Escolar Documentos

Profissional Documentos

Cultura Documentos

Astmstruct PDF

Enviado por

aferrufino01Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Astmstruct PDF

Enviado por

aferrufino01Direitos autorais:

Formatos disponíveis

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 1 de 6

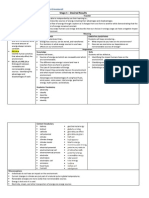

Maryland Metrics: Technical Data METRIC ASTM STRUCTURAL FASTENERS FASTENER MATERIALS AND GRADES U.S. Customary Unit Fasteners

Although metric fastener standards have been available in the US for more than 20 years, metric structural bolting is still not fully implemented in the United States. The Industrial Fasteners Institute publishes an excellent summary of all metric fastener specifications in its Metric Fastener Standards.(1) The specific standards from the American Society for Testing Materials (ASTM) and the American Association of State Highway and Transportation Officials (AASHTO) contain a great deal more information about the geometry, material, manufacturing and marking of these fasteners. Additional information can be found in the AISC Metric Conversion: Load and Resistance Factor Design Specification for Structural Steel Buildings.(2) The following sections describe metric structural bolting but the student should also have some familiarity with the US Customary Unit (USCU) fasteners that have been used throughout the past fifty years. Both USCU and metric fasteners are marked so that iron workers and inspectors can quickly and easily verify that they are using the correct type of fastener (e.g., strength of bolt). The sections that follow show the metric head markings and the figure below shows the markings for the most common types of USCU structural bolts. The most commonly used bolts in the USCU system were A307 bolts (also called "common" or "unfinished" bolts) and A325 bolts although A499 and A490 bolts are also sometimes used. Some common head markings are shown in the figure below. Every bolt head must be marked with the bolt type (e.g., A307-A or A325), an indication of the material (e.g., high-strength material is indicated by three radial lines) and the manufacturers mark (e.g., MFG in the figure).

ASTM F568

ASTM F568 defines materials used for manufacturing a broad category of fasteners with a wide variety of materials strengths. All metric fasteners are made using materials that are specified in ASTM F568. Some classes of bolts in the F568 family that are essentially equivalent to some common types of structural bolts are the following:

� �

Class 4.6 mechanical properties are essentially the same as A307 Grade A, Class 8.8 mechanical properties are essentially the same as A449 and A325 Types 1 and 2 (note: the material is similar to A325 but the geometry is different), Class 8.8.3 mechanical properties are essentially the same as A325 Type 3, a weathering steel, Class 10.9 mechanical properties are essentially the same as A490 Types 1

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 2 de 6

and 2, Class 10.9.3 mechanical properties are essentially the same as A490 Type 3, a weathering steel.

Except for bolts smaller than 5 mm, all bolt heads are marked such that the property class is easily determined as shown in the figure below. The bolt head are also marked with a manufacturers mark (e.g., MFG in the figure). Metric bolts are identified by their nominal diameter and the pitch. A 24-mm diameter bolt with a 3-mm pitch is designated as an M24x3 bolt, the M indicating that this is a metric bolt. Since there is only one pitch per diameter, it is common to refer to metric bolts only with the nominal diameter, for example M24 or M16. The nuts selected for a particular application must match the bolt for both material type and geometry.

Unfinished Bolts

ASTM F568 Class 4.6 fasteners are essentially equivalent to USCU ASTM A307 fasteners. These bolts are often referred to as "common" bolts, "unfinished" bolts or "rough" bolts. Technically they are not really structural bolts at all but are included here because they are often used in bearing connections where the loading is not large or is not critical to the performance or safety of the structure. Such bolts might, for example, be used in a roof truss made up of angle sections in an industrial building or to connect brace members to main structural members. USCU A307 bolts are not proof tested but F568 Class 4.6 bolts are. The proof loads and tensile strengths of Class 4.6 bolts are shown in the table on the following page. Class 4.6 bolts are available in 19 different sizes ranging from as small as a 5 mm diameter to as large as a 100 mm diameter but unfinished bolts smaller than 12 mm or larger than 24 mm would be unusual for structural applications.

ASTM A325M

ASTM A325M bolts are probably the most commonly used fastener for steel construction (ASTM A325M bolts

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 3 de 6

are also sometimes specified as AASHTO M164M bolts in designing transportation structures like bridges). A325 bolts are intended to be tightened to nearly their proof load so that they develop significant bolt tension. Although A325M bolts are made using A568 Class 8.8 material, the geometry of the bolts are larger than common bolts because A325M bolts are always subjected to high tensile loads. A325M bolts have thicker and wider heads to more effectively distribute the head load to the piece and shorter shanks to keep the threads out of the load bearing part of the bolt. These of larger dimensions are referred to as "heavy hex" geometry. A325M bolts are manufactured using material with a minimum yield strength of 660 MPa and a minimum ultimate strength of 830 MPa. There are three types of A325M bolts:

� �

Type 1 -- a general-purpose medium carbon steel materials, Type 2 -- a low-carbon martensite steel for atmospheric temperature applications, and Type 3 -- a weathering steel suitable for use with sections or plate made using ASTM A588 weathering steel.

ASTM A325M specifies that high strength bolts must be tightened such that the bolt tension is 70 percent of the minimum tensile strength of the bolt (see also LRFD Table J3.1). The minimum tensile strength and the minimum bolt installation tension are shown in the table below. The values in the minimum installation strength column are 70 percent of the values in the tensile strength column (e.g., for an M16x2 bolt the minimum installation bolt tension is 91 which is 70 percent of the 130 kN minimum tensile strength).

ASTM A490M

ASTM A490M bolts (also AASHTO M253M) are similar to A325 bolts in that they are heavy-hex geometry but A490 bolts use even higher strength material conforming to F568 Class 10.9. A490 have a minimum yield strength of 940 MPa and a minimum ultimate strength of 1040 MPa.

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 4 de 6

There are three types of A490M bolts:

� �

Type 1 -- a general-purpose medium carbon steel materials, Type 2 -- a low-carbon martensite steel for atmospheric temperature applications, and Type 3 -- a weathering steel suitable for use with sections or plate made using ASTM A588 weathering steel.

ASTM A325M specifies that high strength bolts must be tightened such that the bolt tension is 70 percent of the minimum tensile strength of the bolt (see also LRFD Table J3.1). The minimum tensile strength and the minimum bolt installation tension are shown in the table below. The values in the minimum installation strength column are 70 percent of the values in the tensile strength column (e.g., for an M16x2 bolt the minimum installation bolt tension is 91 which is 70 percent of the 130 kN minimum tensile strength).

METHODS OF TENSIONING BOLTS

When designing slip-critical connections it is very important that the fastener be tightened such that the bolt is in a slightly yielded condition. If a bolt is not tight enough, the bolt tension may not be enough to generate the required friction between the joined parts. If the bolt tension is too large, the bolt may break. The ironworker installing the bolts must, therefore, get the bolt and nut tight enough to develop good friction in the joined pieces while not breaking the bolt. There are four basic methods for making sure a bolt have the proper amount of tension: (1) the turn-of-the-nut method, (2) calibrated wrenches, (3) tension indicating bolts and (4) direct tension indicators.

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 5 de 6

Turn-of-the-Nut Method

The turn-of-the-nut method is the easiest and least expensive method for installing fasteners with the proper bolt tension. The procedure generally works as follows. An iron worker tightens the bolt and nut as tight as possible using a spud(3) wrench or a pneumatic impact wrench. A chalk mark or paint is then made on the bolt and nut. The bolt is tightened further by either hammering on the spud wrench or using a pneumatic impact wrench until the rotating part has rotated the required amount. The paint or chalk mark shows how far the part has rotated and the rotation is always measured relative to the rotation of the bolt. The number of turns past snug is dependent on the length of the bolt relative to its diameter and the geometry of the two surfaces. The previous table shows the number of rotations for a variety of bolt lengths for flat horizontal surfaces.

Calibrated Wrench Method

Most iron workers use pneumatic power wrenches, also called impact wrenches, to tighten bolts. Calibrated wrenches can be set to stall at a specified torque thereby achieving the correct amount of bolt tension. Unfortunately, calibrated wrenches need to be calibrated at least every day since they tend to lose their calibration relatively quickly.

Tension Indicating Bolts

An indirect way to verify that a bolt has been properly tightened is to use tension indicating bolts like the one shown at the right. This type of bolt is tightened with a special pneumatic wrench -- one face of the wrench tightens the nut and the other holds the torque pattern head shown at the right side in the figure. When the bolt is tightened to the proper load, the right end of the bolt shank snaps off. An ironworker would simply keep tightening the bolt until the tip breaks off and an inspector could easily verify that the bolt was properly tighten by ensuring that the tip is missing.

Direct Tension Indicator Method

Direct tension indicators are special washers with grooves on one face. As the bolt is tightened the groves on the washer flatten out. An iron worker or inspector knows that the correct tension has been achieved when the gap between the washer and the piece will no long accept a gauge of a specified thickness. The washers are said to directly indicate the tension since they have a know crush load. With the exception of the calibrated wrench method where the stall speed is set, the tension in the bolt is not directly measured. In fact, it is not necessary to be too careful about achieving some specific amount of tension as long as the bolt is in the yielded condition. If the bolt is over tightened it will probably break in which case the iron worker simply needs to remove the broken bolt and install a new one.

References

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Maryland Metrics: Metric ASTM Structural Fasteners

Pgina 6 de 6

1. IFI, Metric Fastener Standards, The Industrial Fastener Institute, 1505 East Ohio Building, Cleveland, OH (1983). 2. AISC, Metric Conversion: Load and Resistance Factor Design Specification for Structural Steel Buildings (DRAFT), American Institute of Steel Construction, Chicago (1992). 3. The term "spud" wrench is a contribution of Irish-American iron workers. A spud wrench is a hand wrench with the grip at one end and a long tapered handle at the other. The tapered handle is similar to a sailor's marlin spike and is used to jamb into a series of holes to help align the holes before inserting the bolt. The name "spud" comes from the Gaelic word for a digging stick, "spaid." The potato is called a spud because the tool used to dig them out was a simple stick. data source credit: http://www.icaen.uiowa.edu/~sdesign1/Text/fasteners_si.html

Phones: (800) 638-1830 or (410) 358-3130 are available Monday-Friday 8:30 AM to 5:30 PM Eastern time. Faxes: (800) 872-9329 or (410) 358-3142 & E-mail are available anytime. Warehouse & showroom hours are Monday-Friday 10 AM to 5:30 PM. [ To: Maryland Metrics home page ] [ To: Maryland Metrics Product Guide ] [ e-mail to Maryland Metrics ] Please note that all Trademarks and Tradenames are the property of their respective owners. copyright 2001, 2008 maryland metrics -- all rights reserved -- ver dd20f astmstruct.htm

http://mdmetric.com/tech/astmstruct.htm

24/09/2010

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Ansi-Isa 67.04.01 2006Documento23 páginasAnsi-Isa 67.04.01 2006HumbertoRalphOrtizAbacheAinda não há avaliações

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocumento15 páginasA Presentation On Lithium Bromide Absorption Refrigeration SystemAyub GNAinda não há avaliações

- RKB Bearing Tolerances and Radial Internal ClearancesDocumento36 páginasRKB Bearing Tolerances and Radial Internal ClearancesCAT CYLINDERAinda não há avaliações

- Jis g3444-1 PDFDocumento1 páginaJis g3444-1 PDFRokhmatuSivaAinda não há avaliações

- The Core-Periphery Model With Three Regions and MoreDocumento25 páginasThe Core-Periphery Model With Three Regions and MoreJomit C PAinda não há avaliações

- The Knelson Concentrator: Application and Operation at RoseberyDocumento9 páginasThe Knelson Concentrator: Application and Operation at RoseberyVivek RanganathanAinda não há avaliações

- Kcet Chemistry 2015Documento11 páginasKcet Chemistry 2015BURHAN0% (1)

- Australia Shell Spirax S6 AXME 80W-140 TDSDocumento2 páginasAustralia Shell Spirax S6 AXME 80W-140 TDSfdpc1987Ainda não há avaliações

- Pre Stressed ConcreteDocumento5 páginasPre Stressed Concreteridzwan8789Ainda não há avaliações

- ENSC3024 Ideal Gas Lab 1Documento12 páginasENSC3024 Ideal Gas Lab 1Max ShervingtonAinda não há avaliações

- Pushin Fitting PDFDocumento4 páginasPushin Fitting PDFvishal.nithamAinda não há avaliações

- Servo Solenoid ValvesDocumento204 páginasServo Solenoid Valveschandushar1604100% (1)

- Micrologic Trip CurvesDocumento3 páginasMicrologic Trip Curves322399mk7086Ainda não há avaliações

- Chemistry: Pearson EdexcelDocumento28 páginasChemistry: Pearson EdexcelNyraStardollAinda não há avaliações

- UBD Physics Unit 2 - Energy and The EnviornmentDocumento5 páginasUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaAinda não há avaliações

- Unit 2 Electrical InstrumentDocumento45 páginasUnit 2 Electrical InstrumentBoopathy C P100% (1)

- Electronic Structure of The N-V Center in Diamond: ExperimentsDocumento14 páginasElectronic Structure of The N-V Center in Diamond: Experimentspranav1999Ainda não há avaliações

- Bombas La Curva PDFDocumento15 páginasBombas La Curva PDFAnonymous Iuubt0uAinda não há avaliações

- Flux Cored Arc Welding I (Gas Shielded)Documento38 páginasFlux Cored Arc Welding I (Gas Shielded)greatsteelAinda não há avaliações

- Y12 Chemistry Initial AssessmentDocumento58 páginasY12 Chemistry Initial AssessmentGeorge DrakeAinda não há avaliações

- Stats&Prob - WEEK 1Documento3 páginasStats&Prob - WEEK 1Ji PaoAinda não há avaliações

- Airspeed Indicator - Wikipedia, The Free EncyclopediaDocumento6 páginasAirspeed Indicator - Wikipedia, The Free EncyclopediaAnand TRAinda não há avaliações

- One-Factor Short-Rate Models: 4.1. Vasicek ModelDocumento8 páginasOne-Factor Short-Rate Models: 4.1. Vasicek ModelbobmezzAinda não há avaliações

- Mmse Journal Vol11Documento319 páginasMmse Journal Vol11Mmse JournalAinda não há avaliações

- Formation of ElementsDocumento17 páginasFormation of ElementsWinde SerranoAinda não há avaliações

- c1 - Intermolecular ForcesDocumento69 páginasc1 - Intermolecular ForcesNabilah MustafaAinda não há avaliações

- Ari Faba Plus - Kvs Diagram PDFDocumento32 páginasAri Faba Plus - Kvs Diagram PDFgiuseppe.timpone1100% (1)

- A Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisDocumento12 páginasA Lens Is Defined As A Portion of A Refracting Medium Bordered by Two Curved Surfaces Which Have A Common AxisSaif HassanAinda não há avaliações

- Analysis of Non-Uniform Torsion in Curved Incrementally Launched PDFDocumento14 páginasAnalysis of Non-Uniform Torsion in Curved Incrementally Launched PDFYONAS GOSAAinda não há avaliações

- Lx400 PDFDocumento3 páginasLx400 PDFbalab2311Ainda não há avaliações