Escolar Documentos

Profissional Documentos

Cultura Documentos

Sound Velocity in Soap Foams

Enviado por

flamedc00kieDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sound Velocity in Soap Foams

Enviado por

flamedc00kieDireitos autorais:

Formatos disponíveis

CHIN. PHYS. LETT. Vol. 29, No.

10 (2012) 104301

Sound Velocity in Soap Foams

WU Gong-Tao(), L Yong-Jun(), LIU Peng-Fei(), LI Yi-Ning(), SHI Qing-Fan()

School of Physics, Beijing Institute of Technology, Beijing 100081

(Received 8 June 2012)

The velocity of sound in soap foams at high gas volume fractions is experimentally studied by using the time dierence method. It is found that the sound velocities increase with increasing bubble diameter, and asymptotically approach to the value in air when the diameter is larger than 12.5 mm. We propose a simple theoretical model for the sound propagation in a disordered foam. In this model, the attenuation of a sound wave due to the scattering of the bubble wall is equivalently described as the eect of an additional length. This simplicity reasonably reproduces the sound velocity in foams and the predicted results are in good agreement with the experiments. Further measurements indicate that the increase of frequency markedly slows down the sound velocity, whereas the latter does not display a strong dependence on the solution concentration.

PACS: 43.35.Ae, 43.20.+g, 82.70.Rr

DOI: 10.1088/0256-307X/29/10/104301 small bubbles, there are few experiments and theories of the propagation of sound through foams. Recently, Mujica and Fauve measured the sound velocity in a shaving foam and studied the aging and frequency dependence of the sound propagation.[14] They found that sound velocity decreases from 65 to 53 ms1 with coarsening foam, which was comparable to the experimental measurements by Orenbakh and Shushkov in a liquid with the gas volume fraction up to 0.95,[15] and moreover the sound absorption varies signicantly with both the foam age and the excitation frequency. We note that during the coarsening in the above experiments the bubble radius ranges from 15 to 50 m. To the best of our knowledge, the sound propagation through foams containing large sized bubbles (in the order of magnitude of 110 mm) is less reported experimentally up to now, and what the relationship between the bubble size and the sound velocity looks like is of much interest. On the other hand, some theoretical attempts were devoted to describe the sound propagation in foams.[1619] Kann proposed a lm mode to explain the eect of sound retardation in foams, who approximated foam to a periodic arrangement of cubic bubbles in two dimensions.[18,19] Compared with the experimental results, the theoretical prediction by Kann underestimates the size dependence of sound velocities. In fact, the conguration of foams is amorphous-like, and the periodic arrangement of bubbles inevitably deviates the realistic sound propagation in foams. In this Letter, we experimentally measure the sound velocity in foams that contain bubbles with diameters up to the order of 10 mm, study its frequency and concentration dependence, and nally we propose a simple model to explain the present mea-

Foam-like materials are characterized by their disordered structure and low density, which produces many excellent properties in mechanics and thermodynamics. They have attracted intensive interest over the past several years.[14] As one of the most common foams, soap foams provide an ideal prototype in the relevant elds; their structural characteristics and thermodynamic properties have been frequently studied from both experimental and theoretical points of view, for example, sound velocity is a crucial parameter of measuring the elastic modulus of materials.[510] The studies of sound velocity in a gas-liquid bubble system can be traced back to the work of the propagation of sound through a liquid containing bubbles.[7] Early theories and experiments showed that sound velocity in bubbly liquids are rather small, even at very small gas volume fractions, which is lower than not only the velocity in the pure liquid but also the value in the pure gas. An important mechanism responsible for the sound wave damping is the scattering of sound by the bubble walls.[11,12] This process is thought of as a non-dissipation phenomenon, and the energy is just removed from the incident sound waves and then re-emitted in other directions. It is noted that the above-mentioned results were obtained based on the liquid at very small gas fractions and compared with the acoustic wavelength, the bubble size is so small that the eect of bubble interactions on the sound propagation can be ignored. In this case, theoretical studies predicted that the sound velocity increases relative to the results in a pure liquid medium.[6,13] If the gas fraction is large enough, the bubbles are in contact with each other and ultimately form foams. In contrast to the considerable work on liquids containing

Supported by the National Innovative Experimental Projects for University Students, and the National Natural Science Foundation of China under Grant Nos 10975014 and 51171027. Corresponding author. Email: qfshi123@bit.edu.cn 2012 Chinese Physical Society and IOP Publishing Ltd

104301-1

CHIN. PHYS. LETT. Vol. 29, No. 10 (2012) 104301

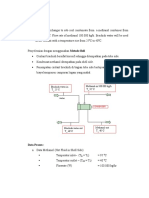

surements. The experiments were carried out by using the time dierence method. Figure 1(a) schematically shows the experimental setup. The transducer A produces a sound wave with the frequency in a range from 2 to 45 kHz that is excited by a signal source and is received by receiver B . The acoustic signals at the transducer and the receiver are recorded using an oscillograph, and then the time interval t for the sound propagation between the transducer and the receiver can be determined through the time dierence between the two signals from the oscillograph. The propagation distance l was xed to 45 cm prior to each measurement by adjusting the location of the receiver on a slide by using knob E . Thus, the sound velocity is available via the ratio between the distance and the time interval. Each measurement is repeated several times and the sound velocity nally results from a simple average. The experiments were performed in an atmospheric environment and the temperature is kept at 20C. In order to eliminate the errors induced by the experimental setup, we measured the sound velocity in air before each experiment, and then corrected the measured results by comparing with the manual values.

(a) E (b)

air is injected into the solution through a pipe from a tank to produce foam, as shown in Fig. 1(b). During this process a steady gas stream is crucial for obtaining an approximately uniform distribution of bubble size. We treat the bubbles as spheres with diameter d, and count the bubble number N in the top layer whose area is S , thus the bubble diameter can be approximated to d = 2(S/N )1/2 . We rst measured the sound velocity as a function of bubble size at a constant frequency of 17.48 kHz. The sound velocities rise rapidly with increasing bubble diameter in the smaller size range (1 mm< d <12.5 mm), and then asymptotically approach to the value in air (340 ms1 ) as the diameter further increases, as shown in Fig. 2. Compared with the experiments by Mujica and Fauve, the present bubble diameters are much larger (>1 mm), and correspondingly the sound velocities also show larger (the minimum sound velocity exceeds 143 ms1 ). More importantly, the sound velocities in our work are in proportion to bubble diameter, which contradicts the results of Mujica and Fauve.[14] According to the homogeneous model,[20] which was rst proposed to describe the sound propagation in a gas-liquid medium, the sound velocity in the gas-liquid medium c can be expressed as ( c2 = 1 ) 2 + 2 , 1 c1 2 c 2 (1)

A C

Signal source

Oscilloscope

0.5 cm

Fig. 1. (a) Schematic of the experimental setup. A and B are the transducer and the receiver of sound, respectively; C is the signal source, D is the oscillograph and E denotes the knob for adjusting the distance between A and B. (b) The foam used in experiments.

360

)

320 280 240 200 160 120 0 10 20 30 40 50

Diameter (mm)

Fig. 2. Sound velocity as a function of bubble diameter at the frequency of 17.48 kHz.

The solution for producing foams is prepared by adding a commercial detergent into pure water. Meanwhile, in order to avoid the bubbles bursting, a small amount of glycerol is also mixed in. Then, compressive

where and are the density and the gas volume fraction of mixture, respectively; 1 and 2 are the density of liquid and gas, and c1 and c2 are the sound velocities in liquid and gas. The homogeneous model predicts that the sound velocity inversely depends on the gas content when < 0.5, and beyond this value the sound velocity begins to rise with increasing gas content. In our experiments, the foam volume has been much larger than that of the solution. Therefore, the present results actually describe the sound velocity in a large-bubble-size regime. The dierence in sound velocity can be understood as a result of the dierent path of sound propagation in foams. For small gas volume fractions, the sound wave mainly propagates in the liquid, and the scattering of sound by the liquidgas interface is the dominant mechanism of the eect of bubbles on the propagation. In this case, the retardation eect of sound becomes more serious with an increasing amount of bubbles. When the gas volume fraction goes beyond 0.5, a large amount of bubbles tend to aggregate together to form a network conguration of liquid lms. In such a structure, the bubble diameter is comparable to the wavelength, resulting in that a considerable amount of energy transfers through the gas in the bubbles. With the increase of gas fraction, the area of lms decreases and the dissipative eect of liquid-gas interface on sound also weak-

Sound velocity (ms

-1

104301-2

CHIN. PHYS. LETT. Vol. 29, No. 10 (2012) 104301

ens. As a consequence, the sound velocity begins to increase. For foam containing bubbles with an average diameter of 17 mm in our experiments, the measured sound velocity reaches 320 ms1 , and the corresponding wavelength is about 18 mm that approximates to the bubble diameter. When we further increase the bubble size, the sound wavelength is smaller than the bubble diameter. Under this condition, traveling in gas becomes the main mechanism of sound propagation, and the scattering of liquid lms is shown to be much weaker. In other words, the sound propagation is similar to the case in air, as presented in this work.

400

)

velocities can be given by cfoam = cair . (l + l/t) (4)

360 320 280 240 200 160 120 0 10 20 30 40 50

The next problem we are concerned with is how to calculate the parameter l. For the same propagation distance l, the time dierence of sound propagation between the foam and the air medium is t = l(1/cfoam 1/cair ). Assuming that the number of bubbles along the propagation path is Nl , the additional distance l can be written as l = cair t/Nl . For a xed frequency (17.48 kHz was used in our experiments), we nd that the scattering ability of bubble walls is independent of the bubble size. The evidence comes from the approximate constant t/Nl for varying bubbles. Therefore, l is close to a constant of 10 mm. Substituting the value to Eq. (4), we predict the sound velocity versus bubble diameter, as shown by the solid line in Fig. 2, which is in good agreement with the experimental results. This indicates that the present model can reasonably reproduce the sound velocity in foams containing large-size bubbles and, meanwhile, avoid complex mathematic processing.

240

Sound velocity (ms

-1

Frequency (kHz)

In order to describe the sound propagation in foams containing large-size bubbles, here we propose a mean medium model that has an analogy to the homogeneous model mentioned above. In general, after the block of the liquid lm, a sound wave is decomposed into the reected and transmitted parts. The reected wave will interfere with the incident wave. This process proceeds twice considering the two interfaces of a lm. For a foam that is composed of a large number of bubbles, the sound wave is scattered by the lms many times, and moreover, the disordered structure leads to varying incident angles of the sound waves. Therefore, it is very complicated for accurately describing the attenuation and transmission of a sound wave through foams. Regarding these facts, we approximate the foam as a homogeneous gas medium, and the scattering of bubble walls is simply equivalent to the eect of an additional length l. For the propagation distance l, the number of liquid lms k can be written as k l/d. (2) Thus, the equivalent distance of sound propagation s is l (3) s = l + l . d We can readily obtain the sound velocity in air, cair = s/t. Actually, the sound velocity in foams is cfoam = l/t. Thus the relation between the two sound

-1

) Sound velocity (ms

230 220 210 0.0

Fig. 3. Sound velocity versus frequency in foams. The bubble diameter is 5 mm.

0.5

1.0

1.5

2.0

2.5

3.0

Concentration (vol %)

Fig. 4. Sound velocity versus solution concentration. The frequency is 17.48 kHz and the bubble diameter is 5 mm.

We have studied the variation of sound velocity with frequency in foams whose bubbles have a constant diameter of 5 mm. Figure 3 shows that the sound velocity decreases by more than 25% when the frequency increases from 2 to 45 kHz. The similar frequency dependence was also conrmed experimentally by Mujica and Fauve for foams with smallsize bubbles. Furthermore, the present results indicate that the scattering of sound by the bubble becomes more remarkable in the high frequency regime, here a quadratic function is used to t the frequency behavior of sound. Mujica and Fauve argued that the viscous boundary layer decreases with increasing frequency.[14] If the frequency increases enough, the viscous boundary layer decreases well below the bubble wall thickness. This change results in the motion between bubbles. In this case, the thermal dissipa-

104301-3

CHIN. PHYS. LETT. Vol. 29, No. 10 (2012) 104301

tion in the viscous medium may dominate the sound attenuation. Another potential factor inuencing the sound propagation in foams is the concentration of detergent. We measured the sound velocities in foams with the detergent concentration from 0.1 to 3.0vol%. During experiments, the sound frequency was kept at 17.48 kHz and bubble diameter was 5 mm. As shown in Fig. 4, the sound velocities slowly increase with increasing concentration. The most remarkable change induced by increasing concentration is the decrease of surface tension. We measured the surface tension of soap lms in the concentration range of 0 to 50vol% using DataPhysics OCA20. The results show that the surface tension has a rapid decrease, particularly in the range of 05vol%. The decrease of surface tension leads to the shrinking of the pressure difference through the gas-liquid interface according to the YongLaplace equation, which is benecial to the transmission of sound wave. Still, our experimental results show that the frequency dependence is rather weak. In conclusion, we have experimentally measured the sound velocities in soap foams in the regime of a large gas volume fraction. The results show that the sound velocities rise as the bubble diameters increase, and asymptotically approach to the value in air when the diameters exceed 12.5 mm. A simple mean medium model is proposed, which agrees well with the experimental results. We have studied the eect of the sound frequency and the solution concentration

on the sound velocity. The high frequency is found to enhance the sound attenuation, leading to a decrease of sound velocity, whereas there is not a pronounced dependence of sound velocity on the solution concentration.

References

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] Sun Q C and Huang J 2006 Wuli 35 1050 (in Chinese) Sun Q C, Ge W and Huang J 2008 Chin. Sci. Bull. 53 3138 Banhart J 2001 Prog. Mater. Sci. 46 559 Durian D J 1995 Phys. Rev. Lett. 75 4780 Crespo A 1969 Phys. Fluids 12 2274 Caisch R E, Miksis M J, Papanicolaou G C and Ting L 1985 J. Fluid Mech. 153 259 Carstensen E L and Foldy L L 1947 J. Acoust. Soc. Am. 19 481 Fox F E, Curley S R and Larson G S 1955 J. Acoust. Soc. Am. 27 534 Wang W H 2011 J. Appl. Phys. 110 053521 Wang W H 2003 Prog. Mater. Sci. 57 487 Devin C 1959 J. Acoust. Soc. Am. 31 1654 Prosperetti A 1991 J. Fluid Mech. 222 587 Rubinstein J 1985 J. Acoust. Soc. Am. 77 2061 Mujica N and Fauve S 2002 Phys. Rev. E 66 021404 Orenbakh Z M and Shushkov G A 1993 Acoust. Phys. 39 63 Vana F I, Goldfarb I I and Shreiber I R 1992 Sov. Phys. Acoust. 38 139 Goldfarb I I, Shreiber I R and Vana F I 1992 J. Acoust. Soc. Am. 92 2756 Kann K B 2005 Coll. Surf. A 263 315 Kann K B and Kislitsyn A A 2003 Coll. J. 65 31 Nakoryakov V E Pokusaev B G and Shreiber I R 1990 Wave Dynamics of Gas- and Vapor-Liquid Media (Moscow: Energoatomizdat)

104301-4

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Pressure MeasurementDocumento36 páginasPressure MeasurementYohan Plavartala100% (1)

- Shaft Calculation BaseDocumento40 páginasShaft Calculation BaseObaciuIonel100% (1)

- Internal Combustion Engines - H. B. Keswani - 2Documento169 páginasInternal Combustion Engines - H. B. Keswani - 2Salman ShaxShax HeissAinda não há avaliações

- Day 3Documento5 páginasDay 3John Cyril0% (1)

- Questio 1Documento2 páginasQuestio 1Ankit GuptaAinda não há avaliações

- Power Electronics Prof. B.G. Fernandes Department of Electrical Engineering Indian Institute of Technology, Bombay Lecture - 15Documento20 páginasPower Electronics Prof. B.G. Fernandes Department of Electrical Engineering Indian Institute of Technology, Bombay Lecture - 15sunitha vAinda não há avaliações

- Electronic Devices: EEE F214/INSTR F214 Lecture 1-6Documento63 páginasElectronic Devices: EEE F214/INSTR F214 Lecture 1-6KapilAgrawalAinda não há avaliações

- Tugas Perpindahan PanasDocumento20 páginasTugas Perpindahan PanasLiyan Fajar GintaraAinda não há avaliações

- Analytical Evaluation of Third Virial Coefficient With Lennard-Jones (12-6) Potential and Its ApplicationsDocumento6 páginasAnalytical Evaluation of Third Virial Coefficient With Lennard-Jones (12-6) Potential and Its ApplicationsSergey SuvorovAinda não há avaliações

- Composites For Machine Tool Beds: National Institute of Technology Rourkela (India)Documento64 páginasComposites For Machine Tool Beds: National Institute of Technology Rourkela (India)kunalAinda não há avaliações

- Science 1206 Physics Worksheet 12 AccelerationDocumento4 páginasScience 1206 Physics Worksheet 12 Accelerationawash0takuAinda não há avaliações

- Some Interesting Facts About: Mechanical EngineeringDocumento9 páginasSome Interesting Facts About: Mechanical EngineeringHaraprasad SAinda não há avaliações

- Atomic Structure QB 2Documento8 páginasAtomic Structure QB 2vengateshwaran kAinda não há avaliações

- OATBooster Formula Sheet (July 2022) PDocumento11 páginasOATBooster Formula Sheet (July 2022) PzainabAinda não há avaliações

- Design of 765kv Transmission LineDocumento10 páginasDesign of 765kv Transmission LineNaveen SabbavarapuAinda não há avaliações

- Seismic Slope Safety - Determination of Critical Slip Surface Using Acceptability CriteriaDocumento221 páginasSeismic Slope Safety - Determination of Critical Slip Surface Using Acceptability CriteriaJvv GudboyAinda não há avaliações

- Chi, M. T., Slotta, J. D., & de Leeuw, N. (1994) - From Things To Processes: A Theory of Conceptual Change For Learning Science Concepts. Learning and Instruction, 4 (1), 27-43.Documento17 páginasChi, M. T., Slotta, J. D., & de Leeuw, N. (1994) - From Things To Processes: A Theory of Conceptual Change For Learning Science Concepts. Learning and Instruction, 4 (1), 27-43.Lina Sierra100% (1)

- The Evolution of Lifter TechnologyDocumento8 páginasThe Evolution of Lifter TechnologyCristian ViolaAinda não há avaliações

- Kinetic TheoryDocumento26 páginasKinetic TheoryDelano PeteAinda não há avaliações

- Chemistry Lab ReportDocumento6 páginasChemistry Lab ReportVilashenan Sivanasvaran0% (1)

- Dipole Antenna Solution2Documento44 páginasDipole Antenna Solution2David GAinda não há avaliações

- FormulaSheet For EM and SHM v1.1.1Documento1 páginaFormulaSheet For EM and SHM v1.1.1陳輝王Ainda não há avaliações

- Pile Settlement - EnCE 4610Documento36 páginasPile Settlement - EnCE 4610undf25Ainda não há avaliações

- UNITS AND MEASUREMENTS Assignment PDFDocumento3 páginasUNITS AND MEASUREMENTS Assignment PDFvanshika MorAinda não há avaliações

- Diffraction and Interference in QEDDocumento7 páginasDiffraction and Interference in QEDYashAinda não há avaliações

- Time: 2 Hours Maximum Marks - 208: Physics Test (Electrostatics)Documento11 páginasTime: 2 Hours Maximum Marks - 208: Physics Test (Electrostatics)ZomatoswiggyAinda não há avaliações

- Ekaterina Izgorodina Ionic LiquidsDocumento6 páginasEkaterina Izgorodina Ionic LiquidsizabelaAinda não há avaliações

- Rinsing - A Critical Process in Contamination RemovalDocumento6 páginasRinsing - A Critical Process in Contamination Removalfreebee12345Ainda não há avaliações

- Mechanical Properties of Undoped GaAs III Indentation ExperimentsDocumento12 páginasMechanical Properties of Undoped GaAs III Indentation Experimentskelsiu1Ainda não há avaliações

- Vortex Behaviour of An Unbaffled Surface Aerator PDFDocumento6 páginasVortex Behaviour of An Unbaffled Surface Aerator PDFjbsantoAinda não há avaliações