Escolar Documentos

Profissional Documentos

Cultura Documentos

Pub 1440

Enviado por

kapilnandwanaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pub 1440

Enviado por

kapilnandwanaDireitos autorais:

Formatos disponíveis

I-CORE SANDWICH PANEL OPTIMIZATION EMPLOYING DIFFERENT PLATE

MODELS.

I-SERDES TIPA DAUDZSL#U PANE&U OPTIMIZCIJA, IZMANTOJOT DA(DU

PLT#U MODE&US

K. Kalni#, E. Sku&is

Keywords: optimization, response surface method, sandwich panels, finite element method

Introduction

Validation between different plate models used to optimize I-core sandwich panels will be

discussed in this paper. The effectiveness of determination the most suitable plate element will

lead into development of the fast and reliable reanalysis tool since application of direct

minimization algorithm and multiple finite element analysis is too expensive from a

computational point of view. For this reason four different numerical solution approaches were

chosen to investigate sandwich panel:

1) Analytic with trigonometrical functions.

2) Substitution of sandwich panel with an equivalent orthotropic material plate model.

3) Replacement of sandwich panel with an equivalent multi-layered laminate plate model.

4) Full-scale finite element model.

Optimization technique for sandwich panel has been developed employing the method of

experiment design. This methodology is based on a collection of mathematical and statistical

techniques that are useful for the modeling and analysis of problems in which a response of

interest is influenced by several variables and the objective is to optimize this response.

Optimization procedure based on experiment design is not only an effective tool for the optimum

design of different systems and processes requiring computationally expensive analyses, but it

also easily combines modeling and optimization stages in comparison with other approaches.

Moreover, this approach is general in the sense that it permits the optimization of any systems or

processes under arbitrary conditions with respect to any objective function (e.g. weight,

durability, reliability, cost) taking into account all practical requirements. That is why the

methodology examined is used so widely in different areas: aerospace engineering [1],

mechanical engineering [2], electrical engineering [3], electrochemical engineering [4], civil

engineering [5], material science [6], etc. All these applications can be related to optimization of

different technological and operational processes or systems including the obtaining of materials

and structures with predicted properties.

Finite element modeling

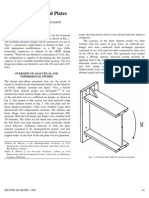

At present, optimization of steel I-core sandwich panels (Fig.1), with general dimensions of one

meter, is considered for square plate, such an assumption will simplify parametric studies and a

definition of the cost function. I-core sandwich constructions are made from steel with Youngs

moduli of E=210 GPa and poissons ratio of =0.3. All numerical calculations are carried out by

the finite element code ANSYS [7], except analytical solution, which was directly incorporated

into the optimization algorithm. Two different types of shell elements were used to describe

behavior of the I-core sandwich shell. A 4node Shell 63 element was used in calculations for a

full-scale model as well as an equivalent orthotropic plate, while an 8node Shell 99 element

was used to describe an equivalent multi-layer I-core sandwich plate. Since sandwich plate is

admitted as square plate, a span between I stiffeners is a constant 125 mm. It is assumed that the

first and the last spans in an I-core panel have half the span dimensions than those in the middle.

In this particular case the distance between I stiffeners p are taken based on previous experience

from the sandwich panel optimization procedure [8]. Simply supported boundary conditions are

applied at all outer edges with the uniformly distributed pressure load acting on top of the panel

with a magnitude of 1MPa.

h

t

tpl

pl

st

tst

125

2p p

Figure 1. Sandwich panel construction.

Determination of the equivalent plate properties

To considerably decrease the dimension of the numerical problem, the I-core sandwich panel

could be considered as an homogeneous orthotropic plate [9] with equivalent stiffness and

thickness properties. These equivalent stiffnesses properties for an empty I-core sandwich panel

are given in Table 2. Where t

pl

is the thickness of the face and the bottom plates, t

st

is the

thickness of the stringer plates and h

st

is the height of the stiffener as well as d being the distance

between centroids of the face sheets with G as the shear modulus of the steel. To use ANSYS,

homogenized orthotropic material properties should be introduced. These properties are defined

from the following relations presented in Table 1.

Table 1. Homogenized orthotropic material properties.

3

12

d

D

E

x

x

3

6

d

D

G

xy

xy

f xy

3

12

d

D

E

y

y

kd

S

G

x

xz

xy

x

y

yz

D

D

3

12

d

D

E

y

z

kd

S

G

y

yz

xy

x

y

xz

D

D

Where the shear correction factor k is equal to 5/6. In this case the equivalent thickness of the

homogeneous plate is equal to the distance d between centroids of faces.

Table 2. Equivalent stiffness for empty I-core sandwich panel

Stiffness Determination of stiffness Additional

terms

Longitudinal

bending

p

E I

E d t E t

D

wx

pl pl

x

2 2 12

2

2 3

+ +

12

3

st st

wx

h t

I

I

wx

-

moment of

inertia of stiffener

Lateral

bending

2 12

2

2 3

E d t E t

D

pl pl

y

+

Twisting

) 1 ( 2

2

+

E

d t D

pl xy

Longitudinal

shear

d

h

p

h

t

t

p

h

t

t

h

d

p

d

t G S

st st

st

pl

st

st

pl

st

st x

2 3

1

2 6

1

2

2

+

,

_

+

12

3

pl

pl

t

I

I

pl

-

moment of

inertia of face

Lateral shear

1

1

]

1

,

_

,

_

+

,

_

2 3

12

1

2

1

6

1

1

3

3

d

t

d

t

pd

EI

t

p

p EI

S

pl pl

st

st

pl

y

12

3

st

st

t

I

I

st

- moment of

inertia of stiffener

Besides as the authors [10,11] note, an equivalent multi-layer laminate theory approach is

suitable to describe an equivalent sandwich plate. In the multi-layered laminate plate approach,

two outer layers have the same material properties as in a real structure, but middle the layer uses

reduced properties as determined and presented in Table 3.

Table 3. Equivalent multi-layer laminate properties

E

x

E

y

= E

z

G

xy

= G

yz

G

xz

v

xy

v

xz

=

v

yz

Top layer

E E G

t

G

t

t

Middle layer

p

t

E

st

2

0 0

p

t

G

st

2

p

t

st

w

2

0

Bottom layer

E E G

b

G

b

b

Due to unavoidable singularity in finite element calculations, all zero values have been replaced

with the equivalent modulus value divided by a thousand. For comparison one particular

example of equivalent properties is presented in Table 4.

Table 4. Comparison of the different equivalent material properties

Full-scale model

properties

Homogenized orthotropic

material properties [MPa]

Equivalent multi-layer

laminate properties [MPa]

t

pl

= 2.5 mm E

x

= 120100 MPa E

x

=7000 MPa

t

st

= 2.5 mm E

y

= E

z

=114900 MPa E

y

= E

z

=7 MPa

h

st

= 25 mm G

xy

= 44060 MPa G

xy

= 2692 MPa

2p = 125 mm G

xz

= 3377 MPa G

xz

= 2.6 MPa

d = 27.5 mm G

yz

= 20 MPa G

yz

= 2.6 MPa

h =30 mm v

xz

= v

yz

=0.2875 v

xz

= v

yz

=0.006

Design of experiments

The design of experiments is formulated for a three-dimensional space (3 design parameters, see

Table 5.). For global approximations, it is planned to use second order polynomial functions. It is

well known that for such approximating functions the D-optimal experimental design is the most

suitable [12]. Since we have discrete and continuous design variables, the combined Latin

hypercube and D-optimal experimental design was chosen. The second order model contains

L=(k+1)(k+2)/2 parameters. Therefore for k=3, the number of parameters is L=10. It is

recommended that the minimal number of runs is about twice that number of coefficients L in

the approximating function. For this reason we should carry out 20 numerical experiments.

Table 5. Boundaries of design parameters

Minimum bound Design parameter Maximum bound

1.5 mm t

pl

4 mm

1.5 mm t

st

4 mm

50 mm h

st

100 mm

Since thicknesses of the top and the bottom panels, as well as stinger thickness from a

manufacturing point of view could be produced with step 0.5 mm, these two variables have been

discretized into 6 levels as presented in figure 2.

t

pl

thickness of the plate [mm]

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

h

p

a

n

e

l

h

e

i

g

h

t

[

m

m

]

40

50

60

70

80

90

100

110

t

st

thickness of the stringer [mm]

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

h

p

a

n

e

l

h

e

i

g

h

t

[

m

m

]

40

50

60

70

80

90

100

110

Figure 2. Experimental design in planes 1-3 and 2-3.

Numerical analysis

A numerical analysis can be divided into two parts: the first approach is based on analytic

formulas (1,2) evaluated by Zenkert [9,10] the second approach is connected with a finite

element code ANSYS solution.

))

2

sin( )

2

sin( )

2

(sin(

max

b

b

a

a

a

a

W f

(1)

) ) ( (

16

) ) ) ) 1 ( ( 2 (

) 1 ( 16

2 4

2

2 4

6

4

y x

y xy xz xy xz x x

xz xy

S

a

b

S

qb

D

a

b

D v v v D

a

b

D

v v qb

W

+

+

+

,

_

+ +

,

_

(2)

Where equivalent stiffness for empty I-core sandwich panel (presented in Table 2.) and q is

uniformly distributed pressure load, a and b panel longitudinal and transverse edge length. Finite

element modeled with mesh of 20 x 20 with 642 degrees of freedom was used to solve sandwich

panel with equivalent orthotropic material properties. In comparison 1882 degrees of freedom

where used to model an equivalent multi layered laminate material plate. In contrast a full-scale

model was elaborated with 49476 degrees of freedom. In the full-scale model (presented in

Figure 3.) local and global bending of the sandwich plate could be observed contrariwise to

equivalent material properties of the multi-layered model and analytical solution.

Figure 3. Full-scale sandwich plate bending (h=76;t

pl

=3.5;t

st

=2.5) and laminate plate bending.

Response surface technique

Approximations

(

F of the finite element results F are performed by the second order polynomial

functions

+ +

K

i

K

i k

k i ik

K

i

i i

x x x x F

1 1

0

) (

(

(3)

These approximations for all functions have been obtained using a conventional un-weighted

least squares estimation with the elimination of three outlier runs for each function. The error of

approximations is calculated by the following expressions

( ) ( )

2 2

1 1

0

( (

( ) ( ) ( ) ( )

,

N N

i i i i

i i

F x F x F x F x

N N L

(4)

where is a squared error,

0

is a standard deviation, ( )

i

F x is the value of original function in

the sample point x

i

of the experimental design,

(

( )

i

F x is the value of approximating function in

the sample point x

i

of the experimental design and N is the number of points used for

approximation.

At the beginning, approximations have been obtained for all functions employing all sample

points. The relative errors for all examined variants and variants where the three worst points

were deleted due to cross validation are given in Table 6.

Table 6. Approximation relative errors

Analytical

solution

Homogeneous

ortothropic plate

Multi-layer

laminate plate

Full-scale FEM

model

Without

elimination

6.63% 8.96% 9.73% 7.41%

With elimination

of 3 worst points

5.66% 4.88% 4.50% 4.00%

Parametric studies

Parametric studies are carried out additionally for designer convenience to investigate the

influence of different design parameters on behavioral functions. This can be done by displaying

contour plots 2D or 3D graphs of the approximating functions (surrogate models). The plate

deflection dependencies over different design parameters are given in Figures 4-5.

t

pl

thickness of the plate [mm]

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

P

l

a

t

e

d

e

f

l

e

c

t

i

o

n

[

m

m

]

1

2

3

4

5

6

7

Surrogate model 1

Surrogate model 2

Surrogate model 3

Surrogate model 4

Analytical solution

Orthotropic solution

Laminate solution

Full-scale FEM solution

Figure 4. Plate deflection dependency over

thickness of the sandwich panel.

h height of the sandwich panel [mm]

40 50 60 70 80 90 100 110

P

l

a

t

e

d

e

f

l

e

c

t

i

o

n

[

m

m

]

0

2

4

6

8

10

Surrogate model 1

Surrogate model 2

Surrogate model 3

Surrogate model 4

Analytical solution

Orthotropic solution

Laminate solution

Full-scale FEM solution

Figure 5. Plate deflection dependency over

height of the sandwich panel.

In these figures the approximation functions (surrogate models 1-4) of four different approaches

are plotted compared with values obtained with the direct solution of a particular case.

Optimization results

The present weight minimization problem (5) is solved using the random search method.

Optimum results for the sandwich construction modeled by different plate elements are

presented in Table 7. In this particular optimization example, deflection constrained up to 1/400

from panel length and h height of the sandwich panel could exceed 75 mm.

00000785 . 0 ) 8 ) 2 ( (

st pl pl

at t h ab t G + min G (5)

Table 7. Optimum solution

Optimum solution

Analytic

solution

Homogeneous

orthotropic

plate

Multi-layer

laminate plate

Full-scale FEM

model

Weight [kg] 71.52 61.06 53.27 56.82

t

pl

thickness of the plate

[mm]

3.5 3.5 3 2.5

t

st

thickness of the stringer

[mm]

4 1.5 1.5 4

h height of the sandwich

panel [mm]

72.99 71.90 71.53 74.94

Conclusions

The I-core sandwich optimization problem has been formulated and methodology based on

experimental design and response surface technique has been developed for the minimization of

the construction weight. To describe the behavior of sandwich construction under bending loads,

the finite element method together with the analytical solution has been applied in the sample

points of experimental design. Approximations of the original functions for behavioral

constraints have been obtained using second order polynomials. The minimization problem has

been solved for the real construction by a method of random search employing the

approximating functions instead of original functions. Parametric studies and sensitivity analysis

has been carried out additionally for designer convenience. Based on the collected results

equivalent material properties could not be used to determinate I-core stringer thickness, plate

thicknesses and plate height. These are parameters that could be used to optimize sandwich

construction.

References

1.Rikards R., Abramovich H., Auzins J., Korjakins A., Ozolinsh O., Kalnins K., Green T.

Surrogate models for optimum design of stiffened composite shells // Composite Structures, 69

issue, 2004 -p. 243-251.

2. Barnwal S., Bayoumi A. E. and Hutton D. V. Prediction of flank wear and engagement from

force measurements in end milling operations // Wear, Vol. 170, 1993 -p. 255-266.

3. Christopher M., Su H. and Ismail M. Yield optimization of analogous integrated circuits

including transistor mismatch. In: Proceedings of IEEE International Symposium on Circuits

and Systems, Vol. 3, 1993 - p. 1801-1804.

4. Hewidy M. S. and Fattouh M. Electrochemical cutting using tubular cathodes: response

surface approach // International Journal of Production Research, Vol. 27, 1989 -p. 953-963.

5. Krakovski M. B. Optimization of RC structures using design of experiments // Computers &

Structures, Vol. 63, 1997 -p. 119-132.

6. Rikards R., Goracy K., Bledzki A. K. and Chate A. Prediction of mechanical properties of

composites with recycled particles // Mechanics of Composite Materials, Vol. 30, No. 6, 1994 -p.

781-796.

7. ANSYS. Version 8.1., 2004 ANSYS, Inc., Canonsburg, PA, USA

8. Rikards R., Barkanov E., Kalnins K. and Kovalovs A. Surrogate models for optimal design of

composite structures // In: First International Conference on Finite Element Applications

(LUXFEM03)2003 on CD.

9. Zenkert D. An Introduction to Sandwich Construction // EMAS, London, 1997 p. 277.

10. Zenkert D. The Handbook of Sandwich Construction // EMAS, London, 1997 p.442.

11. Skudra A.M., Skudra A.A. Ievads sl)aino materi)lu un konstrukciju meh)nik) // RTU,

R,ga, 2002.

12. Myers R. H. and Montgomery D. C. Response surface methodology. Process and product

optimization using designed experiments. 2

nd

edition. // Wiley, New York, 2002 p. 352.

Kaspars Kalni+- M.sc.ing

Riga Technical University, Institute of Materials and Structures

Address: Ka.&u Street 1, R,ga LV-1658, Latvia

E-mail: kasisk@latnet.lv

Eduards Sku/is M.sc.ing

Riga Technical University, Institute of Materials and Structures

Address: Ka.&u Street 1, R,ga LV-1658, Latvia

E-mail: edskukis@bf.rtu.lv

Kalni+- K., Sku/is E. I-core sandwich panel optimization employing different plate models.

Validation between different plate elements used to optimize I-core sandwich panels will be discussed in this present

paper. The effectiveness of determining the most suitable plate element will lead into development of the fast and

reliable reanalysis tool since application of a direct minimization algorithm and multiple finite element analysis is

too expensive from a computational point of view. For this reason four different numerical solution approaches

were chosen to investigate an I-core sandwich panel. Surrogate models were elaborated using response surface

methodology. Based on these response function approximations, parametric studies were performed. Design

optimization were performed using the random search method.

Kalni+- K., Sku/is E. I-serdes tipa daudzsl1+u pane3u optimiz1cija, izmantojot da51du pl1t+u mode3us

Dotaj darb tiek sal#dzinta efektivitte da%du plt(u apr+-ina mode/iem, tos izmantojot I-serdes tipa daudzsl(u

pane/u optimizcij. Nosakot vispiem+rotko pltnes apr+-ina modeli nodro1intu efekt#vu trs simulcijas

proced3ras izstrdi, jo tie1a minimizcijas algoritma pielieto1ana un daudzkrt+ji gal#go elementu apr+-ini ir prk

laikietilp#gi no skait/o1anas viedok/a. 5# iemesla d+/ 7etras da%das skaitliskas metodes tika izv+l+tas, lai p+t#tu

parametru ietekmi I-serdes daudzsl(u panel#. Surogtie mode/i pltnei tika izstrdti ar virsmas atbildes

metodolo9iju. Izmantojot ieg3tos rezulttus parametru ietekmes anal#ze tika veikta. Svara minimizcijai nejau1as

mekl+1anas metode tika izmantota.

7. 789:;:<=, >. @BCB;E. GIJ;K;L8M;N IIOQS;9N ET:VW;X I8:Y9;, E ;EIQ9<LQW8:;YK O8L9;X:[\

KQVY9Y^ I98EJ;:.

<>@ABCBDC >CEFHIJ@JLA NCOPF >@EBQND NLPCH@ND >CRCBDS TH@UJDB, VLJL>QC DUTLHIEFWJUX A IT>LYDHX

UZBPAD[ T@BCHCS, \QHD >@UUNLJ>CBQ A P@BBLS >@\LJC. ]YYCVJDABLUJI LT>CPCHCBDX B@D\LHCC TLP^LPX`CS

ZVADA@HCBJBLS ^@>@VJC>DUJDVD TH@UJDBQ, ACPCJ V \QUJ>LNF D B@PCOBLNF >@EADJDW DBUJ>FNCBJ@

>@U[CJ@ D @B@HDE@ J.V. T>DNCBCBDC T>XNLaL LTJDNDE@bDLBBLaL @HaL>DJN@ D NBLaLV>@JBLaL >@U[CJ@

VLBC[BLaL ZHCNCBJ@, TLHF[@CJUX UHDRVLN PL>LaL U JL[VD E>CBDX AQ[DUHCBDS. c P@BBLN UHF[@C, PHX DEF[CBDX

IT>LYDHX UZBPAD[ T@BCHCS \QHL AQ\>@BL 4 [DUHCBBQ^ >CRCBDX. <F>>La@JB@X NLPCHI \QH@ >@E>@\LJ@B@ TL

NCJLPF [@UJLJBLaL LJVHDV@. eUBLAQA@XUI B@ YFBVbDD [@UJLJBLaL LVHDV@, \QHD DEF[CBQ T@>@NCJ>Q

AHDXBDX. gHX LTJDNDE@bDD NLPCHD \QH AQ\>@B UHF[@SBQS NCJLP TLDUV@.

Você também pode gostar

- Optimisation of Plate Thickness Using Finite Difference MethodDocumento5 páginasOptimisation of Plate Thickness Using Finite Difference MethodhemanthsridharaAinda não há avaliações

- Fea For A 2D Metal Plate Using Matlab: March 2017Documento17 páginasFea For A 2D Metal Plate Using Matlab: March 2017VivekAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- FEA Benchmark For Dynamic Analysis of Perforated PlatesDocumento18 páginasFEA Benchmark For Dynamic Analysis of Perforated Platesmatteo_1234Ainda não há avaliações

- Cosmos Design Star Study - The Tensile Test of The Rectangular PlateDocumento12 páginasCosmos Design Star Study - The Tensile Test of The Rectangular PlateapsarasoAinda não há avaliações

- Dynamic Damage and FragmentationNo EverandDynamic Damage and FragmentationDavid Edward LambertAinda não há avaliações

- FEA Assignment OTHERDocumento13 páginasFEA Assignment OTHERZeashaan AkhmedAinda não há avaliações

- Ijems 15 (6) 452-458Documento7 páginasIjems 15 (6) 452-458Rahul GoswamiAinda não há avaliações

- Elastic-Plastic Analysis of R/C Coupled Shear Walls: The Equivalent Stiffness Ratio of The Tie ElementsDocumento8 páginasElastic-Plastic Analysis of R/C Coupled Shear Walls: The Equivalent Stiffness Ratio of The Tie ElementsAurela Meço ZeqoAinda não há avaliações

- Moment End ConnectionsDocumento8 páginasMoment End ConnectionsEfrainz TorresAinda não há avaliações

- Effect of Fiber Orientation On Stress Concentration Factor in A Laminate With Central Circular Hole Under Transverse Static LoadingDocumento7 páginasEffect of Fiber Orientation On Stress Concentration Factor in A Laminate With Central Circular Hole Under Transverse Static LoadingSiva BhaskarAinda não há avaliações

- Discrete Optimum Design of Cable-Stayed BridgesDocumento9 páginasDiscrete Optimum Design of Cable-Stayed BridgesspoorthissAinda não há avaliações

- Equivalent Analysis of Honecomb PanelsDocumento5 páginasEquivalent Analysis of Honecomb Panelsprateekg92Ainda não há avaliações

- Wrinkling StressDocumento8 páginasWrinkling StressCandace FrankAinda não há avaliações

- Composite Structures: Quantian Luo, Liyong TongDocumento11 páginasComposite Structures: Quantian Luo, Liyong TongSaid DjaballahAinda não há avaliações

- An Investigation Concerning Optimal Design of Solid Elastic PlatesDocumento19 páginasAn Investigation Concerning Optimal Design of Solid Elastic Platescasoj29Ainda não há avaliações

- Natural Frequencies of Plates With Uniform PerforationsDocumento7 páginasNatural Frequencies of Plates With Uniform Perforationsspider1970Ainda não há avaliações

- ISTAM - Stress Concentration Factor Convergence Study of A Thin PlateDocumento7 páginasISTAM - Stress Concentration Factor Convergence Study of A Thin PlateKanak_KalitaAinda não há avaliações

- Reanalysis of Plates Modified by Free Damping Layer TreatmentDocumento7 páginasReanalysis of Plates Modified by Free Damping Layer TreatmentUmanath R PoojaryAinda não há avaliações

- Efficient Sensitivity Analysis and Optimization of Shell Structures by Abaqus CodeDocumento10 páginasEfficient Sensitivity Analysis and Optimization of Shell Structures by Abaqus CodeNazim NarimanAinda não há avaliações

- Blank Optimization in Sheet Metal Forming Using An Evolutionary Algorithm-LibreDocumento9 páginasBlank Optimization in Sheet Metal Forming Using An Evolutionary Algorithm-Libreicv.xaviAinda não há avaliações

- 9-2-Specimen For A Novel Concept of Biaxial Tension Test - Design and OptimisationDocumento7 páginas9-2-Specimen For A Novel Concept of Biaxial Tension Test - Design and OptimisationmrbeegzAinda não há avaliações

- I T.her Al Stress Analysis of Laminated Composit Plates Using I Shear Flexible ElementDocumento6 páginasI T.her Al Stress Analysis of Laminated Composit Plates Using I Shear Flexible ElementSelva KumarAinda não há avaliações

- Stacking Sequence Optimization With Genetic Algorithm Using A Two-Level ApproximationDocumento11 páginasStacking Sequence Optimization With Genetic Algorithm Using A Two-Level Approximationzeeshanahmad111Ainda não há avaliações

- SCF in Isotopic & Orthotropic Plates Part I: Uniaxial LoadDocumento7 páginasSCF in Isotopic & Orthotropic Plates Part I: Uniaxial LoadNandit JadvaniAinda não há avaliações

- Symmetric Bending of Laminated PlatesDocumento3 páginasSymmetric Bending of Laminated PlateskkkrajaAinda não há avaliações

- Frequency Optimization For Laminated Composite Plates Using Extended Layerwise ApproachDocumento8 páginasFrequency Optimization For Laminated Composite Plates Using Extended Layerwise ApproachDEEPAKAinda não há avaliações

- Implementation of A Multisurface Cap-Plasticity Model For Concrete and Its Application To The Simulation of Composite Joint TestsDocumento14 páginasImplementation of A Multisurface Cap-Plasticity Model For Concrete and Its Application To The Simulation of Composite Joint Testsklomps_jrAinda não há avaliações

- Finite Element Analysis-Assignment 2: Ucemome@ucl - Ac.ukDocumento15 páginasFinite Element Analysis-Assignment 2: Ucemome@ucl - Ac.ukOmar El-SharkawyAinda não há avaliações

- Comparison of Analysis of Folded Plate Structures by Simplified Bending Theory and Ansys ProgramDocumento8 páginasComparison of Analysis of Folded Plate Structures by Simplified Bending Theory and Ansys Programimad rashidAinda não há avaliações

- Vibration AnalysisDocumento4 páginasVibration AnalysisGanesamoorthy ThirunarayananAinda não há avaliações

- Homework2 Confined RC Section AnalysisDocumento13 páginasHomework2 Confined RC Section AnalysisQingzhi Liu100% (1)

- Finite Element Method Analysis of Rectangular Plate With Circular Hole Using Ansys PDFDocumento12 páginasFinite Element Method Analysis of Rectangular Plate With Circular Hole Using Ansys PDFVikashAinda não há avaliações

- Finite Element Method Analysis of Rectangular Plate With Circular Hole Using AnsysDocumento12 páginasFinite Element Method Analysis of Rectangular Plate With Circular Hole Using AnsysNarayana Swamy GAinda não há avaliações

- 14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilDocumento6 páginas14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilWondwosen BelayAinda não há avaliações

- The Optimisation of Shot Peen Forming ProcessesDocumento5 páginasThe Optimisation of Shot Peen Forming ProcessesbkhmohamedAinda não há avaliações

- Experiment For Bending Analysis of 3-Phase Composite Plate in Ship StructureDocumento5 páginasExperiment For Bending Analysis of 3-Phase Composite Plate in Ship StructureAscanio BarbosaAinda não há avaliações

- Comparison of The Optimal DesignDocumento10 páginasComparison of The Optimal DesignAlexander DeckerAinda não há avaliações

- Circular Plate Ribbed 1Documento6 páginasCircular Plate Ribbed 1Ascanio BarbosaAinda não há avaliações

- Raft FoundationDocumento9 páginasRaft FoundationSantosh KumarAinda não há avaliações

- Machine Design, Vol.3 (2011) No.4, ISSN 1821-1259 Pp. 273-276Documento4 páginasMachine Design, Vol.3 (2011) No.4, ISSN 1821-1259 Pp. 273-276Nizam Sudin Dan KhatijahAinda não há avaliações

- Fullc03 960321Documento14 páginasFullc03 960321Ali KhubbakhtAinda não há avaliações

- International Journal of Engineering Research and DevelopmentDocumento5 páginasInternational Journal of Engineering Research and DevelopmentIJERDAinda não há avaliações

- MECH3300/3302 COMPUTER TUTORIAL 2 - Modelling 2D Problems 1. Plane Strain Crack ModelDocumento7 páginasMECH3300/3302 COMPUTER TUTORIAL 2 - Modelling 2D Problems 1. Plane Strain Crack Modelcaojin259Ainda não há avaliações

- Stability Factors of Cantilever Sheet Pile Walls in Clays by Using Finite Element MethodDocumento5 páginasStability Factors of Cantilever Sheet Pile Walls in Clays by Using Finite Element MethodSothoan Pro ÐGAinda não há avaliações

- Application of Physical and Mathematical Modelling in Underground ExcavationsDocumento8 páginasApplication of Physical and Mathematical Modelling in Underground ExcavationsrannscribdAinda não há avaliações

- Vehicle Structure Design & Material Selection: DR Meftah HrairiDocumento19 páginasVehicle Structure Design & Material Selection: DR Meftah Hrairi'Atif AliAinda não há avaliações

- MECH3300/3302 COMPUTER TUTORIAL 2 - Modelling 2D Problems 1. Plane Strain Crack ModelDocumento7 páginasMECH3300/3302 COMPUTER TUTORIAL 2 - Modelling 2D Problems 1. Plane Strain Crack ModelTarek AbulailAinda não há avaliações

- Comparison of Workpiece Geometry and Its Effects On ECAP Process by FEADocumento5 páginasComparison of Workpiece Geometry and Its Effects On ECAP Process by FEAijsretAinda não há avaliações

- G6206029035 PDFDocumento7 páginasG6206029035 PDFShilpa Dheeraj GunwantAinda não há avaliações

- Hexahedral and Tetrahedral Element StudyDocumento6 páginasHexahedral and Tetrahedral Element Studylpararasasingam91Ainda não há avaliações

- 10 1 1 193 4173 PDFDocumento7 páginas10 1 1 193 4173 PDFRohit GadekarAinda não há avaliações

- II Biaxial LoadDocumento7 páginasII Biaxial LoadNandit JadvaniAinda não há avaliações

- 2004 Int Ansys Conf 51Documento10 páginas2004 Int Ansys Conf 51maitoravi78Ainda não há avaliações

- Bending Response of FGM Plate Under Sinusoidal Line Load.Documento9 páginasBending Response of FGM Plate Under Sinusoidal Line Load.International Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Optimal Design of Hollow Core PanelsDocumento26 páginasOptimal Design of Hollow Core Panelspaulo_arrieiroAinda não há avaliações

- Free Vibration of Laminated Plates by A Variable-Kinematic Chebyshev-Ritz MethodDocumento3 páginasFree Vibration of Laminated Plates by A Variable-Kinematic Chebyshev-Ritz MethoddozioAinda não há avaliações

- Fatigue Crack Paths in Shafts Subjected To Bending and TorsionDocumento8 páginasFatigue Crack Paths in Shafts Subjected To Bending and TorsionkapilnandwanaAinda não há avaliações

- Print - Hex Head Bolt Dimensions ASME B18.2.1 - R. E. Glover LTDDocumento2 páginasPrint - Hex Head Bolt Dimensions ASME B18.2.1 - R. E. Glover LTDkapilnandwanaAinda não há avaliações

- Dark Triad TestDocumento3 páginasDark Triad TestkapilnandwanaAinda não há avaliações

- CIDECT Design Guide 9Documento213 páginasCIDECT Design Guide 9paris06250% (2)

- J03 2Documento7 páginasJ03 2kapilnandwanaAinda não há avaliações

- 4-13v2 EngDocumento57 páginas4-13v2 EngkapilnandwanaAinda não há avaliações

- 960343Documento209 páginas960343kapilnandwanaAinda não há avaliações

- ASME Ch35 p629-644Documento16 páginasASME Ch35 p629-644kapilnandwanaAinda não há avaliações

- Design OF Flush-Extended End Plate ConnectionsDocumento3 páginasDesign OF Flush-Extended End Plate Connectionskapilnandwana100% (1)

- A Toastmaster Wears Many HatsDocumento12 páginasA Toastmaster Wears Many HatsShinette Brito 蔡姝莉Ainda não há avaliações

- Sjjlj!07: SSC Design Calculation or Analysis Cover Sheet Design Calculation or Analysis Cover Sheet SSCDocumento56 páginasSjjlj!07: SSC Design Calculation or Analysis Cover Sheet Design Calculation or Analysis Cover Sheet SSCkapilnandwanaAinda não há avaliações

- Ac 156Documento8 páginasAc 156kapilnandwana100% (1)

- Introduction To ASME Section III Div1Documento97 páginasIntroduction To ASME Section III Div1Siampol Feepakphor83% (6)

- 51841Documento15 páginas51841Hermenegildo LuisAinda não há avaliações

- Virtual Hil SoftwareDocumento12 páginasVirtual Hil SoftwareDibyaraj Krishna BeheraAinda não há avaliações

- Contoh Program ScannerDocumento6 páginasContoh Program ScannerEkoNurdiyantoAinda não há avaliações

- Mathematical LogicDocumento15 páginasMathematical LogicEfean KimAinda não há avaliações

- Project 2 Computer ScienceDocumento9 páginasProject 2 Computer SciencethedonutpirateAinda não há avaliações

- Dilger Lustre HPCS May WorkshopDocumento45 páginasDilger Lustre HPCS May WorkshopSebastian GutierrezAinda não há avaliações

- VMware Vcenter Site Recovery Manager With Vsphere Replication DatasheetDocumento4 páginasVMware Vcenter Site Recovery Manager With Vsphere Replication DatasheetFarough BaigAinda não há avaliações

- List of ForumsDocumento99 páginasList of Forumseuro198100% (2)

- QMS Awareness TrainingDocumento25 páginasQMS Awareness Trainingsemeneh haileAinda não há avaliações

- On The BeastDocumento2 páginasOn The BeastClark Ken BiloAinda não há avaliações

- Usando Caché - ODBC PDFDocumento38 páginasUsando Caché - ODBC PDFlvaldeirAinda não há avaliações

- SUNDARDocumento2 páginasSUNDARDavidAinda não há avaliações

- Export PDF From AbiwordDocumento2 páginasExport PDF From AbiwordKarenAinda não há avaliações

- CADWorx Spec Export Template GuideDocumento13 páginasCADWorx Spec Export Template GuideMiguel100% (1)

- Feature List of Huawei UMTS RAN11.0 V1.7 (20090331)Documento14 páginasFeature List of Huawei UMTS RAN11.0 V1.7 (20090331)EmreAinda não há avaliações

- Calculator Techniques For Solving Progression ProblemsDocumento6 páginasCalculator Techniques For Solving Progression ProblemsThomas John Doblas AgrabioAinda não há avaliações

- Kajian Keandalan Utilitas Bangunan Gedung Rusunawa Di Kota Banda AcehDocumento10 páginasKajian Keandalan Utilitas Bangunan Gedung Rusunawa Di Kota Banda AcehUly Ulfa DyahAinda não há avaliações

- COAL Course OutlineDocumento2 páginasCOAL Course Outlineroxter_15100% (1)

- Xi3 Error Message Guide enDocumento502 páginasXi3 Error Message Guide ennapnap5Ainda não há avaliações

- Unity Pro Operating ModesDocumento1.950 páginasUnity Pro Operating Modescanalu1192Ainda não há avaliações

- Taxonomy of BugsDocumento11 páginasTaxonomy of BugsrmvigneshmuraliAinda não há avaliações

- Google Glass: Case StudyDocumento10 páginasGoogle Glass: Case StudyUtkarsh ChaturvediAinda não há avaliações

- Zixi ProtocolDocumento9 páginasZixi ProtocolJvst JashAinda não há avaliações

- Fanuc 16ip - 18ip Model B - Alarm ListDocumento19 páginasFanuc 16ip - 18ip Model B - Alarm Listadeiv20027197Ainda não há avaliações

- 7 0 Saa Sys Man GuideDocumento664 páginas7 0 Saa Sys Man GuideNi Kadek SuastiniAinda não há avaliações

- SAP Payroll ProcessDocumento20 páginasSAP Payroll Processlohit111780% (5)

- Continuous Time ConvolutionDocumento28 páginasContinuous Time ConvolutionlhslhinAinda não há avaliações

- 978 3 642 17752 1Documento270 páginas978 3 642 17752 1Fasasr ThdasAinda não há avaliações

- SMM Project Report - Group 3Documento33 páginasSMM Project Report - Group 3Akarsh AgarwalAinda não há avaliações

- Java Lab ProgramsDocumento27 páginasJava Lab Programsaknumsn7724Ainda não há avaliações

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®No EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Ainda não há avaliações

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)No EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Nota: 5 de 5 estrelas5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsAinda não há avaliações

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNo EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsAinda não há avaliações