Escolar Documentos

Profissional Documentos

Cultura Documentos

Ipc SM 785s

Enviado por

Wandyy GonçalvesDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ipc SM 785s

Enviado por

Wandyy GonçalvesDireitos autorais:

Formatos disponíveis

ASSOCIATION CONNECTING ELECTRONICS INDUSTRIES

IPC-SM-785

Guidelines for Accelerated Reliability Testing of Surface Mount Solder Attachments

IPC-SM-785

November 1992 A guideline developed by IPC

2215 Sanders Road, Northbrook, IL 60062-6135 Tel. 847.509.9700 Fax 847.509.9798 www.ipc.org

IPC-SM-785

November 1992

Table of Contents

1.0 SCOPE .................................................................... 1

1.1 1.2

2.0

Purpose................................................................. 1 Document Organization ....................................... 1

APPLICABLE DOCUMENTS ................................... 2

7.6 7.7 7.8 7.9 7.10 7.11

Creep Rupture Tests........................................... 33 Mechanical Shock Testing................................. 34 Failure Criteria for Solder Joint Fatigue Tests ...................................................... 34 Accelerated Life Test Planning ......................... 35 Failure Mode Analysis....................................... 38 Reporting Results............................................... 41

Step-by-Step Example ........................... 43 References .............................................. 45 Bibliography ........................................... 46 Figures

2.1 2.2 2.3 2.4

IPC........................................................................ 2 Joint Industry Standards ...................................... 2 Military................................................................. 2 Other Publications................................................ 2

Appendix A Appendix B Appendix C

3.0 REQUIREMENTS

3.1 3.2 3.3 3.4 3.5

4.0

Terms and Denitions.......................................... 3 Reliability Concepts and Understanding............. 5 Reliability Assurance ........................................... 6 Damage/Failure Mechanisms ............................ 10 Application Considerations................................ 12

SURFACE MOUNT SOLDER ATTACHMENT FATIGUE BEHAVIOR AND RELIABILITY PREDICTION ......................................................... 15

Figure 1 Figure 2

Flowchart for reliability....................................... 4 Generic reliability bathtub curves comparing electronic components and surface mount solder attachment .............................................. 6 Generic cumulative failure probabilities for electronic component and surface mount solder attachment .............................................. 7 Flow chart for surface mount solder attachment reliability assurance ........................ 8 Cumulative fatigue damage............................. 10 SMT assembly thermo-mechanical deections resulting from thermal gradients in thermal shock .............................................. 13 Thermal cycle/fatigue mechanisms for solder.......................................................... 18 Shear strengths of 60:40 SnPb solder as a function of temperature and strain rate ........ 28 Creep behavior of solder ................................. 34 Example of circuit layout ................................. 36 Internal lead connection schemes for odd lead numbers per side.............................. 37

Figure 3

4.1 4.2 4.3 4.4 4.5

5.0

General Fatigue Life Models ............................ Solder Joint Fatigue........................................... Fatigue Behavior of Solder Joints..................... Acceleration Factors/Acceleration Transform ........................................................... Statistical Considerations...................................

15 15 16 19 20

Figure 4 Figure 5 Figure 6

DESIGN FOR SOLDER ATTACHMENT RELIABILITY ......................................................... 22

Figure 7 Figure 8 Figure 9 Figure 10 Figure 11

5.1 5.2

6.0

Primary Design Parameters ............................... 22 Secondary Design Parameters ........................... 23

MANUFACTURE/PROCESSES ............................. 24

6.1 6.2 6.3

Process Control and Verication ....................... 24 Consequences of Defects................................... 24 Material Properties............................................. 27

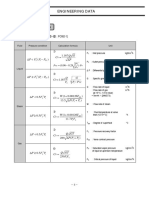

Tables

Table 1 Worst-Case Use Environments for Surface Mounted Electronics and Recommended Accelerated Testing ............................................ 14 Equivalent Mean Accelerated Test Cycles ......... 21 Typical Values .................................................... 29 Properties of Printed Board Laminates.............. 31 Results of Accelerated Reliability Test ............... 43

7.0 ACCELERATED RELIABILITY TESTING

7.1 7.2 7.3 7.4 7.5

Reliability Program/Strategy ............................. 30 Generic Damage Mechanism Investigations..... 30 Thermal Cycling ................................................ 30 Mechanical Cycling ........................................... 32 Vibration............................................................. 32

Table 2 Table 3 Table 4 Table 1A

iv

September 1992

IPC-SM-785

Guidelines for Accelerated Reliability Testing of Surface Mount Solder Attachments

1.0 SCOPE

This document provides guidelines for accelerated reliability testing of surface mount solder attachments and for evaluating and extrapolating the results of these accelerated reliability tests towards actual use environments of electronic assemblies. Background and design information is provided for an understanding of the accelerated test issues. The purpose of accelerated reliability testing is to provide condence that the design and the manufacturing/assembly processes are capable of meeting the intended goals of product performance. These guidelines provide adequate commonality and validity for accelerated reliability tests:

1.1 Purpose

cyclic loads during large temperature excursions or high frequency cycles at low temperatures. Also discussed are the acceleration factors, the acceleration transforms, and statistical considerations. Section 5, Design for Solder Joint Reliability This section details the various design parameters that have a primary inuence on solder attachment fatigue reliability. All aspects of the solder joint formation are addressed including component size, lead stiffness, coefcient of thermal expansion, solder joint uniformity, as well as solder composition, grain structure and the value that conformal coating or compliant layers provide to the attachment system. Section 6, Manufacturing Processes This section provides the relationship between the assembly and attachment processes, including their control and verication, and the resultant defects or potential defects from the original processes or touch-up, rework or repair actions. Material properties of solder (including volume), components, printed boards, adhesives and conformal coatings are discussed as to their interrelationships and the impact that these characteristics have on the manufacturing processes. Section 7, Accelerated Reliability Testing This section deals with the goals of accelerated testing to produce a failure in the shortest time using techniques intended to simulate the use environment in order to establish the appropriate condence level of product performance. Various types of stress cycling are reviewed and correlated to damage mechanisms. Also discussed is the need for developing a strategy which includes a test plan, sampling methodology, test vehicles, and failure mode analysis. Appendix A, Step-by-Step Example This section shows illustrations of applying the principles detailed in the information provided in this publication. Numerical examples are provided that highlight the relationship of the various parameters. Appendix B, References This section provides reference to published information that has a bearing on solder joint reliability and is referenced in the body of the text of this document. Details are shown as to Title, Author, and Publisher. Appendix C, Bibliography This section provides references to additional published information that could be of use to the practitioner. The references are organized into three major topics

1

To allow comparison of results from different test programs To provide the generic technical understanding of the underlying issues necessary to the design for adequate reliability To permit the analytical prediction of reliability based on a generic database and technical understanding To reduce cost and avoid time-consuming testing of every design iteration To establish practical alternatives to replace the excessively long test durations necessary to verify reliability of products subject to severe use environments or low failure tolerances

1.2 Document Organization This document has been organized to provide the reader with consistent information on the various aspects of reliability and identies the parameters that need to be addressed. Each section serves a specic function in the reliability description chain. Where appropriate, references are provided as to where additional information may be obtained.

Section 3, Requirements This section provides an overview of the concepts of reliability and all of the characteristics that need to be considered in the validation of a product design. Included are the denitions of the appropriate terms, as well as generic models for fatigue life and failure probability, manufacturing process ow, use environments, and testing methodology. Section 4, Surface Mount Solder Attachment Fatigue Behavior and Prediction This section deals with the fatigue life models for solder joints including their behavior when subjected to multiple

Você também pode gostar

- The Institute For: Introduction To Surface Mount AssemblyDocumento246 páginasThe Institute For: Introduction To Surface Mount AssemblyryanAinda não há avaliações

- Mil-Std 750Documento685 páginasMil-Std 750sshaffer_9Ainda não há avaliações

- MIL-HDBK-217F N2 Parts Count AnalysisDocumento13 páginasMIL-HDBK-217F N2 Parts Count AnalysisAna MarksAinda não há avaliações

- Applied Sciences: Safety-Oriented System Hardware Architecture Exploration in Compliance With ISO 26262Documento29 páginasApplied Sciences: Safety-Oriented System Hardware Architecture Exploration in Compliance With ISO 26262Girish KasturiAinda não há avaliações

- ISO7637-2 Electrical Transient Conduction Along Supply of Road VehiclesDocumento5 páginasISO7637-2 Electrical Transient Conduction Along Supply of Road Vehiclesvaldesf79Ainda não há avaliações

- MAXXI 6 Sales Presentation 04-2016Documento33 páginasMAXXI 6 Sales Presentation 04-2016Marty SchreckAinda não há avaliações

- Esda-Jedec JTR5.2-01-15Documento11 páginasEsda-Jedec JTR5.2-01-15Orbán NorbertAinda não há avaliações

- Global Ford Packaging SpecificationDocumento2 páginasGlobal Ford Packaging Specificationtony_gstAinda não há avaliações

- What Is The Military Grade PCB StandardDocumento14 páginasWhat Is The Military Grade PCB StandardjackAinda não há avaliações

- Qualification Testing For PCB PDFDocumento48 páginasQualification Testing For PCB PDFSempreInterAinda não há avaliações

- IPC-TM-650-MDP-A: 2020 - March IPC Test Method Development PacketDocumento14 páginasIPC-TM-650-MDP-A: 2020 - March IPC Test Method Development PacketJohnAinda não há avaliações

- Nasa STD 8739 2 PDFDocumento84 páginasNasa STD 8739 2 PDFRanjitha BAinda não há avaliações

- Board Design Guidelines 2003 Rev-ADocumento53 páginasBoard Design Guidelines 2003 Rev-Agre_test_takerAinda não há avaliações

- Solder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFDocumento83 páginasSolder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFQUALITY LABORATORYAinda não há avaliações

- COM3 Latchup Overview: David Orser IP Summit 2010Documento10 páginasCOM3 Latchup Overview: David Orser IP Summit 2010Ravi VarmaAinda não há avaliações

- Ipc J-Std-030a-2014Documento48 páginasIpc J-Std-030a-2014vahid hajihasaniAinda não há avaliações

- A Method To Evaluate PCBA Suppliers PB Free and Leaded Processes For Telecom ApplicationsDocumento12 páginasA Method To Evaluate PCBA Suppliers PB Free and Leaded Processes For Telecom Applicationsrgoulartc100% (1)

- JESD22 B110A Sub Assembly ShockDocumento16 páginasJESD22 B110A Sub Assembly ShockTan Long BinAinda não há avaliações

- JEDEC 22A122 - Power Cycling Test - PCTDocumento18 páginasJEDEC 22A122 - Power Cycling Test - PCTDaus Villa Jr.Ainda não há avaliações

- Digital Signal Integrity-Modeling and Simulation With Interconnects and PackageDocumento548 páginasDigital Signal Integrity-Modeling and Simulation With Interconnects and Packagemachan1Ainda não há avaliações

- 4412A Amendment 1 (3 07)Documento7 páginas4412A Amendment 1 (3 07)Aani MazharAinda não há avaliações

- JEP160Documento26 páginasJEP160ReAdPTAinda não há avaliações

- Information Requirements For Manufacturing Printed Boards and Other Electronic AssembliesDocumento3 páginasInformation Requirements For Manufacturing Printed Boards and Other Electronic AssembliesEmmanuel Mariano Gómez0% (1)

- Intro To SMTDocumento38 páginasIntro To SMTShelly NandalAinda não há avaliações

- Mil STD 704Documento25 páginasMil STD 704josebrigas4530Ainda não há avaliações

- Surface Mounting Guidelines For MEMS Sensors in An LGA PackageDocumento9 páginasSurface Mounting Guidelines For MEMS Sensors in An LGA PackagebobbyccwAinda não há avaliações

- IPC 2223 Design Standard For Flex and Rigid Flex CircuitsDocumento19 páginasIPC 2223 Design Standard For Flex and Rigid Flex CircuitsMariano DiazAinda não há avaliações

- IPC-TM-650 Test Methods ManualDocumento4 páginasIPC-TM-650 Test Methods Manualamal gainAinda não há avaliações

- EMC Field ProbesDocumento152 páginasEMC Field ProbesMarco Vinicio BazzottiAinda não há avaliações

- IPC TM 650 Solder Ball TestDocumento3 páginasIPC TM 650 Solder Ball TestJonas Ricafrente MojicaAinda não há avaliações

- Workmanship Standards QE SeminarDocumento73 páginasWorkmanship Standards QE SeminarJuanPabloJimenezAinda não há avaliações

- Cadence Home Installation Manual (RHEL5)Documento11 páginasCadence Home Installation Manual (RHEL5)KeithAinda não há avaliações

- IEC60749-25 - Contents3Documento11 páginasIEC60749-25 - Contents3Manish GAinda não há avaliações

- Kenexis: FMEDA WorksheetDocumento1 páginaKenexis: FMEDA WorksheetLuc SchramAinda não há avaliações

- Ipc 2223asDocumento4 páginasIpc 2223asWandyy Gonçalves0% (1)

- IPC-TM-650 Test Methods Manual: Contact Tool Contact ToolDocumento2 páginasIPC-TM-650 Test Methods Manual: Contact Tool Contact ToolKaja PrelovsekAinda não há avaliações

- Ionic Contamination Process ControlDocumento26 páginasIonic Contamination Process Controltimeforever aymenAinda não há avaliações

- JEP154Documento34 páginasJEP154yangAinda não há avaliações

- IPC-J-STD-003B PCB的可焊性Documento20 páginasIPC-J-STD-003B PCB的可焊性Sujatha PraveenAinda não há avaliações

- Surface Texture Measurement Fundamentals For Metrology Center Open HouseDocumento54 páginasSurface Texture Measurement Fundamentals For Metrology Center Open HouseSushant VashisthaAinda não há avaliações

- 610E Training Material List For CIT CDDocumento1 página610E Training Material List For CIT CDdruids2000Ainda não há avaliações

- Ipc DRM 18JDocumento6 páginasIpc DRM 18JcdmingAinda não há avaliações

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocumento36 páginasHouston Impact of J-STD-001F and IPC-A-610F Changes安靖Ainda não há avaliações

- Functional Safety in Automotive Electronics: Zhang Xinbo, Luo FengDocumento8 páginasFunctional Safety in Automotive Electronics: Zhang Xinbo, Luo FengVinoth kumarAinda não há avaliações

- JEDEC Solderability 22B102EDocumento26 páginasJEDEC Solderability 22B102EAlex Garcia100% (1)

- Fod - NasaDocumento23 páginasFod - NasaRahul BetgeriAinda não há avaliações

- Summary of EN55011 - IsM Radio Frequency EquipmentDocumento3 páginasSummary of EN55011 - IsM Radio Frequency EquipmentCharles HoAinda não há avaliações

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocumento4 páginasIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesAngus CHUAinda não há avaliações

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocumento4 páginasIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesVenkateswaran venkateswaranAinda não há avaliações

- Cohen'S KappaDocumento10 páginasCohen'S KappaaspiAinda não há avaliações

- IPC9850Documento56 páginasIPC9850Carlos Mascioni100% (1)

- Automotive Electronics Council-Q200 Stress Test Qualification For Passive Components Syfer AEC-Q200-Rev C QualificationDocumento7 páginasAutomotive Electronics Council-Q200 Stress Test Qualification For Passive Components Syfer AEC-Q200-Rev C QualificationgubiliAinda não há avaliações

- Reliability Bde0128g Chap03Documento40 páginasReliability Bde0128g Chap03Anonymous kKYg8kcAinda não há avaliações

- ANSI-ESD S8.1-2012 Symbols - ESD AwarenessDocumento14 páginasANSI-ESD S8.1-2012 Symbols - ESD AwarenessDavino MartinezAinda não há avaliações

- Ipc-Tm-650 Test Methods ManualDocumento5 páginasIpc-Tm-650 Test Methods ManualXuan HoangAinda não há avaliações

- IPC 1720a-1stq-2010Documento48 páginasIPC 1720a-1stq-2010BuiTrungAinda não há avaliações

- 3rd Edition 60601 1web VersionDocumento44 páginas3rd Edition 60601 1web VersionMario H. RodríguezAinda não há avaliações

- 111 Lubricant Sealant - Dow CorningDocumento8 páginas111 Lubricant Sealant - Dow CorningWandyy GonçalvesAinda não há avaliações

- Solder Re Flow Guide For Surface Mount DevicesDocumento13 páginasSolder Re Flow Guide For Surface Mount DevicesWandyy GonçalvesAinda não há avaliações

- Curriculum ElectronicDocumento2 páginasCurriculum ElectronicWandyy GonçalvesAinda não há avaliações

- Csn33 Bga User GuideDocumento11 páginasCsn33 Bga User GuideWandyy GonçalvesAinda não há avaliações

- Electronics: Dow CorningDocumento3 páginasElectronics: Dow CorningWandyy GonçalvesAinda não há avaliações

- Csn33 Bga User GuideDocumento11 páginasCsn33 Bga User GuideWandyy GonçalvesAinda não há avaliações

- 111 Lubricant Sealant - Dow CorningDocumento8 páginas111 Lubricant Sealant - Dow CorningWandyy GonçalvesAinda não há avaliações

- Six Sigma BrasilDocumento2 páginasSix Sigma BrasilWandyy GonçalvesAinda não há avaliações

- Electronic Balance Instruction Manual: TW223L TW323L TW423L TWC323L TWC623LDocumento158 páginasElectronic Balance Instruction Manual: TW223L TW323L TW423L TWC323L TWC623LmarcelloairesAinda não há avaliações

- 001 B Operator TrainingDocumento129 páginas001 B Operator TrainingWandyy GonçalvesAinda não há avaliações

- DRM PTH F PDFDocumento16 páginasDRM PTH F PDFWandyy GonçalvesAinda não há avaliações

- Lean Six Sigma Black Belt BokDocumento11 páginasLean Six Sigma Black Belt BokWandyy GonçalvesAinda não há avaliações

- Ipc 2223asDocumento4 páginasIpc 2223asWandyy Gonçalves0% (1)

- J STD 020Documento13 páginasJ STD 020Wandyy GonçalvesAinda não há avaliações

- NR 10Documento13 páginasNR 10Wandyy GonçalvesAinda não há avaliações

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Documento38 páginasMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسAinda não há avaliações

- PT2 Exam CLASS XI CS 2023Documento2 páginasPT2 Exam CLASS XI CS 2023Aditya AurangeAinda não há avaliações

- Innoversant Solutions - Business Consulting Services IndiaDocumento15 páginasInnoversant Solutions - Business Consulting Services Indiaispl123Ainda não há avaliações

- UntitledDocumento44 páginasUntitledFrancesco TauroAinda não há avaliações

- Orient Technologies Profile PresentationDocumento27 páginasOrient Technologies Profile PresentationNisarg ShahAinda não há avaliações

- Evaluation - Chemical Pit - 0Documento8 páginasEvaluation - Chemical Pit - 0Aiman AmirullahAinda não há avaliações

- DLL - English 5 - Q3 - W8Documento8 páginasDLL - English 5 - Q3 - W8Merlyn S. Al-osAinda não há avaliações

- Dakshin Dinajpur TP ListDocumento5 páginasDakshin Dinajpur TP ListDeb D Creative StudioAinda não há avaliações

- Jeeves in The SpringtimeDocumento14 páginasJeeves in The SpringtimearavindpunnaAinda não há avaliações

- 4naa7 4eeDocumento2 páginas4naa7 4eeDorottya HózsaAinda não há avaliações

- DLPDocumento2 páginasDLPEunice Junio NamionAinda não há avaliações

- Connecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseDocumento1 páginaConnecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseAgusWibowoAinda não há avaliações

- Important Questions - BlockchainDocumento1 páginaImportant Questions - BlockchainHarsh Varshney100% (1)

- GE 8 ETHICS Week2 9Documento54 páginasGE 8 ETHICS Week2 9Jay Ar OmbleroAinda não há avaliações

- P2P L2 Asr9000Documento88 páginasP2P L2 Asr9000ws_595Ainda não há avaliações

- Product Management PRELIM EXAMDocumento24 páginasProduct Management PRELIM EXAMAlyssa marieAinda não há avaliações

- Learner's Book Answers: Unit 1 CellsDocumento31 páginasLearner's Book Answers: Unit 1 CellsLyaz Antony91% (91)

- AbstractDocumento1 páginaAbstractJignesh PrajapatiAinda não há avaliações

- Engineering Data: 2. CV CalculationDocumento1 páginaEngineering Data: 2. CV Calculationdj22500Ainda não há avaliações

- Healing GardensDocumento7 páginasHealing GardensElvaAinda não há avaliações

- Journal Publishing ProcessDocumento1 páginaJournal Publishing Processmohamedr55104Ainda não há avaliações

- Cop4600 Exam1 sp13Documento2 páginasCop4600 Exam1 sp13chavAinda não há avaliações

- Topic 2 Evidencias Clase 7 L Reading - Young PilotsDocumento4 páginasTopic 2 Evidencias Clase 7 L Reading - Young PilotsJam C. PoloAinda não há avaliações

- SF DumpDocumento17 páginasSF DumpBeatríz YañezAinda não há avaliações

- 027 03 Dec13 CseDocumento647 páginas027 03 Dec13 CseParth NagarAinda não há avaliações

- 67 - Es - Ut Republic Csalamade BooDocumento47 páginas67 - Es - Ut Republic Csalamade BooTyler LeeAinda não há avaliações

- (English) Time and The Brain - The Illusion of Now - Hinze Hogendoorn - TEDxUtrechtUniversity (DownSub - Com)Documento14 páginas(English) Time and The Brain - The Illusion of Now - Hinze Hogendoorn - TEDxUtrechtUniversity (DownSub - Com)Диана ТатарчукAinda não há avaliações

- One Word SubstitutionDocumento5 páginasOne Word SubstitutionPranaykant Singh PanwarAinda não há avaliações

- Intellectual Property Rights: Indian PerspectiveDocumento20 páginasIntellectual Property Rights: Indian PerspectiveFateh Singh RawatAinda não há avaliações

- Dr./Ar. Jocelyn A. Rivera-Lutap, Fuap, FriaDocumento1 páginaDr./Ar. Jocelyn A. Rivera-Lutap, Fuap, FriaShanaia BualAinda não há avaliações

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (138)

- A Complete Guide to Safety Officer Interview Questions and AnswersNo EverandA Complete Guide to Safety Officer Interview Questions and AnswersNota: 4 de 5 estrelas4/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNo EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNota: 1 de 5 estrelas1/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersNo EverandRules of Thumb for Maintenance and Reliability EngineersNota: 4.5 de 5 estrelas4.5/5 (12)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- Structural Cross Sections: Analysis and DesignNo EverandStructural Cross Sections: Analysis and DesignNota: 4.5 de 5 estrelas4.5/5 (19)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Guidelines for Auditing Process Safety Management SystemsNo EverandGuidelines for Auditing Process Safety Management SystemsAinda não há avaliações

- Workbook to Accompany Maintenance & Reliability Best PracticesNo EverandWorkbook to Accompany Maintenance & Reliability Best PracticesNota: 3.5 de 5 estrelas3.5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityNo EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityNota: 5 de 5 estrelas5/5 (2)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesNo EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraNota: 4.5 de 5 estrelas4.5/5 (4)

- Pile Design and Construction Rules of ThumbNo EverandPile Design and Construction Rules of ThumbNota: 4.5 de 5 estrelas4.5/5 (15)

- Fire Fighting Pumping Systems at Industrial FacilitiesNo EverandFire Fighting Pumping Systems at Industrial FacilitiesNota: 4.5 de 5 estrelas4.5/5 (3)

- Epidemiology and Demography in Public HealthNo EverandEpidemiology and Demography in Public HealthJaphet KillewoNota: 5 de 5 estrelas5/5 (1)