Escolar Documentos

Profissional Documentos

Cultura Documentos

10 Tips For Using Infared Effectively

Enviado por

kats2404Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

10 Tips For Using Infared Effectively

Enviado por

kats2404Direitos autorais:

Formatos disponíveis

for Using Infrared Effectively

Using infrared effectively doesnt have to be guess work or a big mystery to solve. A few practical tips can get you prepared to make a better buying decision as well as use an existing oven more effectively.

1. More is not always better. More heat does not accelerate some coatings and it can increase the cooling time or create a need for forced cooling. Especially with air dry coatings, they do not harden until the excess heat has cooled back out of the part. Until then the part will be prone to damage and fingerprints. In these cases it is better to minimize the heat to accelerate the cure process and dont treat it like a bake enamel. Reaching 350o F isnt going to help the drying and may change the coating properties or scorch it! Use a medium or long wave emitter for the best results. Force cooling with something as simple as a floor fan can help immensely too. emitters will result in very fast cure cycles. Various parts, racked with maximum exposure to IR, staggered patterns, or rotated parts can be cured with a well designed medium or long wave radiant oven. The convection produced will cure hidden areas and the parts will also have a longer cycle during which the heat can spread through the part via conduction. Experiment with rack designed to find your optimum arrangement. Generally speaking, if you can easily apply the coatings you should be able to cure it.

10 tips

tips

4. Not all elements are created equal. Different elements deliver heat differently and are therefore better suited to certain applications. As already discussed, the way heat is generated can vary from element to element even though they are all infrared elements. I cant tell you how many times prospective customers have told me, Weve already tried infrared and it doesnt work. When I ask what kind was used or details of the test rig, they have no idea. That to me is a challenge! I try lots of different emitters. Gas, electric, short, medium, long, ceramic, quartz tube, metal sheath, and combinations of the above are all options until they are ruled out. Dont forget infrared and convection combinations or get wild and throw in UV technology. There is a best way to get the job done and sometimes you have to forget what the old timers told you about this newfangled IR stuff not working. Coatings and materials have changed. Try a different wavelength to put a little different spin on the electrons in your materials. 5. Try before you buy. It is always best to take advantage of testing services offered by manufacturers. You wouldnt buy a car without a test drive. Why buy an oven without seeing the results you can expect in your plant? Expect it. Demand it. Dont ignore it. Hopefully by now I have convinced you that the infrared manufacturing wizards can tell you all kinds of things from behind that big curtain. Go see it for yourself. If your process is one that must be done in your plant, most manufacturers can send a test set to your location. Keep in mind that the results from a test set wont be as good as the final engineered oven. Tests prove feasibility and approximate cure cycles. Your actual production results will be even better.

2. Bigger or longer is not always the answer. Look at watt density to determine what will work for you. Dont get over or undersold. Extra oven length uses valuable floor space that could be used for other processes. Would the process be more efficient if a higher watt density emitter is utilized? Some materials or coatings wont handle the increased intensity however if the product can absorb it you can save 1/3 or even half of the floor space. Of course with infrared ovens, you can also plan for a ceiling mounted oven thus utilizing virtually no floor space. This is where an educated buyer would examine all wavelengths to determine the time required and the expected performance of short, medium and long wave emitters.

3. Line Density pack it in! It is best to go for a high line density. Your elements are creating heat and it is a use it or lose it situation. The more parts that are in the oven to absorb the heat produced the better. This is especially true of systems that are percentage timer or SCR controlled with no closed loop feedback. The heaters will continue to produce heat according to the cycle setting. If there are no parts in the oven, radiant heat will be reflected between the oven walls and convection heat that is not contained will escape the oven cavity. Different types of emitters will create a different balance between the radiant and convection heat that they produce. For example, a T-3 lamp has a high efficiency in terms of producing upwards of 95% radiant heat out of the energy applied. Emitters with ceramic materials are less efficient in terms of radiant heat, usually 65-80%, however most the balance is converted into convection heat. A good oven builder will design the oven to contain this heat and utilize it in the process. It offers some of the advantages of a convection oven with the speed and efficiency of IR ovens. It is true that line of sight can be a problem but it is primarily an issue with short wave emitters. Uniformly shaped and a fixed presentation to the

6. Maintenance Are you really going to do it? Maintenance, regardless of how simple it is, is critical for operating an oven at peak efficiency. If you arent likely to do any maintenance, buy an element that doesnt need much. I have gotten requests to add ovens to a line where actually a little maintenance cured the problem. It is simple to do and usually only required monthly or quarterly but yet most people

For more information contact Blasdel: (800) 661-3213 495 W. McKee Street P.O. Box 260 Greensburg, IN 47240 www.blasdel.net blasdel@blasdel.net

10 tips for Using Infrared Effectively

dont do anything to their ovens. If you buy a short wave oven, expect to keep the area clean and dust free. Dust or fingerprints on the lamps will cause premature element burnouts. Reflectors must be clean or they become re-radiators thus changing the wavelength produced and the results of the cure.

continued needed to cover a part. If you are running small parts, there is no reason to turn on the entire oven as you would with a convection oven. You can also zone in length which allows ramping the temperature up or down for optimal curing. The additional money that is spent on zone controls will have a very short payback time if you properly utilize the features.

7. Dont over engineer controls. Match the controls to the reaction speed of the heater. If the emitter takes five minutes to heat up, controlling them with SCRs is over kill. You wont reap the benefits of SCR control. Any style of quartz tube heater cannot be controlled with a percentage timer. The thermal shock on the element will cause element failure very quickly and your parts wont receive proper heat. PLC controls can be a cost savings if your oven has several zones. They can be used as a time controlled device or they will also accept thermocouple inputs. Another benefit is the ability to lock out the controls so the settings cannot be changed at anyones whim. Since infrared emitters respond quickly, adding a phase down controller can save you money when the line stops for breaks. When the conveyor stops or when the controller is activated, the oven temperature drops to a lower temperature setting. When work resumes or the conveyor starts, normal operating parameters are restored. It also saves parts from over baking when they are left in the oven for longer times than the proper cure cycle.

Medium wave quartz tubes are much the same situation. Other sorts of medium and long wave elements can tolerate less maintenance but you will pay for it through bottom line operating costs. Gas or electric makes no difference here. Ignoring gas catalytic heaters that need repacked is just as costly as dirty reflectors and burnt out elements. Maintenance is not that much different from a convection oven. Exhausts should be checked for proper operation and filters changed as applicable. Reflectors or side wall should be cleaned per the manufacturers guidelines. Tighten all electrical connections that may have loosened due to plant vibrations. Replace or repair elements that are not operating at peak efficiency. Clean the floor of the oven and remove any parts that may be in the cavity. That is about it. Surely you can reserve a little maintenance time to prevent a disaster or emergency later when you are pressed for more production.

10. Infrared technology is not rocket science. Even the most casual cook is familiar with the principles behind infrared by using appliances in their own kitchen. The gas burner or electric resistance heater in your oven function just like a gas or electric infrared heater. Enclosing that heat and the other convection heat produced turns it into a convection oven. It isnt new in the market place. It isnt experimental. It has been around since the 1940s or maybe even earlier. Dont be afraid to examine IR as potential solution for your heating, drying or curing needs. n

8. IR can go around corners sort of. Depending on the amount of convection vs. infrared that is created, heating around corners and into blind spots can be a breeze. As already discussed, certain emitters are better for this than others. Medium and long wave emitters are best because they produce some convection heat along with the infrared. They are also going to have a bit slower cure cycle which gives the convection heat time to help cure hidden areas. This convection heat is no different than the heat in a convection oven. IR ovens usually have minimal air flow which helps to minimize contamination. Infrared is not limited to strictly flat parts or those that are rotated. 9. Make it flexible. Use zoning, adjustable width or height to operate in the zone. There are many options that can be built into an oven to make it more flexible. Adjustable widths on vertical ovens or adjustable heights on a horizontal oven are common. Both allow you to maintain optimal focal distance for your emitter. Zone controls allow the operator to use only the portions of the oven that are

For more information contact Blasdel: (800) 661-3213 495 W. McKee Street P.O. Box 260 Greensburg, IN 47240 www.blasdel.net blasdel@blasdel.net

Você também pode gostar

- Us 5890441Documento21 páginasUs 5890441kats2404100% (1)

- Us 7249732Documento42 páginasUs 7249732kats2404Ainda não há avaliações

- F135 Engine SpecificationDocumento2 páginasF135 Engine Specificationkats2404100% (1)

- CB-8491 Heat Recovery BrochureDocumento8 páginasCB-8491 Heat Recovery Brochurekats2404Ainda não há avaliações

- Thin Gap Brochure 2015 WebDocumento12 páginasThin Gap Brochure 2015 Webkats2404Ainda não há avaliações

- Cabin Boom Noise DampingDocumento1 páginaCabin Boom Noise Dampingmanzoni1Ainda não há avaliações

- Lift Calculations: FT LBF FT LBF A F PDocumento3 páginasLift Calculations: FT LBF FT LBF A F Psabzg89Ainda não há avaliações

- Comparison of 10s, 12s, and 14s Lipo Power Systems for RC JetsDocumento1 páginaComparison of 10s, 12s, and 14s Lipo Power Systems for RC Jetskats2404Ainda não há avaliações

- Dillon Aero M-240 Mount Quick Change 500 Round MagazineDocumento2 páginasDillon Aero M-240 Mount Quick Change 500 Round Magazinekats2404Ainda não há avaliações

- Helio ServicesDocumento68 páginasHelio Serviceskats2404Ainda não há avaliações

- StackEconomizer CRE-CCE Boiler BookDocumento22 páginasStackEconomizer CRE-CCE Boiler BookBorisvukic89Ainda não há avaliações

- Heat ExchangersDocumento8 páginasHeat Exchangerskats2404Ainda não há avaliações

- Combined GearboxDocumento8 páginasCombined Gearboxkats2404Ainda não há avaliações

- Computer Controlled Air Isolation SystemDocumento2 páginasComputer Controlled Air Isolation Systemkats2404Ainda não há avaliações

- Von Klip Tip Cs PropellerDocumento12 páginasVon Klip Tip Cs PropellergerezairAinda não há avaliações

- Professor Von Kliptip Explains Constant Speed Propeller SystemsDocumento16 páginasProfessor Von Kliptip Explains Constant Speed Propeller Systemskats2404100% (1)

- Variable Pitch Constant Speed Propellers For Light AircraftDocumento72 páginasVariable Pitch Constant Speed Propellers For Light Aircraftkats2404100% (1)

- Gas Metering System-Woodward - SwiftDocumento4 páginasGas Metering System-Woodward - Swiftkats2404Ainda não há avaliações

- Mil HDBK 1783b Notice 1Documento1 páginaMil HDBK 1783b Notice 1kats2404Ainda não há avaliações

- Mil HDBK 1783bDocumento171 páginasMil HDBK 1783bkats2404Ainda não há avaliações

- Besander TD English 02Documento1 páginaBesander TD English 02kats2404Ainda não há avaliações

- IC 900 IC 910 Ignition ControllerDocumento50 páginasIC 900 IC 910 Ignition Controllerkats2404Ainda não há avaliações

- Q A About Infrared 1Documento2 páginasQ A About Infrared 1kats2404Ainda não há avaliações

- IC 900 IC 910 Ignition ControllerDocumento50 páginasIC 900 IC 910 Ignition Controllerkats2404Ainda não há avaliações

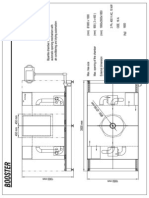

- BOOSTER - EnglishDocumento1 páginaBOOSTER - Englishkats2404Ainda não há avaliações

- Powder Coating IR CuringDocumento4 páginasPowder Coating IR Curingkats2404Ainda não há avaliações

- Silicone MoldingDocumento6 páginasSilicone Moldingkats2404Ainda não há avaliações

- Adjustable OvenDocumento3 páginasAdjustable Ovenkats2404Ainda não há avaliações

- Horizontal and Vertical OvensDocumento2 páginasHorizontal and Vertical Ovenskats2404Ainda não há avaliações

- Rotary and Conveyorized OvensDocumento2 páginasRotary and Conveyorized Ovenskats2404Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Radiation 22021Documento84 páginasRadiation 22021Manas ChuriAinda não há avaliações

- Exergetic Analysis of A Solar Thermal Power PlantDocumento8 páginasExergetic Analysis of A Solar Thermal Power PlantBranislavPetrovicAinda não há avaliações

- Human ComfortDocumento50 páginasHuman ComfortArgha Sang PemimpiAinda não há avaliações

- Cryogenic GuidelinesDocumento31 páginasCryogenic Guidelineszvola100Ainda não há avaliações

- Pool FireDocumento12 páginasPool Firejanelle ramdahinAinda não há avaliações

- Solar Thermophotovoltaics: An Assessment: Related ArticlesDocumento7 páginasSolar Thermophotovoltaics: An Assessment: Related Articlesherdi sutanto adigunaAinda não há avaliações

- Asnt Level 1 Thermography Course ManualDocumento45 páginasAsnt Level 1 Thermography Course Manualchitturi jagadish100% (1)

- Exercise - I: Objective ProblemsDocumento6 páginasExercise - I: Objective ProblemsRishabhAinda não há avaliações

- Astm16 0406Documento6 páginasAstm16 0406kvijaymurAinda não há avaliações

- Introduction To Heat TransferDocumento14 páginasIntroduction To Heat TransferNabil HifzhanAinda não há avaliações

- Heating, Ventilation and Air Conditioning: Building Design 2Documento8 páginasHeating, Ventilation and Air Conditioning: Building Design 2Darren MartinezAinda não há avaliações

- MOgi Jet FireDocumento9 páginasMOgi Jet FireMauro MascheroniAinda não há avaliações

- The Art of Radiometry - J.M. Palmer B. G. GrantDocumento384 páginasThe Art of Radiometry - J.M. Palmer B. G. GrantMaría Ester Oyarzún GuzmánAinda não há avaliações

- SEN710 Engineering Project Initiation: Graded Task 5.2 7.2 9.2 and 11.2: Individual ReflectionDocumento14 páginasSEN710 Engineering Project Initiation: Graded Task 5.2 7.2 9.2 and 11.2: Individual ReflectionDattapriy PathakAinda não há avaliações

- JKLDocumento9 páginasJKLanon_314301380Ainda não há avaliações

- Ch11 GeneralDocumento60 páginasCh11 GeneralPa Loma B. SantosAinda não há avaliações

- HT NotesDocumento197 páginasHT NotesT.AnbukumarAinda não há avaliações

- Thermal Radiation PresentationDocumento42 páginasThermal Radiation PresentationRajan PrasadAinda não há avaliações

- Fire Safety Engineering Design of Combustible Facades - Issue 1Documento42 páginasFire Safety Engineering Design of Combustible Facades - Issue 1octy-san100% (1)

- Heat Transfer Notes EbookDocumento110 páginasHeat Transfer Notes Ebookmichael100% (1)

- Marketing PlanDocumento48 páginasMarketing PlanSarah Abrar0% (1)

- Thermodynamical Modeling of A Car CabinDocumento64 páginasThermodynamical Modeling of A Car Cabinchristopher_moran_6Ainda não há avaliações

- Progress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidDocumento14 páginasProgress in Energy and Combustion Science Volume 6 Issue 2 1980 (Doi 10.1016/0360-1285 (80) 90002-7) F. Briscoe P. Shaw - Spread and Evaporation of LiquidFarahatAinda não há avaliações

- Effects of Solar Radiation On Animal ThermoregulationDocumento27 páginasEffects of Solar Radiation On Animal ThermoregulationVaibhav MaskeAinda não há avaliações

- NF71 Guide To Underfloor HeatingDocumento40 páginasNF71 Guide To Underfloor Heatingngocdhxd92Ainda não há avaliações

- Tutorial 6. Using The Discrete Ordinates Radiation ModelDocumento42 páginasTutorial 6. Using The Discrete Ordinates Radiation ModelIjaz FazilAinda não há avaliações

- HSL Internship Report on Safety Hazards and Control MeasuresDocumento44 páginasHSL Internship Report on Safety Hazards and Control Measureskarthik rajuAinda não há avaliações

- AStudyontheOverheatingofthePowerCableTray IeeeDocumento7 páginasAStudyontheOverheatingofthePowerCableTray IeeebitshitassAinda não há avaliações

- Chapter Four Solar Thermal Energy CollectorsDocumento30 páginasChapter Four Solar Thermal Energy CollectorsJoel LogboAinda não há avaliações