Escolar Documentos

Profissional Documentos

Cultura Documentos

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPING

Enviado por

arockiyathassTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS FOR HOT TAP PIPING

Enviado por

arockiyathassDireitos autorais:

Formatos disponíveis

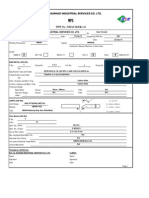

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application: Service

Hot Tap Piping Sour Non-Sour Group

WPS Revision No. X Pipeline X

PQR No.

P1-5 Tank

PQR Revision No. Structural PWHT Yes No

0 Other

Page

1 of 1

Pressure Vessel Yes No 1 Minimum Design Temperature

Impact Toughness

Welding Process

SMAW

BASE METAL P-No. 1

1, 2

TO P-No.

Group

1, 2

FILLER METAL Spec. No. (SFA) AWS No. (Class.) Size of Filler Metals Max. Deposit Thickness SAW Electrode-Flux (Class.) Flux Trade Name SAMS S/N Other None

A5.1 E7018-1 2.3, 3.2, 4.0 50.8mm N/A N/A

Material Specification (typical) BM Thickness Range:

Carbon Steel, to API 5L X60, equivalent grade Groove Fillet 4.8-50.8mm Unlimited 50.8mm-Unlimited Unlimited

Pipe Diameter Range:

Groove Fillet

Other PREHEAT Preheat Temp. 107 C For all welding

POST WELD HEAT TREATMENT Temperature Range None Time Range N/A N/A N/A None All V-UP Fillet All

Interpass Temp.

315 C Maximum. N/A

Heating Rate Cooling Rate Other POSITION Groove

GAS Shielding Gas (Type) Flow Rate N/A

Gas Backing (Type) Gas Backing Flow Rate Other None

None N/A

Welding Progression Other None

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type N/A String or Weave Bead Method of Backgouging Stringer and Weave N/A

Orifice or Gas Cup Size Multiple or Single Passes

N/A Multiple N/A

Contact Tube to Work Distance Brushing & Grinding

PASS PROCESS FILLER METAL SIZE (mm) POL.

Initial & Interpass Cleaning (Brushing, Grinding, etc.) JOINT SKETCH

SIDE

VOLT.

AMP.

TRAVEL SPEED (cm/min)

1 1 1 1

Fill Fill1 Fill Fill

SMAW SMAW SMAW SMAW

E7018-1 E7018-1 E7018-1 E7018-1

2.4 3.2 3.2 4.0

DCRP DCRP DCRP DCRP

23-29 22-28 20-26 20-25

70-100 90-160 90-160 140-185

A= B= Other Department . Consulting Services Department

C= D=

Other Dimensions/Comments:

Revision Date

Oct 5, 2008

Approval restrictions WPS No. Hot Tap

None WPS Revision No. 0 PQR No. P1-5 PQR Revision No. 0 Page 2 of 2

Hot Tap welding Procedure; Rev. 0 Page 2 of 2 October 5, 2008 D. Niemeyer

1 Hot tap fitting and sleeve details shall be in accordance with Drawing AB-036719-001. Typical details for full encirclement sleeve longitudinal and fillet welds are shown in figures 1 and 2. The installation of Hot taps shall be in accordance with SAEP-311. The preheat shown on the welding procedure must be followed for all welding. E7018-1 electrode must be maintained dry. Electrodes must be used from newly-opened, sealed metal containers or maintained dry in accordance with the storage and baking procedure listed in SAES-W-012 Table 1. When a sticker is applied to a header pipe, the weld shall be examined visually and by MPI and UT prior to installing the reinforcing pad. The testing and acceptance criteria shall be in accordance with API 1104. The testing and acceptance criteria shall be in accordance with API 1104. The non-pressure retaining reinforcing pad fillet welds (Types 1, 2, 5 and 6.) shall be visually and MPI examined. The testing and acceptance criteria shall be in accordance with API 1104. The longitudinal welds and fillet at the end of full encirclement sleeves (Type 3) shall be examined visually and by MPI and UT after the completion of welding. The testing and acceptance criteria shall be in accordance with API 1104. The ends of the sleeve and bands on the branch pipe will be buttered with a single layer of stringer beads. This welding is performed prior to completing the fillet weld. See Figure 2 for clarification details. When welding on the line pipe, the heat input shall not exceed 1.8 KJ/mm.

2 3

Hot Tap welding Procedure; Rev. 0 Page 3 of 3 October 5, 2008 D. Niemeyer

Figure1

K+gap

Figure2

Você também pode gostar

- PQR-WPS-WPQR XXX Rev 0Documento6 páginasPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Hot Tapping GuidlinesDocumento14 páginasHot Tapping GuidlinesSomesh100% (1)

- Tie in Joint Welding (Gold Weld) SpecDocumento8 páginasTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- Method Statement For Hot TappingDocumento13 páginasMethod Statement For Hot TappingAmb Patrick OghateAinda não há avaliações

- Welding Manual Nov 2010Documento187 páginasWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Hydro Test Procedure for Berri Development Onshore PipelinesDocumento14 páginasHydro Test Procedure for Berri Development Onshore PipelinesARJUN100% (4)

- Golden WeldDocumento4 páginasGolden Weldenels77Ainda não há avaliações

- Flange Bolt Tightening Procedures PDFDocumento11 páginasFlange Bolt Tightening Procedures PDFjerrymcfly100% (1)

- Method Statement For Hot Tapping Rev 0Documento9 páginasMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- Hot TappingDocumento21 páginasHot TappingnayakyaAinda não há avaliações

- CMS For Cad WeldingDocumento9 páginasCMS For Cad WeldingarockiyathassAinda não há avaliações

- Inspect Hot Tap Installation: Saudi AramcoDocumento53 páginasInspect Hot Tap Installation: Saudi AramcoSivaram SivaAinda não há avaliações

- Saudi Aramco Pre-Commissioning Form: Battery SystemDocumento4 páginasSaudi Aramco Pre-Commissioning Form: Battery SystemarockiyathassAinda não há avaliações

- IEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireDocumento12 páginasIEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireEnzo Ochoa100% (1)

- Class/Division Hazardous Location GuideDocumento26 páginasClass/Division Hazardous Location GuidecloobpspAinda não há avaliações

- Fabrication of ManifoldDocumento2 páginasFabrication of Manifoldsarangpune100% (1)

- Ansi C80 - 3Documento9 páginasAnsi C80 - 3sultanalamoudiAinda não há avaliações

- Flang ManegmentDocumento12 páginasFlang ManegmentYasser Abd El Fattah100% (1)

- RT II QueastionsDocumento14 páginasRT II QueastionsEbin Charles100% (1)

- Hot Tap Check ListDocumento4 páginasHot Tap Check Listborisortiz100% (1)

- Procedure - Hot TappingDocumento6 páginasProcedure - Hot Tappingmanimaran_ratnam100% (4)

- Saep 1142Documento11 páginasSaep 1142shaban100% (2)

- Strategic TechnologiesDocumento556 páginasStrategic TechnologiesMajmaah_Univ_PublicAinda não há avaliações

- Saudi Aramco Pressure Testing SafetyDocumento17 páginasSaudi Aramco Pressure Testing Safetytarique100% (1)

- 04 Samss 005Documento10 páginas04 Samss 005ShojikuriakoseT100% (1)

- Golden Weld PhilosophyDocumento8 páginasGolden Weld PhilosophyOmar TocmoAinda não há avaliações

- Pipeline Welding Procedure SpecificationDocumento11 páginasPipeline Welding Procedure SpecificationVijo Jose100% (1)

- 0.hydro Test Package Index - 1Documento13 páginas0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASAinda não há avaliações

- Natural Gas Hot Tap Connections Reduce LossesDocumento12 páginasNatural Gas Hot Tap Connections Reduce LossesSmith JasonAinda não há avaliações

- Replacement of Isolation Valves by Hot Tap WorksDocumento88 páginasReplacement of Isolation Valves by Hot Tap WorksAlexis Pacheco100% (1)

- To Commissioning Manual: Appendix No. 1Documento7 páginasTo Commissioning Manual: Appendix No. 1Bassem BalghouthiAinda não há avaliações

- Wps S - Ea-6gr-01.Doc Rev2 j4662Documento1 páginaWps S - Ea-6gr-01.Doc Rev2 j4662cisar0007Ainda não há avaliações

- Mohamed Ashim: Mechanical InspectorDocumento5 páginasMohamed Ashim: Mechanical InspectorMad TahaAinda não há avaliações

- QP - STD.R.006.R1 Welding Onshore Transmission Pipelines PDFDocumento39 páginasQP - STD.R.006.R1 Welding Onshore Transmission Pipelines PDFSivaAinda não há avaliações

- WPS 204 NewDocumento6 páginasWPS 204 Newarockiyathass100% (1)

- Welding Procecure SpecificationDocumento9 páginasWelding Procecure SpecificationNwoha PeterAinda não há avaliações

- Sample API 1104 WpsDocumento1 páginaSample API 1104 Wpsippon_osoto100% (1)

- JOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentDocumento7 páginasJOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentOrdu Henry Onyebuchukwu100% (1)

- PIPELINE WELD NUMBERING SYSTEMDocumento9 páginasPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- Hot Tap ProcedureDocumento7 páginasHot Tap Procedurerashid zamanAinda não há avaliações

- Quality Control Procedure for Hot Tap Tie-inDocumento9 páginasQuality Control Procedure for Hot Tap Tie-inarockiyathassAinda não há avaliações

- HOT TAPPING PROCEDUREDocumento4 páginasHOT TAPPING PROCEDUREvijimurugan2003100% (1)

- WPS-PQR For Split TeeDocumento9 páginasWPS-PQR For Split TeemaheshmalaichamyAinda não há avaliações

- Procedure Welding Part 2Documento14 páginasProcedure Welding Part 2mohammadAinda não há avaliações

- Hot TappingDocumento15 páginasHot Tappingghkashyap150% (2)

- Welding Procedure Specification for Hot Tap WeldingDocumento6 páginasWelding Procedure Specification for Hot Tap WeldingOgbonde100% (1)

- Hot Tapping ProcedureDocumento6 páginasHot Tapping ProcedureLu Min HanAinda não há avaliações

- QP-SPC-R-010-1 - 1 - Welding Procedures PDFDocumento40 páginasQP-SPC-R-010-1 - 1 - Welding Procedures PDFMohamed100% (1)

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Documento14 páginasPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82Ainda não há avaliações

- VBTDocumento5 páginasVBTMohdHuzairiRusliAinda não há avaliações

- Msog-M1402-P-Rp-006 Rev 1Documento44 páginasMsog-M1402-P-Rp-006 Rev 1Mohd Nazir NorlanAinda não há avaliações

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Hydratight Hot Tap ProcedureDocumento39 páginasHydratight Hot Tap Proceduremitesh0% (1)

- QCP For Hot Tap PDFDocumento30 páginasQCP For Hot Tap PDFjahaan100% (1)

- THE HIGH PRESSURE ROLLER PRESSDocumento27 páginasTHE HIGH PRESSURE ROLLER PRESSThaigroup Cement100% (10)

- Method Statement for Pipe Handling and StorageDocumento14 páginasMethod Statement for Pipe Handling and StorageShambu S VtkAinda não há avaliações

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Documento15 páginasQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassAinda não há avaliações

- Cold Cut Tie-In Procedure 24'' Bypass LineDocumento14 páginasCold Cut Tie-In Procedure 24'' Bypass LineMahaboob Pasha100% (1)

- Microdroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)Documento249 páginasMicrodroplet Technology - Principles and Emerging Applications in Biology and Chemistry - Philip Day Et Al. (Springer, 2012)CA Uttam Prakash Agarwal100% (1)

- Golden Joint Procedure Rev1Documento9 páginasGolden Joint Procedure Rev1Mohd Effiezool Yaser100% (3)

- GTAW Welding ParametersDocumento1 páginaGTAW Welding ParameterssahadAinda não há avaliações

- Hot Tapping GuideDocumento3 páginasHot Tapping GuidegshdavidAinda não há avaliações

- Groove DesignDocumento4 páginasGroove DesignElizabeth SpenceAinda não há avaliações

- Conductimetric Analysis of Water Soluble Ionic Contamination of Blasting AbrasivesDocumento3 páginasConductimetric Analysis of Water Soluble Ionic Contamination of Blasting AbrasivesCristhian CoariteAinda não há avaliações

- Saep 327Documento11 páginasSaep 327brecht1980100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Documento1 páginaWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaAinda não há avaliações

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocumento1 páginaIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayAinda não há avaliações

- Pneumatic Test ProcedureDocumento3 páginasPneumatic Test Procedurevijay padale50% (2)

- Post-hydrotesting procedure for Dadri-Bawana pipelineDocumento7 páginasPost-hydrotesting procedure for Dadri-Bawana pipelineVineet SinghAinda não há avaliações

- Materials System SpecificationDocumento15 páginasMaterials System SpecificationAwais CheemaAinda não há avaliações

- R3215-005041 Appendix A 2.0 - Datasheet For Corrosion CouponDocumento1 páginaR3215-005041 Appendix A 2.0 - Datasheet For Corrosion Couponsaiful anwarAinda não há avaliações

- Foreign Affairs Policy PresentationDocumento36 páginasForeign Affairs Policy PresentationarockiyathassAinda não há avaliações

- Physical Science: Chapter 5Documento2 páginasPhysical Science: Chapter 5arockiyathassAinda não há avaliações

- Foreign Affairs Policy PresentationDocumento36 páginasForeign Affairs Policy PresentationarockiyathassAinda não há avaliações

- Wescosa Site Test Procedure STP - DL Services Department Title: Distribution ListDocumento2 páginasWescosa Site Test Procedure STP - DL Services Department Title: Distribution ListarockiyathassAinda não há avaliações

- Attachment 1 - Microcor® Transmitter: Inspection ChecklistDocumento1 páginaAttachment 1 - Microcor® Transmitter: Inspection ChecklistarockiyathassAinda não há avaliações

- Pressure Conversion ChartDocumento1 páginaPressure Conversion ChartarockiyathassAinda não há avaliações

- CRMSCL 001 1Documento7 páginasCRMSCL 001 1arockiyathassAinda não há avaliações

- CRMS ItpDocumento2 páginasCRMS Itparockiyathass100% (1)

- NEMA Type 4X Junction Box Terminal Marking IdentificationDocumento22 páginasNEMA Type 4X Junction Box Terminal Marking IdentificationarockiyathassAinda não há avaliações

- QCP 040 QCP CrmsDocumento7 páginasQCP 040 QCP Crmsarockiyathass100% (1)

- CRMSCL 001 2Documento3 páginasCRMSCL 001 2arockiyathassAinda não há avaliações

- QC InterviewDocumento1 páginaQC InterviewarockiyathassAinda não há avaliações

- PDITDocumento7 páginasPDITarockiyathassAinda não há avaliações

- FAT Report - Part 1Documento11 páginasFAT Report - Part 1arockiyathassAinda não há avaliações

- Sealing Cables in Explosive Atmospheres CMP David OBrienDocumento38 páginasSealing Cables in Explosive Atmospheres CMP David OBrienarockiyathassAinda não há avaliações

- Pre CommDocumento17 páginasPre CommarockiyathassAinda não há avaliações

- Data Sheet Increased Safety Dpe Breather Drain 0912 PDFDocumento2 páginasData Sheet Increased Safety Dpe Breather Drain 0912 PDFarockiyathassAinda não há avaliações

- Electrical Heat Tracing Inspection ChecklistDocumento1 páginaElectrical Heat Tracing Inspection ChecklistarockiyathassAinda não há avaliações

- IB Biology HL IA (MAY 2021)Documento14 páginasIB Biology HL IA (MAY 2021)Insiyah Huzefa BasraiAinda não há avaliações

- Resins Word DocumentDocumento8 páginasResins Word DocumentHarish KakraniAinda não há avaliações

- Role of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless SteelDocumento5 páginasRole of Nitrite Addition in Chloride Stress Corrosion Cracking of A Super Duplex Stainless Steelherschel5Ainda não há avaliações

- Structure of Atom - Key Facts in 38 CharactersDocumento2 páginasStructure of Atom - Key Facts in 38 Characterspiyush shuklaAinda não há avaliações

- Artículo Toxic JuiceDocumento6 páginasArtículo Toxic JuiceSonia Fernández PradosAinda não há avaliações

- Oxidative WearDocumento17 páginasOxidative WearManish Kumar SinghAinda não há avaliações

- Hydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesDocumento26 páginasHydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesRahul AroraAinda não há avaliações

- Specialized lubricants maximize steel industry productivityDocumento16 páginasSpecialized lubricants maximize steel industry productivitySioney MonteiroAinda não há avaliações

- CostingDocumento5 páginasCostingJalindar BansodeAinda não há avaliações

- First Project ExamplesDocumento49 páginasFirst Project ExamplesMeleti Meleti MeletiouAinda não há avaliações

- Megtron 6Documento3 páginasMegtron 6rfduh100% (1)

- 4ch1 1c Que 20230112Documento29 páginas4ch1 1c Que 20230112Ahmed MangoudAinda não há avaliações

- Multistage Restriction Orifice Assembly PDFDocumento1 páginaMultistage Restriction Orifice Assembly PDFlimin zhang100% (1)

- TDS Energrease MP-MG 2 InfoDocumento9 páginasTDS Energrease MP-MG 2 InfoLucian IftemieAinda não há avaliações

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDocumento38 páginasBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQAinda não há avaliações

- Flowserve Lined Flush BottomDocumento32 páginasFlowserve Lined Flush BottomDevdatt WaghuleAinda não há avaliações

- Premiere - Ukrainian Tile ClaysDocumento4 páginasPremiere - Ukrainian Tile ClaysqualityceramicsAinda não há avaliações

- PC1Documento11 páginasPC1Allen Low100% (1)

- Air Freshener Safety Data Sheet RevisionDocumento8 páginasAir Freshener Safety Data Sheet RevisionCitra Rizky FernandaAinda não há avaliações

- Ia On Solubility EquilibriumDocumento8 páginasIa On Solubility Equilibriumapi-235913605100% (1)

- Operating Instructions for Clinical AutoclavesDocumento11 páginasOperating Instructions for Clinical AutoclavesEduardo0% (1)

- Groundwater Fluoride in Haryana State: A Review On The Status and Its MitigationDocumento5 páginasGroundwater Fluoride in Haryana State: A Review On The Status and Its MitigationSEP-PublisherAinda não há avaliações

- Understanding The Results of An Intelligent Pig InspectionDocumento18 páginasUnderstanding The Results of An Intelligent Pig InspectionLeonardo VazAinda não há avaliações