Escolar Documentos

Profissional Documentos

Cultura Documentos

Adamatic Model ADR 2c 2 Poket Divider Rounder

Enviado por

Rogelio OtelioDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Adamatic Model ADR 2c 2 Poket Divider Rounder

Enviado por

Rogelio OtelioDireitos autorais:

Formatos disponíveis

ADR-2 DIVIDER/ROUNDER

Extremel y accurate scaling and rounding.

Producti onspeeds up to 4,800 pieces per hour.

STANDARD FEATURES:

Speeds up to 40 strokes per minute.

Fully adjustable hydraulic main piston,

assuring accurate scaling with minimal

dough punishment.

Mechanical variable speed and rounding

control.

I

Stainless steel covers... electrically

E interlocked for safety.

Adjustable gravity feed oiling system.

Flour duster.

Simple weight adjustment.

-l-'---.J3 L27---

BISSC approved. Easyto clean and

maintain.

UL listed control panel.

ADRtool group.

DIVIDING RANGES:

1 pocket: (bread) 10to 19 oz (280 to 532 gr).

2 pocket: (bread & rolls) 1to 8 oz (28 to 224 gr).

3 pocket: (rolls) 1to 3 oz (28 to 84 gr).

OPTIONAL EOUIPMENT:

1

Digital total stroke counter.

SPECIFICATIONS:

Electrical - 220/60/3 (other voltages available).

271 /2"

Total amps - 20 at 220 volts.

Shipping weight - 2,150 lb.

Scaling and production weights may vary with

different dough consistencies.

34"

591/2"

Manufacturerreservesthe right tomakechanges in sizes and specifications.

nDnmnTIC

607 Industrial Way. Eatontown. NJ 07724 * Teleohone 800 526-2807 * FAX (732) 544-0735

ADAmATIC

MANUFACTURERS OF AUTOMATIC MAKEUP SYSTEMS FOR THE BAKING AND FOOD INDUSTRIES

TABLE OF CONTENTS

INTRODUCTION.........................................................................

CONTACTS

ADR-2CMANUALINTRODUCTION

GENERALDESCRiPTION............................................................ 2

INSPECTION..... .......................................................................... 3

INSTALLATION&START UP..................................................... 4

OPERATINGINSTRUCTIONS.................................' ................... 5

SAFETYPRECAUTIONS.............................................................. 6

MAINTENANCE.......................................................................... 7

DRAWiNGS.................................................................................. 8

COMPONENTTECHINFO....................................................... 9

CUSTOMERAPPENDIX.............................................................10

607 INDUSTRIAL WAY WEST EATONTOWN, NJ 07724-2299 732-544-8400 FAX: 732-544-0735

ADAmATIC

MANUFACTURERS OF AUTOMATIC MAKEUPSYSTEMS FORTHE BAKING ANDFOOD INDUSTRIES

ADAMATICCONTACTS

Please usethefollowingnumbertocontactADAMATIC personnel. The main

phone'numberis1-800-526-2807andthemainfaxnUlnberis732-544-0735

SALES DEPARTMENTEXTENSIONS

CustomerService Ext. 3056,3055

LouGiliberti Ext. 3046

ENGINEERING DEPARTMENTEXTENSIONS

Rohin Mirza Ext. 3064

WalterKopp Ext. 3066

SERVICE DEPARTMENTEXTENSIONS

BILLCUNNIFFE Ext. 3034,3035

PARTS DEPARTMENTEXTENSIONS

Bob Kelly Ext. 3038,3039

607 INDUSTRIALWAYWEST EATONTOWN, NJ 07724-2299908-544-8400FAX: 908-544-0735

ADAmATIC

. ADR2C MANUAL

INTRODUCTION

1.1 Thefollowing instructions and assemblydrawings havebeen carefully

preparedtoassistyou in the installing and operating theADAMATIC

2 POCKET DIVIDER/ROUNDERSYSTEM. Theyillustratethearrangement

and installationforthis equipmentonly. The information and suggestions

aretoassistyou in obtainingthe mostsatisfactoryperformance, and alsoto

guideyou in giving itthe reasonable attention andcarethatanyfine

equipmentdeserves. .

1.2 ADAMATIC recommendsthattheinstructions and applicablesafety

precautions befullyunderstood byall personnel directlyinvolved with the

ADR-2C SYSTEM operationand/ormaintenance. Failureto followthe

recommendations ofthis manualcan result in potential hazardsto

personnel and property.

ROLL& BREAD DIVIDER ROUNDER MODEL ADR-2

ROLLS: Divides and rounds 1 oz. to 8

1

/2 oz.

pieces up to 4800 per hour*

BREADS: Divides and rounds 8V2 oz. to 19 oz.

pieces up to 1800 per hour*

DESIGN FEATURES:

Fully adjustable hydraulic main piston drive which

assures extremelyaccurate scaling while minimizing

dough punishment

Uniform, smooth variable speed rounding

Adjustable gravityfeed oiling system

Heavyweight discharge belt

Stainless steel covers ...all electrically interlockedfor

safety

BISSC approved sanitarydesign

Continuous hopperfeeding

Simple weight adjustment

Easyto keep clean and maintain

Standard equipmentincludes one rounding drum and

one scaling die

OPTIONAL EQUIPMENT

Rounding drums and scaling diesfor varied scaling.

weights

Flourduster

Total stroke indicator

Variable speed drive

ELECTRICAL SPECIFICATIONS

1V2 H.P. 220/440/60/3 Total Connected Load

6amp @ 220V

*Scaling weights and production rates mayvarywith differentdougl1

ANOTHER FINE PRODUCTMANUFACTUREDIN U.S.A. consistency.

BYADAMATIC .

SYSTEMS

FORTHE

ADAmATIC

COMPLETE

BAKING

AND FOOD

INDUSTRIES

ROLL &BREAD DIVIDER ROUNDER MODEL ADR-2

FOR ROLLS:THE ADAMATIC

, SPECIFICATIONS:

?d

o

n

n

>-'

13

:::!

0

:z

82" OVERALL LENG1H.

27"

J-J

ROLLPLANT

Produces 1to 8% oz. pieces, upto

4800perhour- forall typesof

varietyrolls (Kaiser, hoagies,.

bagels, pita breads, etc.)

1-----i60'-----'---l1

------rr

'" iII

----+

.

THEADAMATICCOMBINATION FOR BREADOR COMBINATION BREAD&ROLL PLANTS

FORM F-7614 (9/95)

BREADS:Produces6oz.to 19oz.doughpiecesup to 1800perhour. Idealfor productIon ofall types ofvariety breads(rye, Italian,French, white, etc.)

*

*

e

III

*

STRAIGHTLINEINSTALLATION

*

g

N

-.......

ROLLS: Produces 1oz.to8% oz.doughpiecesup to 4800perhour.

I"

"I

j;f--(t)

VI

IIIo Dill

g

8

U-SHAPEDINSTALLATION

Manufacturer reserves the right to make changes in sizes and specifications.

..... . . .. '......

NO OF POCKETS A B

IN PROOFER SLINGS OVERALLHT. OVERHEAD HT.

720 2 1171,h" 31 '12,"

960 3 130" 44",

1200 4 142%" 56'h"

,REFERENCEDIMENSIONSONLY

-----j]]T

... __il

4 @

1. ADAMATICADR-22 POCKETDIVIDER-ROUNDER "G'N'

2. FLOUR DUSTER

3. ADAMATIC ROLL PROOFER-4ACROSS

4. CROSS CONVEYOR

5. STAMPING MACHINE

NO'OF POCKETS DIMENSIONS (INCHES) REFERENCE ONLY

IN PROOFER

A B C D E F

264NET 40 89 73 95 131 156

300NET 40 ,93 73 95 131 156

360NET 40 74% 73 110 131 156

480NET 57'12 125 83 105 148Y:! 173%

600NET 57% 104 83 120 148Y:! 173'12

'

NOOF POCKETS

IN PROOFER

DIMENSIONS(INCHES) REFERENCE ONLY

A B C D E F

264NET 40 180 223 89 73 95

300NET 40 184 223 93 73 95

360 NET 40 165Y:! 223 74Y:! 73 110

480 NET 40 216 223 125 83 105

600NET 57Y:! 195 240Y:! 104 83 120

720NET 57% 235 240% 144 83 120

960 NET 57% 246 240% 155 83 135

1200NET 57'12 300 240% 209 83 135

ADAmATIC

607 INDUSTRIALWAYWEST

EATONTOWN, NEWJERSEY 07724-2299

(908) 544-8400

FAX (908) 544-0735

ADAmATIC

. INSPECTION

3.1 Checkthe parts received with the shipping lists; reportany

shortages.

3.2 Immediatelyafterunpackingthe DividerRounder, checkfor

possibleshipping damages. Ifthis unitis found to bedamaged

afterunpacking material, contact the carrierwithin 15days of

delivery.

3.3 ContacttheAdamaticService Departmentat(732) 544-

8400.

l_.

1

nDnmnTIC

('"

'--

MODELADR2C

2 PocketDivider/Rounder

INSTALLATION

When installing a newmachine,careful attentionshould bepaidtothefollowing

points:

1. Ensurethatthemachineis level and stable.

2. Remove all covers andcheckforanyobvious damagethatmayhave

occurred duringtransit. Anyhidden damagemustbe reported tothe

delivering carrierwithoutdelay.

3. Wipetheworking surfaceswith a clean clothto remove all traces of

preservativewhich is applied bythemanufacturerforprotection during

transit.

4. Before initial startup,coatthemain plunger, main plungerchamberand

backpocketslides with specified mineral oil, as itwill taketheautomatic

lubricatora fewminutestoinitiallydistributeoil totheworking surfaces.

ADnmATIO

MODEL ADR2C

2 POCKET DIVIDER/ROUNDER

OPERATION

Procedureswhich entail dismantling anypartofthe machineshould notbe

undertaken until itis ensured thatthe main powerswitch is in the "OFF"position.

STARTING PROCEDURES (each run)

Thefollowing description coversthefull procedurenecessarytopreparethe

machineforeach production run, butitwill befound thathaving onceachieved a

specificresult, manyofthe adjustmentswill notbenecessaryforsubsequentruns

unless a differentdough mixis introduced.

1. Checkthelevel ofthespecified mineraloil in thetransparentreservoir

andfill ifnecessary. NOTE: Oil mustalways completelycoverthe

filter.

2. Selecttheweightattachmentto givethe required weightofroll. This will

~ determined mainlybyexperiencedepending uponthe type ofdough

used.

3. Coat"the weightattachmentwiththemineral oil and insertintotheback

pocketofthe machine. Ensure thatitis pushed fullyuptothestop.

Then lockin posi"tion withthe hexagonalscrew. It is importantthatthe

screwis fullytightened.

4. Selectandfitthe outermoulding drumcorrespondingtotheweightand

volumeofroll being produced. The correctposition in which thedrum

should be keyed will bedeterminedwhenthe machineis running and

shouldthen be markedforfuture use. Tightenthedrum in position by

meansofthe largehand-wheel ensuring thatthedrum is fullyseated.

Thereshould be noend playonthedrumwhen it is tightened.

5. Tighten the moulding beltwiththe ratchet handle.

6. Coatthe main plunger, main plungerchamberand backpocketslides

with the mineral oil.

7. Insertthe main plungerintothe hopperpocketand connectthe main

piston connecting road to mainpiston arm.

8. Coottheinsideofthe hopperwith the mineraloil.

9. Selecttheweightsetting onthe handwheellocatedatthebackblock.

Turn clockwiseto reducetheweightand counterclockwiseto increase

theweight. Then lockwiththethumbscrew. Makesurethatall covers

areon securelyand doorsareclosed.

10. Turn themainswitch liON".

11. Startthe machine.

12. Ifthemachinecycles satisfactorily,fillthehopperwith dough. The

weightcontrol barshould positivelytouch thestop attheend ofthe

. weightadjustmentscrew. Exceptwith certain difficultorelastic doughs,

accurateweights will resultwhenthe hydraulicpressure is just high

enough fortheweightcontrol bartotouch thestopwithouthammering.

Ifanelasticdough is being used,thepressure n1ay haveto beset higher

toachieveaccurateweight, butcaremust betaken notto run the

machineatneedlesslyhigh pressure becauseofthe resultantshock

loading onthe machine.

13. Checktheproductweightsand adjustifnecessaryas described in

paragraph 12,or, ifgreatervariation is necessary, paragraphs 2 and

12.

14. Observe ifthedoughpieces dropcorrectlyintothe mouldingdrum. If

thepiecesfall in frontofthe holes, slackthe moulding beltand move

thedrumcounterclockwisethe required amount,and re-engage inthe

appropriateslotandtighten. Tension the belt. Ifthepieces fall behind

the holes,thedrumshould be moved clockwise.

15. Ifmoremouldingturns arerequired onthe inne'rmoulding drum,the

small handwheel belowthedischargeconveyorshould beadjusted. Do

notadjustwhen machineis stationary.

16. Theflowofthe mineral oil tothe main plungerorbackpocketslides

maybe varied byturningtheadjustablescrews ofon/offvalves located

insideoil container. We recommend approximatelyon (1) dropofoil

perstroke ofthe machineateach outlet.

WEIGHTRANGES

Thefollowing weightattachmentsand drumsareshown againsttheirapproximate

weightranges. These mayvaryaccording tothe baker'sdough recipe.

MEASURING PISTON AND LINERASSEMBLIES

Item #24180- Piston andlinerassembly

1-5 oz. and 9-20oz.

Item #12637- Piston and linerassembly#4(I/O")

5 - 8oz.

MOULDINGDRUMS

Item #19121 1-2 oz.

Item #19122 2-31/40z.

Item #19123 3-6oz.

Item #19124 5-8oz.

Item #12675 Upto 20oz.*

* The 1/12675" mouldingdrum is builtto orderforspecificweights (8-20ozs.).

Onedrumwill nothandleall dough pieces inthat rangeand itis necessaryto

design a drumforthe exactsealingweight.

LARGE SINGLE PIECE (Maximum 20oz.)

When producing largesingle pieces ofdough,thefollowingvariations in starting

procedureshould be undertaken:

A. Insert measuring piston 1/24180" into backblock.

B. Remove thedoughchutes fromthe machineinterior.

C. Fit largeslotted bread moulding drum"12675".

CLEANING DOWN

BEFORE CLEANINGMACHINEmake sure electrical power to machine is

disconnected. These procedures mustbe carried outaftereach production run

and maypossiblybe necessaryduringthe run. Clean all components which

contactthe productusing a dampcloth. Makecertainthatall hard and glutinous

deposits arecompletelyremoved toallowfreeactiontothesliding components.

When removing componentsfromthe machine, do notunderanycircumstances

use undueforce, as serious distortion could result.

A. Withdrawpin connecting arm main piston and main plunger

arm.

B. Withdrawmain plungerfrom hopperpocket.

C. Thoroughlyclean the hopperchamberand plunger.

D. Removeweightattachment. Ifthe plungerand lineraredifficult

toremove, use the"T"shaped tool provided. This should be

screwed intothe attachmentandthen pulledfirmlyoutwards.

E. Cleantheweightattachmentplungerand liner,then coatwith

mineraloil.

F. Cleantheweightattachmentchamberandcoatwith mineral oil.

G. Clean innerand outermoulding drums.

H. Clean moulding belt.

/. Clean machineframework, etc., ofdough,flourand oil.

PS

GENERALSAFETYRULES

Please reviewthefollowingsafety proceduresand practicethem duringyour

dailyoperationofequipmentObservethesegeneralsafetyguidelinesto secure

asaferworking environmentforyourselfandyourfellowemployees.

1.Equipmentshould notbe operated with safetydevicesby-passedorguards

removed.

2. Onlyqualifiedpersonnel should operatethe machine.

3. Machinesshould notbe started until all personnelareclear.

4. Serviceor maintenanceproceduresshould neverbe performedon amachine

in motion.

S. Mostequipmentrequires ahigh voltageelectrical system. Toavoid shockor

serious injury, onlyqualified personnel shouldperformmaintenanceon the

electricalsystem.

6. All air,hydraulicand electricpowermustbeOFF beforeservicing the

machine.

OPERATING ZONE

An operating zoneshould beestablishedaroundall machines.Abrightly

paintedguardrail orwarning stripeshould definethezone. Onlytheoperatoror

otherauthorized personnel should be withinthe operatingzone when machine

control circuitsareenergizedorthemachineis running.

Notoolsorotherequipmentshould be keptwithin theoperating zone.

BakeryEquipmentManufacturersAssociation

111 EastWackerDrive

Chicago,IL60601

312/644-6610

Produced aspart of BEMA's Safety Label Program.

I

ADAmATIC

'\

,

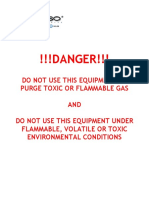

SAFETY PRECAUTIONS

The safety covers on the machine must remain in place during

operation of the machine. Never disconnect safety switches on the

machi ne. All power must be turned off prior to removal of safety

covers for cleaning and maintenance.

Personnel operating the machine must be instructed by the purchaser

in the proper cleani ng, maintenance and safety procedures.

Failure to follow these instructions may result in personal Inlury or

property damage.

NOTE: The following cautions are placed on the machine at

the factory for the safety of operating personnel. Should

any of these labels become missing or damaged, contact the

ADAMATIC Service Department at (732) 544-8400 for

replacements.

CAUTION: DO NOT REACH INTO RUNNING EQUIPMENT.

CAUTI ON: Guards, access doors and covers must be

securely fastened before operating this equipment. Lock out

power before removing guards, access doors and covers.

Failure to follow these instructions may result in personal

iniury or property damage.

CAUTION: Contains moving parts. Keep clear. Disconnect

power before servicing.

DANGER: ELECTRICAL HAZARD. AUTHORIZED PERSONNEL

ONLY.

If

POWER L O C l \ ~ JT lJSEAGE

PLEASE FOLLOW LOCKOUT PROCEDURES FOR Y01JR OWN AND OTI-IERS SAFETY

DATE OUT NAME LOCK # DATE OF' NAME LOCK # EQUIP AND JOB # USED ON

RETURN

I

-

-

~

I

ADAmATIC

Total Performance Lubricants

Raylene Anti-Wear Hydraulic Fluid Series Dependable

Provides Long Service Life and Minimum Wear

Thisis agroup ofanti-wearfluidsspecificallydesignedto meetthe requirements

ofmodern, highperformancepumpsand hydraulicsystems. Theyare blendedfrom

.premiumqualitybasestockswith asuperbcombination ofoxidation inhibitorsto

preventsludgingand depositformation. Further, theirdesign includesahigh level of

wearprotectionto meetthe requirementsofall pumpmanufacturers.

RayJene Anti-Wear Hydraulic Fluids offersuperiorprotection againstcorrosion

and foam and rubberswell, and exhibitexcellentwaterdemulsibilitycharacteristics.

Thesearethequalitiesthatarerequiredto assureefficient, trouble-freeoperationofthe

newhigh-pressurehydraulicsystem. Thisseriesis offered in awide rangeof

!

\

viscositiesto meetall the requirementsoftemperatureand load conditions.

To workeffectively, thehydraulicfluid musthavecertain flowcharacteristicsat

operatingtemperatures and atstart-up. Thegeneral guidelineforthisis asfollows:

Start-up maximumviscosity 400SUS

Operating minimumviscosity 70SUS

Operating maximum viscosity 250SUS

Natura.lly,these parameterswill varysomewhatwiththemanufacturerandthe

specificapplication. However, recommendations based on these limitswillperform

. verywell. .

. RayleneAnti-WearHydraulicFluidsare premium qualityoilswith naturallyhigh

resistancetoviscositychangewith temperature. Theirmanufactureis carefully

checkedto assurethattheymeasureup to thespecification. Finally, beforefilling, the

fluid isfilteredthrough a 10micronfilterto removeall materialsthatcould adversely

affecttheworking partsofthesystem. ' Itisthis carefulattentionto formulation,

manufacture, andcontrolthatassuresoutstanding,dependableperformancefrom

RayleneAnti-WearHydraulicFluid. Forapplicationswith special requirementssuch as

awide range ofoperatingtemperatures,verylowstart-uptemperature, orextremely

high operating pressure's, we recommend RayleneAnti-WearHydraulicFluid L Tseries.

12

ADAmATIC

Model ADR-2C

2 Pocket Divider/Rounder

PERIODIC MAINTENANCE

NewMachine

Afteran initial running in period ofapproximately50 hours, all nutsand screws

should be checked forsecurityand tightened. Anylooseness is duetotheinitial

bedding down ofthe machine.

DailyMaintenance

1. Disconnect main power!

2. Fill edibleoil tank. (Use edibleU.S.P. mineraloil onlywith viscosityof340to

360. Useoflighterviscositymineral oil will voidwarranty.)

~ 3. Lubricateplungersand slideswith mineraloil.

4. Clean machinethoroughlyafteruse.

WeeklyMaintenance

1. Disconnect main power!

2. Givaoneshotofgreaseto all greasenippled

3. Checkoil levelofthehydraulicunitandtopoffifnecessarY.

4. Lubricateall chain driveswith SAE30 MotorOil orhigh qualitymachineoiL

Sufficientaccessto thechainsmaybe obtained by removing machinetopcovers

only.

MonthlyMaintenance

1. Disconnect main power!

2. Removethe innermoutding drum forcleaning. First removetheouterdrum.

Then unscrewthetwohexagonal nuts and withdrawtheinnerdrum complete

with thefront plate.

8

3. Giveoneshotofgreaseto all grease nipples.

4. Remove the main drivesidecoverand brush all chain driveswith oil. Checkthe

chain drivesforcorrecttension and adjustthetensionersprocketsifnecessary.

5. Greaseflourdustereccentric(ifsuppliedwith machine).

6. Lubricatewith oil all pivotpointsand bushing bearings.

7. Checkall nuts and boltsfortightness.

HydraulicUnit

Thefollowing hydraulicfluids are recommended:

ShellTellus32

Bel-RayRaylene HydraulicOil #00-611894

Chevron AWHydraulicOil #32

Exxon Nuto-H32

Failureto use recommended oilsand/orlubricantsvoidswarranties.

Do not use edibleoil orhydraulicbrakefluid. (-

Food grademineraloil: Bell Ray NoToxOil 300 - FoodgradeH-1.

9

I

ADAmATIC

Hydraulicunitbecomes Pressure regulator#13015

solidandwill notcollapse. issticking.

Machinedriveslips. Vbeltworn orstretched.

Hydraulicunitleaks 1. Worn ordamagedseal.

throughmain seal. 2. Damagedpiston rod.

Motorstops. Electrical overloadcutout.

Machine laborsunder Bindingofmain piston

load. and/ormeasuring piston.

Electrical circuitis not

closed.

Machinewill notstart.

10

REMEDY

1. Tighten.

2. Dismantleand clean.

3. Dismantleand replace.

4. Dismantleand clean.

Dismantleand clean.

Replaceifnecessary.

Replace.

1. Replacesesal.

2. Replacecylinder.

Checkmachineon

overloadingand

mechanical binding.

Resetoverload.

Clean main pistonand

measuringpiston.

Checkfuses, checklimit

switches in doorsand

covers.

Hydraulicunitdoesnot

operateorwill notreach

full pressure and is not

fillingthe measuring

pocketsatmaximum

!

\.

pressureadjustment.

ModelADR-2C

2 PocketDivider/Rounder

GENERALSERVICE

It is recommended thatthe O-ringsand hydraulicoil bechanged every2000

hours. Beforechangingtheoil, wash thehydraulicwith hotwaterand drycompletely

with air.

Troubleshooting

FAULT PROBABLECAUSE

1. Bypassvalve not

tightened.

2. Leaking checkvalve,

item #14783.

3. Leaking regulatornot

working, item#13015.

4. Pressure regulatornot

working,item#13015.

1. Lock screw of liner is 1.Tighten correctly.

backblock.

Dough "strings" from

not fastened. 2. Replace knife.

3. Remove shims located 2. Damaged cut-off knife.

between backpocket

between backblock and

3. Excessive wear

bearing guide #12606 and

hopper surface. hopper. Make su re

clearance between hopper

not fully come flush with

4. Measuring piston does

and backblock is .002",

backblock surface. 4. Adjust lever push-out

#15747.

1. See under "Hydraulic." Uneven weights. 1. See under "Hydraulic."

2. Stop machine and

cleaning.

2. Machine requires

clean.

3. Adjust oil flow. See

piston and backblock.

3. Insufficient oil to main

page 3, Par. 16.

4. Adjust oil flow. Check

air.

4. Main plunger leaking

for wear.

Readjust V belt.

working.

Rounding section is not V belts slipping.

11

ADR PREVENTATIVE MAINTENANCE

DAILY

1. FILLEDIBLEOILTANK. (USEEDIBLEU.S.P.MINERALOILONLYWITHVISCOSITYOF340TO360.

USEOFLIGHTERVISCOSllYMINERALOILWILLVOIDWARRENTY.)

2. LUBRICATEPLUNGERSANDSLIDESWITHEDIBLEOIL.

3. CLEANMACHINETHOROUGHLYAFTERUSE.

WEEKLY

1. GIVEONESHOTOFGREASETOALLNIPPLES.

2. CHECKOILLEVELOFTHEHYDRAULICUNITANDTOPOFFIF NECESSARY

3. LUBRICATEALLCHAINDRIVESWITHSAE30MOTOROILOR HIGHQUALITYMACHINEOIL.

SUFFICIENTACCESSTOTHE'CHAINSMAY BEOBTAINEDBY REMOVINGMACHINETOPCOVERS

ONLY.

MONTHLY

. 1. REMOVETHE INNERMOULDINGDRUMFORCLEANING. FIRSTREMOVETHEOUTERDRUM,

THENUNSCREWTHETWOHEXAGONNUTSANDWITHDRAWTHE INNERDRUMCOMPLETEWITH

THE FRONTPLATE.

2. CHECKPINSANDLINKAGEFROM FINGERASSEMBLY.

ADR PREVENTATIVE MAINTENANCE

MONTHLY(CONT'D)

3. GIVEONESHOTOFGREASETO ALLNIPPLES.

4. REMOVETHE MAINDRIVESIDECOVERAND BRUSHALLCHAINDRIVESWITHOIL. CHECK

THE CHAINDRIVESFORCORRECTTENSIONANDADJUSTTHETENSIONERSPROCKETSIF

NECESSARY. CORRECTTENSIONSHOULDALLOWFLEXINGEQUALTO2% OFTHECHAIN

LENGTHBETWEENCENTERS.

5. GREASEFLOURDUSTEHECCENTRIC(IFSUPPLIEDWITHMACHINE).

6. LUBRICATEWITHOILALLPIVOTPOINTSANDBUSHINGBEARINGS.

7. CHECKALLNUTSAND BOLTSFORTIGHTNESS.

HYDRAULICUNIT

THE FOLLOWINGHYDRAULICFLUIDSARE RE;COMMENDED:

SHELLTELLUS32

BEL-RAYRAYLENEHYD.OIL#00

CHEVRONAWHYDRAULICOIL#32

EXXONNUTO-H32

FAILURETO USE RECOMMENDED OILSAND/ORLUBRICANTSVOIDSWARRANTIES.

DO NOTUSEEDIBLEOILOR HYDRAULICBRAKEFLUID.

ADAmATIC

MANUFACTURERSOFAUTOMATIC MAKEUPSYSTEMS FORTHE BAKINGANDFOODINDUSTRIES

ADR 2MANUALS- NEWSTYLE

DRAWINGS INCLUDED:

1. E13233 (REV. D) (3 SHEETS) MAIN ASSEMBLY

OPERATOR'S & DRIVE'S SIDES, WITH SPLIT CONVEYOR

2. e 12601A (REV. M) HOPPER W/ BACKPOCKETASSEMBLY . (Item # 8)

3. e 12648 (REV. S) ROUNDING UNIT ASSEMBLY (Item # 10)

4. e12741 (REV. E) SUB-DRIVE ASSEMBLIES (Item# 12)

5. e 15756 (REV. I) WEIGHT ADJUSTMENT ASSEMBLY (Item # 52)

6. e 18282 (REV. J) V R I B ~ E SPEED MAIN DRIVEASSEMBLY (Item # 55)

7. e17095 (REV. I) CRANKSHAFT & PIVOTARMASSEMBLY (Item # 63)

8. E20211 (REV. G) HYDRAULIC UNIT ASSEMBLY (Item # 81)

W/ B18532- HOSE, HYDRAULIC ASSEMBLY (REV. B)

. 9. D24207 (REV.E) RATCHET BELTTENSIONER ASSEMBLY . (Item # 831.

10. 0625343 FLOUR DUSTER ASSEMBLY, EXTERNAL (Item # 86)

_11.e 27856 (REV. H) DUALCONVEYOR ASSEMBLY .(Item # 87)

. .

12. B618830 (C) ELECTRIC SCHEMATIC

12/01

607 INDUSTRIAL WAYWEST EATONTOWN,NJ 07724-2299 732-544-8400' FAX: 732-544-0735

ITEiVI OPT FIRST LT EFFECYIVE DATES

s

ITEM NO. OESCR I F'T I ON

ENGINEERING

DRAWING NUMBER

DUANTITY

PER UI'1 TYP 1'10. OP SEQ AD,J FROM TO

Ji

8:

.

,, ..-.---b.ABB..:::-.. .. " - .. ---WH_ITE ON-BUJE - .. ,,1,000 EA 2

FRAME ASY AOR :2 E13231 1.000 EA 1

NUT HEX FINISHED 1/2-13 GR5 ZP 8.000 EA 4

.. - 8 .0(l()u EA -4

PLATE I"IT C12802E 1.000 EA 9

SUB ASS V : ADR2 0615844 (11) 1. 000 EA 2

-I;}6-1280502 (MlL000 EA 2

SClST :2. 000" X 2.000" X O. 188" 4 :50:3 FT :3;

SQST 2.000" X 2.000" X 0.188" 4.:50:5 FT :::'

-

.. ,-4-....1-b7 .' :FT 3

. 3.834 FT:::.

3.834 FT 3

--'- '2-.0-42 .. FT 3

1.021 FT 3

2. (;)42 FT

.. , .. r

.250' FT:3

. '"" .. -" -, .. -., -- ';3-65FT :::.

.485 FT::::'

1::;757 SClST X 2.000" X 0.188" 3.8311

0005 1.::,7:::"'7 SnST 2.000" X 2.000" X 0.188" 3.834

....."...., .

. Q068: 00612829 BRACI<ET !'10UNT J 1\PR..' C12820 1 .000 EA 2

, _y ' ''i . --." "- -"'--'--:'''---''-''-;'Q-3!:i'''--FT- '3

LB 2.000" X 2.000" X 0.250" 271 FT 3

LB 2.000X2.000XO.187u A36 .167 FT 3

.. .

S(JST 2.000" X 2.000" X 0.188" 1.417 FT 3

. 1.417

4.000

3.188

FT 3

EA 2

FT 3

.. ...:.._'-"..... '"'-:d'

.0

,,.0-

.. 0

.0

. 0

.0

"..(.) .. _.

.0

.0

-,.0.

0

......

."J

.0

, .(>......

.0 .-----------

.0

, ',"

__

13

,,) 17

" '--'-21,

22:

" , 'ii.-Gl. ..... ! '}' ., U<, == .fl4

.0

... ..:.......:.-... 37'

.0

.0

- .. ..

39;

s* a

.{).

."'__ .. .-- ' 1 ; J:Tl.:::

46:

.0

.0 Hi

.0

.. -;e.... --

.0

.0

-c. ..... W

INDENTED BILL. DATE 12/12/01 TIME 8.05.02 PAGE 2 AMEF72

LT-bl"l ,

ITEM FIRST LT

UM TYP NO. OP SEQ

EFFECTIVE DATES

TO

-6

EA '

2.000 EA 4-

6.000 EA 4

..

.-....._.- .. ,.... _,...........:........ ..i9'--3

1.000 EA 9

.766 FT::::

.

4.000 EA 4

.---..-.-..... .....-_.-. '-' -'....:.......2-;ertJ'6- ..-Er.;--4

4,,000 E(l 4

4.000 EA 4

.

2.000 EA 4

1. 000 4

...

CASTING 1.000 EA 3

C61263101 1.000 EA 3

.0

.. 0

14:

15:

' IS;

. ', ';',

.0

.0

.0

.0

17

.

': ..:.

:..

.0

.0

37

36:

,39'

140'

'""9i'"..:O: ..... ... If'S II:

12'

(1' :".. ' "

J)

c,._ ..." .: _. _.__.... _... _.:..., .. .. _._.,.__ _ __.:...

...-;;-(t-

.0

.0

'" 'Q7

_.___ ..___ .. .. ..

c' :54!

.0

. "

5S'

.. .. ,: i .,"

.0

.0

iS3

....._..... _.. . ' .. .....68;

2.000 EP,

1.000 EA

. . EA 4

dUM fi ...... >.go

EA 4

2.00Q EA 4

j:.-t)!;it)----EA "1'

i .000 . EA

1.000 EA 1

""" .-"'-- .. .. .. '-4- .

i.obo 2

1.0-00 EA::::;

-.-.-......---...- . ''''- -..-.. ---..---.. ....E-A-4- ..

C12658

ADR,VDR,ND A612659 Ie)

2,000 EA 4

1.000 -EP, 4

'1.000 EA 2

.. ---.-- ..----- - -.. -.. -- ..;29Z---- FT 3

1. (lOG E;A 4

1.000 EA 9

_

.0

.(1

16'

: '.. '.-. ., ...

';'El- ... .. ....-.....---.- -' ,,\',

.0 .

.0

..

.0

ITEM OPT FIRST LT

UM TYP NO. OP SEQ ADJ

EFFECTIVE DATES

FROM TO

.. -..:-; - ..

.0

... ___1)_.._._....__..._ _._____ .-; .' . "I

.0

,0

:\4.

15

;. - ' :

.0

..-.

'''''

--------

.0

.0

.0

.:.'" .... ... ..J...

'-0.' . .

.....- . -"--" -.. - ... .. ".

.

. 0 138'

.0 ;39.

.... .. ..__..

.0

.0

-.-.... ....,.....P-l.. ,

.0

.0

____.____ ...___ -

....,.(1.....

.0

.0

.. .. ...

{''<DAI'-lIYr I C INDENTED DILL DATE 12/12/01 TiME 8.05.02 PAGE (')I'IEF72

) II

EA 2

1.000 EA 3,

2

'4

4

'-7.000 EA 4

4

EA ,4

- '" -"

SeREl-! FH HXSOC j.l4-20XO .7::.0" 1.0C)() EA 4

F(1NG HOLDING o. :162"L. it'll 1. 000 EA 2

" '

. :,, ' " ,"':' ""',-," 1:.0bo , 4

, ' ' 3.000 4

-t- Po __ ,____'._.'._'...._ w' ___.'.. __. , .. '-EA' '' 4'

END 1.000 EA 4

A19504 (M) 1.00 0 EA 9

.1..000 _

.. 021

._._._- ._- ',. -.. .. .. "'--.--- _. .... ':-' ...._--:-:-:-:--:-

4

..:::.

3

I'

I!

3 .

,I

5

,.

.,0

.0

::..

, (J

n!

'''- ..

;'9:

;'lli

,0

.0

2;

....,"..

.0

---1')"""-- ,,",,,"-- '

: (:) ::1

.0

.0

, ___ .. ,i-,,:> ' ,. -' ,' X' --. ';r, 1\10

.0

II;"

40

.1..000 E?) 4

1.000 EA 4

.. -, ,

" F'! 4-

'-4-

1 .. 000 E?) 4

.0

.0

12;

13

1

14i

:,5:

.... ....

.0

.0 D

:sitE [( .W ,. 14.1

,!

,,0

.38i

.0 39'

-.. ---'..

40'

.' C

....-. <:;

.0

.0

..______..__.___ ' ,' - .,- , . ,.. ." ..,',: ,'a.

,0

c

',

. ,

61

:631

':: .. ... ":',: '-r:<l....,.,. tl..i.lIi!p;;:;., .....

,0

........ ___....... ... .._......-..... . or- - , ;,: ""' -";--w

1.000 EA 2 ,,(I

1 .000 E(.'1 ,0

.. ,:,..tr. __

.___..__ .,;. . .. 1 .. ----..---.--,--.. :.":'.':' _..---,, --'--.__..... -. ---..

ADi;!"l AT I C I!\I !) f,'.r,jTE.D 1::1Ll_ DATE 12/12/01 TIME 8.05.02 PAGE I'> At'IEF72

-." ., ", '/ I f /. ":. . ,l ",'UOO

- ---".--.-.... -..: ".

DESCF: I F'T I DN

ENGINEERING

NUMBER

.. ..

QUANTITY

F'EF:

ITEM FIRST LT

UM TYP NO. Dr SEa ADJ

EFFECTIVE D(.lTE-:S

TD

"--

:'.;,.

.(1

.0

:IJ

NUT HE X 7 / 8-9 S5 1.000 EA 4 . 0

IDLER 104 1/ 2 " 1.000 EA 4 .. 0

. 0

C1018 1.032 FT 3 " .0

C1018 .125 FT 3

..._Jt.."I:,4SF' ... ..... I t """? i)

1.000 EA 4

1.000 EA 4 .0

'j1f.,.,t!i'I..Mf"';c:.

) .l .. ____

4.000 EA 4 0 '38;

4 .0

.. t'!f- ,;L$Lf.' tI'

EA 9

.0

.0

.0

4i

.3;

44!

:45[

.-......_......_- .-._....._. .. ....... t e

J J '

1..000

1.000 EA 4

...

20.000 FT 4

1.000 EA 4

o '" ,' _ , P " ,......

-.----..-:.. --.. . -.t. 1; ....... ,t. '''_

.0

.0

J.....MIL., ,1.k/..LJ;';'f'.' ..L 1.111e. rHl'Jt:. HI'let- I:L

QUANTITY ITEM OPT FIRST LT EFFECTIVE DATES

PER UM TYP NO. OP SEQ ADJ FROM TO I

__1 :

EA 4

5.000EA 4

... __n ______...__ _ ...._ _ .._ __ I.,,-...t;).()(,.__ .. EA -4

B12829 1M) 2.000 EA 9

.1'70 LB::';.

.. ...

ipf' -"..... ,t. . ......-_..--... _ _.... .. .. (}64 nLB .-l'

A795494

1.000 EA 2

.

.-- 2- .... - FT 3

2.000 EA '-1

EA 2

" .' : '. . . S'

",'fiil:l6!io '1t7;;

....... . , iDf!;:: , ". ,

C,'

C612965

B12679

_._ .. ___

.0

.0

....... _. __. ...,.,.

,3;

"':

15;

or

\8'

0"

.0

..... .{). _.. .._:._..______.. __..____ . ... ....__n_.....

.0

.0

.-. ..

11

1"2:

13:

....

.() .... " .-: "

, 5:

ADAI'IATIC INDENTED BILL DATE 12/12/01 TIME

.. 1:1

..,. _,::;t,

...

E?; 2

EA 3

.. ':!:'I' Of ! , titl'C"W ..: .

__ ___ .._..__ __ .. .. ..

.750 FT 3

1.000 EA 1

:"

,.-

.0

.0

: .

.'0

.06:::; FT 3 .0

3" ADR2 A2:,267 (t'n 1. 000 EA:2 .0

at.

Q.

It " , , 41 .. .. :Cl

r '., - (It ',"'d. ...ll) - \; rAJ .......... ''ih:. r' t\' !'flr.l .' ':'" ... .. 2 '.0

- -- --- -

CDF l.OCH)" X 1.500" Cl018 .:::;7::. FT 3.0 U!

F'UiTE I1\1DICATOR 2.625"l.; ADF:2 A19201 l.000 EA 2 .0

52

1 . ...

. '.;3'

51

'."'5: ',1 ] .. A'9'i"".o;i$'"'}Efif.

T J:'?

1

QUANTITY ITEi"I

PEl:;: ut<1 TYP NO. SEQ ADJ FROM

/ .

.. ____

.:A

.0 ,.;

.0

"'

.,.. --_.

1.000 EA 4

.209 FT 4

-- ---- ---- ----.- ..._ - ._---_. ----------------_._._---.-_._-- - - ._--_.........._-_._.-._-- ._--- --_. - -.. .......

ENGINEERING QUANTITY ITEI'1 'OF'T FIF:ST L.T I:::rl-I:::C11VI:". UR It.ti 6i

.._..__.._ __ _ _ _ ..._ _ _. ...... _

ADF\I'IATIC

,

nmD.JTED BILL DATE 12/12/01 8.05.02 PAGE 10 AI'l EF72

___"""-"",,, ___ _ . . .._ _ , ,, , "

s!F: ELATIVE SED COi'1F'DNEI' lT

6 LEljEL I'm. I1H1 1'10. DESCF:I F'TION DRAW1NG NUMBER F'ER Ui'l TYP NO. OF' SEQ ?)DJ FF:m1 TO Il !

.-=."...-:-:r.=:,.--.-...,..,.,.,.,;;;mE:-.J...-.--,..,.,.....--=--r..-n_..8'

8'" .

s .. .

11' . ',..

'II ... 3

12 " If''::'

,.' . .." . . . ., <",I ' ....-.. .:.-..,-.-..-. ..r"':- __

z.p 4.000 EA 4.0 '1,1

1.000

9

EP, 9

FT 3

.. u

112" 1000 EP, 4-

EA 4

.0 'lsi

'".-'- ';' \:jl

---_ .-... ..-._-- -. '\'"'. '

II - i211

.0

.0 "' __ . .. ,._.-.

_... _.._ .. ....

FT 3

.!.',,,.,!

;:eA4 .

of ..... DA. ... ... . f 50 .->....1

--..

EA 4

1.000 EA 2

...... .. .......: ... -biQ.. " 't,

51

,t: ' l.""if.!HF! * I. " 1

.."

ENGINEERING

NUMBER,

ITEM OPT FIRST LT

DESCRIPTION PER UM TVP NO. SEQ ADJ FF:OI1

f:?::r.ent

i

6 ",.

2.000

1.000 EP, 4

rt:L\""'" ..... ,.

... t:t', 9 '

... ..

1.000 EA 1

EA 4

B797046CC)

's' .. ggg,:':

; r'FfI'1'I 9\-" . -- 't - --_ __ ___ ..__.._:,L_ :'-' --'- .-:2-.-2-sEf--F-f---3-- " ,

C18581 1. .000 EA.1.

ADR28<4. (NO Dt-JG.) 1 .000 EP, 3

C"''''I j."\",, ..rt tl'll!h ..

. :: ;:: .. :' , ..

, .0

____... _ . ___ _ _

.0

.0

- ... .., ..

:'6

.0

.0

'8ftEROAWi

:

.0

.0

. . '," ': .. ... .. ..

0,0

-------.tl--.:. . '

.0 -

.0

;)

I C INDENTED BILL

")

......... .....--.--- -.---..-.-------- ---..-..-.....- ..

DATE 12/12/01 TIME 8.05.02 PAGE 12

ENGINEERING

DRAWING NUMBER

.-'----- ----_._--_...._....

QUAl\rrlTY

PEF::

ITEM OPT FIRST LT

UM TYP NO. OP SEQ ADJ

.......

.0

.0 1.000 EA 3

EFFECTI\IE

':1

I

---------------i-;\"tOO-- EA--9

.256 FT 3

:.21 FT3

._._..___..._(.\_.________......._ .._.___ : .. -.; r ... ' .... " I.

4

9

"3-"

if

4

.0

.0

.1. ..::, ,owlt::.t-j L

ADP,I'IAT I C INDENTED BILl. DATE 12/12/01 TIME B.05.D2 PAGE 14 Al'IEF72

1 ""AI.\>..

., c_ . . .. ' . . _ . .. _- .-. .. , . -- '.' . I,.' ".'" .

' "' . .. ...:..u:r .- . . __ .... -'/1 C--;-- -J, f,;F Uz'"J 'S" 4'

ITEM OPT FIRST

UM TYP NO. OP SEQ

J,.. ,",c . "t3- -IQ.:. .' ...... ... Ui: f. . .,---- ." " <'" 'W;: "'!"I

. 0

.0

,,0

.... " I,:' ..?iH. i

. 0

.. ____ --. ...,.... ...- ... . .""!f.' "'{s

.0

.0

.0

.0

.. t . .. iii , r\j"i """'" ; .. WW _""' ZL

. . C> .

0. .

, ... .. .. --:....- ....-.--.. .

.:.-.-----=--.::..-....-.. -.'''--' ."_....

HI'Ir.:.r /

ITEM OPT FIRST LT

PER UM TYP NO. OP SEQ ADJ TO

"-,, .'

.. :-.;- '.

.0

.

:!:

.0 flj

INDENTED BII_L DATE 12/12/01 TIME 8.05.02 PAGE 16 N'lEFi2

ADAI'1ATIC

14

PAGE 17 At1EF72

COt,IV ADR2 B29621 1.000

.' ..:-l.?

... .} t ";'i . :::;:,,_"'1;'" 0" ,",

tti>,,)i __._.. .. .. ...... ...... . I.)

INDENTED BILL.

DATE 12/12/0 1 TIME 8.05.02 PAGE 18 ?)1'1EF72

ADAI'1ATIC

ITEM OPT FmST L T EFFECT WE D,'-ITE S

NO. or SEQ ADJ - FROM TO

.,.no "!"" Wf'':"'l!!Git&tlt:, ..'!NIiiYtrii , lib .\ ca::a:zeJ"'!JII!!III!! p:o;: p, _A

4

_c ' e l' ,J1" - .. .. -- ..'--l-..-t:Of'G'G----EA 4

4.000 EA 4

2.000 EA' 4

18 ..

2

) .. ;; ..

21 '

d23 .2 ,

24' .3

.0

.0

..., "ie::;t ..

""' ________

"

.;:)

.J 'l2

.0

.0

/Ill

... """

Você também pode gostar

- Instruction Manual MODEL 1200 Atmospheric Consistometer: Revision B.5 - March 2008 P/N: 12-0185 S/NDocumento25 páginasInstruction Manual MODEL 1200 Atmospheric Consistometer: Revision B.5 - March 2008 P/N: 12-0185 S/NAli AliievAinda não há avaliações

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003No EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Nota: 5 de 5 estrelas5/5 (1)

- C - 49-49D-49SL-59-59D-59SL-89-89D-89P-89SL-89T Star PopcornDocumento18 páginasC - 49-49D-49SL-59-59D-59SL-89-89D-89P-89SL-89T Star PopcornMark MihalkoAinda não há avaliações

- Sterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceDocumento21 páginasSterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceNoel GarciaAinda não há avaliações

- 6head Syrup Filling Line Automatic PDFDocumento18 páginas6head Syrup Filling Line Automatic PDFSrinivas0% (1)

- CQ6280 For BJ-32120 Manual TornoDocumento81 páginasCQ6280 For BJ-32120 Manual TornoJuan Daniel Frias Sosa100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- Inversor Secador Pct-AdwDocumento38 páginasInversor Secador Pct-AdwJohn Néstor Ramirez CalderónAinda não há avaliações

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryAinda não há avaliações

- Ecomax - 802 - A - EA - BA 21715 B 12 12 ENDocumento22 páginasEcomax - 802 - A - EA - BA 21715 B 12 12 ENHugo RoMo0% (1)

- Glutomatic System: Operation ManualDocumento36 páginasGlutomatic System: Operation ManualGonzalo MuleroAinda não há avaliações

- Sterilizer Manual (h2115)Documento32 páginasSterilizer Manual (h2115)Paulina LizzethAinda não há avaliações

- Alto Shaam QC100 QuickchillerDocumento2 páginasAlto Shaam QC100 Quickchillerwsfc-ebayAinda não há avaliações

- SVC Manual 4kp-4kt-4kd Mixers Lit 4176981Documento17 páginasSVC Manual 4kp-4kt-4kd Mixers Lit 4176981David EidamAinda não há avaliações

- Manual - User - Urs500-600 SeriesDocumento21 páginasManual - User - Urs500-600 SerieslawiAinda não há avaliações

- Catalogue Farine UkDocumento24 páginasCatalogue Farine UkAnonymous PFVwRcAinda não há avaliações

- Hobart CMA66 ManualDocumento26 páginasHobart CMA66 ManualJostin Castillo HurtadoAinda não há avaliações

- XHD Skid Mounted CTUDocumento31 páginasXHD Skid Mounted CTUYuri BadretdinovAinda não há avaliações

- Excell SI-132Documento37 páginasExcell SI-132gust van oerleAinda não há avaliações

- Unique Rais-01 (Bun103112) PDFDocumento117 páginasUnique Rais-01 (Bun103112) PDFMilutin JankovicAinda não há avaliações

- TP0003 BM Series BulkmeterDocumento0 páginaTP0003 BM Series Bulkmeterwferry27Ainda não há avaliações

- 01-06225-226 Manual Mezc ScottDocumento26 páginas01-06225-226 Manual Mezc ScottLaura MalagarrigaAinda não há avaliações

- Osm-093 57800-100Documento86 páginasOsm-093 57800-100Taller cncAinda não há avaliações

- Nieco Modelo 1424G PDFDocumento26 páginasNieco Modelo 1424G PDFAbimael AlonsoAinda não há avaliações

- Komatsu PC75R 2Documento8 páginasKomatsu PC75R 2Shailesh Khodke100% (1)

- BDC6015 Ultra Speed Manual CaframoDocumento66 páginasBDC6015 Ultra Speed Manual CaframojesusAinda não há avaliações

- PolyClad Manual, 200 SeriesDocumento69 páginasPolyClad Manual, 200 SeriesDave ManchesterAinda não há avaliações

- New Age GeneratorDocumento26 páginasNew Age GeneratorDaud Ahmed Fihawango100% (1)

- Omnicrimp 21 ManualDocumento16 páginasOmnicrimp 21 ManualYipper ShnipperAinda não há avaliações

- D1252C RIP Roller Idler Press - Complete Manual PDFDocumento29 páginasD1252C RIP Roller Idler Press - Complete Manual PDFmarlon diazAinda não há avaliações

- 3082 Conductivity Meter ManualDocumento19 páginas3082 Conductivity Meter ManualEquipDocAinda não há avaliações

- Ledeen Actuator General Catalogue - Entire LineDocumento24 páginasLedeen Actuator General Catalogue - Entire LineJair LamasAinda não há avaliações

- MR - Ranjeet Kumar Kurkure Process Line With PackingDocumento12 páginasMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiAinda não há avaliações

- FGRC AD 21W - SPMDocumento22 páginasFGRC AD 21W - SPMPedro Pablo Ferreiro GonzalezAinda não há avaliações

- Harrison M450Documento104 páginasHarrison M450zul_ats100% (1)

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocumento26 páginasHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- BC360L Weighing Indicator PLC VIET NAMDocumento40 páginasBC360L Weighing Indicator PLC VIET NAMVu QuynhAinda não há avaliações

- Hydrostatic System - Test and Adjust: Pruebas y AjustesDocumento22 páginasHydrostatic System - Test and Adjust: Pruebas y AjustesJose PichinteAinda não há avaliações

- Manual VT+660Documento21 páginasManual VT+660alejjavierdelgadoAinda não há avaliações

- Goodman GSX16 Specifications SheetDocumento88 páginasGoodman GSX16 Specifications Sheet63ragtopAinda não há avaliações

- C-8056sa 2015 PDFDocumento30 páginasC-8056sa 2015 PDFvasiliy vasilievichAinda não há avaliações

- System 20Documento5 páginasSystem 20ezeizabarrenaAinda não há avaliações

- PC8000 6 HandbookDocumento8 páginasPC8000 6 Handbookmmaidana2001100% (2)

- Model 55000-100 Hydraulic Tubing TongDocumento75 páginasModel 55000-100 Hydraulic Tubing TongPrejit Radhakrishna50% (2)

- Oil Country TongsDocumento79 páginasOil Country TongsKevin PaulAinda não há avaliações

- Omega RG-2500Documento27 páginasOmega RG-2500Haidar AlifAinda não há avaliações

- Orbit: Digital ShakersDocumento12 páginasOrbit: Digital ShakerslataodeprasticoAinda não há avaliações

- Catalogohce090 150Documento18 páginasCatalogohce090 150Xol DiaMa GarciaAinda não há avaliações

- Operation and Maintenance Manual: Model 15E VibroDocumento32 páginasOperation and Maintenance Manual: Model 15E VibroMark EsguerraAinda não há avaliações

- Manual - User - Urs500-600 SeriesDocumento21 páginasManual - User - Urs500-600 SeriesHiram MartinezAinda não há avaliações

- CS Series Operation Manual PDFDocumento70 páginasCS Series Operation Manual PDFDArio Mainini60% (10)

- BNDT Catalog 04162012 v13 WEBsecureDocumento31 páginasBNDT Catalog 04162012 v13 WEBsecureEsin DenizAinda não há avaliações

- BL HV 100E HV 100G HVH 100E HVH 100G - Iom.Documento37 páginasBL HV 100E HV 100G HVH 100E HVH 100G - Iom.Hector Uc ChableAinda não há avaliações

- WD420 Washer DrierDocumento32 páginasWD420 Washer Driermenderman100% (1)

- Hydraulic Windlass and Mooring Winch PDFDocumento55 páginasHydraulic Windlass and Mooring Winch PDFstamatis100% (2)

- NASA Corrosion of SS TubingDocumento14 páginasNASA Corrosion of SS TubingClaudia Mms100% (1)

- 2013 Casel GuideDocumento80 páginas2013 Casel GuideBobe MarinelaAinda não há avaliações

- CNA Candidate HandbookDocumento57 páginasCNA Candidate HandbookSummerAinda não há avaliações

- Week 4 (Theories)Documento15 páginasWeek 4 (Theories)Erica Velasco100% (1)

- Harvard Referencing GuideDocumento6 páginasHarvard Referencing GuideKhánh Nguyên VõAinda não há avaliações

- Design and Fabrication of Floor Cleaning Machine - A ReviewDocumento4 páginasDesign and Fabrication of Floor Cleaning Machine - A ReviewIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- 5 Keto Pancake RecipesDocumento7 páginas5 Keto Pancake RecipesBai Morales VidalesAinda não há avaliações

- Secrets of Sexual ExstasyDocumento63 páginasSecrets of Sexual Exstasy19LucianAinda não há avaliações

- Edunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Documento377 páginasEdunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Education SolutionsAinda não há avaliações

- Untitled Form - Google Forms00Documento3 páginasUntitled Form - Google Forms00Ericka Rivera SantosAinda não há avaliações

- Z0109MN Z9M TriacDocumento6 páginasZ0109MN Z9M TriaciammiaAinda não há avaliações

- Project Report On MKT Segmentation of Lux SoapDocumento25 páginasProject Report On MKT Segmentation of Lux Soapsonu sahAinda não há avaliações

- FS011 Audit Plan Stage 2Documento2 páginasFS011 Audit Plan Stage 2Ledo Houssien0% (1)

- Cervical Changes During Menstrual Cycle (Photos)Documento9 páginasCervical Changes During Menstrual Cycle (Photos)divyanshu kumarAinda não há avaliações

- Mediclinic Weekly Progress Report No 29Documento27 páginasMediclinic Weekly Progress Report No 29Julius Ceasar SanorjoAinda não há avaliações

- Electronic Fetal MonitoringDocumento4 páginasElectronic Fetal MonitoringMauZungAinda não há avaliações

- De Thi Chon HSGDocumento10 páginasDe Thi Chon HSGKiều TrangAinda não há avaliações

- ICGSE Chemistry Chapter 1 - The Particulate Nature of MatterDocumento29 páginasICGSE Chemistry Chapter 1 - The Particulate Nature of MatterVentus TanAinda não há avaliações

- Fitness Program: Save On Health Club Memberships, Exercise Equipment and More!Documento1 páginaFitness Program: Save On Health Club Memberships, Exercise Equipment and More!KALAI TIFYAinda não há avaliações

- Melancholic PersonalityDocumento5 páginasMelancholic PersonalityChris100% (1)

- 3M Window Film PR SeriesDocumento3 páginas3M Window Film PR SeriesPhan CrisAinda não há avaliações

- Ceilcote 222HT Flakeline+ds+engDocumento4 páginasCeilcote 222HT Flakeline+ds+englivefreakAinda não há avaliações

- Fire BehaviourDocumento4 páginasFire BehaviourFirezky CuAinda não há avaliações

- MLT IMLT Content Guideline 6-14Documento4 páginasMLT IMLT Content Guideline 6-14Arif ShaikhAinda não há avaliações

- ត្នោត (Borassus flabellifer L.)Documento11 páginasត្នោត (Borassus flabellifer L.)yeangdonalAinda não há avaliações

- Financial Markets & Institutions: Lecture Notes #3Documento90 páginasFinancial Markets & Institutions: Lecture Notes #3Joan MaduAinda não há avaliações

- Business Process Dashboard (Raj Mishra)Documento22 páginasBusiness Process Dashboard (Raj Mishra)Raj MishraAinda não há avaliações

- Bonding and Adhesives in DentistryDocumento39 páginasBonding and Adhesives in DentistryZahn ÄrztinAinda não há avaliações

- 2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetDocumento2 páginas2012 U.S. History End-of-Course (EOC) Assessment Field Test Fact SheetswainanjanAinda não há avaliações

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsAinda não há avaliações

- Analog Design and Simulation Using OrCAD Capture and PSpiceNo EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceAinda não há avaliações

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNo EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceNota: 4 de 5 estrelas4/5 (19)

- Laws of UX: Using Psychology to Design Better Products & ServicesNo EverandLaws of UX: Using Psychology to Design Better Products & ServicesNota: 5 de 5 estrelas5/5 (9)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsAinda não há avaliações

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsNo EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsNota: 4 de 5 estrelas4/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNo EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsNota: 5 de 5 estrelas5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableNo EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableAinda não há avaliações

- Practical Troubleshooting of Electrical Equipment and Control CircuitsNo EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsNota: 4 de 5 estrelas4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesNo Everand507 Mechanical Movements: Mechanisms and DevicesNota: 4 de 5 estrelas4/5 (28)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNo EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersNota: 4 de 5 estrelas4/5 (13)

- Understanding Automotive Electronics: An Engineering PerspectiveNo EverandUnderstanding Automotive Electronics: An Engineering PerspectiveNota: 3.5 de 5 estrelas3.5/5 (16)

- Design for How People Think: Using Brain Science to Build Better ProductsNo EverandDesign for How People Think: Using Brain Science to Build Better ProductsNota: 4 de 5 estrelas4/5 (8)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesNo EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesNota: 3 de 5 estrelas3/5 (1)