Escolar Documentos

Profissional Documentos

Cultura Documentos

CAD/CAM Program for Drilling Operation

Enviado por

ideepujDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CAD/CAM Program for Drilling Operation

Enviado por

ideepujDireitos autorais:

Formatos disponíveis

Code.

No: 07A6EC04

R07

SET-1

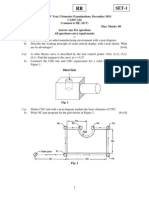

III B.TECH II SEM EXAMINATIONS, DECEMBER - 2010 CAD/CAM (COMMON TO ME, MECT, MEP, AME) Time: 3hours Max.Marks:80 Answer any FIVE questions All questions carry equal marks --1. What is meant by product life cycle? Explain the product life cycle in conventional and computer-aided manufacturing environments. [16] What is concatenation? Explain its importance in the transformation of graphics. A triangle is defined in a two dimensional coordinate system by its vertices (0,2), (0,3) and (1,2). Perform the following transformations on this triangle: i) Rotate the triangle by 450 about the origin. ii) Rotate the triangle by 450 about (-1,-1). [6+10] What are the various requirements of geometric modeling ? A cubic Bezier curve is described by the four control points: (0,0), (2,1), (5,2), (6,1). Find the tangent to the curve at t = 0.25. [6+10] What are the various display control commands? Explain them with an example. [16] Discuss the influence of friction in CNC machine slides? The part drawing of a component is shown in Fig.1. Five holes of 12.5 mm diameter are to be drilled at five places. The speed and feed rate are 592 RPM and 100 mm/min respectively. The machine has a floating zero feature and absolute positioning. The thickness of plate is 10 mm. Write the manual part program. [6+10]

2. a) b)

3. a) b)

4. 5. a) b)

6.a) b) 7.a) b) 8.a) b)

What is group technology? Explain the concept of part families. Discuss Optiz coding system with an example. Define quality. What are the techniques employed to achieve quality control? What are the various methods of automated inspection? Explain.

[8+8]

[8+8]

Discuss various types of manufacturing systems with an example. What is computer integrated manufacturing? Explain the various components of it. [8+8] --ooOoo--

Code.No: 07A6EC04

R07

SET-2

III B.TECH II SEM EXAMINATIONS, DECEMBER - 2010 CAD/CAM (COMMON TO ME, MECT, MEP, AME) Time: 3hours Max.Marks:80 Answer any FIVE questions All questions carry equal marks --1.a) b) Discuss about various types of automation with examples. Explain the working principle of direct view storage tube display with a neat sketch. [8+8] Explain Raster Scan Graphics with a neat diagram. Reflect the polygon whose vertices are A(-1,0), B(0, -2), C(1,0) and D(0,2) about the lines (a) horizontal line y = 2 and (b) vertical line x = 3. [6+10] What is meant by sweep ? Discuss in detail the various types of sweep techniques. A cubic Bezier curve is described by the four control points: (1,1), (3,2), (6,3), (7,2). Find the tangent to the curve at t = 0.35. [6+10] What are the basic commands in drafting? Explain the use of any five commands with examples. [16] Write the block format of G02, G41 and G 81 preparatory functions used in NC programming It is required to mill the cavity of the component shown in Figure 1. The cutter radius diameter is 20 mm. Write a manual program considering the cutter size into account. The spindle speed if 600 RPM. The feed rate is 100 mm/min. [6+10]

2.a) b)

3.a) b)

4.

5.a) b)

6.a) b) 7.a) b) 8.a) b)

Define Part Families, Parts classification and coding. What is Production Flow Analysis? Discuss the various steps involved in PFA. Distinguish between Inspection and Testing. What is CMM? Explain various types of CMM with neat sketches.

[6+10]

[6+10]

Discuss various types of material handling systems with a neat sketch. Explain about various types of computerized components in a CIM environment. [8+8] --ooOoo--

Code.No: 07A6EC04

R07

SET-3

III B.TECH II SEM EXAMINATIONS, DECEMBER - 2010 CAD/CAM (COMMON TO ME, MECT, MEP, AME) Time: 3hours Max.Marks:80 Answer any FIVE questions All questions carry equal marks --1.a) b) 2.a) b) Discuss the role of computers in industrial manufacturing. Explain the working principle of raster refresh display with a neat sketch.

[8+8]

Explain two dimensional transformations with an example. A triangle ABC having vertices A (1,1), B (1,7) and C (5,4) is scaled by 3 units in x-direction and then rotated by 300 in anticlockwise direction keeping point (1,1) fixed. Find the transformation matrix. [8+8] What is lofting ? Explain with an example. Draw the Bezier curve with the following control points (1,2), (3,4), (6, -6) and (10,8). [6+10] What are the various types of editing commands used in drafting? Explain them with an example. [16] Define different methods of expressing a circle in APT language. It is required to make a stepped shaft as shown in Fig.1 on a NC machine. Write the manual part program. Take speed = 3000 rpm and feed = 30 mm/minute. [6+10]

3.a) b)

4.

5.a) b)

6.a) b) 7.a) b) 8.a) b)

Discuss about various types of classification and coding systems. With an example explain Multi Class coding system. What is SQC? Explain role of various control charts in SQC. Explain various types of non-contact inspection methods. . Describe the role of human workers in the future automated factory. What is CIM? Discuss the scope of CIM in a manufacturing industry. --ooOoo--

[8+8]

[8+8]

[8+8]

Code.No: 07A6EC04

R07

SET-4

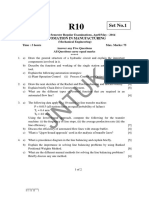

III B.TECH II SEM EXAMINATIONS, DECEMBER - 2010 CAD/CAM (COMMON TO ME, MECT, MEP, AME) Time: 3hours Max.Marks:80 Answer any FIVE questions All questions carry equal marks --1.a) Classify manufacturing industries on the basis of type of production, plant layout and automation. b) Explain the working principle of inkjet printer with a neat sketch. [8+8] 2.a) b) What is a database ? Explain various types of database models. A line having end points (3,3) and (5,5) is reflected about a line with equation y = 2x + 3. Find the final position of the line. [10+6] Distinguish between wire frame and solid modelling. Generate a Bezier curve using the following control points: (2, 0), (4,3), (5,2), (4,-2), (5,-3) and (6, -2). [6+10] What are the various types of basic geometric commands used in drafting? Explain at least five types of commands with an example. [16] Explain the salient features of a CNC machining centre. Write a NC part program to drill four holes in a work piece using a drilling machine as shown in Figure 1. The work piece is a rectangular plate of 200 mm x 100 mm x 15 mm. The diameter of holes is 10 mm. Take feed rate of 0.10 mm/rev and spindle speed of 800 rpm. Assume the target point is located at x = - 10 mm, y = -10 mm and z = 10 mm. The work piece surface is fixtured such that its bottom surface is 30 mm above the machine tool table surface so as to provide sufficient clearance beneath the part for drilling through holes. [6+10]

3.a) b)

4.

5.a) b)

6.a) b) 7.a) b)

What is Group Technology? Explain the various methods of grouping parts into part families. Describe retrieval-type of CAPP system with an information flow chart. [8+8] What is Quality Control? Discuss the role of computers in Quality Control. What are various types of non-contact inspection methods? Explain about machine vision inspection system. . [8+8]

8. (a) Discuss about various types of computer control systems (b) What is CIM? Discuss the benefits of CIM in modern manufacturing systems. --ooOoo--

[8+8]

Você também pode gostar

- Manual of Engineering Drawing: British and International StandardsNo EverandManual of Engineering Drawing: British and International StandardsNota: 3.5 de 5 estrelas3.5/5 (4)

- Chapter 1 Introduction To AutoCADDocumento34 páginasChapter 1 Introduction To AutoCADGroup 4 Soft SkillsAinda não há avaliações

- Mechanics of Materials (Best BOOK)Documento595 páginasMechanics of Materials (Best BOOK)HundeejireenyaAinda não há avaliações

- Shivayu Aerospace CompanyDocumento33 páginasShivayu Aerospace CompanyVasudevan Govindaraj100% (1)

- Concurrent EngineeringDocumento238 páginasConcurrent EngineeringBest ThingAinda não há avaliações

- Complete PCB Design Using OrCAD Capture and PCB EditorNo EverandComplete PCB Design Using OrCAD Capture and PCB EditorNota: 5 de 5 estrelas5/5 (1)

- Dental Lab Freedom of Choice: InlabDocumento23 páginasDental Lab Freedom of Choice: InlabJsjwiwia DjjdjsjaAinda não há avaliações

- Model-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelNo EverandModel-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelAinda não há avaliações

- ME-mit Admission FormDocumento1.057 páginasME-mit Admission FormBittu50% (2)

- Combustion of FuelDocumento18 páginasCombustion of FuelSandeep BuntyAinda não há avaliações

- Siemens Industry JournalDocumento88 páginasSiemens Industry JournalhifyAinda não há avaliações

- Systems Engineering Principles and PracticeNo EverandSystems Engineering Principles and PracticeNota: 3.5 de 5 estrelas3.5/5 (4)

- Set No - 1: CODE NO: 07A6EC04Documento4 páginasSet No - 1: CODE NO: 07A6EC04Jithesh VAinda não há avaliações

- R07 SET-1: Code No: 07A6EC04Documento4 páginasR07 SET-1: Code No: 07A6EC04Jithesh VAinda não há avaliações

- CAD/CAM exam questions and answersDocumento8 páginasCAD/CAM exam questions and answersideepujAinda não há avaliações

- R07 Set No. 2Documento7 páginasR07 Set No. 2nandusp1Ainda não há avaliações

- Set No. 1Documento4 páginasSet No. 1venkey355Ainda não há avaliações

- Cad CamDocumento4 páginasCad Camdurga323Ainda não há avaliações

- BTME 2nd Year AssignmentDocumento15 páginasBTME 2nd Year AssignmentshishunalAinda não há avaliações

- rr410302 Cad CamDocumento5 páginasrr410302 Cad CamSrinivasa Rao GAinda não há avaliações

- Embedded Systems Model Question PaperDocumento6 páginasEmbedded Systems Model Question PaperSubramanyaAIyerAinda não há avaliações

- JNTU Industrial Management Exam QuestionsDocumento7 páginasJNTU Industrial Management Exam Questionszahid_polyAinda não há avaliações

- Code No: 127BD - Jawaharlal Nehru Technological University Hyderabad B. Tech IV Year I Semester Examinations, May/June - 2019 CAD/CAM (Common to ME, AE, AME, MSNTDocumento3 páginasCode No: 127BD - Jawaharlal Nehru Technological University Hyderabad B. Tech IV Year I Semester Examinations, May/June - 2019 CAD/CAM (Common to ME, AE, AME, MSNTKollan Manivardhan ReddyAinda não há avaliações

- Old Q.papers M.tech I SemDocumento15 páginasOld Q.papers M.tech I SemallakagopichandAinda não há avaliações

- B.E. (2003 Patt.)Documento517 páginasB.E. (2003 Patt.)Aniket SankpalAinda não há avaliações

- RR411808 Cad CamDocumento5 páginasRR411808 Cad CamSrinivasa Rao GAinda não há avaliações

- Embedded Signal Processing QuestionsDocumento14 páginasEmbedded Signal Processing QuestionsManu SeaAinda não há avaliações

- Be Oct 2014Documento108 páginasBe Oct 2014TusharbondeAinda não há avaliações

- Me (2002Documento1.031 páginasMe (2002rahimmullaAinda não há avaliações

- Dba 1651 Sem IIDocumento11 páginasDba 1651 Sem IIthamiztAinda não há avaliações

- M.E. (VLSI & Embedded Systems) Analog & Digital Cmos Ic Design (2008 Course)Documento4 páginasM.E. (VLSI & Embedded Systems) Analog & Digital Cmos Ic Design (2008 Course)Manu SeaAinda não há avaliações

- Hours: Questions:091 IDocumento2 páginasHours: Questions:091 IAsad MohammadAinda não há avaliações

- Set No: 1: Code No: V3212/R07Documento4 páginasSet No: 1: Code No: V3212/R07sanyasirao1Ainda não há avaliações

- Competitive Manufacturing Systems I 002Documento58 páginasCompetitive Manufacturing Systems I 002Rajueswar100% (1)

- bt31R07 P1 10 11 2009rahulDocumento31 páginasbt31R07 P1 10 11 2009rahulashok1261Ainda não há avaliações

- TE 2003&2008 PatternDocumento623 páginasTE 2003&2008 PatternAshashwatmeAinda não há avaliações

- T.E (2008-2012 Pattern)Documento298 páginasT.E (2008-2012 Pattern)Sai Tejesh Reddy GurijalaAinda não há avaliações

- CAM Program for NC MachinesDocumento3 páginasCAM Program for NC Machineskapil kumarAinda não há avaliações

- (3hours) : CompulsoryDocumento7 páginas(3hours) : CompulsorySaima ZainabAinda não há avaliações

- Advanced ManufacturingDocumento5 páginasAdvanced Manufacturingmukesh3021Ainda não há avaliações

- Computer Graphics JNTU Question PaperDocumento4 páginasComputer Graphics JNTU Question PapermannanabdulsattarAinda não há avaliações

- 10me848qpset Design For Manufacturing and AssemblyDocumento13 páginas10me848qpset Design For Manufacturing and AssemblyDr. N. S. Sriram100% (1)

- Advanced Manufacturing ProcessDocumento2 páginasAdvanced Manufacturing Processmukesh3021Ainda não há avaliações

- Question Paper Code:: Reg. No.Documento2 páginasQuestion Paper Code:: Reg. No.ESWARANAinda não há avaliações

- Manufacturing Technology II Exam QuestionsDocumento3 páginasManufacturing Technology II Exam QuestionscbeprabhugmailAinda não há avaliações

- Model Test Paper: ABES Institute of Technology, GhaziabadDocumento2 páginasModel Test Paper: ABES Institute of Technology, GhaziabadYogesh Kumar GaurAinda não há avaliações

- R05 Set No. 2Documento8 páginasR05 Set No. 2nandusp1Ainda não há avaliações

- Me 1Documento436 páginasMe 1Akshay Mane0% (1)

- RT31055102020Documento2 páginasRT31055102020elisha emilianAinda não há avaliações

- M.Tech.: Computer Aided Design and ManufacturingDocumento2 páginasM.Tech.: Computer Aided Design and ManufacturingbrarsidhuAinda não há avaliações

- Cams - 2022 C20Documento3 páginasCams - 2022 C20CALVARY NIBANDHANAAinda não há avaliações

- QP of UniversityDocumento1.132 páginasQP of UniversityKunal Ranjane100% (1)

- Nov Dec 2016Documento3 páginasNov Dec 2016pecoxor808Ainda não há avaliações

- 5 Oct11Documento12 páginas5 Oct11Manu SeaAinda não há avaliações

- 2014 MFE2201 Advanced Manufacturing SystemsDocumento5 páginas2014 MFE2201 Advanced Manufacturing SystemsBernice JohnsonAinda não há avaliações

- WWW Manaresults Co inDocumento2 páginasWWW Manaresults Co inShilpaNanduriAinda não há avaliações

- r05311902 Computer GraphicsDocumento4 páginasr05311902 Computer GraphicsSRINIVASA RAO GANTAAinda não há avaliações

- T.E (2019 Pattern)Documento852 páginasT.E (2019 Pattern)Shubham SagarAinda não há avaliações

- Dec 2009Documento2 páginasDec 2009Asad MohammadAinda não há avaliações

- End Semester Examination, May 2 EC Microprocesso: 008 /COEIIC-311: RSDocumento10 páginasEnd Semester Examination, May 2 EC Microprocesso: 008 /COEIIC-311: RSDheeraj AnandAinda não há avaliações

- B.E. (IT) (Semester - I) : (2008 Course)Documento3 páginasB.E. (IT) (Semester - I) : (2008 Course)prathmesh suryawanshiAinda não há avaliações

- Automation in Manufacturing Exam QuestionsDocumento8 páginasAutomation in Manufacturing Exam QuestionsPradeepkumarKatgiAinda não há avaliações

- SPOS - Pune University (E&TC)Documento3 páginasSPOS - Pune University (E&TC)aniruddhaphatak93Ainda não há avaliações

- ME (2002 & 2008 Patt.) PDFDocumento1.132 páginasME (2002 & 2008 Patt.) PDFadheshAinda não há avaliações

- Modeling and Simulation of Logistics Flows 3: Discrete and Continuous Flows in 2D/3DNo EverandModeling and Simulation of Logistics Flows 3: Discrete and Continuous Flows in 2D/3DAinda não há avaliações

- Course Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE TotalDocumento2 páginasCourse Code Category Hours / Week Credits Maximum Marks L T P C CIA SEE TotalideepujAinda não há avaliações

- Building RepairDocumento8 páginasBuilding RepairideepujAinda não há avaliações

- dOM lESSON PLANDocumento6 páginasdOM lESSON PLANideepujAinda não há avaliações

- Cost Report EdditedDocumento25 páginasCost Report EdditedideepujAinda não há avaliações

- A Guide To Building Maintenance and RepairDocumento40 páginasA Guide To Building Maintenance and RepairAndre MarsAinda não há avaliações

- Department of Mechanical Engineering Graduate Feedback FormsDocumento1 páginaDepartment of Mechanical Engineering Graduate Feedback FormsideepujAinda não há avaliações

- Mid Exam or Internal Question BankDocumento2 páginasMid Exam or Internal Question BankideepujAinda não há avaliações

- Me I SemDocumento92 páginasMe I SemideepujAinda não há avaliações

- Unit-Wise Question BankDocumento1 páginaUnit-Wise Question BankideepujAinda não há avaliações

- Expert Systems With Applications: Ali Shemshadi, Hossein Shirazi, Mehran Toreihi, M.J. TarokhDocumento3 páginasExpert Systems With Applications: Ali Shemshadi, Hossein Shirazi, Mehran Toreihi, M.J. TarokhideepujAinda não há avaliações

- 0075327-3 0 PDFDocumento12 páginas0075327-3 0 PDFideepujAinda não há avaliações

- Strength of Materials James BoydDocumento392 páginasStrength of Materials James BoydideepujAinda não há avaliações

- Rakshith Course File Part 1 r15Documento82 páginasRakshith Course File Part 1 r15ideepujAinda não há avaliações

- St. Peter's Engineering College budget for 2017-18Documento2 páginasSt. Peter's Engineering College budget for 2017-18ideepujAinda não há avaliações

- ST Peter'S Engineering College: Work Order Request FormDocumento2 páginasST Peter'S Engineering College: Work Order Request FormideepujAinda não há avaliações

- Professional Industrial Engineer PDFDocumento3 páginasProfessional Industrial Engineer PDFideepujAinda não há avaliações

- Account Statement As of 10-01-2018 15:54:43 GMT +0530: TXN Date Value Date Cheque No. Description Debit Credit BalanceDocumento3 páginasAccount Statement As of 10-01-2018 15:54:43 GMT +0530: TXN Date Value Date Cheque No. Description Debit Credit BalanceideepujAinda não há avaliações

- HVAC Cooling Load Estimate SheetDocumento1 páginaHVAC Cooling Load Estimate SheetideepujAinda não há avaliações

- Onkar Pathak: Master of Industrial and Systems EngineeringDocumento2 páginasOnkar Pathak: Master of Industrial and Systems EngineeringideepujAinda não há avaliações

- Gate Me 2011 PDFDocumento22 páginasGate Me 2011 PDFmartiinAinda não há avaliações

- Matlab 13 Install GuideDocumento161 páginasMatlab 13 Install GuideBen Umobi JnrAinda não há avaliações

- 6.assignment QuestionsDocumento10 páginas6.assignment QuestionsideepujAinda não há avaliações

- Course Information SheetDocumento5 páginasCourse Information SheetideepujAinda não há avaliações

- Course File Contents - For StatusDocumento2 páginasCourse File Contents - For StatusideepujAinda não há avaliações

- 6.assignment QuestionsDocumento10 páginas6.assignment QuestionsideepujAinda não há avaliações

- Dme I ConsolidatedDocumento6 páginasDme I ConsolidatedideepujAinda não há avaliações

- Theory of Machines by S K Mondal PDFDocumento123 páginasTheory of Machines by S K Mondal PDFBinoy KrisHna100% (1)

- Maintenance of Facilities & Equipment: Back Up GeneratorsDocumento1 páginaMaintenance of Facilities & Equipment: Back Up GeneratorsideepujAinda não há avaliações

- PMTF Information MemorandumDocumento50 páginasPMTF Information Memorandumghufran1986Ainda não há avaliações

- Ch-11 NC CNC DNC FMS Automation and RoboticsDocumento143 páginasCh-11 NC CNC DNC FMS Automation and RoboticsShafiq AhmadAinda não há avaliações

- Cad Cam Syllabus PDFDocumento2 páginasCad Cam Syllabus PDFBrijesh Kumar ChaurasiyaAinda não há avaliações

- Fixture Design PDFDocumento9 páginasFixture Design PDFali ahmadiAinda não há avaliações

- Operations Management: - Design of Goods and ServicesDocumento26 páginasOperations Management: - Design of Goods and ServicesKhairul AmerAinda não há avaliações

- 03 0450 12 MS Prov Rma 08022023110937Documento24 páginas03 0450 12 MS Prov Rma 08022023110937abin alexanderAinda não há avaliações

- Bharat Forge: India's No. 1 Forging CompanyDocumento13 páginasBharat Forge: India's No. 1 Forging CompanyAkhil SidanaAinda não há avaliações

- Diploma - VIII Fabrication Engg SyllabusDocumento52 páginasDiploma - VIII Fabrication Engg Syllabusprashant4455Ainda não há avaliações

- Nur Aqilah Binti Adnan - 2021505009Documento17 páginasNur Aqilah Binti Adnan - 2021505009cactuswillsaAinda não há avaliações

- Computer Aided Process Planning CAPPDocumento32 páginasComputer Aided Process Planning CAPPعبدالله عبداللهAinda não há avaliações

- Design and Fabrication of 3-Axes Mini CNC Milling MachineDocumento15 páginasDesign and Fabrication of 3-Axes Mini CNC Milling MachinePavaniAinda não há avaliações

- Entry Level Manufacturing JobsDocumento2 páginasEntry Level Manufacturing JobssumitAinda não há avaliações

- Technical MeetDocumento7 páginasTechnical MeetsameertutejaAinda não há avaliações

- HAAS CNC MAGAZINE 1997 Issue 2 - Summer PDFDocumento17 páginasHAAS CNC MAGAZINE 1997 Issue 2 - Summer PDFguytr2Ainda não há avaliações

- CNC Working Centre for Stone - Master One SeriesDocumento32 páginasCNC Working Centre for Stone - Master One Seriesluu huy phuocAinda não há avaliações

- Cim QBDocumento23 páginasCim QBSenthilsuja Kumar67% (3)

- 2.0 PROCESS SELECTION & FACILITY LAYOUTDocumento28 páginas2.0 PROCESS SELECTION & FACILITY LAYOUTShanthiyaah ArumugamAinda não há avaliações

- Automatic Programming For Industrial Robot To WeldDocumento9 páginasAutomatic Programming For Industrial Robot To WeldAgus WidyiantoAinda não há avaliações

- Computer Aided Manufacturing - Janak ValakiDocumento23 páginasComputer Aided Manufacturing - Janak ValakijanakAinda não há avaliações

- A Review of Literature On Employability Skill Needs in EngineeringDocumento15 páginasA Review of Literature On Employability Skill Needs in EngineeringLeong Joshua100% (1)

- Mechanical Eng Handbook 2018Documento117 páginasMechanical Eng Handbook 2018binukAinda não há avaliações

- Introduction To Computer Aided ManufacturingDocumento6 páginasIntroduction To Computer Aided ManufacturingitzgayaAinda não há avaliações

- 50 Exercises - Extruded Boss - BaseDocumento51 páginas50 Exercises - Extruded Boss - Basecốnguat dientuAinda não há avaliações

- CAQC Methods Improve QualityDocumento30 páginasCAQC Methods Improve Qualitymuniraju mAinda não há avaliações

- Manufacture Product Design and Process SelectionDocumento23 páginasManufacture Product Design and Process SelectionShah Maqsumul Masrur TanviAinda não há avaliações