Escolar Documentos

Profissional Documentos

Cultura Documentos

SJ Repacking Longsweep STD

Enviado por

Vipul ShahTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SJ Repacking Longsweep STD

Enviado por

Vipul ShahDireitos autorais:

Formatos disponíveis

l

C

P

l

=

5

0

0

5

2

(

2

7

)

Cbiksan

SwivcI ]oints

Rcpacking lnstructions

Att tONGSWffP MODftS

STANDARD SfRVlCf

TooIs Rcquircd

1ruerc pllers, evl or slmller polnted tool, vlse, screvdrlver

DlSASSfMtY

1. Remove ball plug snap rings using Truarc pliers.

2. Remove ball plugs using awl or pointed tool.

3. Secure female component in vise with ball plug holes positioned over a

suitable container.

4. Rotate male component. Ball bearings should drop out.

NOTE: It may be necessary to thin hardened lubricant with petroleum

solvent.

5. Separate male and female components after ball bearings have been

removed.

CAUTION: Do not damage machined surfaces when separating

components. Protect sealing surfaces at all times.

6. Carefully remove old packing from female packing chamber using a screw-

driver.

CAUTION: Use extreme care in removing old packing to prevent

damage to sealing surfaces.

7. Remove grease retainer and secondary O-ring seal from female

component except as indicated in Inset A.

8. Clean all parts with petroleum solvent.

9. Inspect parts for excessive wear, corrosion or other damage.

a. Inspect ball races for dents or grooves.

b. Check male and female components for excessive erosion or

corrosion.

c. Carefully inspect the inside surfaces of elbows for evidence of

erosion or corrosion.

WARNING: Longsweep Swivel Joints exhibiting a wall thickness

below the minimum allowable shall be removed from service.

Replace all parts that show evidence of damage in the ball races,

sealing surfaces, or other areas.

10. Sealing surfaces must be completely smooth. Remove minor scratches or

pitting by polishing with fine abrasive.

11. Reclean all parts after polishing to remove metal particles and foreign

matter.

ASSfMtY

1. Apply a thin coat of lubricant to ball races, sealing surfaces and new

packing.

CAUTION: Make sure correct lubricant is used for intended service

conditions. (See Lubricant Data).

2. Install new grease retainer in female component or on male. (See

inset A.)

CAUTION: Retainer lip must face away from ball races.

3. Install new secondary O-ring seal on male component.

4. Install new packing in female component packing chamber.

CAUTION: Anti-extrusion ring must face outward, toward ball races.

5. Secure female component in vise with ball plug holes on top.

6. Insert male component into female component.

7. Look through ball plug hole to align ball races.

8. Drop balls into races. Rotate male component and add balls until

all three races are filled with the proper number of balls.

WARNING: Count the number of balls installed in each race to be

certain that the proper number of balls are installed. Incorrect

number may cause binding or excessive wear and reduced pressure or

structural capacity.

9. Insert ball plugs. (See Inset B for 3 XHTL.)

10. Insert ball plug snap rings.

11. Lubricate bearings as follows:

a. Install grease fitting

b. Use small, hand-held grease gun to force a small amount of

lubricant through the fitting.

CAUTION: Make sure correct lubricant is used for intended service

conditions (See Lubricant Data).

c. Rotate male component 90 degrees (quarter turn) and add more

grease through each fitting.

d. Repeat step c (above) two more times, lubricating at each

quarter turn.

e. Check smoothness of rotation.

CAUTION: Excessive lubrication can cause swivel to bind, distort the

anti-extrusion ring and displace the packing. Use only enough

lubricant to obtain smooth rotation. If the swivel is more difficult to

rotate after greasing than before, or if lubricant is detected on inside

of primary packing, or if distortion of packing is noted on inner

diameter, disassemble joint and carefully inspect all seals for damage.

Replace damaged seals and any packing which has been distorted or

displaced into the bore.

12. Remove grease fitting and install lube fitting plug.

13. After assembly the swivel joint should be pressure tested to the

full rated pressure.

1rlrece shovn. Some

models heve tvo reces

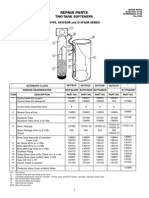

NO. GREASE LUBE BALL REPAIR PACKING BALL PLUG SINGLE PLUG

MODEL RACES RETAINER PLUG PLUG KIT SET SET SET

1 LS10, LS15 3 a d f 3143455 3143454 3143211 3142813

1-1/2 HPLS 2 b d f 3127210 3137068 3129000 3139416

1-1/2 LS10, LS15 3 a d f 3143327 3142960 3143211 CF

2 XHLS 2 c d f 3126627 3137070 3129001 3139418

2 LS10, LS15 3 a d f 3139666 3143979 3144007 3139418

2 EHLS 2 c d f 3127211 3137071 3129001 3139418

2 LS20 3 a d f 3144633 3144636 3144007 3139418

3 HPLS 2 c d g 3124431 3137074 3129004 3139421

3 XHTL 3 c e h 3122371 3137079 3129006 3139423

3 LS7.5, LS10, LS15 3 a d f 3144795 3144796 3144007 3139418

3 EHTL 3 c e h 3124644 3137081 3129007 3139424

3 LS20 3 a d f 3145398 3145262 3145264 CF

4 XHTL 3 a e j CF 3137083 3137086 CF

4 LS15 3 a d f 3145399 3145263 3145264 CF

4 LS10 3 a d f 3261027 3261023 3145264 CF

Division Headquarters

6677 North Gessner Road

Houston, Texas 77040 U.S.A.

Phone: 713/510-6800

Fax: 713/510-6803

http://www/fmc/com/Eteg

E-mail: fluid_control@fmc.com

FMC Fluid Control Division

2825 West Washington

P.O. Box 1377

Stephenville, Texas 76401

Toll Free: 1-800-772-8582

Fax: 254/968-5709

Anchorage, Alaska

Phone: 907/563-3990

Fax: 907-563-5810

Aberdeen, Scotland

Phone: (44) 1224/898-555

Fax: (44) 1224/249-460

The Netherlands

Phone: (31) 172/470-024

Fax: (31) 172/470-026

LaTalaudiere, France

Phone: (33) 4/7747-5015

Fax: (33) 4/7747-5014

Singapore

Phone: (65) 862-3659

Fax: (65) 861-8251

Dubai, United Arab Emirates

Phone: (971) 4/310-948

Fax: (971) 4/310-950

Los Morochas, Venezuela

Phone: (58) 65/26901

Fax: (58) 65/23406

Maturin, Venezuela

Phone: (58) 92/220003

Fax: (58) 92/220178

Villahermosa, Mexico

Phone: (52) 93/50-0123

Fax: (52) 93/50-1661

l

C

P

l

=

5

0

0

5

2

(

2

7

)

Odessa, Texas

Phone: 915/550-2084

Fax: 915/366-8538

Broussard, Louisiana

Phone: 318/837-9263

Fax: 318/837-5844

Denver, Colorado

Phone: 303/623-4622

Fax: 303-623-7347

Direct orders to sales offices at the following locations:

FEATURES AND REPLACEMENT PARTS

(a) Female groove, (b) 42 ring, (c) notched ring in male groove, (d) screw in body, (e) screw in ball plug,

(f) rubber plug, no seal, (g) rubber plug, nylon disc, (h) rubber plug, o-ring seal, (j) metal plug, o-ring seal.

CF = Consult Factory

NOTE:

Refer to FMC product catalogs, brochures and installation, operating and maintenance manuals for additional product safety

information or contact FMC at 800/772-8582.

PACKING IDENTIFICATION

Unless otherwise specified on purchase order, or required for application described on purchase

order, FMC will supply nitrile packing with brass anti-extrusion ring (OOB).

Compound

Code* Compound Anti-Extrusion Ring Designation

OO Nitrile Brass OOB

HH Fluorocarbon Rubber Stainless Steel HHS

*Compound code and part number appear on inside diameter of each packing.

Lubricant Temperature Range Container* Part Number

Standard Swivel Joint Lubricant 50F to 212F 2-lb can 3115574

*For special service conditions, consult factory for lubrication recommendations.

LUBRICANT DATA

Você também pode gostar

- Remove & Install Connecting Rod BearingsDocumento4 páginasRemove & Install Connecting Rod BearingsRichard ChuaAinda não há avaliações

- 1CV Overhaul PDFDocumento15 páginas1CV Overhaul PDFsteve@air-innovations.co.zaAinda não há avaliações

- Instructions: 6 Speed Transmission Super KitDocumento14 páginasInstructions: 6 Speed Transmission Super KitthailanAinda não há avaliações

- Prensa Kurt D688Documento17 páginasPrensa Kurt D688Arnulfo Larragoitia Martinez100% (1)

- Lubrication Specifications Universal JointsDocumento6 páginasLubrication Specifications Universal Jointsmohammed barghothiAinda não há avaliações

- Group 4 Disassembly and Assembly: 1. Main PumpDocumento23 páginasGroup 4 Disassembly and Assembly: 1. Main PumpPriscila RodriguesAinda não há avaliações

- Preventive Maintenance of Electroglas Eg2001Documento8 páginasPreventive Maintenance of Electroglas Eg2001Tan Chiang Li100% (1)

- Air CylinderDocumento4 páginasAir Cylindersimbua720% (1)

- 4000 Winch NarDocumento14 páginas4000 Winch NarJITENDRA KUMAR SHARMAAinda não há avaliações

- Motor Eaton 1000 A PartsDocumento12 páginasMotor Eaton 1000 A PartsJuan Hernan Valdiviezo DiasAinda não há avaliações

- Connecting Rod ReplacementDocumento11 páginasConnecting Rod Replacementfjafarvand100% (1)

- Workshop Manual Newage 85m2 GearboxesDocumento15 páginasWorkshop Manual Newage 85m2 Gearboxesdjordjes123Ainda não há avaliações

- G3406 Connecting Rod BearingsDocumento4 páginasG3406 Connecting Rod BearingsnobodymagdesignAinda não há avaliações

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Documento9 páginasRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Disamble Cylinder HeadDocumento17 páginasDisamble Cylinder HeadFredy Mauricio Diaz VargasAinda não há avaliações

- TCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UpDocumento8 páginasTCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UphidraulicAinda não há avaliações

- Atlas Copco Service & Maintenance InstructionsDocumento20 páginasAtlas Copco Service & Maintenance Instructionsaaron alicanoAinda não há avaliações

- Figure 1-126 Rear Oil Seal Removal: Series 60 Service ManualDocumento2 páginasFigure 1-126 Rear Oil Seal Removal: Series 60 Service ManualvictoverAinda não há avaliações

- Harley-Davidson Dyna Shortshots Staggered Installation Instructions PART# 17217Documento4 páginasHarley-Davidson Dyna Shortshots Staggered Installation Instructions PART# 17217Isai GarzaAinda não há avaliações

- SKF Wheel Bearing Installation Guide With Free End PlayDocumento20 páginasSKF Wheel Bearing Installation Guide With Free End Play2bjornAinda não há avaliações

- Snow Thrower Operator's ManualDocumento32 páginasSnow Thrower Operator's ManualDavid Weisenberger100% (1)

- DisassemblyDocumento4 páginasDisassemblyKalpeshkumar PatelAinda não há avaliações

- Hydraulic Pump Repair GuideDocumento234 páginasHydraulic Pump Repair GuideVeselina Gaidarska91% (22)

- Kawasaki ZX9R 98-99Documento307 páginasKawasaki ZX9R 98-99motomech100% (3)

- Assembly TECHLOK 3 Fold English v3 2013Documento2 páginasAssembly TECHLOK 3 Fold English v3 2013Chup AlaAinda não há avaliações

- 3304-3306 Medidas de Bielas y BancadasDocumento3 páginas3304-3306 Medidas de Bielas y BancadasJuan Carlos RivasAinda não há avaliações

- 03-04 SID Rear Service Guide - Rev - BDocumento5 páginas03-04 SID Rear Service Guide - Rev - Bmaxpower2004Ainda não há avaliações

- Rockwell Hardness Tester Model 3814 Setup GuideDocumento15 páginasRockwell Hardness Tester Model 3814 Setup GuidecdokepAinda não há avaliações

- 320D & 320D L Excavator Hydraulic System SchematicDocumento15 páginas320D & 320D L Excavator Hydraulic System SchematicchanlinAinda não há avaliações

- Ajuste de Carburador Honda ATCDocumento3 páginasAjuste de Carburador Honda ATCRigobertoAinda não há avaliações

- Remove & Install Bucket CylinderDocumento8 páginasRemove & Install Bucket CylinderchanlinAinda não há avaliações

- ZT 6000 VSDocumento14 páginasZT 6000 VSdesign_artAinda não há avaliações

- ISX 871 Flywheel RunoutDocumento13 páginasISX 871 Flywheel RunoutJ.T. NoneyaAinda não há avaliações

- LT 77Documento50 páginasLT 77begbie5100% (1)

- Install piston governorDocumento2 páginasInstall piston governorJose ChuctayaAinda não há avaliações

- Mitsubishi Transfer Case Recall BulletinDocumento20 páginasMitsubishi Transfer Case Recall BulletinSteven LewisAinda não há avaliações

- คู่มือบำรุงรักษา root blowerDocumento17 páginasคู่มือบำรุงรักษา root blowervarayutjAinda não há avaliações

- Toyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairDocumento18 páginasToyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairROSA GIMENEZAinda não há avaliações

- KZ1000 KZ1100Documento370 páginasKZ1000 KZ1100motomech100% (12)

- Cummins Ism, QSMDocumento11 páginasCummins Ism, QSMibnu67% (6)

- Cummins Ism QSM PDFDocumento11 páginasCummins Ism QSM PDFEng-AhmedRashadAinda não há avaliações

- R&I Track Roller MenDocumento5 páginasR&I Track Roller MenDanAinda não há avaliações

- Grid Coupling Installation InstructionsDocumento2 páginasGrid Coupling Installation Instructionsakashwsl92Ainda não há avaliações

- RD Circulating ValveDocumento6 páginasRD Circulating ValvearslanadeelAinda não há avaliações

- 2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXDocumento34 páginas2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXYadi RomaAinda não há avaliações

- Choke Technical Manual - RADocumento16 páginasChoke Technical Manual - RAGuilherme Vanni100% (1)

- 904 RebuidDocumento7 páginas904 RebuidDaniel WildAinda não há avaliações

- Fox Shocks Float and Float 2 RebuildDocumento22 páginasFox Shocks Float and Float 2 RebuildJules De MontignyAinda não há avaliações

- Mini Lathe Dismantling and Reassembly Guide PDFDocumento18 páginasMini Lathe Dismantling and Reassembly Guide PDFkennkki100% (4)

- 2011 Ford Expedition Oil Pan PDFDocumento9 páginas2011 Ford Expedition Oil Pan PDFAnonymous yGKSwu8lP0Ainda não há avaliações

- DD15 Detroit DieselDocumento10 páginasDD15 Detroit Dieselstarsky100% (4)

- Rear SealDocumento9 páginasRear SealHammad Uddin JamilyAinda não há avaliações

- Telescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPDocumento14 páginasTelescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPdaryanto widodoAinda não há avaliações

- Installation - Instruction Instruction - File 47 v1Documento4 páginasInstallation - Instruction Instruction - File 47 v1DavidAinda não há avaliações

- Triumph Service Bulletin 1964Documento48 páginasTriumph Service Bulletin 1964tr_freundeAinda não há avaliações

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNo EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingNota: 4.5 de 5 estrelas4.5/5 (9)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003No EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Nota: 5 de 5 estrelas5/5 (1)

- Blanking Chart HT Pin 01D680 Rev 002Documento1 páginaBlanking Chart HT Pin 01D680 Rev 002Vipul ShahAinda não há avaliações

- Manual Torque WrenchDocumento2 páginasManual Torque WrenchVipul ShahAinda não há avaliações

- Sa 516Documento4 páginasSa 516Vipul ShahAinda não há avaliações

- Lobestar NozzleDocumento2 páginasLobestar NozzleVipul ShahAinda não há avaliações

- FMC Color CodeDocumento1 páginaFMC Color CodeVipul ShahAinda não há avaliações

- Cisco As5300 Voice GatewayDocumento12 páginasCisco As5300 Voice GatewayAbderrahmane AbdmezianeAinda não há avaliações

- Fundamentals 2014Documento959 páginasFundamentals 2014Angelo Vittorio VettorazziAinda não há avaliações

- LogDocumento27 páginasLogmilli0chilliAinda não há avaliações

- Design of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockDocumento10 páginasDesign of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockStalynMEcAinda não há avaliações

- OD Main Switch & OD OFF Indicator Light CircuitDocumento4 páginasOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoAinda não há avaliações

- Recovering Valuable Metals From Recycled Photovoltaic ModulesDocumento12 páginasRecovering Valuable Metals From Recycled Photovoltaic ModulesNguyễn TriếtAinda não há avaliações

- Electronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEDocumento2 páginasElectronic Ticket Receipt, November 03 For MR ARAYA GEBRESLASSIE BERHEMengstu Gebreslassie50% (2)

- bbk-lt2614-lt3214 Service Manual PDFDocumento42 páginasbbk-lt2614-lt3214 Service Manual PDFrj arcinasAinda não há avaliações

- Engineering Data, Summary of Productivity 2022Documento2 páginasEngineering Data, Summary of Productivity 2022Listya AnggrainiAinda não há avaliações

- 13-2021مواصفات الفنية لقطع غيار المكيفاتDocumento4 páginas13-2021مواصفات الفنية لقطع غيار المكيفاتTawfeeq Al-HababbiAinda não há avaliações

- Software Hardware Tech x86 VirtDocumento9 páginasSoftware Hardware Tech x86 VirtwyfwongAinda não há avaliações

- Oracle Database Question Bank 1Documento5 páginasOracle Database Question Bank 1subbaraomca2010Ainda não há avaliações

- Report On Corporate Communication Strategy Analysis ofDocumento38 páginasReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMAinda não há avaliações

- Duotone GuideDocumento1 páginaDuotone Guideapi-648378651Ainda não há avaliações

- Adhokshaj Mishra: Thwarting The Surveillance in Online CommunicationDocumento24 páginasAdhokshaj Mishra: Thwarting The Surveillance in Online CommunicationGauravRajAinda não há avaliações

- Sanju MT 799 PT Swi 100kDocumento2 páginasSanju MT 799 PT Swi 100kSumantri On LineAinda não há avaliações

- Tyre ManufacturingDocumento18 páginasTyre ManufacturingniteshkrisAinda não há avaliações

- Programmability in SPSS 16 & 17, Jon PeckDocumento36 páginasProgrammability in SPSS 16 & 17, Jon PeckJasmin MaricAinda não há avaliações

- 4c - Expanded - RevisedDocumento132 páginas4c - Expanded - RevisedMartín Serena75% (4)

- Player Alex's SEO-Optimized Character Sheet for Antero VipunenDocumento2 páginasPlayer Alex's SEO-Optimized Character Sheet for Antero VipunenAlex AntiaAinda não há avaliações

- PDF Saa6d140e 2 Seriespdf CompressDocumento8 páginasPDF Saa6d140e 2 Seriespdf CompressNathawatAinda não há avaliações

- Msds Thinner 21-06Documento8 páginasMsds Thinner 21-06ridhowibiiAinda não há avaliações

- The Top 200 International Design Firms - ENR - Engineering News Record - McGraw-Hill ConstructionDocumento4 páginasThe Top 200 International Design Firms - ENR - Engineering News Record - McGraw-Hill ConstructiontarekhocineAinda não há avaliações

- Wa0001Documento8 páginasWa0001varshasharma05Ainda não há avaliações

- Rising Stem Ball ValveDocumento6 páginasRising Stem Ball ValveAnupam A. GandhewarAinda não há avaliações

- Star S07FS32DR Water Softener Repair PartsDocumento1 páginaStar S07FS32DR Water Softener Repair PartsBillAinda não há avaliações

- UAV Course SyllabusDocumento3 páginasUAV Course Syllabushindaputra374100% (3)

- COSTECH Accelration of Innovation ImbejuDocumento42 páginasCOSTECH Accelration of Innovation Imbejuhamidumajid033Ainda não há avaliações

- 12 Fa02Documento4 páginas12 Fa02corsovaAinda não há avaliações

- Yellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousDocumento4 páginasYellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousSuman BajracharyaAinda não há avaliações