Escolar Documentos

Profissional Documentos

Cultura Documentos

Merlin Diesel Systems Ltd injector calibration and testing documentation

Enviado por

Lucas Man100%(2)100% acharam este documento útil (2 votos)

527 visualizações126 páginastabel

Título original

Tabel Test CR i by Merlin

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentotabel

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(2)100% acharam este documento útil (2 votos)

527 visualizações126 páginasMerlin Diesel Systems Ltd injector calibration and testing documentation

Enviado por

Lucas Mantabel

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 126

MERLIN DIESEL SYSTEMS LTD

189-191, Bradkirk Place, Walton Summit Centre

Preston, Lancashire, PR5 8AJ, England

Tel: +44 (0)1772 694180 Fax: +44 (0)1772 314565

E: sales@merlindiesel.com W: www.merlindiesel.com

Manufacturers part numbers are given for reference purposes only and do not imply that in all cases the parts are of their manufacture.

Illustrations and Technical Data are non-binding and are subject to change as a result of technological progress. DATA REF: MDS-TE 0140-0112

Pumps Parts Test Equipment Filters New Generation Workshops Diagnostic & Vehicle Care Centre

FOR MORE INFORMATION PLEASE CALL 01772 694180

T016- 852

Digital External Micrometer

Range: 0-25mm Resolution: 0.001mm

T016- 848

40x Magnifier

T021- 958

Vacuum pen for steel ball

T021- 959

Insulation Tester for pre-checking

T016- 851

Tweezers for steel ball

New Common Rail Tools & Accessories

MERLIN S350K

New Merlin kit for stage 3 repair

(pilot valve replacement) on all

Bosch common rail injectors

including:-

CRI 2.1 AND CRIN 1, 2 & 3

Consists of:-

T021- 956

Dial gauge holder kit

For measuring ball bearing stroke on all

Bosch common rail injectors.

Supplied with 17 & 19mm adaptors

S350

Armature stroke test unit c/w 3 adaptor

cables

T016- 850

Digital dial indicator 12.5/0.001mm

Range: 12.500 mm

Resolution: 0.001 mm

T021- 957

Pin for T016-850 & T021-956

All parts are available separately

IMPORTANT

IT IS ESSENTIAL THAT PIEZO INJECTORS HAVE A CAPACITANCE AND INSULATION

TEST CARRIED OUT BEFORE CONNECTING TO S3000 AS SEVERE DAMAGE COULD

OCCUR TO THE ELECTRONICS IF FAULTY INJECTORS ARE TRIGGERED.

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

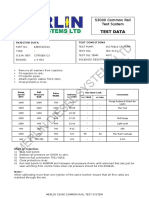

Injector Designation:- 0 445 110 002

Type Designation:- CR/IPS19/ZEREK10S

Manufacturer I.D.:- FIAT 46472233

Engine:- 182 B 4000 1.9 JTD

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Start of Injection (S.O.I)

Stop the test bench. Reduce rail pressure to zero, remove fuel connection, close

cover and SLOWLY increase pressure as per test.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

50-55

<35.0/55.0 Max Fuel

400 250 700

9.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 012

Type Designation:- CR/IPS19/ZERAK10S

Manufacturer I.D.:- DB 611 070 05 87

Engine:- OM611-961/980

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

73-77

<35.0/55.0 Max Fuel

400 250 700

14.0-15.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 015

0 986 435 005

Type Designation:- CR/IPS19/ZEREAK20S

Manufacturer I.D.:- DB 668 070 02 87

Engine:- OM668-941

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

52-57

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 019

Type Designation:- CR/IPS19/ZERAK10S

Manufacturer I.D.:- FIAT 46547897

Engine:- 188 A 2.000 1.9JTD

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Commen

ts

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

60-65

<35.0/55.0 Max Fuel

400 250 700

12.0-13.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 021

0 986 435 007

Type Designation:- CR/IPS19/ZEREK10S

Manufacturer I.D.:- RENAULT 7700 107 165

Engine:- F9Q 1.9DCi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

64-69

<35.0/55.0 Max Fuel

400 250 700

9.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 025

0 986 435 020

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 611 070 06 87

Engine:- OM611-961 611-981

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

65-70

<35.0/55.0 Max Fuel

400 250 700

13.0-14.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 029

Type Designation:- CR/IFS17/ZERAK10S

Manufacturer I.D.:- BMW 13 53 7 785 437

Engine:- 30 6 D1 3.0D

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

61-66

<35.0/55.0 Max Fuel

400 250 700

5.0-7.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 030

0 986 435 011

Type Designation:- CR/IFS17/ZERAK10S

Manufacturer I.D.:- BMW 13 53 2 354 045

Engine:- 30 4 D1 2.0D

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

55-60

<35.0/55.0 Max Fuel

400 250 700

8.0-9.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 035

0 986 435 012

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 613 070 01 87

Engine:- OM611.981 OM611.987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

71-76

<35.0/55.0 Max Fuel

400 250 700

12.0-13.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 036

Type Designation:- CR/IFS17/ZEREW10S

Manufacturer I.D.:- PSA 96533448

Engine:- PSA2.2HDi 4HX

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

62-66

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

Remove all washers from injectors.

Fit injectors to rack.

Fit injector pipe.

Attach injector cables T031-3003.

Close protective cover.

Pump

Speed

RPM

Rail

Pressure

BAR

Pulse

Width

Delivery

cc/1000

Max Back Leak

cc/1000 cc/min

Comments

1000 1000 700 N/A - -

Purge System & Check for

Leaks

1500 1350 900 76-78 <35.0 <55.0 Max Fuel

400 250 700 8-9 <20.0 <9.0 Idle

2000 1350

Run pump

only

N/A <12.5 <25.0 Seat Test

400 150-250 700 N/A - - S.O.I

400 400 60 0.2-3.0 - - Pre Injection

Start of Injection

1) Stop test bench.

2) Reduce rail pressure on S3000 to zero.

3) Remove fuel connection.

4) Close protective cover.

5) Run test bench to 400RPM and increase rail pressure slowly until atomised fuel can just be

seen emitting from nozzle holes when rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow rates are

matched through the set.

S3000 Common Rail

Test System

TEST DATA

INJECTOR DATA

PART No: 0 445 110 038 (0 986 435 016)

TYPE: CR/IFS17/ZEREK10S

O.E.M. REF: RENAULT 8200 010 074

ENGINE: G9T-710

TEST CONDITIONS

TEST PUMP: SUITABLE CR PUMP

TEST OIL: ISO 4113

TEST OIL TEMP: 40C

SOLENOID RESISTANCE @ 20C - 600m

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 044

0 986 435 003

Type Designation:- CR/IPS17/ZEREK10S

Manufacturer I.D.:- PSA 96375360/1980-72

Engine:- 2.0 HDi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

57-60

<35.0/55.0 Max Fuel

400 250 700

10.0-11.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 047

Type Designation:- CR/IFS17/ZEREK10S

Manufacturer I.D.:- BMW 13 53 778 984

Engine:- 30 6 D1

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

70-72

<35.0/55.0 Max Fuel

400 250 700

8.0-9.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 048

Type Designation:- CR/IFS17/ERAK10S

Manufacturer I.D.:- BMW 13 53 7 785 574

Engine:- 25 6D1

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

55-60

<35.0/55.0 Max Fuel

400 250 700

7.0-9.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 049

Type Designation:- CR/IFS17/ZERAK10S

Manufacturer I.D.:- BMW 1353 7 785 983

Engine:-

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Comments

1000 1000 1200 Purge System

2000 1500 1200 N/A Check for Leaks

1500 1350 900 53.0-57.0 Max Fuel

400 250 700 6.0-8.0 Idle

1500 1350 900 <35 Max Back leakage

2000 1350 Run pump only <12.5 Max Back leakage

400 150-200 700 - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 054

Type Designation:- CR/IPL19/ZERAK20S

Manufacturer I.D.:- DB 611 070 11 87

Engine:- OM646-951/961

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

73-77

<35.0/55.0 Max Fuel

400 250 700

14.0-15.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 057

Type Designation:- CR/IPS17/ZERAK10S

Manufacturer I.D.:- PSA 1980-78

Engine:- RHW 2.0HDi 16v

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

55-60

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 059

Type Designation:- CR/IPL19/ZERAK10S

Manufacturer I.D.:- VM 1506 2036F

Engine:- 2.5CRD

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T016-3052 Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

80-83

<35.0/55.0 Max Fuel

400 250 700

11.5-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 062

0 986 435 077

Type Designation:- CR/IPS17/ZEREK10S

Manufacturer I.D.:- PSA 96400887

Engine:- PSA 2.0HDi RHY

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

60-64

<35.0/55.0 Max Fuel

400 250 700

13.0-14.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 063

Type Designation:- CR/IPS17/ZERAK10S

Manufacturer I.D.:- RENAULT 8200010075

Engine:- 1.9 DCi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052 Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Comments

1000 1000 1200 Purge System

2000 1500 1200 N/A Check for Leaks

1500 1350 900 55-60 Max Fuel

400 250 700 10.0-12.0 Idle

1500 1350 900 <35 Max Back leakage

2000 1350 Run pump only <12.5 Max Back leakage

400 150-200 700 0.01-0.1 S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 064

0 445 110 101

Type Designation:- CR/IPL17/ZERAK10S

Manufacturer I.D.:- HYUNDAI 33800-27000

Engine:- D3EA/D4EA

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

65-68

<35.0/55.0 Max Fuel

400 250 700

10.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 068

Type Designation:- CR/IPS19/ZERAK10S

Manufacturer I.D.:- FIAT 46787376

Engine:- 182 B 9.000/ 186 A 6.000 1.9JTD

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors.

Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

77-80

<35.0/55.0 Max Fuel

400 250 700

10.0-11.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 069

Type Designation:- CR/IPS19/ZERAK10S

Manufacturer I.D.:- DB 611 070 08 87

Engine:- OM611-981/OM611-987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

72-75

<35.0/55.0 Max Fuel

400 250 700

14.0-15.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 069

0 445 110 070

Type Designation:- CR/IPS19/ZERAK10S

Manufacturer I.D.:- 611 070 08 07

Engine:- OM611.981 / 987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

72-75

<35.0/55.0 Max Fuel

400 250 700

14.0-15.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 072

0 986 435 071

Type Designation:- CR/IPS19/ZEREAK20S

Manufacturer I.D.:- DB 611 070 09 87

Engine:- OM611-962

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

64-68

<35.0/55.0 Max Fuel

400 250 700

12.0-13.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 075

0 986 435 076

Type Designation:- CR/IPL20/ZEREAK20S

Manufacturer I.D.:- PSA 96386523

Engine:- 8HX / 8HZ

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

43-47

<35.0/55.0 Max Fuel

400 250 700

10.0-11.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 076

0 986 435 077

Type Designation:- CR/IPS17/ZEREK10S

Manufacturer I.D.:- PSA 96533448

Engine:- PSA2.0HDi RHS/RHY

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

60-64

<35.0/55.0 Max Fuel

400 250 700

13.0-14.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 078

Type Designation:- CR/IFS19/ZERAK20S

Manufacturer I.D.:- VOLVO 8658350

Engine:- D5244T

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052 Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

69-71

<35.0/55.0 Max Fuel

400 250 700

9.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 080

0 986 435 084

Type Designation:- CR/IFL17/ZEREAK20S

Manufacturer I.D.:- BMW 13 53 7 787 234

Engine:- 20 4 D4 / 30 6 D2

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

80-84

<35.0/55.0 Max Fuel

400 250 700

14.5-15.5

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 081

Type Designation:-

Manufacturer I.D.:-

Engine:-

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

84.0-87.0

<35.0/55.0 Max Fuel

400 250 700

8.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 083

Type Designation:- CR/IPL17/ZERAK10S

Manufacturer I.D.:- FIAT 55184536

Engine:- 1.3JTD /OPEL 1.3CDTI

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

65-70

<35.0/55.0 Max Fuel

400 250 700

8.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 084

Type Designation:- CR/IFL19/ZERAK10S

Manufacturer I.D.:- RENAULT 8200084534

Engine:- REN 2.2 DCi 110KW G9T-742

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

68-73

<35.0/55.0 Max Fuel

400 250 700

11.5-12.5

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 087

Type Designation:- CR/IFS19/ZERAK10S

Manufacturer I.D.:- RENAULT 8200101135

Engine:- REN 1.9 DCi OPEL 1.9 DTi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052 Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

77-80

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 090

0 986 435 033

Type Designation:- CR/IPL19/ZEREAK10S

Manufacturer I.D.:- DB 668 070 08 87

Engine:- OM668-914

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

56-60

<35.0/55.0 Max Fuel

400 250 700

14.0-15.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 091

Type Designation:- CR/IPL19/ZERAK10S

Manufacturer I.D.:- HYUNDAI 33800-4A000

Engine:- D4CB 2.5CRDI

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

78-84

<35.0/55.0 Max Fuel

400 250 700

5.5-7.5

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 093

0 986 435 035

Type Designation:- CR/IPL19/ZEREAK10S

Manufacturer I.D.:- DB 611 070 03 87

Engine:- OM628-962

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

67-71

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 095

0 986 435 037

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 613 070 05 87

Engine:- OM611-981 / OM611-987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

75-78

<35.0/55.0 Max Fuel

400 250 700

9.0-10.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 096

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- OM612.965

Engine:- MB

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3901 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

70-75

<35.0/55.0 Max Fuel

400 250 700

10.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 098

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- OM612.965

Engine:- MB

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3901 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

70-75

<35.0/55.0 Max Fuel

400 250 700

10.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 100

0 986 435 041

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 611 070 13 87

Engine:- OM611-962

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

67-72

<35.0/55.0 Max Fuel

400 250 700

11.0-12.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 101

Type Designation:- CR/IPL17/ERAK10S

Manufacturer I.D.:- HYUNDAI 33800-27000

Engine:- D3EA/D4EA

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

67-72

<35.0/55.0 Max Fuel

400 250 700

10.5-11.5

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 102

Type Designation:- CR/IFS19/ERAK10S

Manufacturer I.D.:- RENAULT 8200 112 289

Engine:- G9T-722 / G9T-750 2.2DCi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

57-62

<35.0/55.0 Max Fuel

400 250 700

10.0-11.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 106

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 611 070 14 87

Engine:- OM611-981 OM644-987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

73-77

<35.0/55.0 Max Fuel

400 250 700

13.0-14.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 108

0 986 435 047

Type Designation:- CR/IPS19/ZEREAK10S

Manufacturer I.D.:- DB 611 070 16 87

Engine:- OM611-981 OM644-987

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

73-77

<35.0/55.0 Max Fuel

400 250 700

13.0-14.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 110

0 986 435 080

Type Designation:- CR/IPS19/ZEREK10S

Manufacturer I.D.:- RENAULT 8200 100 272

Engine:- 1.9 DCi

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3201 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

64-67

<35.0/55.0 Max Fuel

400 250 700

10.0-11.0

<20.0/9.0 Idle

2000 1350 Run pump only N/A <12-5/25.0 Seat test

400 150-250 700 N/A - S.O.I

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

Injector Designation:- 0 445 110 111

Type Designation:- CR/IPL17/ZERAK10S

Manufacturer I.D.:- Fiat 55192534

Engine:- 192 B / 537 A

Testing Prerequisites

Mount Suitable Test Pump

Test Oil Specification- ISO 4113

Test Oil Temperature- 40 C

Solenoid Resistance @ 20C - 600 m

S3000 Common Rail

Test System

TEST DATA

Remove all washers from injectors

Fit Injectors to Injector rack. Attach cables T031-3003 and metering pipes to

injectors. Close protective cover.

Start of Injection

Stop Test Bench. Reduce Rail Pressure on S3000 to Zero.

Remove Fuel Connection T031-3052. Close Protective cover. Run Test Bench to

400RPM. Increase Rail pressure slowly until atomised fuel can just be seen emitting

from nozzle holes. Rail pressure should be 150-200BAR.

Note:-

When calibrating more than one injector of the same number ensure that all flow

rates are matched through the set.

Pump Speed

RPM

Rail Pressure

BAR

Pulse Width Delivery

cc/1000

Max Back Leak

Mm3st/ccmin

Comments

1000 1000 1200 N/A - Purge

System

2000 1500 1200 N/A - Check for

Leaks

1500 1350 900

85-90