Escolar Documentos

Profissional Documentos

Cultura Documentos

Continuous Ship Unloading (CSU) Efficiency

Enviado por

ZoebairDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Continuous Ship Unloading (CSU) Efficiency

Enviado por

ZoebairDireitos autorais:

Formatos disponíveis

DRY BULK AND SPECIALST CARGO HANDLING

PT3530_2

Continuous ship unloading (CSU) efficiency

Tomas Kisslinger, Managing Director, NEUERO Industrietechnik, GmbH, Melle, Germany

This paper compares the use of pneumatic and mechanical unloaders mainly for grain. Therefore it gives a brief overview of what options are available in the market but also goes into more detail with a comparison between chain type mechanical vs. pneumatic unloaders.

CSU principles

The principle of CSU is to avoid peak unloading by distributing materials in time at the receiving conveyors.

CSU types

Efficiency = average capacity/maximum capacity

The goal is to develop an unloader that achieves higher performance by increasing the average capacity, therefore making better use of the complete installation. The ideal case would be average = maximum, but this is impossible to achieve due to a series of variables, including some of which that are not even equipment related, including rain delays or the amount of visits to each hatch for ship stability.

Pneumatic CSU developments

The main CSU groups are mechanical and pneumatic. The mechanical group can be divided into belt, screw, chain and bucket conveying types.

Average compared with batch

The development of software which uses frequency inverters to control turbo blower rotation speed has resulted in a more constant capacity during operations. It has also increased the ability to control the unloaded capacity. This helps when materials with different specific weights are unloaded or capacity needs to be adjusted to match receiving conveyors. By traditional design the boom should reach the centre of the hatch to achieve ship stability. However, a longer boom would allow one to reach the hatch corners resulting in the need to move less material with payloaders, while bigger payloaders for the clean up work would also help. With these measurements, it is possible to achieve 75 per cent capacity with pneumatic unloaders. As you can see, it is not only the unloader itself but all of the receiving conveyors which determine the maximum capacity of the system; i.e. the system is only as strong as the weakest link in the chain.

CSU is normally compared with a traditional grab batch unloading system. The grab capacity is calculated on the basis of the movement cycle. A buffer is needed to distribute the material load along the cycle, avoiding the extreme peak. CSU does not need a buffer because the peak is not distributed in time cycles, but instead it is continuously transporting material. The consequence of this is normally a lower weight and the fact that operations are environmental enclosed.

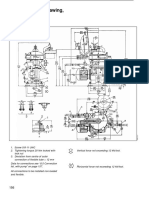

Chain X Pneumatic

A regular chain unloader is used in the same application as a pneumatic unloader because they do not have a feeder, but instead use a free flowing characteristic to feed the unloader. However, this is where the similarities end. The pneumatic unloader is the only CSU that picks up material from the bottom of the hatch. Figure 1 and Figure 3 show it can act like a vacuum cleaner, and remove all products from the hatch. The chain however relies on product pressure to introduce the material in the chain through. The product pressure is achieved by a product column. Looking at Figure 2, the material height is shown as h1 while the remaining height which does not to hit the bottom of the hatch is shown as h2. This is also seen in Figure 4. The distance of the chain unloader from the bottom is dependent on the chain size (2-3m). The design characteristic of the chain system makes it difficult to achieve better average capacities, especially when only one unloader is available and no pneumatic system is available. In many cases portable pneumatic units are used to get better results, although they increase the operating cost.

Capacity definitions

There are many types of capacity, including, for example, nominal, project, peak and average.

Nominal

Nominal capacity is defined by the equipment, normally the maximum capacity it can reach.

Project

Project capacity is normally higher than the nominal and includes some safety.

Peak

Peak capacity is the maximum capacity achievable by the system in short time.

Average

In Figure 1 you can see that the pneumatic unloader reaches the bottom of the hatch, while in Figure 2, the chain unloader does not.

This is the most significant capacity for the customer because in the end it will identify the ship unloading cost. Average capacity measured from the arrival of the bulk carrier until its departure.

P O RT T E C H N O L O G Y I N T E R N AT I O N A L 1

DRY BULK AND SPECIALIST CARGO HANDLING

PT3530_2

Figure 3. Again, the pneumatic unloader picks up material from the bottom of the hatch.

Figure 4. How far away the chain unloader is from reaching the bottom is dependent on its chain size.

The average capacity depends on many factors. Some are influenced directly, while others indirectly i.e. by the unloading system, by local circumstances, available tools and accessories and manpower. Some factors are also not changeable by the system used, therefore they are easier to compare due to physical characteristics. Depending on the type of system, more or less material is left in the hatch and the unloading system needs more or less help to take this material out of the hatch. Inside the hatch, the unloader is normally positioned five times (once in the centre or four in the corners) or nine times. This method of unloading means that the total number of times each hatch must be visited influences the average capacity and also the geometry of the equipment. It is important that the equipment can reach the bottom of the hatch in any situation. For example, one hatch may need to be unloaded and cleaned, leaving only material in the other hatches. Also the method of unloading, (moving five-nine times into the same hatch), means that the total number of times each hatch must be visited influences the average capacity and also the geometry of the equipment. It is important that the equipment can reach the bottom of the hatch in any situation. For example, one hatch may need to be unloaded and cleaned, leaving only material in the other hatches. Some ship designs now allow for this while in the past each hatch had to be partially unloaded three times so that the ship would rise (due to less weight in the hull) and thus the equipment could reach the bottom of the hatches. All these points

ABOUT THE AUTHOR

Tomas Kisslinger has twenty years experience in bulk handling, especially in grain related areas. He has been Managing Director of NEUERO Industrietechnik since 1992.

are important, but they apply to all unloaders as general rules. If we consider the same is true for all CSU types, then the real difference remaining in the end is that the unloading system influences the average capacity. This is shown through the ability of the system to pick up materials right to the hatch bottom, and not only two thirds of the ship.

Conclusion

Average capacity is defined by many variables. When doing a direct comparison between a mechanical system and a pneumatic system, it is easier to calculate. For pneumatic we calculated average capacity between 7075 per cent and achieved it even on barges. Grab use is normally 50 per cent, while chain use is less than 60 per cent. For example, a mechanical system with a nominal capacity of 750t/h and efficiency of 60 per cent should be compared with a 600t/h pneumatic unloader that has 75 per cent efficiency. The client gets results reducing the total unloading time, not to mention that the investment of the receiving conveyors could be reduced accordingly if average capacity gets closer to nominal capacity.

ABOUT THE COMPANY

NEUERO started in pneumatic grain conveying over 80 years ago with the manufacture of small agricultural machines. Since then, the company has delivered equipment in the 20 t/h to 2,000 t/h range to many installations around the world. NEUERO has two companies with sales, engineering, manufacturing and service facilities in Germany and in the US.

ENQUIRIES

Tomas Kisslinger NEUERO Industrietechnik Neuerostr. 1 49324 Melle Germany Tel: +49 5422 9503 20 Fax: +49 5422 9503 50 Email: tk@neuero.de Website: www.neuero.de

2 P O RT T E C H N O L O G Y I N T E R N AT I O N A L

www.porttechnology.org

Você também pode gostar

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingNo EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingNota: 5 de 5 estrelas5/5 (9)

- Chute Design EssentialsDocumento29 páginasChute Design EssentialsJakes100% (3)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- The Issue of Dwell Time Charges To Optimize Container Terminal CapacityDocumento21 páginasThe Issue of Dwell Time Charges To Optimize Container Terminal CapacityAnonymous 3tf6k3alrQ50% (2)

- Share Lect 01 MINE FLEET-1Documento98 páginasShare Lect 01 MINE FLEET-1Goodluck AnaniaAinda não há avaliações

- Facts About Pneumatic Ship Unloaders: LimitationsDocumento2 páginasFacts About Pneumatic Ship Unloaders: LimitationscabekiladAinda não há avaliações

- BSH Efficiency of Ship LoadingDocumento3 páginasBSH Efficiency of Ship Loadingannccknarime100% (1)

- Air Caster-A New Approach in Material HandlingDocumento21 páginasAir Caster-A New Approach in Material HandlingDIPAK VINAYAK SHIRBHATEAinda não há avaliações

- Principle of PDTDocumento9 páginasPrinciple of PDTJoseph OrjiAinda não há avaliações

- Ship Unloading Systems: Mechanical Vs Pneumatic?Documento6 páginasShip Unloading Systems: Mechanical Vs Pneumatic?Milling and Grain magazineAinda não há avaliações

- Hood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheDocumento11 páginasHood Types: Enclosing Hoods Are Those in Which The Source Is Either Partially or Totally Enclosed To Provide TheSudhakar KarnanAinda não há avaliações

- Engineering Letter: PneumaticconveyingDocumento4 páginasEngineering Letter: PneumaticconveyingMangatur SimamoraAinda não há avaliações

- Developments IN Chute Design FOR High Capacity Multi Product ConveyingDocumento23 páginasDevelopments IN Chute Design FOR High Capacity Multi Product ConveyingAlejandra A. Nuñez VidalAinda não há avaliações

- SPE-197302-MS Unmanned Facilities: The Way To $30bn Savings: Michael Nevin, Io ConsultingDocumento8 páginasSPE-197302-MS Unmanned Facilities: The Way To $30bn Savings: Michael Nevin, Io ConsultingzachAinda não há avaliações

- Dust Control in Pharma IndustriesDocumento18 páginasDust Control in Pharma Industriessushant_jhawerAinda não há avaliações

- Adams 2015Documento9 páginasAdams 2015Evan FNHAinda não há avaliações

- Optimizing Pressure Relief SystemsDocumento6 páginasOptimizing Pressure Relief SystemssgrsthAinda não há avaliações

- Conveying: E A. Zenz and D. F. Othmer, "Pneumatic and Hydraulic Conveying," Chapter 10, FluidizaDocumento18 páginasConveying: E A. Zenz and D. F. Othmer, "Pneumatic and Hydraulic Conveying," Chapter 10, Fluidizavalerio.garibay100% (1)

- Pneumatic ConveyingDocumento6 páginasPneumatic Conveyingsudhirm16100% (1)

- Hygienic and Economic Advantages of Low Pressure Pneumatic ConveyingDocumento7 páginasHygienic and Economic Advantages of Low Pressure Pneumatic ConveyingmnoAinda não há avaliações

- Otc 15179 MSDocumento10 páginasOtc 15179 MSHafiz AsyrafAinda não há avaliações

- Calculo Sistemas Alto VacioDocumento3 páginasCalculo Sistemas Alto VacioJulio C.Ainda não há avaliações

- Chute Design Essentials How To Design and Implement Chutes in Bulk Solids Handling SystemsDocumento26 páginasChute Design Essentials How To Design and Implement Chutes in Bulk Solids Handling SystemsKevin HofmannAinda não há avaliações

- Screw ConveyorsDocumento4 páginasScrew ConveyorsAshish SharmaAinda não há avaliações

- Articulos de Tranportadores de SolidosDocumento18 páginasArticulos de Tranportadores de SolidosKYRA NAZARETH MOREIRA BERGESAinda não há avaliações

- Development of A Belt Conveyor For Small Scale Industry: Journal of Advancement in Engineering and TechnologyDocumento5 páginasDevelopment of A Belt Conveyor For Small Scale Industry: Journal of Advancement in Engineering and TechnologyMuhammad Salman KhanAinda não há avaliações

- Dense Phase Pneumatic ConveyingDocumento0 páginaDense Phase Pneumatic Conveyingheroj83Ainda não há avaliações

- Development of A Low-Cost Vibration Damper Dynamometer For Suspension Damper TestingDocumento15 páginasDevelopment of A Low-Cost Vibration Damper Dynamometer For Suspension Damper TestingwkchanxxAinda não há avaliações

- Cement PackingDocumento7 páginasCement PackingCao Ngoc AnhAinda não há avaliações

- Reciprocating Compressor Optimum Design PDFDocumento6 páginasReciprocating Compressor Optimum Design PDF최승원Ainda não há avaliações

- Report of HydraulicsDocumento9 páginasReport of HydraulicsOmaroMohsenAinda não há avaliações

- Material Handling Systems To Boost ProductivityDocumento5 páginasMaterial Handling Systems To Boost ProductivityIntelligratedAinda não há avaliações

- Air Engine Literature ReviewDocumento6 páginasAir Engine Literature Reviewafmzkbysdbblih100% (1)

- 1.1 GeneralDocumento7 páginas1.1 GeneralAravind AravindAinda não há avaliações

- Pneumatic Lift Research PaperDocumento5 páginasPneumatic Lift Research Papertqpkpiukg100% (1)

- Local Exhaust: Design PrinciplesDocumento12 páginasLocal Exhaust: Design Principlesvalerio.garibayAinda não há avaliações

- Implementation Analysis of Vacuum Area Gripping System in Pick and PlaceDocumento12 páginasImplementation Analysis of Vacuum Area Gripping System in Pick and PlaceHaider AliAinda não há avaliações

- Pneumatic Conveying - GJ74, HauckDocumento6 páginasPneumatic Conveying - GJ74, Hauckjfejfe100% (1)

- Project Report ON: Center Jack For CarsDocumento10 páginasProject Report ON: Center Jack For CarsKmineyAinda não há avaliações

- Going Offshore With Membrane Containment Systems - Gastech 2009 2009 PDF 2 1 Mo 2012 04 11Documento26 páginasGoing Offshore With Membrane Containment Systems - Gastech 2009 2009 PDF 2 1 Mo 2012 04 11sililloAinda não há avaliações

- Tech Note 2Documento4 páginasTech Note 2Nitin TembhurnikarAinda não há avaliações

- Primary StructureDocumento47 páginasPrimary StructureKusum GuptAinda não há avaliações

- Pneumatic Mobile CraneDocumento21 páginasPneumatic Mobile CraneMayilai AshokAinda não há avaliações

- Volltext PDFDocumento14 páginasVolltext PDFErik HendersonAinda não há avaliações

- Selección de CangilonesDocumento5 páginasSelección de CangilonesEduardo Jose HerreraAinda não há avaliações

- Efficient Pneumatic ConveyingDocumento14 páginasEfficient Pneumatic Conveying설동하100% (2)

- Bulk Separation of GasDocumento7 páginasBulk Separation of GasEnnecyr Pilling PintoAinda não há avaliações

- A New Engineering Method For Fuzzy Reliability Analysis of Surge Detection and Isolation in Centrifugal CompressorDocumento6 páginasA New Engineering Method For Fuzzy Reliability Analysis of Surge Detection and Isolation in Centrifugal CompressorMohamed HamedAinda não há avaliações

- Simplified Pneumatic Conveying Design Guide: Aman KapurDocumento20 páginasSimplified Pneumatic Conveying Design Guide: Aman KapurKundzo100% (6)

- Inpit CrusherDocumento34 páginasInpit Crusheredgardo olateAinda não há avaliações

- AFC Application On Airline Aircraft - State of The Art - AST 2017-FINALDocumento11 páginasAFC Application On Airline Aircraft - State of The Art - AST 2017-FINALAADITYA SHAHAinda não há avaliações

- 69-Chiara Gilardi Foster Wheeler Italiana-Relief-EDocumento16 páginas69-Chiara Gilardi Foster Wheeler Italiana-Relief-EKamil MarszałekAinda não há avaliações

- Pick and Place Robot For Material HandlingDocumento4 páginasPick and Place Robot For Material Handlingpramo_dassAinda não há avaliações

- Capital Costs EstimationDocumento7 páginasCapital Costs Estimationajaypathak85100% (1)

- SPE 141234 Coiled Tubing Operations From A Work BoatDocumento9 páginasSPE 141234 Coiled Tubing Operations From A Work BoatAli mohammadAinda não há avaliações

- IwsmDocumento3 páginasIwsmJAN JERICHO MENTOYAinda não há avaliações

- Marine Crane Lifecycle CostDocumento3 páginasMarine Crane Lifecycle CostesvalAinda não há avaliações

- Handle With Care: Back To BasicsDocumento2 páginasHandle With Care: Back To Basicskumar_chemicalAinda não há avaliações

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshAinda não há avaliações

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.No EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.Ainda não há avaliações

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocumento9 páginasInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairAinda não há avaliações

- Structures and Mechanisms ClassificationsDocumento1 páginaStructures and Mechanisms ClassificationsminakirolosAinda não há avaliações

- Spring-Supported Thrust BearingsDocumento4 páginasSpring-Supported Thrust BearingsZoebairAinda não há avaliações

- Installation and Operating Procedures: Manual Grease InterceptorsDocumento8 páginasInstallation and Operating Procedures: Manual Grease InterceptorsZoebairAinda não há avaliações

- Datasheet TurbineDocumento2 páginasDatasheet TurbineZoebairAinda não há avaliações

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Documento1 página8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairAinda não há avaliações

- Indigenous ManufacturersDocumento6 páginasIndigenous ManufacturersZoebairAinda não há avaliações

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocumento7 páginasCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairAinda não há avaliações

- Hy 25 ValvesDocumento3 páginasHy 25 ValvesZoebairAinda não há avaliações

- Construction Specification 71-Water Control Gates: Instructions For UseDocumento2 páginasConstruction Specification 71-Water Control Gates: Instructions For UseZoebairAinda não há avaliações

- Pennsylvania: Lehigh University'Documento5 páginasPennsylvania: Lehigh University'ZoebairAinda não há avaliações

- DAMS CFD ModellingDocumento2 páginasDAMS CFD ModellingZoebairAinda não há avaliações

- Lot DHL Com Story Cross DockingDocumento2 páginasLot DHL Com Story Cross DockingMayra SanchezAinda não há avaliações

- Textile Excellence Publication Issue 16-31 August 2020Documento41 páginasTextile Excellence Publication Issue 16-31 August 2020sagarkanzarkarAinda não há avaliações

- Automatic Pneumatic HammerDocumento3 páginasAutomatic Pneumatic HammerIyappan40% (5)

- AnsiDocumento4 páginasAnsiHendrie NMcAinda não há avaliações

- Planning System in IndonesiaDocumento40 páginasPlanning System in IndonesiaHerwan Hardian100% (1)

- FEMCO Holdings, LLC Acquires Capital City Machine Shop, Inc.Documento2 páginasFEMCO Holdings, LLC Acquires Capital City Machine Shop, Inc.PR.comAinda não há avaliações

- 5SDocumento56 páginas5SInderpreet Singh AhujaAinda não há avaliações

- Scrap MetalDocumento23 páginasScrap Metalhermankl73Ainda não há avaliações

- Denitex Ltd. - Operation Management: Course: MGT 314 (Section-5) (Fall 2019)Documento18 páginasDenitex Ltd. - Operation Management: Course: MGT 314 (Section-5) (Fall 2019)Moyurica Amin50% (2)

- World Class Manufacturing, 16Documento14 páginasWorld Class Manufacturing, 16Santhilal S Pillai100% (1)

- Improving The Properties of Green Sand by The Process of Pre Cooling Using Preliminary Cooling SetupDocumento5 páginasImproving The Properties of Green Sand by The Process of Pre Cooling Using Preliminary Cooling SetupSaravanan NandagopalanAinda não há avaliações

- HempShive PresentationDocumento11 páginasHempShive PresentationNabeelAhmedAinda não há avaliações

- Spe 76-202 Sep 2012Documento8 páginasSpe 76-202 Sep 2012akashdruva892100% (1)

- Steel Monkey LadderDocumento14 páginasSteel Monkey LadderGhayas JawedAinda não há avaliações

- C 1047 - 99 QzewndcDocumento3 páginasC 1047 - 99 QzewndcGarcia ManuelAinda não há avaliações

- Actma Batch 14 Quiz..Documento3 páginasActma Batch 14 Quiz..Mark Tozuka100% (1)

- Most Common Cause of Bearing FailureDocumento7 páginasMost Common Cause of Bearing FailureTim KuAinda não há avaliações

- Demo2000 Rev BrosjyreDocumento36 páginasDemo2000 Rev Brosjyre1mmahoneyAinda não há avaliações

- Me 5600 Term ProjectDocumento14 páginasMe 5600 Term Projectapi-324383351Ainda não há avaliações

- Compression Molding: Neslihan Yağmur 11/12/2012Documento17 páginasCompression Molding: Neslihan Yağmur 11/12/2012Not-Not MarkonotAinda não há avaliações

- Role of Different Samples in The Export Oriented Apparel IndustryDocumento7 páginasRole of Different Samples in The Export Oriented Apparel Industrymehedi_mollah50% (2)

- Project Apollo End Item Specification Boilerplate Number 26Documento65 páginasProject Apollo End Item Specification Boilerplate Number 26Bob Andrepont100% (1)

- Project Report PDFDocumento15 páginasProject Report PDFabubakar09ectAinda não há avaliações

- NCR Supplier PPAP Training PresentationDocumento166 páginasNCR Supplier PPAP Training Presentationmelissa mendoza0% (1)

- Interating TQM & SCMDocumento20 páginasInterating TQM & SCMKhanh Chi TranAinda não há avaliações

- JLT CompaniesDocumento4 páginasJLT CompaniesAjay KrishnanAinda não há avaliações

- C20 Extraction of MetalsDocumento31 páginasC20 Extraction of MetalsKris DookharanAinda não há avaliações

- VP Engineering Program Management in Detroit MI Resume George MouaikelDocumento2 páginasVP Engineering Program Management in Detroit MI Resume George MouaikelGeorge MouaikelAinda não há avaliações