Escolar Documentos

Profissional Documentos

Cultura Documentos

Quick Reference Guide For Troubleshooting 7683 Autosampler Errors

Enviado por

gfailenDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Quick Reference Guide For Troubleshooting 7683 Autosampler Errors

Enviado por

gfailenDireitos autorais:

Formatos disponíveis

Quick Reference Guide for Troubleshooting 7683 Autosampler Errors

A16009

This document is believed to be accurate and up-to-date. However, Agilent Technologies, Inc. cannot assume responsibility for the use of this material. The information contained herein is intended for use by informed individuals who can and must determine its fitness for their purpose.

a16009.doc

http:// www.chem.agilent.com

Page 1 of 13

Installation Guide Faults

Faults

Four lights on the injector indicate its status. During normal operation, the Ready light is on. If the injector is busy, the Run light is on. If another combination of lights are on, an error has occurred. Use the following instructions to try to solve the problem before obtaining Agilent service.

Align Mode light Fault light Run light Ready light

Figure 16 Injector status lights

26

Installation Guide Faults

No Light Is On

Probable causes The line voltage to the GC is off. The injector cable or connection to the GC is bad. Your GC requires service.

Suggested actions 1. 2. 3. Verify the injector is properly connected to the GC. Check the power source for your GC. Obtain Agilent service.

The Fault Light Is On Probable cause The injector door is open. Suggested actions 1. 2. Ensure that the injector door is closed. If the fault light stays on, obtain Agilent service.

The Fault And The Run Lights Are On Probable causes The injector is mounted incorrectly on the mounting post. Incorrect mounting post.

Suggested actions 1. 2. 3. Ensure that the injector is mounted properly. For more information, see page 4. Ensure the correct mounting post is installed. See page 4. If the fault lights stay on, obtain Agilent service.

27

Installation Guide Faults

Align Mode Light Is On Probable causes The turret is not properly installed. The type of turret was changed while the power was on. The system was not initialized. There is an injector memory error.

Suggested action 1. 2. Verify the turret is properly installed. See Removing The Turret on page 16. Perform the alignment procedure to initialize the system. See Turret Alignment on page 17.

All Lights Are On

Probable causes The cables connections are loose. There is a board failure. There is a firmware revision conflict.

Suggested action 1. 2. 3. Check all cable connections. Turn the instrument off, then on again. If the lights remain on, obtain Agilent service.

28

Installation Guide Error Messages

Error Messages

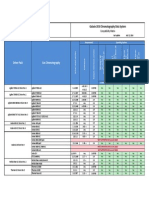

Below is a table of sampler error messages reported on the 6850 and 6890 Plus GCs. If you receive an error message that is not shown below, record it. Then, make sure that your GC is properly configured and that your sample vials and equipment match your method and/or sequence. If the problem continues, report your error message to Agilent service.

6890 message Bottle in gripper Front (or back) door open or injector not mounted Front (or back) injector com error Front (or back) injector incomplete injection Front (or back) injector reset Front (or back) plunger error Front (or back) syringe error Front (or back) turret error Injector not present Injector offline No bar code reader No bottle in gripper Tray not present Tray offline 6850 message Inj door or mounting injector comm error Incomplete injection Injector reset Plunger error Syringe error Turret error Autoinject aborted Invalid sequence No injector Prerun> 10 min Sampler error

29

Installation Guide Error Messages

Bottle In Gripper

Probable cause The sample vial was not delivered properly and stayed in the tray gripper. Suggested actions 1. 2. 3. Remove the vial and return it to its position in the tray. Ensure that the tray quadrants are snapped into place. Ensure that the injector is plugged into the correct connector on the back of the 6890 GC and is configured properly. See Configuring Your Gc (6890) on page 12. Check the deliver to location for the vial and verify that the location is empty and free from obstructions. Make sure that the injector is upright/vertical on the GC. Restart the sequence. If the error occurs again, obtain Agilent service.

4. 5. 6. 7.

Front (Or Back) Door Open Or Injector Not Mounted

See Faults on page 26.

Front (Or Back) Injector Com Error

Probable cause There is a communications error between the injector and the GC. Suggested action Obtain Agilent service.

30

Installation Guide Error Messages

Front (Or Back) Injector Incomplete Injection

Probable causes The syringe needle is bent. The plunger or syringe carriage is operating incorrectly during injection.

Suggested actions 1. 2. 3. 4. See Correcting Syringe Problems on page 24. Remove the syringe from the injector, and check the plunger for stickiness or binding. Replace the syringe if necessary. Restart the sequence. If the error occurs again, obtain Agilent service.

Front (Or Back) Injector Reset

Probable cause There is an interruption in the power supply from the GC. Suggested action Obtain Agilent service.

31

Installation Guide Error Messages

Front (Or Back) Plunger Error

Probable causes The syringe plunger is sticking, or not securely connected to the plunger carrier. The plunger solenoid is binding. The plunger carrier encoder is inoperable.

Suggested actions 1. Remove the syringe, and check it for plunger stickiness or binding. Replace the syringe if necessary. For more information, see Inspecting a syringe in the Operation Guide. Check the viscosity of the sample against the viscosity parameter. Reset the viscosity parameter if necessary. Restart the sequence. If the error occurs again, obtain Agilent service.

2. 3. 4.

Front (Or Back) Syringe Error

Probable causes The syringe carriage motor is defective. The syringe is not currently installed or is an incorrect type. The syringe carriage sensor is inoperable.

Suggested actions 1. 2. 3. Ensure the syringe is installed correctly. For more information, see your Operation Guide. Ensure the syringe meets specifications. If the syringe needle is bent, see Correcting Syringe Problems on page 24.

32

Installation Guide Error Messages

4. 5.

Restart the sequence. If the error occurs again, obtain Agilent service.

Front (Or Back) Turret Error

Probable causes Something has interfered with the turret rotation. The turret motor/encoder assembly is inoperable. The turret type was changed while the power was on and the turret alignment procedure was not performed. Turret is loose.

Suggested actions 1. 2. 3. 4. Clear any obstructions. Check the Align Mode light. If it is lit, perform the alignment procedure. (See Turret alignment in this section.) Tighten the knurled nut on the top of the turret. If the error occurs again, obtain Agilent service.

Injector Not Present

Probable causes There is a board failure in the injector or GC. The injector cable is bad or not securely connected to the GC. There is a cable failure in the GC. Your method specifies an incorrect injector location (method mismatch).

Suggested actions 1. Make sure that the injector to GC cable connection is secure. 33

Installation Guide Error Messages

2. 3.

Check your method to make sure it uses the appropriate injector location. If the error remains, obtain Agilent service.

Injector Offline

Probable causes There is a board failure in the injector or GC. The injector cable is bad or not connected. There is a cable failure in the GC.

Suggested actions 1. 2. Make sure that the injector to GC cable connection is secure. If the error remains, obtain Agilent service.

No Bar Code Reader

Probable causes Bar code reader cable not securely connected. Bar code reader is defective. Tray is defective.

Suggested actions 1. 2. Ensure the bar code reader cable connection is secure. If the problem continues, obtain Agilent service.

34

Installation Guide Error Messages

No Bottle In Gripper

Probable causes The sample vial was not found by the gripper. The gripper could not grasp the vial. The vial was dropped during transfer to or from the turret. The sensor in the gripper is defective.

Suggested actions 1. 2. 3. 4. Make sure that the sample vials are in the locations specified by the sequence. Make sure that the sample vials meet recommended specification. See your Sampling Techniques Handbook. If you are using adhesive labels verify that the labels are properly installed. See your Operation Guide. If the error recurs frequently, obtain Agilent service.

Tray Not Present

Probable causes There is a board failure in the tray or GC. The tray cable is bad or not connected between the GC and tray. There is a cable failure in the GC.

Suggested actions 1. 2. 3. Make sure that the tray cable connection is secure. Replace the tray cable. If the error remains, obtain Agilent service.

35

Installation Guide Error Messages

Tray Offline

Probable causes There is a board failure in the tray or GC. The tray cable is bad or not connected. There is a cable failure in the GC.

Suggested actions 1. 2. 3. Make sure that the tray to GC cable connection is secure. Replace the tray cable. If the error remains, obtain Agilent service.

Autoinject Aborted

The autoinject sequence on the 6850 was aborted. The other error messages shown on the GC display provide more information on what caused the sequence to abort.

Invalid Sequence

Probable causes The sequence is set up for the wrong injection device. Hardware required by the sequence is not installed and configured. The GC configuration was changed during sequence execution. The injector cable is bad or not connected properly.

Suggested actions 1. 2. 3. Make sure that the connection to the GC is secure. Verify the sequence parameters against the GC configuration. If the error remains, obtain Agilent service.

36

Installation Guide Error Messages

No Injector

Probable causes The cabling connection to the GC became loose during a run. An injector board or GC board failed during a run.

Suggested actions 1. 2. Make sure that the connection to the GC is secure. If the error remains, obtain Agilent service.

Prerun > 10 Min

The GC is Not Ready. Check for Not Ready and other GC messages to determine the cause.

Sampler Error

The sampler could not function for an undocumented reason. Record the code number shown in the G2629A Control Module error message. If the problem persists, obtain Agilent service and report the error number.

37

Você também pode gostar

- Customer Information: Varian 450 GC - Preventive Maintenance Checklist StandardDocumento12 páginasCustomer Information: Varian 450 GC - Preventive Maintenance Checklist StandardChung NguyenAinda não há avaliações

- Agilent ALS Turret Manual PDFDocumento260 páginasAgilent ALS Turret Manual PDFEric MetzgerAinda não há avaliações

- Agilent U1241A ManualDocumento85 páginasAgilent U1241A ManualBobDAinda não há avaliações

- 7820A GC Illustrated Parts BreakdownDocumento102 páginas7820A GC Illustrated Parts BreakdownRuy Santana Jr.Ainda não há avaliações

- Fluorospectrometer RF-20A:20Axs Prominence User ManualDocumento352 páginasFluorospectrometer RF-20A:20Axs Prominence User ManualChristos Georgiou100% (1)

- Analytical SFC System Service ManualDocumento140 páginasAnalytical SFC System Service ManualEdwin Guevara RAinda não há avaliações

- ThermoregulationDocumento64 páginasThermoregulationapi-3703371Ainda não há avaliações

- HP 8093 Operation and CalibrationDocumento247 páginasHP 8093 Operation and CalibrationenergiculAinda não há avaliações

- Jenway 6310 Service ManualDocumento84 páginasJenway 6310 Service ManualJorge OliveiraAinda não há avaliações

- Perkin Elmer ICP-OES Instructions - 0Documento11 páginasPerkin Elmer ICP-OES Instructions - 0Luis Alberto Ramirez PerezAinda não há avaliações

- URIT-800 URIT-800 URIT-800 URIT-800 Installation Installation Installation Installation Procedure Procedure Procedure ProcedureDocumento6 páginasURIT-800 URIT-800 URIT-800 URIT-800 Installation Installation Installation Installation Procedure Procedure Procedure ProcedureArnoldo FelixAinda não há avaliações

- Agilent 1290 Infinity II LC: Specification CompendiumDocumento38 páginasAgilent 1290 Infinity II LC: Specification CompendiumAmarpreet Singh MalhanAinda não há avaliações

- SPS4Documento98 páginasSPS4María Díazgranados Jiménez100% (1)

- ENG-Service Manual (IB-G) R0 IncubatorDocumento47 páginasENG-Service Manual (IB-G) R0 Incubatorjose navaAinda não há avaliações

- Tecan Sunrise Absorbance Reader Analyser - User ManualDocumento74 páginasTecan Sunrise Absorbance Reader Analyser - User Manualomer oartbAinda não há avaliações

- UV-1800 Operation ManuyalDocumento453 páginasUV-1800 Operation Manuyalmahadev1907Ainda não há avaliações

- Advantest R3131 Spectrum Analyzer Operator ManualDocumento277 páginasAdvantest R3131 Spectrum Analyzer Operator ManualMartin Argay100% (1)

- K2042 ManualDocumento20 páginasK2042 ManualAthanasios S. ArampatzisAinda não há avaliações

- Config. g1512Documento10 páginasConfig. g1512mardonioandradeAinda não há avaliações

- Thermo Easy NLC Service Manual PDFDocumento364 páginasThermo Easy NLC Service Manual PDFrajeeshAinda não há avaliações

- G1969 90006 TOF Maintenance v4Documento150 páginasG1969 90006 TOF Maintenance v4Jeramiah SpencerAinda não há avaliações

- G1946 1956 Parts TableDocumento37 páginasG1946 1956 Parts TabledegindelAinda não há avaliações

- ELAN Improvements Service Training RevBDocumento19 páginasELAN Improvements Service Training RevBJOSE ABADAinda não há avaliações

- 7683 ServiceDocumento33 páginas7683 ServiceMarine JolieAinda não há avaliações

- Service Manual I A Me RexDocumento31 páginasService Manual I A Me Rexgabo2516100% (2)

- Agilent 1260 Infinity Isocratic Pump and Quaternary Pump: User ManualDocumento194 páginasAgilent 1260 Infinity Isocratic Pump and Quaternary Pump: User ManualsaidvaretAinda não há avaliações

- HW Overview QQQDocumento20 páginasHW Overview QQQCuong Ngo MinhAinda não há avaliações

- ADVIA Centaur XPT Volume Check GuideDocumento7 páginasADVIA Centaur XPT Volume Check GuideAleksandar MisicAinda não há avaliações

- Trace MS Hardware Manual Rev BDocumento153 páginasTrace MS Hardware Manual Rev BGC powerAinda não há avaliações

- Service Manual: Wellwash 4 / 4Mk2Documento156 páginasService Manual: Wellwash 4 / 4Mk2luisAinda não há avaliações

- Manual FTLA2000 PDFDocumento92 páginasManual FTLA2000 PDFAdenilton de Diva33% (3)

- PE 560 Atomic Absorption Spectrophotometer ManualDocumento176 páginasPE 560 Atomic Absorption Spectrophotometer ManualDavid Allan100% (1)

- Bruker 430 GC User Manual PDFDocumento2 páginasBruker 430 GC User Manual PDFOsama AhmedAinda não há avaliações

- Varian DS-102 202 302 402 602 Instruction ManualDocumento71 páginasVarian DS-102 202 302 402 602 Instruction ManualHumbertoAinda não há avaliações

- Manual de Usuario de Centrifuge McKessonDocumento6 páginasManual de Usuario de Centrifuge McKessonfoxhoundforces100% (1)

- 001 G4212-90112 DAD-AB SVC EN Preliminary 02Documento372 páginas001 G4212-90112 DAD-AB SVC EN Preliminary 02Caesar100% (6)

- 5010 Serial MonitorDocumento17 páginas5010 Serial Monitormohamed abdelzaherAinda não há avaliações

- Agilent E3634A Service Manual PDFDocumento136 páginasAgilent E3634A Service Manual PDFHữu ThiệnAinda não há avaliações

- ELSDDocumento78 páginasELSDTanya HiltzAinda não há avaliações

- TRACE 1300 Series New PresentationDocumento59 páginasTRACE 1300 Series New Presentationmikicacica100% (1)

- QQQ Method Development Triple and OptimizationDocumento46 páginasQQQ Method Development Triple and OptimizationCLPHtheoryAinda não há avaliações

- 91494711Documento97 páginas91494711vzimak2355Ainda não há avaliações

- 05 AAS TroubleshootingDocumento10 páginas05 AAS Troubleshootingeko budinugroho100% (1)

- BioRad CFX96 10021337Documento178 páginasBioRad CFX96 10021337Helder VieiraAinda não há avaliações

- HLC-8320GPC OperatorsManual GDocumento199 páginasHLC-8320GPC OperatorsManual GPrianurraufikachmadAinda não há avaliações

- ICPMS-2030: Pre-Installation RequirementsDocumento17 páginasICPMS-2030: Pre-Installation Requirementspilar100% (1)

- Mitsubishi p93dw Digi Monochrome PrinterDocumento65 páginasMitsubishi p93dw Digi Monochrome PrinterTony KututoAinda não há avaliações

- 5977 MSD and MassHunter Acquisition EFamiliarization ChecklistDocumento10 páginas5977 MSD and MassHunter Acquisition EFamiliarization ChecklistcamiloviviAinda não há avaliações

- Guia para CromatografiaDocumento98 páginasGuia para Cromatografiasaidvaret100% (1)

- G8000-90002 MP-AES Users GuideDocumento54 páginasG8000-90002 MP-AES Users GuideXU JIASHUNAinda não há avaliações

- Agilent 1260 Infinity Binary Pump: User ManualDocumento252 páginasAgilent 1260 Infinity Binary Pump: User ManualPetrAinda não há avaliações

- HPLCDocumento24 páginasHPLCPh.Nabil Al-SharafAinda não há avaliações

- Gas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemDocumento3 páginasGas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemmardonioandradeAinda não há avaliações

- ErbaLyte ServiceManualDocumento31 páginasErbaLyte ServiceManualBio-Scientific GroupAinda não há avaliações

- Elix Essential Manual Millipore - Water-PurificationDocumento54 páginasElix Essential Manual Millipore - Water-PurificationDino Sk100% (1)

- Alternator Problem - Charging Problem and or Noisy Operation - 3516HDocumento3 páginasAlternator Problem - Charging Problem and or Noisy Operation - 3516Hwagner_guimarães_1Ainda não há avaliações

- C13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationDocumento3 páginasC13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationRaphael ThornerAinda não há avaliações

- Acceleration Is Poor or Throttle Response Is Poor: TroubleshootingDocumento7 páginasAcceleration Is Poor or Throttle Response Is Poor: TroubleshootingEshop ManualAinda não há avaliações

- Injector Solenoid Circuit - Test: TroubleshootingDocumento13 páginasInjector Solenoid Circuit - Test: TroubleshootingGolbert GolbiAinda não há avaliações

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideNo EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideNota: 4.5 de 5 estrelas4.5/5 (8)

- SoccerDocumento16 páginasSoccergfailenAinda não há avaliações

- All The Things You AreDocumento1 páginaAll The Things You AregfailenAinda não há avaliações

- All The Things You AreDocumento1 páginaAll The Things You AregfailenAinda não há avaliações

- 59890162EN ColorDocumento2 páginas59890162EN ColorgfailenAinda não há avaliações

- 3005-Embedded Web Server User GuideDocumento58 páginas3005-Embedded Web Server User GuidegfailenAinda não há avaliações

- 74LVC14APWDHDocumento11 páginas74LVC14APWDHIlie GrecuAinda não há avaliações

- Product Position and Overview: Infoplus.21 Foundation CourseDocumento22 páginasProduct Position and Overview: Infoplus.21 Foundation Courseursimmi100% (1)

- 141A Service PDFDocumento101 páginas141A Service PDFAndrás SzabóAinda não há avaliações

- Defects in Fusion WeldingDocumento83 páginasDefects in Fusion WeldingBalakumar100% (1)

- Rough Surfaces in ANSYSDocumento17 páginasRough Surfaces in ANSYSIgor BlanariAinda não há avaliações

- 2020 Specimen Paper 1Documento16 páginas2020 Specimen Paper 1YuanWei SiowAinda não há avaliações

- Bis 12894 - 2002Documento7 páginasBis 12894 - 2002rabindora6588100% (1)

- Discovery of A New Energy VortexDocumento4 páginasDiscovery of A New Energy Vortexnblack3335140Ainda não há avaliações

- GD33-12 12V33AH: GD SERIES-Deep Cycle BatteryDocumento2 páginasGD33-12 12V33AH: GD SERIES-Deep Cycle BatteryMarcel BaqueAinda não há avaliações

- Weighted BWF V3.0Documento7 páginasWeighted BWF V3.0Efrain CorroAinda não há avaliações

- Magnetic Resonant Coupling Based Wireless PowerDocumento7 páginasMagnetic Resonant Coupling Based Wireless PowerHartantoAinda não há avaliações

- Spring State Machine TransitionsDocumento6 páginasSpring State Machine TransitionsGroza CristiAinda não há avaliações

- English To MetricDocumento2 páginasEnglish To MetricJohn Reynard PacsonAinda não há avaliações

- Design of Torque ArmDocumento16 páginasDesign of Torque ArmRonak PanchalAinda não há avaliações

- Wärtsilä NOXDocumento35 páginasWärtsilä NOXDeepesh MerchantAinda não há avaliações

- Polymers 14 03693 v2Documento20 páginasPolymers 14 03693 v2Abd BAGHADAinda não há avaliações

- TK-315 CPI2 - 1 - NonReacting SystemsDocumento34 páginasTK-315 CPI2 - 1 - NonReacting SystemsMuhammad IkbalAinda não há avaliações

- Triple Chocolate Layer Cake Triple Chocolate Layer CakeDocumento3 páginasTriple Chocolate Layer Cake Triple Chocolate Layer CakeJuhyun LeeAinda não há avaliações

- Diagnostic Trouble Codes For Sinotruk HOWO Engines PDFDocumento4 páginasDiagnostic Trouble Codes For Sinotruk HOWO Engines PDFhektor AtkinsonAinda não há avaliações

- Bone Specific Alkaline PhophataseDocumento6 páginasBone Specific Alkaline PhophataseMohan DesaiAinda não há avaliações

- K.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Documento581 páginasK.T. Chau, R.H.C. Wong, T.-f. Wong (Auth.), STAVROS K. KOURKOULIS (Eds.) - Fracture and Failure of Natural Building Stones_ Applications in the Restoration of Ancient Monuments-Springer Netherlands (2Daniel Ruperto CanoAinda não há avaliações

- SIMULATION of EMERGENCY ROOMS USING FLEXSIMDocumento10 páginasSIMULATION of EMERGENCY ROOMS USING FLEXSIMBrandon VarnadoreAinda não há avaliações

- Unit 3 Study Guide and ExercisesDocumento2 páginasUnit 3 Study Guide and ExercisesTuan NguyenAinda não há avaliações

- MPDFDocumento1 páginaMPDFVipul WankarAinda não há avaliações

- REvision Test - 1Documento2 páginasREvision Test - 1JagendraAinda não há avaliações

- Brugg Cables Presentation ECMC PDFDocumento47 páginasBrugg Cables Presentation ECMC PDFlilcristiAinda não há avaliações

- Chapter 4 Solutions To Exercises PDFDocumento70 páginasChapter 4 Solutions To Exercises PDFWilly Rodríguez GuerreroAinda não há avaliações

- Chapter3 Torsion FinalDocumento78 páginasChapter3 Torsion FinalNaveen KumarAinda não há avaliações

- Math Ed 04: TrigonometryDocumento5 páginasMath Ed 04: TrigonometryCharles SilerioAinda não há avaliações

- CHAPTER 31 Faraday S LawDocumento27 páginasCHAPTER 31 Faraday S LawSattishZeeAinda não há avaliações