Escolar Documentos

Profissional Documentos

Cultura Documentos

Ej53 2003 487pramanik

Enviado por

Borcuejon BorcuejonDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ej53 2003 487pramanik

Enviado por

Borcuejon BorcuejonDireitos autorais:

Formatos disponíveis

Author is presently with National Institute of Technology, Rourkela Archived in Dspace@nitr, http://dspace.nitrkl.ac.in/dspace mondal_kp@yahoo.co.

in

J. Chin. Inst. Chem. Engrs., Vol. 34, No. 4, 487-492, 2003

Short communication

Parametric Studies on Batch Alcohol Fermentation Using Saccharomyces Yeast Extracted from Toddy

K. Pramanik

Department of Chemical Engineering, Regional Engineering College Warangal, Warangal-506004, Andhra Pradesh, India

AbstractThe present study deals with the development of a Saccharomyces cerevisiae yeast strain from toddy and the study of important process parameters which will facilitate the fermentation of sugar to alcohol using the developed strain. Evaluation of the yeast strain was performed in a batch fermenter of 1 L capacity under varying pH, temperature, sugar concentration, inoculum time and medium constituents. The optimum pH and temperature were found to be 4.25 and 30C. The present yeast strain was found to be efficient to ferment 200 g/L sugar solution without any difficulty and 90 g/L ethanol was formed with an ethanol yield based on sugar utilized of 0.462. The fermentation time was reduced from 96 to 63 hours by increasing the inoculum time from 12 to 48 hours. From the study of the nutrient composition it was established that beef extract can be substituted for costly yeast extract. A higher concentration and yield of ethanol were obtained using a yeast strain developed from toddy compared to bakers yeast Saccharomyces cerevisiae. Key Words : Alcohol, Fermentation, Ethanol, Saccharomyces cerevisiae, Toddy

INTRODUCTION

Due to rapid depletion of world petroleum reserves and its rising prices day by day, new sources of hydrocarbons must be found to supply our chemical and energy needs (Sitton and Gaddy, 1980; Lee et al., 1983). In this context alcohol fermentation offers promising alternative as it can be produced from various sources of raw materials. In view of increasing importance of alcohol as an alternative source for chemicals & liquid fuel, a great deal of research interest in ethanol fermentation has been generated in the last two decades (Vega et al., 1987; Deway et al., 1984; Mancilha et al., 1984; Converti et al., 1985). The overwhelming advantage of fermentation is that the raw materials are renewable, but at present, the major draw back of alcohol fermentation is that the cost of production is high due to several factors. Keeping this in view, improvements in ethanol fermentation have been focused on taking up of renewed interest in research works in several areas such as use of improved mutant strains, yeast strain development from cheaper sources, use of cheaper source of raw materials (renewable source), optimum reactor design, better nutrients for optimum cell growth etc. (Mancilha et al., 1984; Converti et al., 1985; Gregory et al., 1984; Shiyun et al., 1987; Torres et al., 1986; Tobias et al., 1983). Toddy is produced abundantly in India and is easily available. So,

it may be used as a cheaper source for the development of a suitable yeast strain for ethanol fermentation. The present study is therefore aimed to develop a suitable biocatalyst from toddy and to determine the favorable conditions under which the yeast will function well, giving a high yield of ethanol.

MATERIALS AND METHODS Organism and culture media

The Saccharomyces yeast was extracted from toddy using series dilution technique in our laboratory. The yeast was maintained on agar slants containing 1% glucose, 0.5% peptone, 0.3% beef extract, 3% malt extract, and 2% agar-agar. After keeping at room temperature for 5 days the culture was stored at 4C.

Preparation of inocula for fermentation

The medium was prepared with 10 g sucrose, 0.2 g beef extract, 0.04 g magnesium sulfate, 0.2 g ammonium sulfate, and 0.5 g KH2PO4. The pH of the solution was adjusted to pH 4.25 with sulfuric acid and then sterilized in an autoclave for 15 min at 15 psi pressure. After the broth was cooled to room

488

J. Chin. Inst. Chem. Engrs., Vol. 34, No. 4, 2003

temperature, colonies of the yeast were introduced in to it. Then the culture was kept for growth in an incubator at 30C and the speed of the agitator was maintained at 110 rpm.

Equipment and the experimental procedure

A fermenter of one liter capacity, equipped with an agitator, pH, and temperature control systems was used as the batch fermenter in this study. The fermenter was cleaned and steam sterilized at 15 psi for 15 minutes. Then the sterilized medium containing the inoculum was transferred to the fermenter. The temperature of fermentation was maintained within 0.5C. The pH of the fermentation broth was regulated within pH 0.1 unit by the peristaltic pump which injected a fine stream of sulfuric acid or sodium hydroxide. The fermentations were carried out at atmospheric pressure. The agitator speed was maintained constant through out the experiment at 200 rpm.

Analytical procedures

Fig. 2. Effect of pH on sugar conversion (sugar 100 g/L, 30C, inoculum time 24 h).

The concentrations of ethanol and sugar were monitored spectrophotometrically. Ethanol was determined by measuring OD at 600 nm after standard distillation. The sugar was assayed by OD measurement at 550 nm using DNS reagent.

RESULTS AND DISCUSSION Effect of pH

The pH has a significant influence on fermentation due to its effect on yeast growth, fermentation rate and by product formation. Therefore maintenance of pH is of paramount importance in fermentation processes. In the present study, the efficiency of the yeast strain was evaluated in the pH range 3.75 to 5.5. The results are shown in Figs. 1 and 2. From

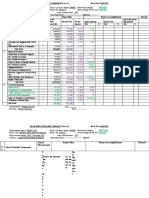

Fig. 1 it is observed that ethanol concentration was in creased steadily with time with all pH values though the rate of production varied considerably. The maximum ethanol concentration of 48 g/L was achieved with pH 4.25 followed by 40 g/L ethanol with pH 5.0. The lower activity of the yeast strain at pH 3.75 is because the pH is too low to activate the enzymes to react. The rate of ethanol production initially was higher at higher pH but maximum ethanol concentration achieved was less than those obtained with pH 4.25. Figure 2 shows that the sugar concentration was reduced steadily with time for all pH values. However percentage conversion was decreased with increase of pH from 4.25 to 5.5. The time taken for maximum sugar conversion was 72 h for pH 4.25, where as the fermentation time for other pH values was found to be more. From yield calculation data as shown in Table 1 it is indicated that maximum ethanol yield of 0.48 g ethanol/g sugar consumed was obtained with both pH 4.25 and 3.75 which is higher than the yields obtained with pH values 5.0 and 5.5. The lower ethanol yield and sugar conversion obtained with higher pH values was possibly due to the formation of undesired products like glycerol, organic acids etc. at the expense of ethanol. Therefore from the pH study pH 4.25 was found to be the optimum pH value for ethanol fermentation using yeast extracted from toddy.

Table 1. Effect of pH on ethanol yield. pH 3.75 4.25 5.00 5.50 Ethanol Yield (g ethanol/g sugar consumed) 0.48 0.48 0.46 0.45

Effect of temperature Fig. 1. Influence of pH on ethanol concentration (sugar 100 g/L, 30C, inoculum time 24 h).

The temperature has a marked influence on the production of biomass and ethanol. Usually, the rate

K. Pramanik : Parametric Studies on Batch Alcohol Fermentation Using Saccharomyces Yeast Extracted from Toddy

489

of alcoholic fermentation increases with temperature to an optimum between 30C and 40C using conventional yeast. However, both optimum and temperature tolerance for growth and fermentation are strongly strain dependent (Rousseau et al., 1992). Therefore, fermentation experiments were conducted under varying temperature in the range 30-38C to see the effect of the newly developed strain towards ethanol production. The results are shown in Figs. 3 and 4.

enzyme activity at higher temperatures. So 30C was found to be optimum with respect to optimum ethanol concentration and rate of reaction.

Table 2. Effect of temperature on ethanol yield. Temperature (C) 30 35 38 Ethanol Yield (g ethanol/g sugar consumed) 0.48 0.46 0.42

Effect of sugar concentration

Fig. 3. Effect of temperature on ethanol concentration (pH 4.25, sugar 100 g/L, inoculum time 24 h).

An interesting research field in alcoholic fermentation is the study of yeast strains able to utilize sugar solutions more concentrated than those generally fermented in usual practice (Converti et al., 1985) and hence it is important to establish the limits of ethanol tolerance of the yeast strain (Shiyun et al., 1987). Therefore the fermentations were conducted with sugar concentrations range from 50 to 250 g/L with an intention to obtain high yield of ethanol in reasonable time. The results shown in Figs. 5 and 6 indicate that ethanol concentration increased with increase in substrate concentration but there was wide variation in

Fig. 4. Effect of temperature on sugar conversion (pH 4.25, sugar 100 g/L, inoculum time 24 h).

Fig. 5. Effect of sugar concentration on ethanol production (pH 4.25, 30C, inoculum time 24 h).

Figure 3 shows that the ethanol concentration increased steadily with time. Though, the rate of production was initially found to be higher at the high temperatures 35C and 38C but the optimum ethanol concentration of 48 g/L achieved at 30C. The sugar concentration as shown in Fig. 4, initially reduced rapidly for higher temperatures and then the rate of substrate consumption became slow comparatively. The percentage conversion of sugar was found to be 100%, 97%, and 87.3% at 30C, 35C, and 38C, respectively. From Table 2 it is indicated that a very high yield of 0.48 was obtained at 30C which is higher than those obtained with other temperatures studied. The lower efficiency of the yeast towards ethanol formation may be attributed to the loss of

Fig. 6. Effect of sugar concentration on sugar conversion (pH 4.25, 30C, inoculum time 24 h).

490

J. Chin. Inst. Chem. Engrs., Vol. 34, No. 4, 2003

time taken for complete fermentation. Maximum ethanol concentrations of 23.9 g/L, 48 g/L, and 93 g/L were obtained in 50 h, 72 h, and 105 h with 50 g/L, 100 g/L, and 200 g/L sugar solutions. The corresponding conversion of substrate was 100%, 100% and 96%. As was observed for the lower concentration of sugar, the production of ethanol was growth associated only for a short period of time and hence required less fermentation time. There was no difficulty in fermenting solutions containing up to 200 g/L sugar. However when a still higher concentration of sugar, i.e., 250 g/L was fermented, ethanol concentration and sugar conversion were observed to be lower than those obtained with 200 g/L sugar solution. The inhibitory effect of high sugar concentrations for alcoholic fermentation may be due to plasmolysis of yeast cells as reported. Further it was observed that ethanol became inhibitory when its concentration reached about 95 g/L. So, it was found that the new yeast is tolerant of sugar concentrations to at least 200 g/L with an ethanol yield of 0.47 as shown in Table 3 which is comparable to the yield obtained with 100 g/L sugar solution. Complete and efficient fermentation of such highly concentrated sugar solutions is beneficial from energy consumption point of view for distillation of the alcohol.

Table 3. Effect of sugar concentration on ethanol yield. Sucrose (g/L) 50 100 200 250 Variation in inoculum time Ethanol Yield (g ethanol/g sugar consumed) 0.49 0.48 0.47 0.43

time and therefore required less time for achieving maximum sugar conversion. The high rate of ethanol production and substrate uptake with increase in inoculum time is due to the high cell mass concentration achieved in 48 h and hence time of fermentation was reduced from 96 to 63 h to achieve the maximum ethanol concentration.

Table 4. Effect of inoculum time on ethanol yield. Inoculum Time (h) 12 24 48 Ethanol Yield (g ethanol/g sugar consumed) 0.476 0.480 0.478

Fig. 7. Effect of growth time on ethanol production (pH 4.25, 30C, sugar 100 g/L).

In fermentation reactions, inoculum time is very important in obtaining maximum ethanol production with minimum time. After the particular cell density is reached the growth phase slows and the life cycle of the yeast deviates from the growth path and produces ethanol. If the cell density is less, more time will be taken for complete fermentation. In the present study, the inoculum for fermentation was grown in incubator for different periods of time 12 h, 24 h, and 48 h and 10 vol% of inoculum was added to the fermenter. Table 4 indicates that the variation in inoculum time did not have any remarkable influence on the yield of ethanol. However, inoculum time had a considerable effect on the overall time of the fermentation. It was observed from Figs. 7 and 8 that the rate of ethanol production was increased with increase in growth

Fig. 8. Effect of growth time on sugar conversion (pH 4.25, 30C, sugar 100 g/L). Variation in medium constituents

The competitive position and potential profits from fermentation products are closely tied to the costs of the various components of the production medium. Inoculum medium is usually less expensive. In contrast, a single high cost medium component for the production medium can virtually dictate the selling price of the fermentation product. So attempts should be made to find an alternate low cost re-

K. Pramanik : Parametric Studies on Batch Alcohol Fermentation Using Saccharomyces Yeast Extracted from Toddy

491

placement for such a medium component (Casida, 1993). In this context, fermentations were carried out using beef and yeast extracts keeping the other nutrients same. It was observed that there is no significant change in the performance of the new yeast strain towards alcoholic fermentation using yeast and beef extract as medium constituents as shown in Figs. 9 and 10. In fact, a slightly higher concentrations and yields of ethanol were obtained with beef extract within the same fermentation time. Therefore, it is evident that beef extract which is cheaper than yeast extract can be used as medium component in alcoholic fermentation.

duced by the new yeast compared to the bakers yeast. The yield of ethanol was also higher than the yield obtained with the conventional yeast strain.

Table 5. Comparison of Saccharomyces cerevisiae developed from toddy and bakers yeast.

Yeast Bakers yeast Yeast strain (from toddy) Initial Ethanol Yield Ethanol Sugar Fermentation (g ethanol/g Conc. Conc. Time (h) sugar (g/L) (g/L) consumed)

100 100

72 72

45.3 48.0

0.44 0.48

CONCLUSION

Fig. 9. Effect of medium component on ethanol production (sugar 100 g/L, pH 4.25, 30C, inoculum time 24 h).

The saccharomyces yeast developed from toddy has shown substantial alcohol fermentation activity. It was established in this work that pH 4.25 and 30C are the optimum pH and temperature. The new yeast strain was able to ferment the sugar solution containing at least 200 g/L sugar and 93 g/L ethanol was obtained with an ethanol yield based on sugar utilized of 0.47. Inhibition of product was observed above 200 g/L sugar solution. High rate of fermentation was achieved with increase in growth time from 12 to 48 h and hence fermentation time was reduced from 96 to 63 h to obtain optimum ethanol concentration of 48 g/L. The costly addition of yeast extract could be avoided and good growth and ethanol production were obtained using beef extract as medium component. The yeast strain showed better results in terms of both ethanol concentration and ethanol yield compared to a bakers yeast strain.

ACKNOWLEDGEMENT

The author would like to thank the Microbiology Division of Kakatiya University for helping in the development of yeast strain from toddy.

REFERENCES Fig. 10. Effect of medium constituent on sugar conversion (pH 4.25, 30C, sugar 100 g/L, inoculum time 24 h). Comparison with bakers yeast

Casida, L. E., Industrial Microbiology, p.211, JR, Wiley Eastern Ltd., India (1993). Converti, A. P., P. A. Lodi, F. Parisi, and M. D. Borghi, A Kinetic Study of Saccharomyces Strains: Performance at High Sugar Concentrations, Biotechnol. Bioeng., 27, 1108 (1985). Dewey, D. Y. R., Y. J. Kim, and J. H. Kim, Effect of Air Supplement on the Performance of Continuous Ethanol Fermentation System, Biotechnol. Bioeng., 26, 12 (1984). Gregory, P. C., A. M. Carol, and W. M. Inledew, High Gravity Brewing: Effects of Yeast Composition Fermentative

Alcoholic fermentation was carried out to find the suitability of the new yeast over the performance of the bakers yeast. Table 5 compares the productivity and efficiency of Saccharomyces cerevisiae yeast strain obtained from toddy and bakers yeast. It was observed that about 6 wt% more ethanol was pro-

492

J. Chin. Inst. Chem. Engrs., Vol. 34, No. 4, 2003

Ability and Alcohol Production, Appl. Environ. Microbiol., 48, 639 (1984). Lee, J. M., J. F. Pollard, and G. A. Coulman, Ethanol Fermentation with Cell Recycling: Computer Simulation, Biotechnol. Bioeng., 22, 497 (1983). Mancilha, I. M. D., A. M. Pearson, G. J. Waller, and B. B. Hogaboam, Increasing Alcohol Yield by Selected Yeast Fermentation of Sweet Sorghum: 1. Evaluation of Yeast Strains for Ethanol Production, Biotechnol. Bioeng., 24, 632 (1984). Rousseau, S., D. Rouleau, L. Yerushalmi, and R. C. Mayer, Effect of Temperature on Fermentation Kinetics of Waste Sulfite Liquor by Saccharomyces cerevisiae, J. Chem. Tech. Biotechnol., 53, 285 (1992). Shiyuan, Y., W. Morris, and K. P. Sarad, Fermentation of Ethanol of Pentose Containing Spent Sulphite Liquor, Biotechnol. Bioeng., 29, 1144 (1987).

Sitton, O. C. and J. L. Gaddy, Ethanol Production in an Immobilized Cell Reactor, Biotechnol. Bioeng., 22, 1735 (1980). Tobias, J. B., D. Menezes, C. L. M. Das Santo, and A. Azzini, Saccharification of Bamboo Carbohydrates for the Production of Ethanol, Biotechnol. Bioeng., 25, 1071 (1983). Torres, F. E., J. J. Allais, and J. Baratti, Kinetics of Batch Fermentations for Ethanol Production with Zymomonas Mobilis Growing on Jerusalem Artichoke Juice, Biotechnol. Bioeng, 28, 850 (1986). Vega, J. L., E. C. Clausen, and J. L. Gaddy, Acetate Addition to an Immobilized Yeast Column for Ethanol Production, Biotechnol. Bioeng., 29, 429 (1987)

(Manuscript received Nov. 9, 2002, and accepted Apr. 1, 2003)

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Ainsworth, The One-Year-Old Task of The Strange SituationDocumento20 páginasAinsworth, The One-Year-Old Task of The Strange SituationliliaAinda não há avaliações

- Cash and Cash Equivalents ReviewerDocumento4 páginasCash and Cash Equivalents ReviewerEileithyia KijimaAinda não há avaliações

- High CarbonDocumento2 páginasHigh CarbonKarisoAinda não há avaliações

- Artesunat Injection 2009Documento4 páginasArtesunat Injection 2009Franca ImadiyiAinda não há avaliações

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDocumento8 páginasEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumAinda não há avaliações

- People vs. MediosDocumento10 páginasPeople vs. MediostheresagriggsAinda não há avaliações

- Capacitor BanksDocumento49 páginasCapacitor BanksAmal P RaviAinda não há avaliações

- Citizen's 8651 Manual PDFDocumento16 páginasCitizen's 8651 Manual PDFtfriebusAinda não há avaliações

- Gloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Documento10 páginasGloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Scribd Government DocsAinda não há avaliações

- Denagard-CTC US Knowledge ReportDocumento4 páginasDenagard-CTC US Knowledge Reportnick224Ainda não há avaliações

- Cooling SistemadeRefrigeracion RefroidissementDocumento124 páginasCooling SistemadeRefrigeracion RefroidissementPacoAinda não há avaliações

- MSDS Lubriplate 105Documento2 páginasMSDS Lubriplate 105mackyyo0% (1)

- Pakeha (Maori For European New Zealanders) Thinking, in That They Tend To Go OutwardsDocumento11 páginasPakeha (Maori For European New Zealanders) Thinking, in That They Tend To Go OutwardsDwi RahayuAinda não há avaliações

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Documento4 páginasEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeAinda não há avaliações

- TS802 - Support StandardDocumento68 páginasTS802 - Support StandardCassy AbulenciaAinda não há avaliações

- Vicat Apparatus PrimoDocumento10 páginasVicat Apparatus PrimoMoreno, Leanne B.Ainda não há avaliações

- Brachiocephalic TrunkDocumento3 páginasBrachiocephalic TrunkstephAinda não há avaliações

- Corn Fact Book 2010Documento28 páginasCorn Fact Book 2010National Corn Growers AssociationAinda não há avaliações

- Deloitte Uk Mining and Metals DecarbonizationDocumento10 páginasDeloitte Uk Mining and Metals DecarbonizationfpreuscheAinda não há avaliações

- 4th Summative Science 6Documento2 páginas4th Summative Science 6brian blase dumosdosAinda não há avaliações

- Wes Jackson PM PMP OhioDocumento10 páginasWes Jackson PM PMP Ohioraj jdsAinda não há avaliações

- ResearchDocumento13 páginasResearchCHOYSON RIVERALAinda não há avaliações

- Quarterly Progress Report FormatDocumento7 páginasQuarterly Progress Report FormatDegnesh AssefaAinda não há avaliações

- Soil Chapter 3Documento67 páginasSoil Chapter 3Jethrone MichealaAinda não há avaliações

- Creamy and Thick Mushroom Soup: IngredientsDocumento8 páginasCreamy and Thick Mushroom Soup: IngredientsSheila Mae AramanAinda não há avaliações

- Wago PCB Terminal Blocks and Connectors Catalog 7Documento105 páginasWago PCB Terminal Blocks and Connectors Catalog 7alinupAinda não há avaliações

- Test Questions For Oncologic DisordersDocumento6 páginasTest Questions For Oncologic Disorderspatzie100% (1)

- Injection MouldingDocumento241 páginasInjection MouldingRAJESH TIWARIAinda não há avaliações

- 1 Nitanshi Singh Full WorkDocumento9 páginas1 Nitanshi Singh Full WorkNitanshi SinghAinda não há avaliações

- 51 - Methemoglobin ProducersDocumento20 páginas51 - Methemoglobin ProducersCabinet VeterinarAinda não há avaliações