Escolar Documentos

Profissional Documentos

Cultura Documentos

QM

Enviado por

ramvepuriDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

QM

Enviado por

ramvepuriDireitos autorais:

Formatos disponíveis

1) Master Data maintenance Maintain material master QM view with required inspection types as 01/0101/0130 for procurement, 03/04

for in process, 10/11/12 for delivery. Assign characteristics as per requirement (post to inspection stock, check characteristics, automatic assignement etc) (Transaction MM01 / MM02). Maintain sampling scheme (transaction QDP1 / QDP2) & sampling procedure (Transaction QDV1 / QDV2) Maintain inspection method (QS31) Maintain catalogue (Transaction QS31 for code group) & QS41 for selected set). Maintain master inspection characteristics (Transaction QS21). Maintain Quality Info Record for Vendor (Transaction QI01) & for Customer (Transaction QV51) Maintain Inspection Plan (Transaction - QP01) Maintain inspection operation & inspection characteristics for the same in routing for production (Transaction CA01). 2) Process for Procurement Create purchase order (Transaction ME21N). The quality master data is copied to purchase order (like stock type, certificate required). If required create source inspection lot manually (transaction QI07) Carry out source inspection & post the source inspection results (Transaction QE51N). Take usage decision for the source inspection results (Transaction QA11). Post GRN (Transaction MIGO). Inspection lot is created & stock posted to inspection depending on the settings in material master & quality info record). Check the material & post the inspection results (Transaction - QE51N). Take usage decision & post the stock to required stock type (Transaction QA11). 3) Process for Inprocess inspection Create &release Production order (Transaction - CO01) Post the operation results (Transaction - CO11N) Post the quality inspection results (Transaction QE51N) Take usage decision (Transaction - QA11) Confirm Production Order 4) Process for Sales & Distribution Create Sale Order (Tranaction - VA01) Create delivery (transaction - VL01N) when material is ready Inspection lot is generated. Post inspection results (QE51N) Take usage decision (QA11) Post the goods issue (VL02N) Inspection Processing Following are the steps in the process flow of inspection processing Process Flow u2022 Inspection lot Creation u2022 Selection of Inspection Specs u2022 Sample Drawing u2022 Actual Inspection u2022 Results Recording u2022 Defects Recording u2022 Usage Decision u2022 Goods Movement u2022 Information Management System Inspection Lot Creation - Inspection processing begins with the creation of inspection lot, which can be created manually or automatically. There are several functions t\o be carried out that will create and

prepare an inspection lot for processing. Inspection lot gets created as a result of goods movement like goods receipt from Vendor, Goods receipt from Production, Goods issue to Customer....................... Selection of Inspection Specs - As the inspection lot is created an inspection specification gets assigned to it. An inspection specification should be assigned to inspection lot if you want to enter results and take Usage Decision. Inspection specification can be assigned manually by user or automatically by system. There are different criteria considered during inspection specification assignment like the inspection type, inspection lot origin, Material-Vendor-Plant combination......................... Sample Drawing - Relevant sampling procedures are selected, Once the inspection specification is assigned to the inspection lot the sample size is to be calculated for the inspection lot. Calculation of sample size can be done manually or automatically. The system can only calculate the sample size automatically if you use an inspection specification to inspect the goods in the inspection lot. Actual inspection - Inspection method and equipments are selected. Results Recording - Results of Characteristics are recorded. Recording and processing of results for inspection characteristics are carried out. Results recording will be based on Characteristics. The recorded results data will be used for all documentation and evaluation for Quality Control Purposes. Defects Recording - Defects found during inspection are recorded. A defect is any property or attribute of a material, product or process that does not meet the inspection characteristic specifications. You record the defects with the help of predefined defect codes maintained in the inspection catalogs. Once a defect record has been created, it is saved in the system as a quality notification. A quality notification is a system-supported problem message that you can use to process different types of problems relating to poor-quality goods or services. Usage Decision - Decision on Accept/ Reject is recorded. With the Usage Decision we decide if the material is OK/ not OK. Goods Movement - After the Usage Decision the material under inspection is released and posted to Unrestricted/ Blocked Use. List of Masters in QM u2022 Material Master (QM View) u2022 Inspection Plan u2022 Q-Info Record u2022 Inspection Methods u2022 Master Inspection Characteristics u2022 Catalogs / Code Groups / Codes u2022 Sampling Procedures / Sampling Schemes u2022 Dyanamic Modification Rule u2022 Equipment Master u2022 Calibration Plan u2022 Equipment / General Task List Quality Management in Procurement Welcome to the QM-PROC page. Quality department can influence or control the following activities when materials are procured from external suppliers. It supports the procurement activities by means of functions such as: u2022 Vendor Evaluation u2022 Vendor Block u2022 Vendor Release for requests for quotation and purchase orders u2022 Assigning technical delivery terms and quality assurance agreements u2022 Certificate processing u2022 Status administration of the supply relationships u2022 Incoming Inspections u2022 Goods Receipt Inspections Using the functions of the QM in Procurement component, you can: u2022 Manage quality-related information for materials, vendors, and manufacturers in quality info records u2022 Release or block vendors and manufacturers u2022 Monitor the QM systems of vendors and manufacturers u2022 Supply quality documents with requests for quotations and purchase orders u2022 Evaluate vendors on the basis of quality

u2022 Certify vendors or manufacturers that have QM systems implemented, to reduce the inspection requirement u2022 Manage and release supply relationships u2022 Request that quality certificates be submitted with the delivered goods and monitor the receipt of these certificates u2022 Inspect vendor goods at vendor sites (source inspections) u2022 Inspect vendor goods upon receipt (goods receipt inspections) u2022 Manage the posted goods in inspection stock u2022 Block the payment of invoices until the goods have been inspected and accepted u2022 Process goods receipt inspections for manufacturer-specific materials u2022 Inspect goods that have been externally processed when they are returned in a goods receipt The vendor may be required to comply with the technical delivery terms and the quality assurance agreements when a quotation is made. If one of the required documents is not available or not released when a purchase order is opened, the function is blocked. If technical delivery terms are indicated for a material or if a quality assurance agreement exists for a material-vendor combination, the long text is printed out (without attached application files) when the purchase order is created. When the purchase order is placed, the vendor must be released for delivery of the relevant material by the quality department, if this was required. Release of this supply relationship can be restricted to a defined validity period and a maximum delivery quantity. When the goods are ordered, you can stipulate that a certificate is required from the vendor of the material, in addition to compliance with technical delivery terms and quality assurance agreements. If a certificate was not supplied although required, the goods are either posted to blocked stock (if an inspection lot is not generated) or a corresponding status is set in the inspection lot. Receipt of the certificate must be confirmed at the latest when the usage decision is made. Vendor Release - Limits Period/ Quantity, Model, Prototypes, Series. Vendor Inquiry - Includes Technical Delivery Terms, Notify buyer of Inspection Requirements. Vendor Selection - Quality Rating and Quality System. Purchase Order - Technical delivery Terms, QA Agreement, Certificate Requirment. Source Inspection - Inspection Lot Creation intime for receiving date. Inspection for Goods Receipt - Certificate - PO Item, Batch, Goods Receipt, Inspection Lot Creation, Sample drawing instruction/ Inspection Instruction Inspection Completion - Usage/ Stock Posting, Withdrawal from inspection stock from inspection stock, Change Vendor Status. Follow Up Control - Quality Notification, Letter to Vendor Quality Information Record If a quality assurance agreement or a vendor release is required for a material, you must create a quality information record (quality info record). The quality info record determines how the material can be processed further. When a quotation or purchase order is created, the system checks whether a quality info record is required and available for the combination of material and vendor. The system also checks whether the vendor and material-vendor combination is blocked or released for quotations, purchase orders and/or goods receipt. The execution of this check depends on the setting of the QM in procurement control key in the material master. The quality info record displays a vendor block specified in the vendor master, the vendor's QM system, and the lock date. Vendor Master Record The vendor master contains information about the vendors a company uses. This information is contained in individual vendor master records. In addition to the name and address of a vendor, the vendor master record also contains the vendor number and information about the currency and terms of payment that apply to the vendor. In certain cases, you may want block the procurement of goods from a certain vendor (for example, if he delivers poor-quality products). You can block a vendor for quality reasons in two places: In the vendor master record - The vendor block applies to all materials and plants In the Q-info record - The vendor block applies to a specific material and plant For procurement and purchasing functions, the system first checks the vendor master record to determine if the vendor is blocked from these functions. If the vendor is not blocked, the system checks the parameters in the Q-info record, if necessary. The settings in the Q-info record are only checked if a vendor release or quality assurance agreement is specified in the material master record via the control key for QM in procurement.

Quality Management in Production Welcome to the QM-PROD page. During the production process it may be necessary to check the quality at different points or at different intervals or as a result of certain actions. There may be inspections during the process of production within the operation to proceed for next operation or not, inspection at the end of production. With QMProduction we can process the inspection during the production. Following are the QM tasks in prodution u2022 Integration of inspection planning in production operations u2022 Controlling inspections during production u2022 Statistical process control u2022 Defining and valuating batches u2022 Processing internal problem notifications The R/3 quality inspection functions are fully integrated in the logistics processes. An inspection lot has to be created for a quality inspection to take place. Inspection lots are fully integrated in the logistics supply chain. The inspection characteristics in Quality Management (QM) are integrated in the work scheduling (Material Master view) and production processing functions (routing operations) of the Production Planning (PP) component. Inspection Point An inspection point is an identifiable record of inspection results that is assigned to a work or inspection operation. Several inspection points can be assigned to an inspection operation. With inspection points, you can have several inspections and can record multiple sets of characteristic results for an operation. Using inspection points for an inspection during production, we can do the following: u2022 Inspect materials at regular intervals u2022 Time-based intervals (for example, an inspection point every hour or for each work shift) u2022 Quantity-based intervals (for example, an inspection point for each container) u2022 Freely-defined intervals (for example, an inspection point each time a tool change occurs) u2022 Record inspection results for each inspection point (for example, for each container or work shift) and valuate each inspection point with a "usage decision" Assign a produced quantity to each inspection point and allocate the inspection point quantities to partial lots. It is recommended that you allocate inspection points with the same usage decision to partial lots. This allows you to manage partial quantities that differ in quality. In this way, you can monitor the production process continuously with respect to the inspection characteristics. Inspection Points for Inspections During Production If you inspect during production using routings, rate routings or master recipes and you want to record inspection results in specific intervals, choose the inspection point type Free inspection points in production. Inspection Points in Goods Receipt If you carry out goods receipt inspections with inspection points, choose the inspection point type Free inspection points in production. Inspection Points in Sample Management If you use the sample management functions in a goods receipt inspection, or inspection during production with planned physical samples, each sample number is uniquely identified by an inspection point. Choose the inspection point type Physical sample. In the task list header (of application components PP and PI), you can set detail levels for assigning the produced quantities. At the first and most detailed level ("Partial lots not supported"), the produced partial quantities are assigned to the inspection points, for which inspection results are also recorded. At the second detail level ("Partial lot for each inspection point"), the partial quantities that were assigned to the inspection points are combined into partial lots. At the third detail level ("Partial lot and batch for each insp. point"), the partial lots are collected in batches. Inspection Lot Creation When a production order is released, the system creates an inspection lot record to manage the inspection specifications and inspection results for all operations. When a Goods Receipt is taken from production or process order the Inspection lot gets created. '03' inspection lot for inprocess inspection, '04' inspection lot for Receipt from Production. Recording inspection results for an inspection point When you record inspection results in QM, you can also confirm the operations in the PP component. This can occur automatically. You can confirm the inspection point quantities in PP in the form of a partial or

final confirmation. If you want to confirm additional data in production planning (in addition to the inspection point quantities and target activities), you can call up a dialog box for a detailed confirmation. In this dialog box, you can record such information as actual times or personnel-related data. You can also record defects. Inspection completion When you process partial lots and confirm an inspection point, the system automatically proposes a "usage decision" for each partial lot based on the inspection point valuation. You can change the proposed code within the predefined code group. The usage decision for the inspection lot confirms that all inspections have been completed or that the production order has been completed from a QM standpoint. To make the usage decision for the inspection lot, you can define a job that makes automatic usage decisions at predefined intervals, once the orders have been completed. Proposed quantity for a goods receipt from production The inspection point quantities for the last QM-relevant operation are proposed for the goods receipt posting for the order. Only the quantities confirmed to PP as a yield or rework quantities are taken into consideration. Quality Management in Sales & Distribution Welcome to the QM-SD page. Quality Management in Sales and Distribution involves in creating Quality Certificates, inspecting the deliveries, Processing complaints and returns processing.The R/3 Quality Management (QM) component supports the SD processes at various stages. Typical process flows which involve QM are from the sales order and production to delivery and service. In Make to Order Production the characteristics required by the customer are specified in the configuration in the sales order. The limits that are used for inspection are based on the configuration. When goods are shipped, a certificate can be included to document that the goods comply with the customer specification. In Make to Stock production the product is manufactured and inspected according to your own specifications. Batch determination during fulfilling sales order or delivery can be done according to customer specific requirements. When goods are shipped, a certificate can be included to document that the goods comply with the customer specification. Complaints and Returns processing - The complaints can be represented in a Quality Notification, a link to workflow helps to process the complaints. If the goods are returned an inspection can be done at the receipt. Different follow up actions can take place depending on the inspection results. Quality Certificates - An agreement between the vendor and customer can stipulate that the certificate must be included with the delivered goods. The certificate confirms that the delivered goods meet the customer requirements. Certificate management is divided into Planning and processing phases. Certificate planning allows you to flexibly structure your certificates. You plan the layout and content of the certificate. Control data is available for information such as lot selection, data origin, and inspection results. Certificate processing can be automated (takes place without any input from the person responsible for processing). The certificate for a delivery item is processed during the output determination procedure in SD. If required, you can also create a certificate manually for a batch or inspection lot (without reference to a delivery). Certificate Profile To create certificates, you define certificate profiles which are based on standard certificates and forms such as: - Certificates of analysis - Works test certificates - Source inspection certificate The certificate profile predefines the data that appears on the certificate. You can assign certificate profiles at different levels. You set these levels in Customizing. The standard settings include: Material/ship-to party, material, goods group. Certificate profiles can either be of a special or general nature. The option of setting a level in Customizing allows you to control the printing of certificates specific to a customer and material. You can have general certificate profiles, if a group of materials has the same inspection characteristics and if the same type of certificate is to be produced for these characteristics. When a certificate is created, the system starts to search for the special certificate profile entries.

A certificate must also contain all characteristic data that is collected during a multi-stage production process. The characteristic data from materials in the production chain can relate to: Raw materials Semi-finished products Finished products Prerequisites: Universal batch management Update of the batch where-used list The batch where-used list helps you identify which batches were actually used in the production process. The where-used list tracks the batch, using the Inventory Management functions. From the initial posting through to deletion from inventory, each batch has its own document journal. In addition, links between batches across all manufacturing levels through to the sales order and batch splits are logged. Batch determination in sales can take place at the following times: When a sales order is created, the system can search for a suitable batch. If the search is successful, the batch number is passed on to delivery and warehouse management. If it is not successful, this task is left to the subsequent functions.If the batch is not determined until the delivery stage, a batch split can take place. If a suitable batch is found, the batch number is transferred to warehouse management. If you use batch determination in sales for a transaction, you must have created a strategy record. This record contains typical fields (such as, customer or material) for the appropriate transaction. The record is classified by a selection class, allowing you to store the required entries for this transaction as a characteristic value. In the batch determination process, the classification of the batch records is compared with that of the strategy record. The search is successful if matching records are found. If the search is not successful, you must change your search entries and start the batch determination process again. The characteristic values are default values that you can change or exclude from the search. Quality Inspection for Delivery The Quality Management (QM) component supports the Sales and Distribution (SD) component by processing quality inspections for goods issues. The quality inspection for a delivery is necessary to check the quality of a material or product before it leaves the premises of the manufacturer or vendor. Usually, the department responsible for quality assurance at the manufacturing company performs a quality inspection to ensure that the goods are in perfect condition before they are sent to the customer. The QM inspection is activated in the material master. If a delivery for a material is created in SD, QM automatically generates an inspection lot for the delivery items relevant for inspection. The inspection lot is a request to the quality assurance department to inspect the goods. The inspection result can be stored in the system in different ways. If the goods are damaged, defect records can be created. Measured values or valuation codes are stored as characteristic values. You plan the type of inspection and how it is to take place in the QM master data. The usage decision completes a QM inspection. The inspected goods are accepted for use, or rejected. This is referred to as the 'Acceptance' or 'Rejection' of an inspection lot. If the 'QM control data in SD' is set so that goods are only shipped after inspection completion, a positive usage decision must be made for an inspection lot before the goods issue can be posted. Therefore, only goods that have been accepted in a QM inspection can be dispatched. When an inspection is performed parallel to shipping, the goods issue does not necessarily have to wait until the usage decision has been made and the goods have been accepted. Quality control can also release the inspection result after the goods have been issued. An 'inspection by the customer' is not represented in our system; no inspection lot is created. Customers perform a source inspection of our goods at their own premises. The 'usage indicator' can be set in the header or the item for the sales order. It describes whether this is a regular supply to the customer, or whether the goods are intended for a specific purpose. If the customer defines deliveries for different usages, the QM system can react with various inspection plans: For a model delivery, different characteristics may have to be inspected before the delivery than for a regular delivery of the same material. The following dependencies can be set between QM and SD: An inspection can be performed in different ways, depending on the usage indicator from the sales order. The QM inspection can be expected before or during the goods delivery. If an inspection lot is rejected, you can prevent the goods issue from being delivered if necessary. Report Abuse

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Manufacturing and Production Planning Table of ContentsDocumento4 páginasManufacturing and Production Planning Table of ContentsramvepuriAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Cts Final MM TRG Day3Documento30 páginasCts Final MM TRG Day3ramvepuriAinda não há avaliações

- Long TextDocumento1 páginaLong TextramvepuriAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- PO Release StrategyDocumento21 páginasPO Release StrategyShalanki ShashankAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- CTS Final MM TRG Day2Documento16 páginasCTS Final MM TRG Day2ramvepuriAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- SAP AUdit ManagementDocumento11 páginasSAP AUdit Managementkyyagoub100% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- CTS Final MM TRG Day1Documento42 páginasCTS Final MM TRG Day1ramvepuriAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

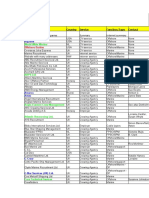

- Course Name Prerequisites Content Bom & Progress Tracker: SCM5.0 - DP File Naming Convention & Row Colour ConventionDocumento10 páginasCourse Name Prerequisites Content Bom & Progress Tracker: SCM5.0 - DP File Naming Convention & Row Colour ConventionramvepuriAinda não há avaliações

- 12 Big Ideas For 2012Documento10 páginas12 Big Ideas For 2012ramvepuriAinda não há avaliações

- 10 Must Have Features in Next Generation Enterprise SoftwareDocumento0 página10 Must Have Features in Next Generation Enterprise SoftwareramvepuriAinda não há avaliações

- Sap QM in Process Inspection User ManualDocumento45 páginasSap QM in Process Inspection User ManualramvepuriAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- 300 Excel TipsDocumento5 páginas300 Excel TipsGlenn96% (23)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Automatic Rework Order Using Reason of Variance Key: Applies ToDocumento21 páginasAutomatic Rework Order Using Reason of Variance Key: Applies ToRitesh Tiwari50% (4)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Syllabus ITV3F English 4Documento11 páginasSyllabus ITV3F English 4adnaanz83Ainda não há avaliações

- Syllabus ITV3F English 4Documento11 páginasSyllabus ITV3F English 4adnaanz83Ainda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Sap Table RefDocumento18 páginasSap Table RefArjun GhattamneniAinda não há avaliações

- SCM - Planning&Manufacturing (ECC 6.0)Documento14 páginasSCM - Planning&Manufacturing (ECC 6.0)saisuni.mAinda não há avaliações

- Company Name Country Service Function/Type Contact: RigzoneDocumento4 páginasCompany Name Country Service Function/Type Contact: RigzonekokabawaAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Perdele Economic B 2VVDocumento4 páginasPerdele Economic B 2VVakitainupufAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Effectiveness of Acceptance and Commitment-BasDocumento18 páginasThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiAinda não há avaliações

- The Running and Maintenance ofDocumento459 páginasThe Running and Maintenance ofantonigor100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- DER11001 Reference DrawingsDocumento2 páginasDER11001 Reference DrawingsPrime Energy Warehouse-YemenAinda não há avaliações

- Segmented Ball Valves s19 PB en UsDocumento18 páginasSegmented Ball Valves s19 PB en UsMarcos Aurelio Rangel GalvánAinda não há avaliações

- Jurnal Limbah MakananDocumento6 páginasJurnal Limbah MakananArdi jombangAinda não há avaliações

- School: Leadstar University College of Graduate Studies MBA Transformational LeadershipDocumento13 páginasSchool: Leadstar University College of Graduate Studies MBA Transformational Leadershipaddisu zewde100% (1)

- Trafo Manual ABBDocumento104 páginasTrafo Manual ABBMarcos SebastianAinda não há avaliações

- Nift Panchkula Thesis Gaurav Bajaj 2009 Uar 646Documento10 páginasNift Panchkula Thesis Gaurav Bajaj 2009 Uar 646vedahiAinda não há avaliações

- RoundingDocumento65 páginasRoundingSourav Kumar100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Ficha Tecnica Talesun 410WDocumento2 páginasFicha Tecnica Talesun 410WIes IngenieriaAinda não há avaliações

- Topray Tpsm5u 185w-200wDocumento2 páginasTopray Tpsm5u 185w-200wThanh Thai LeAinda não há avaliações

- The Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Documento2 páginasThe Power Behind.: Rectifier DPR 2900B-48 (ESR48/56C F)Charmer JiaAinda não há avaliações

- Appexchange Publishing GuideDocumento29 páginasAppexchange Publishing GuideHeatherAinda não há avaliações

- Shot Blasting Machines: Laser PeeningDocumento2 páginasShot Blasting Machines: Laser Peeningrahul srivastavaAinda não há avaliações

- Massey Ferguson 8570 COMBINE Parts Catalogue ManualDocumento22 páginasMassey Ferguson 8570 COMBINE Parts Catalogue ManualdidkskmdmdmAinda não há avaliações

- Multi Class Coding SystemDocumento20 páginasMulti Class Coding SystemDaniel LoretoAinda não há avaliações

- Tesco Shop On The GoDocumento3 páginasTesco Shop On The GoIkram KhokharAinda não há avaliações

- Class 6 Ioel 2017Documento8 páginasClass 6 Ioel 2017A GuptaAinda não há avaliações

- Stone MasonaryDocumento23 páginasStone MasonarypurvaAinda não há avaliações

- BRO MAHA Alle Fahrwerkstechnik ENDocumento8 páginasBRO MAHA Alle Fahrwerkstechnik ENFranco DiacAinda não há avaliações

- Fuzzy LogicDocumento27 páginasFuzzy LogicvibhutiAinda não há avaliações

- Apache Derby DatabaseDocumento4 páginasApache Derby DatabaseJohn KrcmarikAinda não há avaliações

- 2D Position Measurement With Optical Laser Mouse SensorDocumento4 páginas2D Position Measurement With Optical Laser Mouse SensorDhrupad GuptaAinda não há avaliações

- Eaton Fuller FS-4205A Transmission Parts ManualDocumento18 páginasEaton Fuller FS-4205A Transmission Parts ManualJuan Diego Vergel RangelAinda não há avaliações

- Accreditation ScopeDocumento19 páginasAccreditation ScopeTrainer 01Ainda não há avaliações

- Pressostato SUCO - 0159Documento3 páginasPressostato SUCO - 0159Hugo Lemos ArthusoAinda não há avaliações

- RF Power Meter v2: Preliminary Operator's ManualDocumento10 páginasRF Power Meter v2: Preliminary Operator's Manualsalvatore dalessandroAinda não há avaliações

- Catia MaualDocumento44 páginasCatia MaualSai Venkatesh.0% (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações