Sway Brace Calculation

Program

www. .org

Sway Brace Products and Hangers that Help

1500 DRAWINGS

Ss PROTOCOL

INTERPOLATES Cp

PIPE DEFLECTION AUTO CORRECT

CPVC SWAY BRACING

SPECIFIC GRAVITY

PRYING EFFECT

2007

Sway Brace Calculation

Program

www. .org

Sway Brace Products and Hangers that Help

1500 DRAWINGS

Ss PROTOCOL

INTERPOLATES Cp

PIPE DEFLECTION AUTO CORRECT

CPVC SWAY BRACING

SPECIFIC GRAVITY

PRYING EFFECT

26 Sprinkler Age | September 2008

Te American Fire Sprinkler Association

(AFSA) will present a 90-minute virtual

seminar on Step-by-Step Approach to

Seismic Bracing, on October 30, 2008 at

12:00 p.m. EDT, 11:00 a.m. CDT, 10:00

a.m. MDT, and 9:00 a.m. PDT.

As a result of the adoption of the IBC and

its reliance on the requirements in the

ASCE7-05 manual, seismic bracing of

sprinkler systems now require more

supporting documentation than ever

before. Tis seminar will take a systematic

approach on both obtaining and applying

the necessary information.

Kenneth W. Wagoner, S.E.T., is the

speaker for this seminar. He is a 1977

graduate of Bethany College (Kan.), owns

and operates Parsley Consulting, Escon-

dido, Calif. He holds a NICET level IV

certifcation in Automatic Fire Sprinkler

System Layout, and other certifcations in

Fire Alarms, Inspection and Testing, and

Special Hazards. He is an NFPA Certifed

Fire Plan Examiner. He is a member of the

NFPA 13 Hanging and Bracing Technical

Subcommittee, AFSA, NFPA, and the San

Diego Fire Protection Association.

Wagoner is a frequent seminar presenter

on various topics for AFSA and the Center

for Life Safety Education (CLSE).

How does a virtual seminar work?

Connect via an 800 number. Many people

can listen in a single ofce for the price of

one. You can ask questions from wherever

you are. (Touchtone phone required.) Tis

feature is very much like participating in a

talk radio program. You will receive the

PDF slide presentation days before the

seminar. You can also print the PDF fle

presentation and make as many copies as

you need for note taking.

Registration Information Registration

forms can be found online at www.krm.

com/afsa/. Te event ID is 14089. Te

connection cost is $90 for AFSA members

and $130 for non-members. If any listeners

at your site need CEU/CPD credit, the

processing fee is an additional $40 per

person. For further details or questions, call

(214) 349-5965 ext. 118. n

A Step-by-Step Approach

to Seismic Bracing

Dont Miss October 30 Virtual Seminar

MODEL G3000

Advantages

and Features

FACTORY TESTS Hydraulic testing

for pump flow and pressure. Hydrostatic

pressure test in excess of 200PSI.

FAST LEAD TIMES Large inventory

and prompt turnaround allows for

quick shipments.

EASY INSTALLATION Floor and

wall mount systems allow for flexibility

of design and reduced installation time

due to simplified mounting and wiring.

MODEL G5000

S P D Incorporated

1167 Tower Road

Schaumburg, IL 60173

(847) 882-9820

(847) 882-9825 FAX

www.spdinc.com

13D RESIDENTIAL PUMP SYSTEM

RESIDENTIAL

WATER TANKS

Factory

Tested

Ready

to Ship

Easy to

Install

27 Sprinkler Age | September 2008

On August 14, 2008 President George W.

Bush signed into law H.R. 4137, the

Higher Education Opportunity Act. Te

Campus Fire Safety Right-to-Know Act

was included as part of this pivotal piece of

legislation aimed at improving fre safety

on college campuses across the nation.

Te Campus Fire Safety Right-to-Know

Act was originally introduced in the

House by Congressman Bill Pascrell, Jr.

(NJ-8) and in the Senate by Senator

Frank Lautenberg (NJ).

Te provision will require colleges and

universities to provide students with

information on fre safety on campus,

including the number of fres and their

causes, the number of injuries and

deaths related to fres, and the amount

of property damage related to fre. Te

legislation also requires the institutions

to report on fre safety systems, the

number of regular fre drills, fre

prevention and education policies, and

any future fre safety activities and plans.

According to Campus Firewatch (www.

campus-frewatch.com), the Campus

Fire Safety Right-to-Know legislation

was frst introduced in 2001 and has

been under consideration in every

session of Congress since then.

In a prepared statement, Congressman

Pascrell said, I would also like to

recognize the dedication of Campus

Firewatch and the Center for Campus

Fire Safety over the last eight years to

help provide information, advocate our

cause and organize the support Senator

Lautenberg and I needed to move this

legislation through Congress.

To assist in writing the regulations for

this landmark legislation, Campus

Firewatch has initiated a collaborative

project where anyone can contribute to

recommendations on the regulations.

For more information visit Campus

Firewatchs Web site at www.campus-

frewatch.com/. n

President Signs Campus Fire

Safety Right-to-Know Act

College and Universities Required to Provide Fire Safety

Information to Students

28 Sprinkler Age | September 2008

Dont throwaway

your old threading dies...

Recycle them!

FREE PFTE TAPE!

500 rolls of PFTE tape

for every 10 sets of used HSS dies

OVER $100 VALUE!

OR

ARGCO will give you

$5 for each set

of used HSS universal dies

UP TO $300 CREDIT FOR YOUR

300

POWER DRIVE CORES

Ridgid

is a registered trademark of the Ridge Tool Company

ARGCO recycles Ridgid

and

Rothenberger

High Speed Steel

Universal threading dies. Call for details

Its been seven months in the making, but

on July 17, 2008, Joe Harrison, president of

the AFSA Carolinas Chapter, presented a

fre sprinkler equipment training trailer on

behalf of the chapter to Chris Langham,

program coordinator for Fire Protection

Technology at Forsyth Tech Community

College in Winston-Salem, N.C.

[Forsyth Tech] had seen our demonstra-

tion trailer and really liked the idea, reports

Joe Hankins, chapter executive director.

Tey contacted us about how to build it

and weve been working on it since about

the frst of the year.

With the goal of expanding its depart-

ment by educating more up-and-coming

fre professionals about such fre sprinkler

systems, Langham turned to the AFSA

Carolinas Chapter for help after seeing

the chapters own trailer in action.

Because he liked the chapters trailer so

much, Langham asked the chapter to

model Forsyth Techs new training trailer

after the chapters own.

When I was applying for this, I gave the

analogy of a mechanic going through a

program and never getting under the

hood of a vehicle. It just doesnt make

sense, says Langham. I wanted to give

students the opportunity to see how they

work and put their hands on the systems.

Tis [trailer] gives students this hands-on

learning experience.

With an approved budget from the college

of only $20,000 for the trailer, Langham

and the chapter had their work cut out for

them. According to Langham, I contacted

[Joe Harrison] and told him what Im

looking for and that I only had so much

money to do it. He graciously agreed to

help, saying that it would cost more than

$10,000, but hed make it happen.

Te empty trailer, which was purchased by

Carolinas Chapter

Donates Trailer

to Local College

Students Receive Hands-On TrainingThis Fall

Joe Harrison, president of the Carolinas Chapter of AFSA (left) presents a sprinkler equipment training trailer

to Chris Langham, program coordinator for Fire Protection Technology at Forsyth Tech Community College in

Winston-Salem, N.C.

29 Sprinkler Age | September 2008

Forsyth Tech for $10,000, was outtted

with four dierent system risers, which were

generously donated and installed by chapter

members. Langham recalls, When it was

delivered, I remember thinking it was more

than we expected. It was nicely designed

and functional. I handed him the P.O. and

told him Id get them paid as soon as

possible, but he handed it back. He said he

spoke with the rest of the members and

they wanted to make this a donation.

Te portable training facility worth in

excess of $35,000, estimates Langham is

equipped with a backow preventer, a

shotgun wet riser, a wet riser with an alarm

check valve, a dry system riser, a deluge

system riser, and an air compressor for the

dry and deluge systems. It also has tamper

alarms for the control valves installed on

each riser and waterow alarms.

Te donated trailer will be used to educate

Forsyth Techs re protection technology

The empty trailer, which was purchased by Forsyth

Tech, was outfitted with four different system risers.

All of the equipment in the trailer was donated by

Carolinas Chapter supplier members.

students about re sprinkler technology

and how it operates, starting this fall.

Additionally with its portable nature, it can

be delivered to various sites and used by

instructors, says Langham, as a mobile

training prop for reghters from over 40

dierent departments spanning two

counties, as they complete the required

Sprinklers and Auto Alarms coursework

as part of their state certication.

High Point Sprinkler and the AFSA

Carolinas Chapter were great in this

process, comments Langham. Tis was a

very unexpected and gracious surprise that

we received, and we are so thankful to

everyone who contributed. Tis is a

product that will serve the community for

years to come.

All of the equipment was donated by

Carolinas Chapter supplier members: Beco

Inc., Febco SPC Marketing, Ferguson

Fire & Fabricators, General Air Supply,

HD Supply, Leonhardt Pipe and Supply,

NIBCO, Potter Roemer, Te Reliable

Automatic Sprinkler Company, System

Sensor, Tyco Fire & Building Products, and

Victaulic. Te labor was donated by High

Point Sprinkler Company, High Point,

N.C. For details, email Hankins at joe_

hankins@lexcominc.net. n

30 Sprinkler Age | September 2008

NFPA 13 identifes a pipe clamp as a hanger component per section

A.9.1.1. Using a pipe clamp as a sway brace ftting violates NFPA

13. Chapter 9 specifes the use of listed sway brace fttings in sway

brace assemblies. Accordingly, lateral and longitudinal sway brace

assemblies are composed of listed components whose geometry and

ability is unique to their orientation and function. Any indication

to apply pipe clamps in sway brace assemblies is improper and in

violation of NFPA 13.

Pipe clamps are listed per UL 203 to support hanger loads in

tension in conformance to NFPA 13. Sway brace fttings are listed

per UL Sub 203A to resist seismic loads in tension and compression

in conformance to NFPA 13. Tis article will explain the impor-

tance of the structural ability of the fastener fange of a listed clamp

type sway brace ftting, henceforth called ears.

Longitudinal sway brace fttings may look similar to pipe clamps.

In spite of some basic similarities, longitudinal sway brace fttings

are structurally and functionally diferent. Teir UL Sub 203A

Pipe Clamps Are Not Sway Brace

Components

Read and Follow Listings Very Carefully

KRAIG KIRSCHNER | AFCON

listing specifes assembly as part of a longitudinal sway brace in

conformance to NFPA 13. Further, UL Sub 203A requires

alignment of the ftting to resist seismic force parallel through the

fttings ears when oriented on edge, as shown in drawing A. Te

ears are structurally stronger and more able to resist force applied

against their edge than against their fat, as shown in drawing B.

In my opinion, lateral sway brace fttings should not look similar to

pipe clamps for two reasons. Practically, it is very problematic to

achieve the required structural rigidity of the pipe clamp ears when

seismic force is applied against them on the fat, as shown in

drawing B. In this orientation the ears are much weaker and

therefore more susceptible to bending. Further an extra listed

ftting is required to transition the attachment of the ear to the pipe

component of the sway brace assembly. Current listed attachment

fttings also lack required structural rigidity in this orientation. At

this time, the one and only product that looks similar to a pipe

clamp is being reevaluated by UL to determine if its listing will be

retained or rescinded.

In closing, ignore anyone who advises using pipe clamps as

components in sway brace assemblies. NFPA 13 Chapter 9 is very

specifc about the use, features and characteristics necessary of listed

fttings used in sway brace assemblies. Read listings, watch out for

misinformation, and be very careful to avoid misapplication of both

pipe clamps and longitudinal sway brace fttings as outlined in the

above text. n

ABOUT THE AUTHOR: Kraig Kirschner is president and CEO of

AFCON. He is a principal committee member on NFPA 13 Hanging and

Bracing and he serves on the Underwriters Laboratories Standards Tech-

nical Panel for UL 203 and UL 203A. He also holds 20 patents for sway