Escolar Documentos

Profissional Documentos

Cultura Documentos

Calculations/Design Procedures Basic Fire Protection Requirements For Hydrocarbon Hazards Offshore Platforms

Enviado por

aravoof84Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Calculations/Design Procedures Basic Fire Protection Requirements For Hydrocarbon Hazards Offshore Platforms

Enviado por

aravoof84Direitos autorais:

Formatos disponíveis

Calculations/Design Procedures Basic Fire Protection Requirements for Hydrocarbon Hazards Offshore Platforms

The primary purpose of this design manual is to present a recommended calculation procedure to determine basic fire protection requirements for hydrocarbon hazards encountered in today's "typical" offshore platforms. Today's offshore platform operator must be safety and fire conscious, and concerned about minimizing fire losses and operational down time. The requirements, type of equipment and quantity of extinguishing agent for fire control on offshore drilling platforms are dictated by location. Due to the different kinds of hazards encountered on offshore platforms, it is recommended that two types of extinguishing agents be provided. Dry Chemical Protection should be provided to extinguish three-dimensional fires, pressure fed fires (both gaseous and liquid) and electrical fires. Aqueous Film Forming Foam should be provided to extinguish spill and pool fires and to secure and cool liquid hydrocarbon spills. Systems of this type, combining the rapid fire extinguishing capabilities of dry chemical as well as their ability to extinguish three-dimensional fires with the sealing and securing capabilities of an aqueous film forming foam, are of particular importance for protection of flammable liquid hydrocarbon hazards. DESIGN PARAMETERS The parameters of sizing fire-extinguishing equipment for any platform should include the following points:

Flow rate of extinguishing agent Minimum flow time of extinguishing agent Accessibility of equipment by platform personnel

on a level where there are no operating personnel, the fire fighting personnel will have access to the deck from only the two stairways. This dictates the positioning of major fire fighting equipment at the point where the stairways connect to each deck. If operating personnel are on the level where the fire occurs, the first reaction is to run to the stairway. Therefore, the most accessible points for the location of the major fire fighting equipment is the stairway area of each deck. The flow rate of extinguishing agent from a handline is effectively limited by the amount of reaction force one man can withstand and still maintain accurate control of the discharge nozzle. The maximum flow rate of dry chemical a man can accurately control is 5 to 8 lbs. /sec. The maximum flow rate of AFFF is approximately 60 gpm per hand line using 1" hose. The maximum flow rate required from a given piece of equipment is the flow rate per handline times the maximum number of handlines which could be used to combat any single fire. This maximum flow rate should be reviewed as to the maximum flow rate available vs. the potential hazards on that particular deck. (Drip pan size etc.) In review, the following standards should be used: D.C. (Max area size in sq. ft.)x(.04 lbs./sec./sq. ft.) x (60 sec. flow) = Unit size Example: (100 sq. ft.)x (.04 lbs. /sec. /sq. ft.)x (60 sec. flow) = 240 lbs. Unit Capacity Taking into consideration that based on a horizontal impinging natural gas pressure fire each 8 lbs. /sec., hand line can extinguish a fire fed at the rate of 8 mm s.c.f.d. This is based on data covering a gas pressure range up to 750 psi. The information is applicable for higher pressures since the primary effect of pressure in this case is an extension in detachment of the flame zone from the gas source. Due to the complexity of equipment, possible wind

THESE FACTORS DICTATE Taking into consideration that offshore platforms normally are designed with two levels. The decks are normally connected by two stairways on opposite sides of the platforms. If a fire breaks out

CHEMGUARD 204 S. 6th Ave Mansfield, Tx 76063 (817) 473-9964 FAX (817) 473-0606 www.chemguard.com

DATA SHEET #D10D03212 REVISION: 09/2005

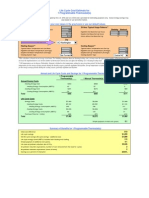

conditions, presence of rapidly heated material (stainless steel tubing etc.), it is recommended that the unit capacity size be calculated by taking the maximum flow rate from the unit times a minimum flow time of one minute. CALCULATIONS: FOUR-PILE PLATFORM On a "typical" four-pile platform, there are two stairways on opposite sides of the platform connecting the two decks. At these two locations, position both an AFFF and a dry chemical hose reel. The dry chemical unit, which contains two hose reels, should be mounted on the sub-deck (where it will be least susceptible to damage). If the unit is placed adjacent to a stairway connection, it will be necessary to furnish only one remote reel (via the other stairway) on the sub-deck. Position two remote reels by each stairway location on the upper deck. There should be five dry chemical hose reels on the platform. (2 on the dry chemical unit and 3 remotes.) The maximum number, which would normally be used at one time, would be three on the lower deck. With a maximum of three 8-lbs. /sec. reels being used at once, a total flow rate from the unit of 24 lbs. /second would be required. Taking a minimum flow time of 1 minute, we calculate the size of the unit to be: (24 lbs. /sec.) x (60 sec.) = 1,440 lbs. of D.C.

1 - CDC1500 Lb. Capacity DC Unit 3 - Remote Reels with 100' x 1" Hose & Nozzle 3 - Remote Actuators Stations 1 - CPM150 AFFF Unit 4 - Remote Reels with 100' x 1" Hose & Nozzle 3 - Remote Actuators Stations CALCULATIONS: EIGHT-PILE PLATFORM On a "typical" eight-pile platform, there are two stairways on opposite sides of the platform. There is a multiple wellhead area separated from the production area by a firewall. Position both an AFFF and a dry chemical hose reel at the stairway connection points on both decks. In addition, due to the extremely large wellhead hazard area, position an AFFF and a dry chemical reel on the production side of the firewall adjacent to both doors. The dry chemical unit contains two hose reels and should be mounted on the sub-deck if possible. With the unit placed adjacent to a stairway connection it will be necessary to provide only three remote reels on the sub-deck. Position two remote reels on the top deck. The total number of hose reels on the platform will be seven. (2 on the D.C. unit and 5 remote reels). With a maximum of five reels being used on the lower deck for one fire and allowing a maximum flow rate of 8 lbs. /sec. for each handline, the maximum flow rate from the unit would be 40 lbs. sec. With a minimum flow, time of one min. the size of the required unit is calculated at: (40 lb. /sec.) x (60 sec.) = 2,400 lbs. of D.C. The closest available dry chemical unit would be 2,500 lbs. and have a maximum flow rate capacity of 100/125 lbs. /sec. Reviewing the systems fire extinguishing capability vs. the platform hazards we find the following: Max. Hazard Area (40 lbs. /sec.) (.04 lb./sec./ft.2) = 1,000 ft. (40 lbs. /sec.) (8 mm scfd.) = 40 mm scfd. (8 lbs. /sec.) This system should be adequate for hydrocarbon hazards found on most eight-pile platforms. To calculate the AFFF unit size, six hose reels will be required, one by each stairway connection on both decks and one by each fire wall door. With each reel having a flow rate of 60 gpm, the maximum number to be used on any single fire would be the four on the sub-deck. The maximum flow rate

The closest size available dry chemical unit would be a 1,500-lb. capacity, which will supply up to 50/70-lbs. /sec. flow if required. A review of the systems fire extinguishing ability vs. the platform hazards, the extinguishing capabilities are as follows: Max. Hazard Area (24 lb. /sec.) x (.04 lb./sec./ft.2) = 600 ft.2 Max. Pressure Fire (24 lb. /sec.) x (8 mm scfd.) = 24 mm scfd. (8 lb. /sec.) Unless a four pilons platform has unusually large hazards, the above system should handle all the pressure and (3) three-dimensional fires that could be expected. The calculations determine that the system required on four-pile platform consists of the following equipment:

CHEMGUARD 204 S. 6th Ave Mansfield, Tx 76063 (817) 473-9964 FAX (817) 473-0606 www.chemguard.com

DATA SHEET #D10D03212 REVISION: 09/2005

required from the AFFF unit would be (60 gpm) x (4) = 240 gpm. The calculations dictate a unit size of not less than 240-gallon capacity. A 300-gallon capacity unit is to be supplied. The unit will provide a maximum flow rate of 300 gpm. A review of the fire extinguishing capabilities of the system vs. the platform hazards indicates: Max. Area: ( 240 gpm. ) x (2.5 min.) = 600 sq.ft. (.16 gpm. sq. ft.) Under normal conditions, an eight-pile platform will not have potential spill areas (drip pans etc.) in excess of 600 ft.2. By consolidating the calculations, the system required on an eight pile consists of the following equipment: 1 - CDC2500 Lb. Capacity Dry Chemical Unit 5 - Remote Reels with 150' x 1" Hose & Nozzle 5 - Remote Actuation Stations 1 - CPM300 AFFF Unit 6 - Remote Reels with 150' x1" Hose & Nozzle 5 - Remote Actuation Stations SPECIAL HAZARDS Individual platforms could have hazards, which the basic fire protection system should not be required to handle. These hazards should be analyzed for system application completely separate from the rest of the platform. Examples of these hazards are: storage tanks, compressors, and electrical generating rooms. In many cases, the system application on these hazards should involve automatically actuated systems.

CHEMGUARD 204 S. 6th Ave Mansfield, Tx 76063 (817) 473-9964 FAX (817) 473-0606 www.chemguard.com

DATA SHEET #D10D03212 REVISION: 09/2005

Você também pode gostar

- 06 Calculations and Design ProceduresDocumento3 páginas06 Calculations and Design ProcedureskskadryAinda não há avaliações

- Sprinkler SystemDocumento16 páginasSprinkler SystemNethaji100% (1)

- Explain The Important Design Requirements For A CO Total Flooding SystemDocumento5 páginasExplain The Important Design Requirements For A CO Total Flooding SystemAdarshGuptaAinda não há avaliações

- Coc Oral Exam Preparation: (Part - 15) : Fire & SafetyDocumento14 páginasCoc Oral Exam Preparation: (Part - 15) : Fire & Safetymanoj chawanAinda não há avaliações

- Oisd 144Documento21 páginasOisd 144Ritika VermaAinda não há avaliações

- Foam Sprinkler System CalculationDocumento5 páginasFoam Sprinkler System CalculationJitheesh Sahadevan75% (4)

- Truck and Rail Loading and Unloading Systems: Design InformationDocumento6 páginasTruck and Rail Loading and Unloading Systems: Design InformationDavidMurciaAinda não há avaliações

- Foam Fire Fighting System, RequirementsDocumento16 páginasFoam Fire Fighting System, RequirementsKedar AltekarAinda não há avaliações

- Aircraft Hangar Fire Protection DesignDocumento7 páginasAircraft Hangar Fire Protection DesignmukeshsinghtomarAinda não há avaliações

- Winding and InsulationDocumento6 páginasWinding and InsulationRatilal M JadavAinda não há avaliações

- Emergency Access and Escape: Portable Fire ExtinguishersDocumento1 páginaEmergency Access and Escape: Portable Fire ExtinguishersmeeAinda não há avaliações

- Designing a firewater network for a gas plantDocumento11 páginasDesigning a firewater network for a gas plantHedi Ben MohamedAinda não há avaliações

- FfaDocumento7 páginasFfaPushkar LambaAinda não há avaliações

- Gas Flare Radiation Analysis for Tambak Lorok Power PlantDocumento10 páginasGas Flare Radiation Analysis for Tambak Lorok Power PlantAhmed Semarang100% (1)

- Truck and Rail Unloading SystemDocumento6 páginasTruck and Rail Unloading SystembalavenguAinda não há avaliações

- Fire, ballast and sewage systems on shipsDocumento23 páginasFire, ballast and sewage systems on shipsvincentAinda não há avaliações

- SafetyDocumento2 páginasSafetyPankaj PatilAinda não há avaliações

- CoC Oral Exam Preparation - (Part - 15) - Fire & Safety - Marine StudyDocumento12 páginasCoC Oral Exam Preparation - (Part - 15) - Fire & Safety - Marine StudyShaip SankarAinda não há avaliações

- New Microsoft Word Document (4)Documento20 páginasNew Microsoft Word Document (4)ISH-QUEAinda não há avaliações

- Designing and Drafting of SPL AppliancesDocumento40 páginasDesigning and Drafting of SPL AppliancesSuriya DasAinda não há avaliações

- Tutorial QuestionsDocumento4 páginasTutorial Questionsn01910077kAinda não há avaliações

- New Microsoft Word Document (5)Documento20 páginasNew Microsoft Word Document (5)ISH-QUEAinda não há avaliações

- Tank ProtectionDocumento27 páginasTank ProtectionGustavo Alejandro Flores GarriAinda não há avaliações

- Flare For DesignDocumento4 páginasFlare For DesignChem.EnggAinda não há avaliações

- Truck Rail Loading SystemDocumento5 páginasTruck Rail Loading SystemMitallAinda não há avaliações

- Design Basis Dtd.3.12.2013Documento10 páginasDesign Basis Dtd.3.12.2013Adil MominAinda não há avaliações

- Design Guide For Air Slide Conveyor PDFDocumento4 páginasDesign Guide For Air Slide Conveyor PDFHasan Barzegar Avval100% (4)

- 10Documento19 páginas10Ahmad mkAinda não há avaliações

- Planning and Design of Extraction SystemsDocumento3 páginasPlanning and Design of Extraction SystemsJulio C.Ainda não há avaliações

- Truck and Rail Loading RacksDocumento5 páginasTruck and Rail Loading Racksabdeslem mouloudjAinda não há avaliações

- Assignment (Air Pollution)Documento7 páginasAssignment (Air Pollution)Durga Prasad Murmu0% (1)

- Fire Safety Guidance for Planning ApplicationsDocumento16 páginasFire Safety Guidance for Planning ApplicationsSenghy MaoAinda não há avaliações

- Fire Fighting DESKTOP BH1MFGPs Conflicted Copy 2021 02 06Documento9 páginasFire Fighting DESKTOP BH1MFGPs Conflicted Copy 2021 02 06WutangAinda não há avaliações

- Fire Water Requirement PresentationDocumento17 páginasFire Water Requirement PresentationOlumuyiwa FasehunAinda não há avaliações

- Hydraulic Calculation Tutorial #1Documento9 páginasHydraulic Calculation Tutorial #1Rahul DevaAinda não há avaliações

- FgsDocumento6 páginasFgs312818203016 KAMARAJ J III CMEAinda não há avaliações

- HE General DDDocumento29 páginasHE General DDKrishanu SahaAinda não há avaliações

- OISD-117 Fire Protection System for Oil Storage TanksDocumento29 páginasOISD-117 Fire Protection System for Oil Storage TanksBALAKRISHNANAinda não há avaliações

- Conveyor Belt Fire SafetyDocumento14 páginasConveyor Belt Fire SafetyFeno0% (1)

- Digitally signed wet dust extraction system design reportDocumento17 páginasDigitally signed wet dust extraction system design reportmathan_aeAinda não há avaliações

- Storage Vacuum CollapseDocumento7 páginasStorage Vacuum CollapsebehnamhfAinda não há avaliações

- StandpipeDocumento17 páginasStandpipedipuAinda não há avaliações

- Fire Fightingunit 4Documento164 páginasFire Fightingunit 4Jeffin AsirAinda não há avaliações

- CB FP 2011 37 PDFDocumento1 páginaCB FP 2011 37 PDFabboudAinda não há avaliações

- Tracerase: Operating and Instruction ManualDocumento16 páginasTracerase: Operating and Instruction ManualKrishnaAinda não há avaliações

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Documento10 páginasES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsAinda não há avaliações

- Oisd ReqDocumento2 páginasOisd ReqvivekvpsfeAinda não há avaliações

- For HEMM and Surface Transportation MachineDocumento4 páginasFor HEMM and Surface Transportation MachinebinhhnAinda não há avaliações

- Local Exhaust: Design PrinciplesDocumento12 páginasLocal Exhaust: Design Principlesvalerio.garibayAinda não há avaliações

- 14-ApGreid - Line Sizing Rev.2Documento18 páginas14-ApGreid - Line Sizing Rev.2Dhanny MiharjaAinda não há avaliações

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocumento16 páginasIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalAinda não há avaliações

- Design and Size DuctworkDocumento6 páginasDesign and Size Ductworkwilderness_666Ainda não há avaliações

- Estimating Air LeakageDocumento5 páginasEstimating Air Leakagenasirmuzaffar100% (1)

- Fire Protection in Conveyor BeltsDocumento11 páginasFire Protection in Conveyor BeltsHernandoAinda não há avaliações

- Pleasanton LEL Calculation For Fume HoodDocumento3 páginasPleasanton LEL Calculation For Fume HoodTu Diep0% (1)

- Automatic SprinklerDocumento3 páginasAutomatic SprinklerrmaffireschoolAinda não há avaliações

- HeuristicsDocumento19 páginasHeuristicsJesús MorenoAinda não há avaliações

- Scramjets: Fuel Mixing and Injection SystemsNo EverandScramjets: Fuel Mixing and Injection SystemsAinda não há avaliações

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentNo EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentNota: 4.5 de 5 estrelas4.5/5 (3)

- Calculator Programmable ThermostatDocumento5 páginasCalculator Programmable Thermostataravoof84Ainda não há avaliações

- Air Duct CalculatorDocumento1 páginaAir Duct Calculatoraravoof84Ainda não há avaliações

- Fire Apparatus Pump Theory 1Documento25 páginasFire Apparatus Pump Theory 1aravoof84Ainda não há avaliações

- Mechanical FormulasDocumento5 páginasMechanical FormulasSenthil KumarAinda não há avaliações

- Hvacprogrammematerial 090703025103 Phpapp02Documento95 páginasHvacprogrammematerial 090703025103 Phpapp02aravoof84Ainda não há avaliações

- Induction unit system design manualDocumento35 páginasInduction unit system design manualNahiyan AbdullahAinda não há avaliações

- Hvac Load CalculationsDocumento68 páginasHvac Load CalculationsPrecisionetica100% (2)

- Airconditioningforlargemultistorybuildings 110522204801 Phpapp02Documento23 páginasAirconditioningforlargemultistorybuildings 110522204801 Phpapp02aravoof84Ainda não há avaliações

- Cooling Coil FormulasDocumento2 páginasCooling Coil Formulasaravoof84Ainda não há avaliações

- Why Change The Chilled Water Temperature RangeDocumento6 páginasWhy Change The Chilled Water Temperature RangeShabeer HamzaAinda não há avaliações

- Sustainable HVACDocumento28 páginasSustainable HVACaravoof84Ainda não há avaliações

- Do Building Energy Codes Go Far EnoughDocumento28 páginasDo Building Energy Codes Go Far Enoughvarshneyrk@rediffmail.comAinda não há avaliações

- Almost Everthing For MEPDocumento55 páginasAlmost Everthing For MEPdkpushp100% (4)

- Flow FansDocumento35 páginasFlow Fansaries26march100% (2)

- How To Determine The Sitting and Facing of A Home, Apartment or BuildingDocumento8 páginasHow To Determine The Sitting and Facing of A Home, Apartment or Buildingaravoof84Ainda não há avaliações

- How To Determine The Sitting and Facing of A Home, Apartment or BuildingDocumento8 páginasHow To Determine The Sitting and Facing of A Home, Apartment or Buildingaravoof84Ainda não há avaliações

- Pump Selection CriteriaDocumento5 páginasPump Selection CriteriaAbbas RizviAinda não há avaliações

- Valve & Type of ValesDocumento82 páginasValve & Type of Valesvipinct83% (6)

- Workshop Exercise - Fans and BlowersDocumento3 páginasWorkshop Exercise - Fans and BlowersShukla SuyashAinda não há avaliações

- Air SeperatorDocumento20 páginasAir Seperatoraravoof84Ainda não há avaliações

- Description & Design of Sprinkler SystemsDocumento20 páginasDescription & Design of Sprinkler SystemsIrfanshah2013100% (4)

- Calculation of Invert LevelsDocumento8 páginasCalculation of Invert Levelsaravoof84100% (1)

- Mechanical FormulasDocumento5 páginasMechanical FormulasSenthil KumarAinda não há avaliações

- Hong Kong Stormwater Drainage Manual: Planning, Design and ManagementDocumento108 páginasHong Kong Stormwater Drainage Manual: Planning, Design and ManagementFree Rain Garden Manuals0% (1)

- Tips For Filling Out The Performance Planning and Appraisal Form (PPAF)Documento5 páginasTips For Filling Out The Performance Planning and Appraisal Form (PPAF)Sudhakar ChollangiAinda não há avaliações

- WWDocumento13 páginasWWonspsnonsAinda não há avaliações

- Module 123Documento7 páginasModule 123aravoof84Ainda não há avaliações

- Air Duct CalculatorDocumento1 páginaAir Duct Calculatoraravoof84Ainda não há avaliações

- Air-Water Systems For Air Conditioning Design ManualDocumento60 páginasAir-Water Systems For Air Conditioning Design ManualSchreiber_Dieses100% (1)

- Resume Dr. R.N.MukerjeeDocumento13 páginasResume Dr. R.N.MukerjeeRahul Mukerjee100% (1)

- PLF-76T Service ManualDocumento40 páginasPLF-76T Service Manualapi-3711045100% (1)

- Amcor 2016Documento69 páginasAmcor 2016Romulo AlvesAinda não há avaliações

- 2007 Bachu Etal CO2 Storage Capacity EstimationDocumento14 páginas2007 Bachu Etal CO2 Storage Capacity EstimationArindam Obzi GuptaAinda não há avaliações

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDocumento4 páginasObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- Motor (ABB Type)Documento50 páginasMotor (ABB Type)Rolando Nunez del Prado B.Ainda não há avaliações

- How Electric Cars Work: A Guide to EV TechnologyDocumento4 páginasHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoAinda não há avaliações

- FMC1278Documento132 páginasFMC1278Herick Douglas PereiraAinda não há avaliações

- CZ-RTC4 - Service ManualDocumento68 páginasCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- GRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSDocumento32 páginasGRUNDFOS DATA BOOKLET FOR HYDRO MULTI-S BOOSTER SYSTEMSHeri SulasionoAinda não há avaliações

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocumento6 páginasRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoAinda não há avaliações

- Siemens Actuator M3K20FXNDocumento10 páginasSiemens Actuator M3K20FXNbasil christopherAinda não há avaliações

- Method of Lighting CalculationsDocumento3 páginasMethod of Lighting CalculationsSpencer Josh RegedorAinda não há avaliações

- Orient Price List NewDocumento3 páginasOrient Price List Newrohan12345670% (1)

- 39CQ Iom 06302014Documento20 páginas39CQ Iom 06302014Non Etabas GadnatamAinda não há avaliações

- Stoke's LawDocumento15 páginasStoke's LawPratik YadavAinda não há avaliações

- Spe 21970 MSDocumento13 páginasSpe 21970 MSasu jaranAinda não há avaliações

- Checklist Water Audit v1Documento19 páginasChecklist Water Audit v1hammad.phistreamAinda não há avaliações

- Chapter 8 ObjectivesDocumento3 páginasChapter 8 ObjectivesdaddlescoopAinda não há avaliações

- 2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSDocumento47 páginas2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSArhamAinda não há avaliações

- 240-56063867 Transformer and Reactor Rapid Pressure Rise RelayDocumento6 páginas240-56063867 Transformer and Reactor Rapid Pressure Rise RelayMichael NgubaneAinda não há avaliações

- Projects Oil and Gas BrochureDocumento20 páginasProjects Oil and Gas BrochureRussel John RamosAinda não há avaliações

- B23 B24 User Manual PDFDocumento168 páginasB23 B24 User Manual PDFAurel BodenmannAinda não há avaliações

- Measuring Instrument Accuracy LimitsDocumento2 páginasMeasuring Instrument Accuracy LimitsDan DanubiusAinda não há avaliações

- New Holland Engine F4ge Backhoe en Service ManualDocumento10 páginasNew Holland Engine F4ge Backhoe en Service Manualenrique100% (47)

- Fupact ISFL SeccionadorDocumento1 páginaFupact ISFL SeccionadormmAinda não há avaliações

- Lumidor Minimax XTDocumento4 páginasLumidor Minimax XTPaky PakicAinda não há avaliações

- SUPER PPTPPTDocumento15 páginasSUPER PPTPPTsrinuAinda não há avaliações

- 937 Letter AttchamentDocumento8 páginas937 Letter AttchamentNeeta RautelaAinda não há avaliações

- Case 1088 Repair Manual (Crawler Excavator) PDFDocumento971 páginasCase 1088 Repair Manual (Crawler Excavator) PDFrida100% (7)