Escolar Documentos

Profissional Documentos

Cultura Documentos

CON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)

Enviado por

mnmsingamDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)

Enviado por

mnmsingamDireitos autorais:

Formatos disponíveis

Wood Group - CCC Ltd (Oman

Branch)

PO Box 1455

Postal Code 133

Bawsher I South Alkhuwair,

Muscat

Sultanate of Oman

T: +968 244 75535

+968 244 78883

F: +968 244 75300

Contract PDO- C311163

Method Statement

for

Structural Steel and Pipe

Support Fabrication

Reference Number: CON-311

Revision 00

30 th May 2011

Wood Group - CCC Ltd

Contract-C311163

Revision Status

00 30/05/2011 Issued for Execution

F 18/05/2011

E 26/04/2011

D 28/03/2011

c 05/03/2011

B 23/01/2011

A 17/01/2011

Rev. Date

Issued for review and approval,

PDO comments incorporated

Issued for review and approval,

PDO comments incorporated

Issued for review and approval,

PDO comments incorporated

Issued for review and approval ,

PDO comments incorporated

Issued for review and approval,

PDO comments incorporated

Issued for review

Description

Structural Steel and Pipe Support Fabri cation

1\

RBK RK 'MAZZ

RBK

RK

MSH

MSH

MSH

MSH

Prepared

by

RK

MAZZ

MAZZ

MAZZ

MAZZ

MAZZ

Checked

by

MAZZ

MAZZ

IG

IG

Approved

by

Reference CON-311

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS Revision 00

Page Page 2 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

INDEX

1. PURPOSE

2. SCOPE

& 3.

4. DEFINITIONS

5. RESPONSIBILITIES

&

6. PROCEDURE

PAINTING 7.

8. SAFETY

FLAWLESS START-UP INITIATIVE

10. ATTACHEMENT

Reference CON-311

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS Revision 00

Page Page 3 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

1.0 Purpose

1. The purpose of this method statement is to define the activities and responsibilities

for performing the Structural steel and pipe support fabrication at WG-CCC EMC

(south) PDQ Oman Facilities.

2.0 Scope

3.0

&

&

&

1 . This Method Statement addresses structural steel and pipe support fabrication

procedure. This procedure is to provide the minimum requirements for the

responsibilities for material handling, workman ship, inspection and acceptance of

structural steel and pipe support fabrication activities at WG-CCC EMC (south) PDQ

Oman Facilities.

References

1. DEP 31.38.01.29 Pipe Support (Jan.-2005).

2. DEP 31.38.01.3 Shop, Field (Aug.-2005).

3. SP-2039 Mechanical Standard Drawing (Ver.1 Sep-2005).

4. SP-1234 HSE Specification - Personal Protection Equipment

(Rev.02 Jul.-2002).

5. GU-363 Guideline for Use of Scaffolding (Ver.1 Aug-2000).

6. SP-1231 HSE Specification - Occupational Health

(Rev.1 Feb.-2002)

7. SP-2001 HSE Specification - Load Safety and Restraining

(Rev.1 Mar.-2003).

8. DEP 34.28.00.31-Gen. Steel Structure (Jan.-2009).

9. DEP 30.10.02.11-Gen. Metallic materials - Selected standards.

10. DEP 30.48.00.31-Gen. Protective Coatings for onshore Facilities.

11. DEP 34.00.01.30-Gen. Structural design and engineering.

12. DEP 34.17.00.32-Gen. Design and engineering of buildings.

13. DEP 30.10.60.18 Welding of Metals.

14 SP-1279G Structure Steel work (Feb.-04).

15. SP-1246 Specification for Painting & Coating (Feb-05).

&16

BS EN 1011 Recommendation for welding of metallic materials

0 -General guidance for arc welding

Reference CON-311

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS Revision 00

Page Page 4 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

17. BS 5950

18. QUA-305

The Design, Fabrication & Erection of Structural Steel

Work.

ITP for Steel Structure & Support Fabrication.

4.0 Definitions

1. COMPANY Petroleum Development Of Oman (PDO).

2. CONTRACTOR Wood Group-CCC Oman LLC.

3. QCP Quality Control Procedure.

4. NDT Non Destructive Testing.

5. PT Dye-Penetration Testing.

6. ss Stainless Steel.

7. RFF Request for Fabrication.

5.0 Responsibilities

1. The following WG CCC personnel shall be involved and responsible for the steel

structure and pipe support fabrication:

Mechanical Engineer

Fabrication Shop Engineer

Fabrication Shop Foremen

Welding Foreman

QC Manager

QC Engineer

Welding Engineer

QC Inspector Welding

QC Inspector Piping

QC Inspection Structure Steel.

2. Mechanical Engineer.

Mechanical Engineer has overall responsibility for monitoring steel structural and pipe

support fabrication operation in accordance with procedures, specifications and

construction drawings.

3. QC Inspector.

QC lnspector(s) in conjunction with Fabrication Shop Engineer and Engineer are

responsible for the inspection, in accordance with specification and procedures, of the

steel structural and pipe support fabrication and the compilation/retention of reports

and records per drawing.

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 5 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

6.0

4. Fabrication Shop Engineer.

The Fabrication Shop Engineer shall ensure the safe and efficient working in the

Fabrication Shop, or site to monitor plant and equipment requirements and to ensure

that productivity and quality are maintained by the personnel under their control.

5. Engineer/Foreman.

The Engineer/Foreman shall be responsible for the safe operation and quality of work

and shall ensure that the procedures are adhered to and that technical standards are

maintained.

6. QC Manager.

The QC Manager is responsible for maintaining present procedure and Quality

requirements.

Procedure:

Workmanship applied during fabrication of structural steel shall comply with PDO

Specifications SP-2039 (Standard Drawings); DEP 31.38.01.29; ISO 10721-2 and AISC.

1. Fabrication engineer (Shall ensure the safe and effective working of his section, in order

to ensure that productivity and fabrication criteria are maintained by the Supervisor

personnel under his control.

2. The Supervisor shall be responsible for the safe execution and quality of the work. He

will ensure that technical standards, safety and quality are maintained.

3. Supervisor shall coordinate with the Quality Department who shall be responsible for the

inspection of the Steel Structure fabrication, the compilation, retention of records and

reports to the specific Inspection as per approved drawings.

6.1 Handling, Storage and Preservation:

1. Handling, Storage and Preservation/Protection of Structural Members shall be carried

out in accordance with the requirements of Material Handling procedure ITP QUA- 007.

2. Care shall be exercised to ensure that identification numbers are readily visible at all

times.

3. Upon receiving the materials from the Supplier the different structural steel members

shall be visually checked by Wood Group CCC for any visual defects or apparent

damage. Any items that are defective or damaged shall not be taken or accepted for

fabrication.

4. Material Department personnel shall ensure that the receiving material shall be valid

test certificates and ready to issue for fabrication.

5. Welding consumables shall be stored and issued in accordance to Project specification

and quality control plan.

Reference CON-311

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS Revision 00

Page Page 6 of 20

Wood Group - CCC Lt d

Contract-C311163 St ructural Steel and Pipe Support Fabricati on

6.2 Fabrication:

The fabrication of struct ural steel and pipe support shall be as per approved shop

Drawings.Using appropriate measuring and marking tools, an experienced and

competent fabricator does lay out according to the approved shop drawing.

The objective of this process is to identify cutting lines and locations to dril l bolt hole

Plates, beams, channels, pipes etc. are marked by center punching (to show the cutting

line) and by hand writing using metal marker for the identification according to shop

drawing.

Using appropriate cutting and grinding tools/ equipment, marked items are cut and

ground (as appropriate) by experienced and competent fabricator in accordance with

the project specification.

When required, cut items are beveled in accordance to drawing.

Accordingly, fit-up assembly is done by fabrication crew to ensure t he require

product fits up correctly as per specifications.

6.3. Structural member's fabricat ion:

Physical verification of structural steel members such as beam section, plates And

colour coding is in accordance with applicable project specification.

Preparing a marking plan and layout as per approved shop drawing to control The

mi nimum scrap generation.

Material conformance with standard drawings and request for fabrication.

Material information is transferred to piece of structural steel member to be cut

Marking and punching the area to be cut as per approved shop drawing

Steel plates and structural members shall be cut using flame cutting, or Mechanical

cutting equipment in accordance with approved shop drawings.

Straightening of structural members to ensure the flatness of the structure.

Preassembly of the structure which includes fit-up, drill ing and tack welding as per

approved shop drawings

Inspection and acceptance of pre-assembly and released for welding shall be as per

approved drawings.

Welding of structural steel members as per approved WPS.

NDT (Non Destructive testing) , Frequency of NDT testing and acceptance criteria

shall be as per Enclosure page (15, 16, 17 & 20).

Ensure tag I mark identification on the fabricated structure.

Released for painting as per approved painting system.

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 7 of20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

1\ 6.4. Pipe support fabrication

Physical verification of structural steel members and pipe material such as Beam,

plates and pipes and colour coding in accordance with project Specification.

Preparing a marking plan and layout as per approved shop drawing to control The

minimum scrap generation.

Material conformance with standard pipe support drawings and request for fabrication

(RFF).

Material information is transferred to piece of structural steel member and pipe to be

cut.

Marking and punching the area to be cut as per approved shop drawing

Steel plates, pipes and structural members shall be cut using flame cutting, Or

Mechanical cutting equipment in accordance with approved shop drawings.

The support of the pipe shoe shall be the same parent material of the pipe as per

standard pipe support drawing.

Preassembly of the pipe support which includes fit-up , drilling and tack welding as

per approved standard pipe support drawings.

Inspection and acceptance of pre-assembly and released for welding of pipe

supports.

Welding of pipe supports shall be as per approved WPS.

NOT (Non Destructive testing), Frequency of NOT testing and acceptance criteria

shall be as per approved ITP- QUA 305.

Ensure tag I mark identification on the fabricated pipe supports.

Released for painting as per approved painting system.

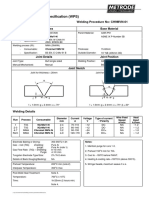

j1 6.5. Welding and Weld Inspection:

& /1 All welding works shall comply with EN 1011; and SP-1279 Section G.

Prior to the commencement of fabrication activities submit the weld procedure

qualifications and associated weld procedure specifications, covering all joint

configurations, to PDO for approval.

WG-CCC shall maintain a suite of relevant weld procedure qualifications, and have

sufficient welders qualified to weld in accordance with project specifications

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 8 of20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

6.6.

Prior to the commencement of welding activities, the WG-CCC shall submit all welder

qualification records and work histories to PDO for approval.

Records of all data, tests and examinations relating to all welding procedures used

during construction and erection shall be made available to the Principal.

Testing procedures and test acceptance criteria shall be subject to the approval of

PDO before fabrication begins.

Any welding shall not be performed unless approved by PDO.

Welding of structural steel and pipe support shall be as per approved WPS

Welding inspection, frequency of NDT testing, and Acceptance criteria shall be as per

ITP (QUA-305) .

Stainless Steel Material Fabrication:

1. All tools used for working on stainless steel including cutting, grinding and buffing

discs, wheels, or brushes shall be those designated for stainless work and shall be

readily recognizable.

2. Cutting of S.S material end preparation shall be carried out using plasma or

mechanical cutting.

3. Only marking materials specifically approved for SS shall be used. Other marking

pens, pencils, chalks are not permitted in the SS shop, in the possession of

materials inspection personnel, or in the possession of welders or fabricators

working on stainless steel at the jobsite.

4. Earthling devices for welding shall be clad or otherwise covered with stainless steel

material.

5. Work areas shall be cleaned of dust and accumulated dirt, sand etc., at regular

intervals. Fabrication shops will be cleaned at the start and end of each work shift

by brooms.

6. Supports and fabrication benches to be used during fabrication activities shall be

lined with wood or rubber.

7. The Mechanical Engineer shall assure that prior to any crews being assigned to

work on stainless steel, the Engineers of those crews, and the crews themselves

have been properly oriented in the requirements of this procedure, and the general

site philosophy regarding the handling of stainless steel materials.

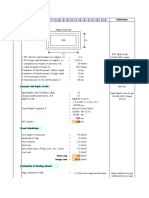

6.7. Fabrication Tolerances:

1. Fabrication tolerances shall be maintain as per approved AFC drawings

Reference CON-311

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS Revision 00

Page Page 9 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

2. Fabrication tolerances shall be maintain as per Enclosure Page 11.

3. Fabrication tolerances shall be maintain as per approved pipe support Standard

drawings

4. Additional or different tolerances shall be specified where necessitated by the

nature of the particular building or structure under consideration. Such tolerances

should be compatible with the design recommendations and product standards as

follows:

1. Rolled Sections:

After fabrication, the tolerances on cross-sections and straightness of rolled

sections(including rolled sections used as components of built-up

members)shall be specified as below.

2. Cross- Sections:

For built up I or H section members with over all depth of less than 1 m., the

tolerances on the cross section shall confirm to those specified for rolled I

and H Sections In BS EN 10034.

For all other built up sections and I and H sections with an overall depth

greater than 1m. the deviations from the specified dimensions shall not exceed

those specified in below table.

Built up box sections shall not deviate from the specified shape at the

diaphragm by more than that specified in below table.

3. Straightness and curvature:

Unless required to be any other shape, the deviation of a built-up member

from a straight line drawn between adjacent points of subsequent effective

lateral restraint shall not exceed 3 mm. or 111000 whichever is the greater,

where I is the distance between restraints(in mm).

For members intended to be curved, the curvature shall not deviate from the

specified curvature by more than the tolerance specified in below table.

4. Length and squareness of ends:

The length of members and square ness of the ends of members shall confirm

to the tolerances specified in below table.

5. Flatness for full contact bearing:

Where a surface is stated in the project specification to require full contact

bearing,the flatness shall be such that measured against a straight-edge laid

against the full length of the bearing surface in any direction:

1. Over at least 50% of the length measured the gap does not exceed0.25mm;

2. Over 90% of the length measured the gap does not exceed 0.75mm.

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 10 of 20

Wood Group -CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

& Tolerance on shape and dimensions:

DIMENSIONS CONDITION TOLERANCE

1. Distortion of web on a gauge length in any direction

equal to the web depth 'd' of the girder. LJ =d/150 or 3 mm

Whichever is greater

d-.(

w

t

b) Overall depth,D

4mm

B < 300 mm 4mm

c) Width offlanges 300 mm 5mm

d) Off-cetre of web

5mm

e)Out- of- squarness of flanfes LJ =B/100 or 3 mm which

ever is greater.

B

Flange

t:LJ

f) Out-of-flatness of flanges f)= B/150 or 3 mm whichever

is greater.

B

Flange width

r

g) Top flange of crane girder, out-of-flatness where rail W=Rail width + 20mm

sits.

.Ll = 1 mm

___. ....

l+-

_1)

v

i

1

Reference CON-311

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS Revision 00

Page Page 11 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pi pe Support Fabrication

6.8. Storage of Fabrication members before and after Painti ng:

6.9.

1. Steel structure member and pipe support shall be stored in their designated area

close to the fabrication shop in accordance with area identification coding. Pipe

supports are stacked in a manner, so it can be easily checked. Steel structure

member and pipe support shall be laid on wooden ballet or other suitable material

above ground level.

Inspection:

1. Non-Destructive Examination Personnel shall be qualified to a minimum level of

ASNT Level II as specified in ASNT Recommended Practice No. SNT-TC-1A,

latest edition, or equivalent as decided by the Company.

2. WG-CCC shall prepare a non-destructive testing requirements form in accordance

with the Contract and design requirements. This form shall specify the types and

extent of non-destructive testing to be performed and the procedure to be followed.

This form shall be referred in the Quality Control Plan specified in the Contract

Quality Assurance schedule or specification.

3. The method and extent of inspection and testing in the absence of a relevant

application standard shall be agreed between the Contracting parties.

4. The acceptance criteria for assessing the quality of welds shall be as specified in

the design code or design specification, or drawing or Contract, as applicable.

5. The acceptance criteria for welded joints in the absence of a relevant application

standard shall be agreed between the Contracting parties. The following may be

used as basis for discussion and agreement:

6. Scope of inspection and I NOT Plan with respect to type of joint and thickness shall

be as per BS5950 and approved AFC drawings.

7. Frequency of NOT Testing and acceptance for joint according to ITP -QUA-305.

8. Final inspection and acceptance shall be controlled by Q.C. Department.

9. WG-CCC to confirm compliance to project specifications and AISC specification.

10. All bolted joints, inspected and approved will be identified by white paint on the

bolts head.

7.0 PAINTING:

& 1. General:

B Surface preparation and painting shall be in accordance with DEP 30.48.00.31-Gen.

The fabricated materi als I members such as structural steel and pipe support shall be

painted as per the method statement CON-307

Special protective measures and handling, storage, preservation shall be conforming to

ITP (Inspection Test Plan- QUA -371).

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 12 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabri cation

2. Painting:

Surface preparation and painting shall be in accordance with DEP 30.48.00.31-Gen.and

SP-1246

Prior to painting the field joint surface area shall be cleaned by blast cleaning. The

surface preparation shall be carried out in accordance with SP-1246.

The blast surface visual appearance shall conform to ISO 8501 grade SA 2.5.Any field

joint not painted within 4 ( four ) hours of blasting shall be reblasted prior to the

application of painting.

The surface cleanliness shall conform to that the chloride contamination is less than

20 mg I m

2

.

Painting of the field joint shall not takes place until the joint has been inspected and

approved by QNQC.

The cleanliness of the blast cleaned surfaces for every field joint shall be inspected and

shall be in accordance with ISO 8501 grade SA 2.5.After the surface has been blast

cleaned and dusted off, a strip of transparent cello tape shall be applied to the surface

and subsequently removed and examined for particle contamination and released for

painting.

The profile of the blast cleaned surfaces shall be tested on site by a suitable profile

gauge. In accordance with SP-1246.

The Painting system shall be as per approved drawing and SP-1246

3. Painting repair work:

The repair procedure is applicable for the fabricated structure and pipe supports at shop

shall be selected based on the criteria of magnitude of the damaged area during handling

and storage.

Minor coating I painting damages up to 100 mm in diameter or width and scratches over

100 mm in length shall be repaired by a two coat applicable painting system shall be

followed by manufacturer instructions.

All contamination shall be removed from the surface by cleaning with solvent and using a

combination of wire brushes, buffing wheels and scrapers. The surface shall then be

abraded by using coarse emery paper or flexible grinding disc and ensure that the coating

surrounding the defect is also abraded but not removed.

Damages other than scratches with a diameter or width greater than 1 OOmm shall be

removed around the entire circumference by blasting.

The blast surface visual appearance shall conform to ISO 8501 grade SA 2.5.Any field

joint not painted within 4 (four) hours of blasting shall be re-blasted prior to the

application of painting.

The profile of the blast cleaned surfaces shall be tested on site by a suitable profile

gauge. In accordance with SP-1246

The Painting system shall be as per approved drawing and SP-1246

THIS COPY IS CONTROLLED - CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 13 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

8.0 SAFETY:

10.0

1. Job safety analysis shall be submitted prior to start work, see JSA attached.

2. All fabrication activities (material handling, cutting, fit up and welding) shall be carried

out adhering to the guidelines of Wood Group CCC method statement.

3. Ensure all lifting tackles and job related load taking tools/ tackles are damage /defect

free and also rated to the requirement.

4. Safety signs to be provided a clear area inside Fib shop, see JSA.

5. Access ways shall be provided inside Fab shop, see JSA.

6. All persons shall be equipped by PPE, see JSA.

7. All welding I cutting tools and equipment should be inspected regularly and should have

appropriate color code sticker.

8. Fire Extinguisher shall be provided for each unit of welding equipment.

9. Housekeeping and cleaning to be done daily.

FLAWLESS START-UP INITIATIVE:

Flawless start- up initiative I FPD shall be fully implemented as per approved FPD/FSI

procedure and approved FSI flaw list.

ATTACHMENTS:

1. NOT inspection & Acceptance tables.

2 Job Safety Hazards Analysis

Reference CON-311

THIS COPY IS CONTROLLED- CHECK CURRENT REVISION STATUS Revision 00

Page Page 14 of 20

-1

::1:

(ij

0

0

(ij

0

0

z

-1

el

r

r

m

c

0

::1:

m

0

"

0

c:

::a

z

-1

VI

5

z

VI

"'0::0::0

Ill CD CD

CQ < """CD

CD ii' -.

-CD

0

0

CD

"'000

11100

CQ z

CD

......

Ul ......

a

'

Table A.l- Soope of i.Dspeetion- Type of joint. and requiring non-destructive teltlng

Woldt1po Butta tun aDd pvtlal-etrUlon (iacWUnt itb reintorctn1 llleu) Fnlot

JolnUypo ln-lioe batt Teo and cnaclform Coraer Lap Tee, cruc:ltui'IZI and CIGJ'II4Ir

hooedureo 818 DIS and 818+8 SIS DIS and 9/9+B All AD AD

!Key Eumpleo

I= createat 1 at a joiat

f

z = peotoot uh joiDI

SISa oill(llulded

DIS= doublo oidod r ,

+B=backiAa

j8

NM" not mandolorJ f

{+I'

f

Grade I (IIID) 1(111111) t(mm) *(mm) l(mm) l(mm) l(mm) :(mm)

=

1!275/I!IIM <10 <U :.zo u.o :.20 "20 INM

ioopcctioa

1:14$1 <10 I <10 :t16 :.16

"16 >ol6 >:16

Ultraoonie S2751S3G5 uo :t12 >:13 :.20 >:SO .NM I.NM 2:20

tealinr

8460 ;tlO uo >:10 HO >:20 .NM :.15 :016

NO')'B 1b ohlll DOt pnc:lude 11\o IIM.o letiiD' em-ide lllelilllituhoWn lllloui lluo lUOI!to ofYJOII& JDepoclion -a.tnl<tive

(ND1) mdiula lluot )a)>H_J& may m opiC16oiolnt.s. __ - __

0

:E

0

0

:I

0

@

c.

(') G)

..... ...

.

0

0

c

I "C

8> .... 0

en 0

w 0

,...

s:

I

J

I

I

en

...

...

c

(')

...

c

!.

en

...

CD

II)

:I

Q.

"'tJ

-g

en

c

"C

"C

0

;:l.

"T1

II)

a'

::::!.

(')

II)

I

!:!:

0

:I

Wood Group -CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

Table A.3 -Acceptance requirements for production welds in steel structures

Feature Parameter Weld

Figure Acceptance crlter!

type reference

fol' aormal quautyb c

aetioulor

lD TableA.4

(AD dimen.ioils in mm)

DOD1lODfonaiJig

welud

Overall weld

Location

,All -

D:t.lO B

pometry

Weld type I All -

D

I .Ill

:Extent (length) All D+l0-0 E

Actual throat

AD

-

i, ii, iii

a. 1 :t: D(60)

thickneu a,asD+6

Leglen,th

I Fillet - i H: D(50)

iE

Toe angle I All Transvene i, ii

1::::

DBIR

(mt.ermce and

l..oniitudinal i, ii DSIR

Profile

inter-run)

diacontinaitiee

Rxceas weld metal Butt

ii hs6 DS

Longitudinal ii hs6 DS

Incomplete groove IBult Tranaverae ii las 0 (60)

or coJDCave root Lougitutlmal ii h s; o.u

l!;!r,!Wgnment

Transverse butt iv D+O.U

Transverse cruciform v h s D+0.4t

AU Longitudinal iv,v Ia :s; D+0.4t E

Undercutf

All Tratuwerse (not lap joint) iv,v ,.1 +fat s;0.05t R

1-NL

R

Fillet Transverae (lap joint) y

"1 + ht $ 0.08t R

's 10

R

All Longitwtinal iv,v la

1

s O.lt R

Surface

ILaclt. of root

iii Ia s D + 0.05t (50) R

breekiq

penetmtion Longitudinal iii 1t :s: D + O.Olt (50) R

dieoontmuitiee Poroslly

!All

'lranavel'lle vi d:s2 R

Ed s 10[100] R

Longitudinal vi ds2 R

I.d s 20 {100] R

I Lack of fWIIOll AU - vii NP

IB

!Cracks AU At crater w.

':

Not at crater

Abbreviated tel'IDII

D Aa apecified on drawiDp For definition of orientatJon see Table A.Z.

DB Dreuamoothly

Thickness applies to minimum member tbiclmeas at weld in

E 1Wer to engineer

question. For thiclmeuea greater than 20 mm "f' shall be taken

NL Nolimit

aa 20 mm. Where permitted lri&e "h" of a dieeontinuity is telated to

"r the .DIBXim11111 permitted value shaD be not leu than 0.3 mm in

NP Not permitted (applies to discontinuities which are

aoyeue.

detectable by NDT methode in Table A.l)

Where mme than one leqUirement ia gi'9en both lhall apply.

R &pair by welding to ap)ltOved procedure

a Where a repair ia aecenary an appl'OVed procedure shall be uaed. If

:t Greater than or equal to (i.e'. not leBB than) on increaaiDg the lOOPS of inspection, further non-conformances are

Leas than or equal to (i.e. nut greater than)

found, the cope .man be increued to 100 % far the joint type in

r. Sum of

question.

() Mmgt.h of weld over which meaauzement ma,y be

Subject to any other locat.ional requireme11ts.

1 "Lap" ahaU apply to any fillet welded attachment whose length in

averaged (mm)

the longitwtiDal direction ezceeda 00 mm.

[] LeDgth of weld over which the swnmation is made (uun)

' Lamallar tears may only be accepted in the longitudinal welda if

I Le.ngth parallel to the weld uia

the eatent does aot eaceed limita tor lack or t'uaion in transverse

THIS COPY IS CONTROLLED CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 16 of 20

Wood Group - CCC Ltd

Contract-C311163

Structural Steel and Pipe Support Fabrication

Table A.l- Scope of inspection- FreqU8Dcy of testing of joints ldentlfted in Table A.l as

requiring non-deatructlve testing

Cai:elloriea of joint typM aeeordlas to location ADd orieJitatiolllu lltnachlre

<-ftaue 'below)

Site welds

Traua- butte in wall 11nd flaDp plates

befbre-bly

r.cmgitnctinal welda

Piret 6 identified joiDU of each t.nJe

haviDJ the aame basic au-u.io1111,

mat.lal aad weld pometry

to the - prooedwee.

'l'herafter, 1 in 5 joiuta of each type

(it the 6nt 5 contorm to Table A.8). b

All ident.iftecl joints

0.& min ach 10 m, or part thaNofb

Secondary attachment e.J. for mine pur)inl, llicle raila, buckling 1 in 20 attaohmen

welda ati!renera etc.

M lll!lllber ZOne5

l Transverse to melllber axis (any direction)

L = Longituclinaf (parallel to me.ater ilxis)

Bounclilly betweefl mnnedion and meMber zones

---- MBibet Axis

THIS COPY IS CONTROLLED CHECK CURRENT REVISION STATUS

--

I

I

I I

1----------J

Reference

Revision

Page

CON-311

00

Page 17 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

Task Name: Structure Steel Assembly & Pipe support Fabrication

Step

No

1

2

3

4

HAZARDS I

THREATS

Description of What could go

Control measures/Recovery

Action I

Task Step wrong? How Consequences Responsible

serious would that

measures

party

be?

1. Prepare the method Statement,

JSA approval.

2. Prior to start of activity work

permit system shall be

obtained.

3. Permit shall be displayed at the

worksite inside permit boxes as

per regulation.

4. Site Engineer's name and

phone no. should be available

Permit

5. Emergency contact numbers

Procedure

Violation of

Personal

and grid reference should be WG-CCC

procedures displayed in the permit boxes. Engineer

6. Daily concurrence from

concerned parties shall be

done on daily basis.

7 All persons involved on the job

have to discuss and understand

the work permit, and the

Method Statement and JSA

Manual handling Training,

General Recommendation as per

PDO SP1231 Section 11. 1

Avoid the need for manual

handling, as far as reasonably

practicable.

WG-CCC

Back Injuries I

Use a lifting device or seek

Manual Handling Incorrect I Permanent Back

assistance to lift loads greater

Engineer/

tasks Improper Posture Injury than 25 kg in weight

Workers

when lifting

Discussion in Toolbox Talks

TBT

Only certified, trained and competent

persons shall conduct this operation.

Welding (Arc and Personnel not All employees shall go through HSE Welding

submerged) and competent I Personal Injuries induction program Engineer I

Cutting certified. Wear proper PPE; welder's gloves, Foreman

goggles/visors and spatter proof

clothing when required.

Gas under

Explosion, pressure

Use competent persons to service

pressure

release may injure or

fire extinguishers off site. Technician

kill.

Inhalation of chemical

Use competent persons to service

Chemicals may lead to

fire extinguishers off site. Wear PPE.

Technician

respiratory disease

Fire safety Inhalation of chemical

Toxic gas

may lead to Use competent persons to service

Technician

respiratory disease or fire extinguishers off site. Wear PPE.

cause death.

Inhalation of fumes

may lead to

Use competent persons to service

Fumes asphyxiation. It may

fire extinguishers off site. Wear PPE.

Technician

also cause eye

irritation.

THIS COPY IS UNCONTROLLED- CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-31 1

00

Page 18 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

Task Name: Structure Steel Assembly & Pipe support Fabrication

Step

No

5

6

7

HAZARDS I

THREATS

Description of What could go

Control measures/Recovery

Action I

Task Step wrong? How Consequences Responsible

serious would that

measures

party

be?

Defective lifting

Third party inspection and

May result to serious certification of lifting equipment and

equipment/

injury appliances. Color code. Maintenance

Engineer

appliances

inspection.

People working Hit by moving Strict supervision, Trained banks

near by the equipment resulting man to give signal, Effective TBT. Engineer

moving equipment injury Restrict entry in loading area,

Unsecured heavy

Secure load before lifting Personnel

Serious injury keep distance while loading. Trained Driver

load

banks man.

Imbalance load in Vehicle accident/ To keep the load in center of the

Driver

vehicle rollover vehicle, and secure.

Movement of

construction

Load slippage Asset damage,

Clean the vehicle before loading.

Operator I

activities Secure the load with proper tackles.

from vehicle Personnel Injury

Follow SP 2001.

Driver

Unsecured load

Asset damage Secure the loads in the vehicle with Operator I

while

transportation

Vehicle Accident proper tackles. Driver

Bad weather/ Load falls, vehicle

Stop work in bad weather

Operator I

Poor visibility accident Driver

Over loading of

Tire failure/ rollover

Load below the max capacity of Operator I

vehicle vehicle. Driver

May cause accident/

Follow the traffic rules and sign.

Driver attitude Maintain the speed limit; follow the Driver

falling of load.

track and speed limit while turning.

Gas under

Explosion, pressure

Use competent persons to service

release may injure or Technician

pressure

kill.

fire extinguishers off site.

Inhalation of chemical

Use competent persons to service

Chemicals may lead to Technician

respiratory disease

fire extinguishers off site. Wear PPE.

Gas cutting of

structure Inhalation of chemical

member

Toxic gas

may lead to Use competent persons to service

Technician

respiratory disease or fire extinguishers off site. Wear PPE.

cause death.

Inhalation of fumes

may lead to

Use competent persons to service

Fumes asphyxiation. It may

fire extinguishers off site. Wear PPE.

Technician

also cause eye

irritation.

Only certified, trained and competent

persons shall conduct this operation.

Personnel no All employees shall go through HSE Gouging

Gouging competent I Personal Injuries induction program Engineer I

certified. Wear proper PPE; welder's gloves, Foreman

goggles/visors and spatter proof

clothing when required.

THIS COPY IS UNCONTROLLED- CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 19 of 20

Wood Group - CCC Ltd

Contract-C311163 Structural Steel and Pipe Support Fabrication

Task Name: Structure Steel Assembly & Pipe support Fabrication

Step

No

8

HAZARDS/

THREATS

Description of What could go

Control measures/Recovery

Action I

Task Step wrong? How Consequences Responsible

serious would that

measures

party

be?

Work area will be kept tidy at all

times with periodic removal of work

waste such as un used wood and

Order of work excess section of steel. Structural

area The inside of the piping system will Engineer

House keeping be kept clean by removal of

consumables or accumulated dust or

sand.

Waste wi ll be disposed of in the

Hygiene

assorted containers according to type Structural

with wood and metal being separated Engineer

from plastic and food waste

THIS COPY IS UNCONTROLLED - CHECK CURRENT REVISION STATUS

Reference

Revision

Page

CON-311

00

Page 20 of 20

Method Statement for Structural Steel Pipes Support Fabrication CON- 311 Comments Incorporated

Sl No. Item No. Comments

Action

Page No. Remarks

Completed

1 Clause 3- 51. No: Check whether DEP 30.48.40.31- GEN. is applicable? Yes Deleted Page 4 of 20

2 Clause 3 -51. No: Mentioned the full title of BS EN 1011 Yes Page 4 of 20 Section 3 of 16

ProCon Page l of 1

Overvi ew Contracts

You are here: Contracts_1'1anjlll. I Contract (C31-1163) I ActiVIties I View Activities I Activit y Profile

Correspondence from PDO (CFP0869) ~ v i e links rec1pient history

MS for Structural Steel and Pipe Support Fabrication- CON-311, Rev F ./ j Title

Originator

Recipient

Gopal Krishna OSETllx Origi nat ed 25 May 2011 OO:OO(Gt1T +4.00)

Alex Deans Owned From./ 2S May 2011

Wi th reference to your letters no: WGC-PDO-'i-00296 dated 21th May 2011, please note that your

submission on above subject matter have been reviewed and is approved with comments.

Description

Created

1

Approved

Approved Comments

Last Updat ed

Documents

MS for Structural Steel and Pipe Support Fabrication- CON-311, Rev F /

Clause 3-SI. No: 11 Check whet her DEP 30.48.40.31 - Gen. is applicable?

Clause 3-SI. No: 17 Mention the full title of BS EN 1011

25 May

2011 by Gopal K1ishna OSETllx

Current State Approved

28 May 2011 by Abdul lah Harthy OSI:: T

28 May

2011 by Alldulfall Hartlw OSET

No documents added, please add documents usi ng the 'Add File' l ink above.

Activity Tasks add task

No tasks have beed added. Please add tasks using the "add task" l ink above.

https://procon.pdo.co.om!ProCon/Supplier Site/home.asp?UscrMcssagcs=%3CUser. .. 28/05/2011

Você também pode gostar

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocumento25 páginas007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanAinda não há avaliações

- Structural Steel Fabrication and Erection SpecificationDocumento21 páginasStructural Steel Fabrication and Erection SpecificationFarid RezaeianAinda não há avaliações

- Steel Fabrication and Erection SOPDocumento8 páginasSteel Fabrication and Erection SOPMDhana SekarAinda não há avaliações

- Method Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Documento9 páginasMethod Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Azel Bumagat94% (18)

- Method Statement For Structural Fabrication & ErectionDocumento11 páginasMethod Statement For Structural Fabrication & ErectionBinay93% (15)

- Erection ProceduresDocumento7 páginasErection ProceduresIbrahim AlsayedAinda não há avaliações

- Structural Steel Checklist 17Documento2 páginasStructural Steel Checklist 17mgb2010hotmailcomAinda não há avaliações

- Piping Fabrication and Erection ProcedureDocumento15 páginasPiping Fabrication and Erection ProcedureMuhammadChabibi83% (6)

- Method Statement For Steel Structure & Erection PDFDocumento16 páginasMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Steel Structure Fabric & Installation - Doc Rev01Documento7 páginasSteel Structure Fabric & Installation - Doc Rev01whah11Ainda não há avaliações

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Documento9 páginasMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepAinda não há avaliações

- 8.steel Structure WorkDocumento15 páginas8.steel Structure Workibal_farhan100% (4)

- Jabali Project Steel Structure ErectionDocumento26 páginasJabali Project Steel Structure ErectionNick LawAinda não há avaliações

- 035-Procedure Structural Steel Repair Works at Site PDFDocumento14 páginas035-Procedure Structural Steel Repair Works at Site PDFKöksal Patan100% (1)

- Structural Steel Procedure.Documento9 páginasStructural Steel Procedure.Janardhan Surya100% (1)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocumento14 páginas016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- Fabrication Procedure Steel Structure TSEDocumento21 páginasFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Method Statement For Concrete ProductionDocumento20 páginasMethod Statement For Concrete ProductionAnduel SelamajAinda não há avaliações

- Method Statement For Structural ErectionDocumento15 páginasMethod Statement For Structural Erectionchallam4239100% (11)

- Steel Fabrication Method StatementDocumento12 páginasSteel Fabrication Method Statementvolcanox1288% (59)

- Method Statement of Steel FabricationDocumento15 páginasMethod Statement of Steel Fabricationjohney290% (10)

- Fabrication Method StatmentDocumento11 páginasFabrication Method StatmentAkhilesh KumarAinda não há avaliações

- Erection Steel Structure ProcedureDocumento15 páginasErection Steel Structure ProcedureOussama Sissaoui100% (1)

- 01 Procedure For Structural SteelDocumento9 páginas01 Procedure For Structural Steelpunitg_2Ainda não há avaliações

- Zee-Method Statement For Construction Steel Platform ErectionDocumento8 páginasZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7Ainda não há avaliações

- 04-1 QCS 2014Documento7 páginas04-1 QCS 2014Raja Ahmed Hassan100% (1)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Documento10 páginasQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- Fabrication and Installation of PipingDocumento26 páginasFabrication and Installation of PipingAlin TomozeiAinda não há avaliações

- X6 Structural Steel Erection Inspection Test PlanDocumento11 páginasX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- Check List of Steel Structure ErectionDocumento1 páginaCheck List of Steel Structure ErectionUtku Can KılıçAinda não há avaliações

- Structural Steel Inspection ReportDocumento2 páginasStructural Steel Inspection ReportAnnaAinda não há avaliações

- Method Statement of Steel FabricationDocumento15 páginasMethod Statement of Steel FabricationLenin100% (3)

- Procedure - Fit-Up & AssemblyDocumento8 páginasProcedure - Fit-Up & AssemblyRakesh RanjanAinda não há avaliações

- HDPE PipesDocumento4 páginasHDPE PipesAshraf Mohammed100% (2)

- Structural Steel FabricationDocumento14 páginasStructural Steel FabricationClarkFedele27Ainda não há avaliações

- Codes Standards For Structural Steel Fabrication ErectionDocumento7 páginasCodes Standards For Structural Steel Fabrication Erectionelangorenga67% (3)

- Working Procedure For Pipes and GatesDocumento29 páginasWorking Procedure For Pipes and GatesAdvance Hydro Power Works Pvt. Ltd.Ainda não há avaliações

- ITP Fencing Rev - 00 PDFDocumento3 páginasITP Fencing Rev - 00 PDFanon_987276020Ainda não há avaliações

- Uganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementDocumento14 páginasUganda Entebbe International Airport Upgrading and Expansion Project Steel Work Method StatementAkatwijuka AllanAinda não há avaliações

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDocumento5 páginasOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanAinda não há avaliações

- Procedure For Steel Structure: Fabrication & ErectionDocumento2 páginasProcedure For Steel Structure: Fabrication & ErectionnksAinda não há avaliações

- Fabrication Procedure for Structural SteelDocumento14 páginasFabrication Procedure for Structural SteelDanang Edi Prasetyo70% (10)

- DBST MSDocumento8 páginasDBST MSKrishan RodrigoAinda não há avaliações

- 3B - Method Statement - StructuresDocumento123 páginas3B - Method Statement - Structuressreesailam100% (2)

- Method Statement For Steel ErectionDocumento15 páginasMethod Statement For Steel Erectionstrikersam95% (20)

- Fabrication ProcedurDocumento7 páginasFabrication ProcedurHarry PangestuAinda não há avaliações

- Inspection and Test Plan For Steel StrucDocumento6 páginasInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Blasting & Painting ProcedureDocumento10 páginasBlasting & Painting ProcedurepraksahAinda não há avaliações

- HSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE FabricationDocumento19 páginasHSTD-PTSCMC-TS-Q-PR-0001 Dimension Control Procedure For TOPSIDE Fabricationngtchung100% (2)

- 026-Itp For Structural Steel PDFDocumento18 páginas026-Itp For Structural Steel PDFKöksal Patan100% (11)

- 5.0 PENSTOCK - OkDocumento10 páginas5.0 PENSTOCK - Okjarabos8609Ainda não há avaliações

- STEEL FABRICATION METHOD STATEMENTDocumento14 páginasSTEEL FABRICATION METHOD STATEMENTKhyle Laurenz Duro100% (4)

- Guidesteelworkssupervision PDFDocumento78 páginasGuidesteelworkssupervision PDFPhạm Văn ĐảngAinda não há avaliações

- Bored Cast in Situ Method LogyDocumento77 páginasBored Cast in Situ Method LogySujan RajkumarAinda não há avaliações

- STRUCTURAL STEEL Rev.1Documento11 páginasSTRUCTURAL STEEL Rev.1mohdAinda não há avaliações

- 05 12 00 Structural Steel FramingDocumento15 páginas05 12 00 Structural Steel FramingAbdul RafiqueAinda não há avaliações

- Power & Water Project Method Statement For Spool Fabrication of Steel PipingDocumento11 páginasPower & Water Project Method Statement For Spool Fabrication of Steel Pipinglion100_saadAinda não há avaliações

- MIP6-CV-0013-008 - METHOD STATEMENT FOR STRUCTURAL STEEL ERECTION - Rev.A4...Documento30 páginasMIP6-CV-0013-008 - METHOD STATEMENT FOR STRUCTURAL STEEL ERECTION - Rev.A4...Kepweng ManggagamotAinda não há avaliações

- 1.method Fabrication Spool (r2)Documento13 páginas1.method Fabrication Spool (r2)sethu109175% (20)

- TS2 - Structural Steelwork Fabrication and ErectionDocumento16 páginasTS2 - Structural Steelwork Fabrication and ErectionmojgfdAinda não há avaliações

- Ultrasonic ProcedureDocumento12 páginasUltrasonic ProceduremnmsingamAinda não há avaliações

- Tradingjournal2 0Documento28 páginasTradingjournal2 0mnmsingamAinda não há avaliações

- MPI Examination Report FormatDocumento1 páginaMPI Examination Report FormatmnmsingamAinda não há avaliações

- Flare Tip Replacement and Flare ModificationsDocumento1 páginaFlare Tip Replacement and Flare ModificationsmnmsingamAinda não há avaliações

- Awareness - 01Documento1 páginaAwareness - 01mnmsingamAinda não há avaliações

- New Microsoft Excel WorksheetDocumento1 páginaNew Microsoft Excel WorksheetmnmsingamAinda não há avaliações

- Tradingjournal2 0Documento28 páginasTradingjournal2 0mnmsingamAinda não há avaliações

- Storage Tank ProcedureDocumento2 páginasStorage Tank ProceduremnmsingamAinda não há avaliações

- Film Process ProcedureDocumento2 páginasFilm Process ProceduremnmsingamAinda não há avaliações

- Flare Tip Replacement and Flare ModificationsDocumento1 páginaFlare Tip Replacement and Flare ModificationsmnmsingamAinda não há avaliações

- Cleaning Tank ProcedureDocumento2 páginasCleaning Tank ProceduremnmsingamAinda não há avaliações

- API-521 Flare KOD Design and Even More - Part 1Documento6 páginasAPI-521 Flare KOD Design and Even More - Part 1Said Ahmed Salem100% (1)

- P91 Profile WpsDocumento6 páginasP91 Profile WpsZead Ali Adal100% (2)

- Chemical STORAGE TANK MSDocumento2 páginasChemical STORAGE TANK MSmnmsingamAinda não há avaliações

- GBA Flare Systems Supplies Flare Equipment WorldwideDocumento14 páginasGBA Flare Systems Supplies Flare Equipment WorldwidemnmsingamAinda não há avaliações

- SIVAGANGAIDocumento1 páginaSIVAGANGAImnmsingamAinda não há avaliações

- GBA Flare Systems Supplies Flare Equipment WorldwideDocumento14 páginasGBA Flare Systems Supplies Flare Equipment WorldwidemnmsingamAinda não há avaliações

- Cut and Weld Works Method StatementDocumento6 páginasCut and Weld Works Method StatementmnmsingamAinda não há avaliações

- Programming in BASIC MSDocumento13 páginasProgramming in BASIC MSmnmsingamAinda não há avaliações

- Cut and Weld Works Method StatementDocumento6 páginasCut and Weld Works Method StatementmnmsingamAinda não há avaliações

- India 2019Documento2 páginasIndia 2019mnmsingamAinda não há avaliações

- Employee pay slip detailsDocumento1 páginaEmployee pay slip detailsmnmsingamAinda não há avaliações

- 7 TET Syllabus Paper 1 Child Development and PedagogyDocumento3 páginas7 TET Syllabus Paper 1 Child Development and PedagogyMohankumar P KAinda não há avaliações

- Driving License in Oman - Some Tips For Beginners.! - Oman Driving License - Some Tips For Beginners - )Documento56 páginasDriving License in Oman - Some Tips For Beginners.! - Oman Driving License - Some Tips For Beginners - )mnmsingam0% (1)

- 16 TET Syllabus Paper 2 Social ScienceDocumento12 páginas16 TET Syllabus Paper 2 Social ScienceMohankumar P KAinda não há avaliações

- TET Paper 1 EnglishDocumento34 páginasTET Paper 1 EnglishKamal KannanAinda não há avaliações

- Programming in BASIC MSDocumento13 páginasProgramming in BASIC MSmnmsingamAinda não há avaliações

- 7566138F-DF69-4990-868A-E7156887E32CDocumento1 página7566138F-DF69-4990-868A-E7156887E32Cmnmsingam0% (1)

- Bonusdream Signed RebrandedDocumento13 páginasBonusdream Signed Rebrandedapi-19972999Ainda não há avaliações

- Materials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersDocumento10 páginasMaterials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersAkilesh Aravindakshan100% (1)

- PavingDocumento14 páginasPavingNur AqilahAinda não há avaliações

- What You Build, We'll Finish For LessDocumento5 páginasWhat You Build, We'll Finish For LessEng Mohammad OmariAinda não há avaliações

- RC STAIR DESIGN CALCULATIONSDocumento3 páginasRC STAIR DESIGN CALCULATIONSAmadi HenryAinda não há avaliações

- Data Sheet - Overhead TravellingDocumento4 páginasData Sheet - Overhead TravellingSugiarto SaptomoAinda não há avaliações

- Spending 2012 02Documento123 páginasSpending 2012 02Mohammod KhanAinda não há avaliações

- Beam-Column Hunch-End Plate Moment Conn PDFDocumento11 páginasBeam-Column Hunch-End Plate Moment Conn PDFnagiA ahmedAinda não há avaliações

- Cement: The Binding Building MaterialDocumento12 páginasCement: The Binding Building MaterialMazharYasinAinda não há avaliações

- MF 200 MekanikDocumento72 páginasMF 200 MekanikNoor Sa'adahAinda não há avaliações

- Repair brickwork safely and effectivelyDocumento8 páginasRepair brickwork safely and effectivelymoni_john_1Ainda não há avaliações

- Lateral Earth PressureDocumento3 páginasLateral Earth PressureDupio German IIAinda não há avaliações

- AWS blank welding formsDocumento3 páginasAWS blank welding formsIvan Garzon100% (1)

- JV0417Q - Item Description DRG - No. REV MATDocumento6 páginasJV0417Q - Item Description DRG - No. REV MATnakultileAinda não há avaliações

- KD Nicholson Bench Lost Art PressDocumento3 páginasKD Nicholson Bench Lost Art PressIulian MihaiAinda não há avaliações

- Country Presentation: MalaysiaDocumento12 páginasCountry Presentation: MalaysiaADBI Events100% (1)

- No No - YesDocumento3 páginasNo No - YesYedda M IlaganAinda não há avaliações

- Back AnalysisDocumento7 páginasBack AnalysisBiren ShethAinda não há avaliações

- Wastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Sección 8-11Documento8 páginasWastewater Engineering - Treatment and Resource Recovery-Metcalf and Eddy 5th Ed (2014) Sección 8-11Ricardo Javier PlasenciaAinda não há avaliações

- Sikalastic®-590: Product Data SheetDocumento5 páginasSikalastic®-590: Product Data SheetKhin Sandi KoAinda não há avaliações

- Revised M.Tech Curricula in Civil Engineering SpecializationsDocumento32 páginasRevised M.Tech Curricula in Civil Engineering SpecializationsMunaganti KiranAinda não há avaliações

- (DR Naik) RCC 1 UpdatedDocumento229 páginas(DR Naik) RCC 1 UpdatedMohammad AliAinda não há avaliações

- DESIGN OF SLAB - ContdDocumento4 páginasDESIGN OF SLAB - ContdmeenuAinda não há avaliações

- Traditional Houses of Rural County WicklowDocumento65 páginasTraditional Houses of Rural County WicklowIndraChelliahAinda não há avaliações

- Investigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA MethodDocumento15 páginasInvestigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA Methodسجى EngAinda não há avaliações

- Actual Lateral Stiffness of Stair in Concrete StructureDocumento10 páginasActual Lateral Stiffness of Stair in Concrete StructureMithun DAinda não há avaliações

- Assignment 3 PDFDocumento14 páginasAssignment 3 PDFVishnu RajgopalAinda não há avaliações

- Jointing Tech - MV Joints & TermsDocumento48 páginasJointing Tech - MV Joints & TermsMichael Hamudikuwanda100% (1)

- Quiz On Construction Contracts 11.19.2022Documento7 páginasQuiz On Construction Contracts 11.19.2022Julian CheezeAinda não há avaliações

- The Best Choice for Network Solutions - Zimmlink IndonesiaDocumento21 páginasThe Best Choice for Network Solutions - Zimmlink IndonesiapuspitagdAinda não há avaliações