Escolar Documentos

Profissional Documentos

Cultura Documentos

Chapter 12 Solutions

Enviado por

KIKIKIKIREALLY4399Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chapter 12 Solutions

Enviado por

KIKIKIKIREALLY4399Direitos autorais:

Formatos disponíveis

CHAPTER 12

DISCUSSION QUESTIONS

1. The advent of low-cost computing should not be seen as obviating the need for the ABC inventory

classification scheme. Although the cost of computing has decreased considerably, the cost of data

acquisition has not decreased in a similar fashion. Business organizations still have many items for

which the cost of data acuisition for a !perpetual" inventory system is still considerably higher

than the cost of the item.

#. The standard EOQ model assumes instantaneous delivery $delivery of the entire lot is made at one

instant of time%, whereas the &roduction 'nventory (odel assumes that delivery ta)es place at a

constant rate over time.

*. +easons for an organization to maintain inventory include,

n The decoupling function,

inventory can be used to decouple stages in the production process within an

organization

inventory can be used to decouple the production process from instabilities or

irregularities in supply of raw materials or labor

inventory can be used to decouple the production process from unstable demand and

thus $a% allow production scheduling to develop a !smoother" schedule, and $b% avoid

shortages or stoc)outs

n -uantity discounts,

inventory can be used to enable the organization to purchase goods in larger lot sizes

and ta)e advantage of uantity discounts

n A hedge against inflation,

investing in inventory now assures one that the price will not increase

.. Costs that are associated with ordering and maintaining inventory include,

n 'nitial purchase cost of the item

n /olding cost $insurance, space, heat, light, security, warehouse personnel, etc.%

n 0bsolescence or deterioration cost $particularly important in perishable goods or in a product

that is undergoing rapid technological evolution%

n 0rdering or setup cost $cost of forms, clerical processing, etc., or cost of machine setup%

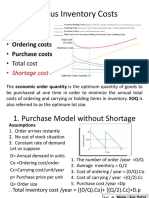

1. The more important assumptions of the basic EOQ model are,

n 2emand is )nown and constant over time.

n The lead time, that is, the time between the placement of the order and the receipt of the

goods, is )nown and constant.

n The receipt of the inventory is instantaneous3 i.e., the goods arrive in a single batch, at one

instant in time.

Chapter 12: Inventory Management 1

n -uantity discounts are not possible.

n The only variable costs are the cost of setting up or placing an order and the cost of holding

or storing inventory over time.

n 'f orders are placed at the right time, stoc)outs or shortages can be completely avoided.

4. The EOQ is relatively insensitive to small changes in demand or setup or carrying costs. 'f, for

e5ample, demand increases by 167, EOQ will increase by appro5imately 17.

8. A decrease in setup time decreases the cost per order, encourages more and smaller orders, and thus

decreases the EOQ.

1#. 'f per unit holding costs increase with increasing inventory, total inventory cost will increase3 EOQ

will decrease.

1.. 'n a fixed-quantity inventory system, when the uantity on hand reaches the reorder point, an order

is placed for the specified uantity. 'n a fixed-period inventory system, an order is placed at the end

of the period. The uantity ordered is that needed to bring on-hand inventory up to a specified

level.

END-OF-CHAPTER PROBLEMS

12.2 /e decides that the top #67 of the 16 items, based on a criterion of demand times cost per unit,

should be A items. $'n this e5ample, the top #67 constitutes only 197 of the total inventory value,

but in larger samples the value would probably approach :67 to 967.% /e therefore rates items ;*

and <# as A items. The ne5t *67 of the items are A#, C:, and 213 they represent #*7 of the value

and are categorized as B items. The remaining 167 of the items $items B9, =8, /#, '1, and >9%

represent 187 of the value and become C items.

Item Annual Demand Cost ($)

Demand Cost

Classification

A# *,666 16 116,666 B

B9 .,666 1# .9,666 C

C: 1,166 .1 4:,166 B

21 4,666 16 46,666 B

=8 1,666 #6 #6,666 C

;* 166 166 #16,666 A

<# *66 1,166 .16,666 A

/# 466 #6 1#,666 C

'1 1,:16 16 1:,166 C

>9 #,166 1 1#,166 C

12.3 Item Annual Demand Cost ($)

Demand Cost

Classification

=16# 966 ..66 *,#66 C

2#* 1,#66 9.66 8,466 A #:7

2#: :66 *.66 #,166 C

+6# 1,666 #.66 #,666 C

+18 #66 9.66 1,466 C

?16: 166 4.66 *,666 C

?1#* 1,#66 1.66 1,#66 C

@11 966 :.66 1,466 B 147

@#* 1,166 1.66 1,166 C **7

A:1 1,166 ..66 4,666 B 1:7

12.4 : 666 616 :66 , . :66 #6 *1 *1 A items per day

: 666 6 *1 # .16 , . , #.16 46 .6 9* . .1 B items per day

: 666 6 11 *916 , . , *916 1#6 *# *1 C items per day

169 items

2 Instructors Solutions Manual t/a Operations Management

12. EOQ

( ) # 1666 4# 16

6 16

166

.

.

units

12.! EOQ

( ) # 9 666 .1

#

466

,

units

12." *66

# 9 666 .1

86 666

:#6 666

( ) ,

,

,

H H

H

:#6 666

86 666

,

,

B9

12.# $a% =conomic 0rder -uantity $/olding cost C B1 per year%,

Q

DS

H

# # .66 .6

1

96 units

where, D C period demand, S C setup or order cost, H C holding cost

$b% =conomic 0rder -uantity $/olding cost C B4 per year%,

Q

DS

H

# # .66 .6

4

:* units

where, D C period demand, S C setup or order cost, H C holding cost

12.$ $a% =conomic 0rder -uantity,

Q

DS

H

# # 1166 116

.1

166

,

units

where, D C period demand, S C setup or order cost, H C holding cost

$b% /olding cost

QH

#

166 .1

#

#16 66 B#, .

$c% 0rder cost

DS

Q

1166 116

166

#16 66 B#, .

$d% +eorder point,

+eorder point C demand during lead time

1166

*66

4 *6

,

units day days units

12.1% +eorder point C demand during lead time

166 #1 #166 units day days units ,

12.11 +eorder point C demand during lead time

166 1. : 666 units day days units ,

12.12 $a% =conomic 0rder -uantity,

Q

DS

H

# # . 666 #1

616 86

1.81

,

.

. or 1.8 valves

where, D C period demand, S C setup or order cost, H C holding cost

$b% Average inventory :. 1 . valves

$c% Dumber of orders per year

2emand

EOQ

. 666

1.8

#4 9

,

.

or #: orders

$d% Assuming #16 business days per year, the optimal number of business days between orders is

given by,

Chapter 12: Inventory Management 3

0ptimal number of days

#16

#:

8

1

.

days

$e% Total annual inventory cost 0rder cost holding cost +

+

+

+

DS

Q

QH

#

. 666 #1

1.8

1.8 61 86

#

4:11. 4:6 16 *.14.

, .

. . B1, .

Dote, 0rder and carrying costs are not eual due to rounding of the EOQ to a whole number.

$f% +eorder point C demand during lead time

14 1 days 96 units day valves

12.13 $a% =conomic 0rder -uantity,

Q

DS

H

# # 1 666 *6

16

:: .4

,

. or :9 units

where, D C period demand, S C setup or order cost, H C holding cost

$b% Average inventory

:9

#

*8 units

$c% Dumber of orders per year

2emand

EOQ

1 666

:9

4.1

,

.

or 4. orders

$d% Assuming #16 business days per year, the optimal number of business days between orders is

given by,

0ptimal number of days

#16

4.

*81 . days

$e% Total cost order cost holding cost +

+

+

+

DS

Q

QH

#

1 666 *6

:9

:9 16

#

18#*6# 1816 9:*69

,

, . , B*, .

Dote, 0rder and carrying costs are not eual due to rounding of the EOQ to a whole number.

'f an EOQ of ::..4 is used, the order and carrying costs calculate to B1,8*4..8 for a total

cost of B*,9:#.89.

$f% +eorder point,

+eorder point C demand during lead time

1 666

16 #66

, units

#16 days

days

units

This is not to say that we reorder when there are #66 units on hand $as there never are%. The

+0& indicates that orders are placed several cycles prior to their actual demand.

12.14 $a% =conomic 0rder -uantity,

Q

DS

H

# # 1#66 #1

#.

16

,

units

where, D C period demand, S C setup or order cost, H C holding cost

$b% Total cost C order cost E holding cost

+

DS

Q

QH

#

;or Q #1,

+

1#66 #1

#1

#1 #.

#

166

,

B1,

4 Instructors Solutions Manual t/a Operations Management

;or Q .6 ,

+

1#66 #1

.6

.6 #.

#

#*6

,

B1,

;or Q 16 ,

+

1#66 #1

16

16 #.

#

#66

,

B1,

;or Q 46 ,

+

1#66 #1

46

46 #.

#

##6

,

B1,

;or Q 166 ,

+

1#66 #1

166

166 #.

#

166

,

B1,

As e5pected, small variations in order uantity will not have a significant effect on total

costs.

12.1 $a% Total cost C order cost E holding cost

+

DS

Q

QH

#

;or Q 16 ,

466 46

16

16 #6

#

:#6 166 ##6

+

+ B1,

$b% =conomic 0rder -uantity,

Q

DS

H

# # 466 46

#6

46 units

where, D C period demand, S C setup or order cost, H C holding cost

;or Q 46 ,

466 46

46

46 #6

#

466 466 #66

+

+ B1,

$c% +eorder point,

+eorder point C demand during lead time

466

16 #.

units

#16 days

days units

12.1! =conomic 0rder -uantity, noninstantaneous delivery,

units . . #*68

#66

16

1 66 . 1

#66 16666 #

% F $ 1 G

#

1

]

1

p d H

DS

Q

where, D C period demand, S C setup or order cost, H C holding cost, d C daily demand rate, p C

daily production rate

12.1" =conomic 0rder -uantity, noninstantaneous delivery,

units . . 1411

116

.6

1 96 . 6

166 9666 #

% F $ 1 G

#

1

]

1

p d H

DS

Q

where, D C period demand, S C setup or order cost, H C holding cost, d C daily demand rate, p C

daily production rate

12.1# $a% =conomic 0rder -uantity, noninstantaneous delivery,

units # . 1#1:

166

16

1 46 . 6

.6 16666 #

% F $ 1 G

#

1

]

1

p d H

DS

Q

Chapter 12: Inventory Management 5

where, D C period demand, S C setup or order cost, H C holding cost, d C daily demand rate,

p C daily production rate

$b% units 1 . 1681

166

16

1 # . 1#1: 1

ma5

,

_

1

]

1

,

_

1

]

1

p

d

Q I

$c%

D

Q

16 666

1#1:

9 ##

,

,

.

$d%

T C

I

H

D

Q

S . . . . .

ma5

+ +

#

*#916 *#996 41:*6

12.1$ =conomic 0rder -uantity,

Q

DS

H

#

where, D C period demand, S C setup or order cost, H C holding cost, P priceFunit

$a% =conomic 0rder -uantity, standard price,

Q

# # 666 16

1

#66

,

units

Total cost order cost holding cost purchase cost + +

+ +

+

+ + + ( )

DS

Q

QH

PD

#

# 666 16

#66

#66 1

#

# 666 1 166 166 # 666 #66

,

, , B#,

$b% -uantity 2iscount,

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

# 666 16

# 666

# 666 1

#

# 666 6 :1

16 1666 1166 116

,

,

,

, .

, , B#,

Dote, Do, EOQ with #66 units and a total cost of B#,#66 is better.

12.2% @nder present price of B16.66 per unit, =conomic 0rder -uantity,

Q

DS

H

Q

#

# 1666 .6

6 #1 16

96

,

.

units

where, D C period demand, S C setup or order cost, H C holding cost, P priceFunit

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

1666 .6

96

96 6 #1 16

#

1666 16

166 66 166 66 16 666 666

, .

,

. . , B11,

@nder the uantity discount price reduction of *7,

6 Instructors Solutions Manual t/a Operations Management

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

DS

Q

QH

PD

#

1666 .6

#66

#66 6 #1 16 6 8:

#

1666 16 6 8:

#66 66 1#1# 16 .9 166 81# 16

, . .

, .

. . , B.8, .

Therefore, the pumps should be ordered in batches of #66 units and the uantity discount ta)en.

12.21 @nder present price of B:.66 per unit, =conomic 0rder -uantity,

Q

DS

H

Q

#

# 4 666 #6

611 :

.:91 .:9

,

.

. or units

where, D C period demand, S C setup or order cost, H C holding cost, P priceFunit

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

4 666 #6

.:9

.:9 611 :

#

: 4 666

#1161 #16 81 .# 666 16# 66

, .

,

. . , B.#, .

Dote, 0rder and carrying costs are not eual due to rounding of the EOQ to a whole number.

@nder the uantity discount price of B4.41 per unit,

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

4 666 #6

* 666

* 666 611 4 41

#

4 666 4 41

.6 66 1.84 #1 *8 866 .*4 #1

,

,

, . .

, .

. , . , B.1, .

Therefore, the new policy, with a total cost of B.1,.*4.#1, is preferable.

12.22 =conomic 0rder -uantity,

Q

DS

H

#

where, D C period demand, S C setup or order cost, H C holding cost, P priceFunit

$a% =conomic 0rder -uantity, standard price,

Q

# .1 16

6 61 #6

*6

.

units

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

.1 16

*6

*6 6 61 #6

#

.1 #6

11 11 866

.

B8*6

$b% -uantity 2iscount, :1 units or more. =conomic 0rder -uantity, discount over :1 units,

Q

# .1 16

6 61 1916

*118

. .

. or *1 units

Chapter 12: Inventory Management 7

Because EOQ C *1 and a discount is given only on orders of :1 or more, we must calculate

the total cost using a :1-unit order uantity,

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

.1 16

:1

:1 6 61 1916

#

.1 1916

4 *. 48 9*# 16 18

. .

.

. . B9:*.

$c% -uantity 2iscount, 166 units or more3 =conomic 0rder -uantity, discount over 166 units,

Q

# .1 16

6 61 11 :1

**91

. .

. or *. units

EOQ C *. and a discount is given only on orders of 166 or more, thus we must calculate the

total cost using a 166-unit order uantity. Calculate total cost using 166 as order uantity,

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

.1 16

166

166 6 61 11 :1

#

.1 11 :1

. 1 *8 *9 :69 :1 4*

. .

.

. . . B:1#.

Based purely upon cost, the decision should be made to order in uantities of 166, for a total

cost of B:1#.4*.

't should be noted, however, that an order uantity of 166 implies that an order will be

placed roughly every two years. Hhen orders are placed that infreuently, obsolescence may

become a problem.

12.23 =conomic 0rder -uantity,

Q

DS

H

#

where, D C period demand, S C setup or order cost, H C holding cost, P priceFunit

$a% 0rder uantity 8 sheets or less, unit price C B19.66

Q

# 166 .1

6 #6 19

16

.

units

Total cost order cost holding cost purchase cost

see note at end of problem re. actual price

+ +

+ +

+

+

+ + ( )

( )

DS

Q

QH

PD

#

166 .1

16

16 6 #6 19

#

19 166

86 86 1966 896

.

, B1,

$b% 0rder uantity 16 to 16 sheets, unit price C B1:.16

Q

# 166 .1

6 #6 1: 16

16 :

. .

. units or 11 units

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

166 .1

11

11 6 #6 1: 16

#

1: 16 166

99#* 98 #1 1:16 66 18#: .9

. .

.

. . . .

8 Instructors Solutions Manual t/a Operations Management

Dote, 0rder and carrying costs are not eual due to rounding the EOQ to a whole number.

?ee note at end of problem regarding price.

$c% 0rder uantity more than 16 sheets, unit price C B1:.#1

Q

# 166 .1

6 #6 1: #1

111

. .

. units or 11 units

Total cost order cost holding cost purchase cost + +

+ +

+

+

+ +

( )

DS

Q

QH

PD

#

166 .1

11

11 6 #6 1: #1

#

1: #1 166

99#. 9: 89 1:#166 861##

. .

.

. . , . B1, .

Therefore, order 11 units.

Dote, 0rder and carrying costs are not eual due to rounding of the EOQ to a whole

number.

'mportant Dote, Calculations of total cost under $a% and $b% are actually inappropriate

because the original assumptions as to lot size would not be satisfied by the calculated EOQs.

12.24 D :66 1# , H 1, S 16

Allen

1I.88 B14.66

166I888 B11.16

1666E B11.66

Bake

1I*88 B14.16

.66I:88 B11.46

966E B11.16

Q

DS

H

( ) # # 9 .66 16

1

.6899 .16

,

.

Aendor, Allen

at .16, TC + + ( ) ( ) ( )

.16

#

1

9 .66

.16

16 9 .66 14 ..8*4

,

, B1*4, .

at 166, TC + + ( ) ( ) ( )

166

#

1

9 .66

166

16 9 .66 111 #86

,

, . B1*#,

at 1666,

TC + + ( ) ( ) ( )

1666

#

1

9 .66

1666

16 9 .66 11 8#6

, ,

,

, B1#9,

B!"#

Aendor, Ba)er

at .16, TC + + ( ) ( ) ( )

.16

#

1

9 .66

.16

16 9 .66 1146 698*8

,

, . B1**, .

at 966, TC + + ( ) ( ) ( )

966

#

1

9 .66

966

16 9 .66 1116 *41

,

, . B1#8,

Chapter 12: Inventory Management $

Você também pode gostar

- The Entrepreneur’S Dictionary of Business and Financial TermsNo EverandThe Entrepreneur’S Dictionary of Business and Financial TermsAinda não há avaliações

- Product, Services, and Brands: Building Customer ValueDocumento39 páginasProduct, Services, and Brands: Building Customer ValueSazzad Shuvo100% (2)

- Inventory MGTDocumento35 páginasInventory MGTPankaj Agrawal100% (1)

- Inventory ManagementDocumento11 páginasInventory ManagementAnirudh Prabhu100% (1)

- TQM PDFDocumento51 páginasTQM PDFCarlo Gojo Cruz HalasanAinda não há avaliações

- Failure Mode Effect Analysis FMEADocumento32 páginasFailure Mode Effect Analysis FMEApsrajjAinda não há avaliações

- Lean CalculatorDocumento28 páginasLean CalculatorFrank RojasAinda não há avaliações

- Inventory ModelDocumento43 páginasInventory Modelndc6105058Ainda não há avaliações

- Overall Weighting Equipment EffectivenessDocumento5 páginasOverall Weighting Equipment EffectivenessHeriSaputraAinda não há avaliações

- Operations Management Pactice QuestionsDocumento8 páginasOperations Management Pactice QuestionsHumphrey OsaigbeAinda não há avaliações

- Pom Inventory ProblemsDocumento8 páginasPom Inventory ProblemsSharath Kannan0% (2)

- Or Assignment 4Documento2 páginasOr Assignment 4api-323462816Ainda não há avaliações

- SMCDocumento37 páginasSMCAmalina ZainalAinda não há avaliações

- Inventory ManagementDocumento37 páginasInventory ManagementSahil ManchandaAinda não há avaliações

- Case Study - Gokaldas ExportsDocumento10 páginasCase Study - Gokaldas ExportsRohit SrivastavAinda não há avaliações

- Practice Problems For The FinalDocumento20 páginasPractice Problems For The FinalThanh Ngân0% (2)

- Ch08 - InventoryDocumento111 páginasCh08 - InventoryjosephdevaraajAinda não há avaliações

- 1.4 Quiz 1 Part 2 Final Manufacturing ProblemsDocumento3 páginas1.4 Quiz 1 Part 2 Final Manufacturing ProblemsRead this Secret100% (1)

- 15 KRM Om10 Tif ch12Documento35 páginas15 KRM Om10 Tif ch12Dingyuan OngAinda não há avaliações

- Forecasting Examples Forecasting Example 1996 UG Exam: Month 1 2 3 4 5 Demand ('00s) 13 17 19 23 24Documento14 páginasForecasting Examples Forecasting Example 1996 UG Exam: Month 1 2 3 4 5 Demand ('00s) 13 17 19 23 24Julius Dacara50% (2)

- CH 12Documento55 páginasCH 12adarshdk1100% (1)

- Inventory Management PPT at BEC DOMSDocumento51 páginasInventory Management PPT at BEC DOMSBabasab Patil (Karrisatte)0% (1)

- Ch-05 Material Inventory Controls (Online Class)Documento6 páginasCh-05 Material Inventory Controls (Online Class)shayan zamanAinda não há avaliações

- CHAPTER 11 Inventory ModelDocumento24 páginasCHAPTER 11 Inventory ModelmulunehAinda não há avaliações

- Inventory ModelDocumento24 páginasInventory ModelRichard Sinchongco Aguilar Jr.Ainda não há avaliações

- Homework - Supply Chain Design Chapter 5: Capacity Planning 1: (25 Points)Documento4 páginasHomework - Supply Chain Design Chapter 5: Capacity Planning 1: (25 Points)Minh Hoàng TrầnAinda não há avaliações

- Ch5 Capacity PlanningDocumento8 páginasCh5 Capacity PlanningJess JerinnAinda não há avaliações

- Production Operation ManagemenT (ALL 5 UNITS)Documento134 páginasProduction Operation ManagemenT (ALL 5 UNITS)Archi VarshneyAinda não há avaliações

- Construction Material Management Through Inventory CONTROL TECHNIQUESDocumento5 páginasConstruction Material Management Through Inventory CONTROL TECHNIQUESMohamed WayrahAinda não há avaliações

- Vda6 1Documento56 páginasVda6 1Armando Flores100% (1)

- Why Is It Important To Consider Uncertainty When Evaluating Supply Chain DesignDocumento3 páginasWhy Is It Important To Consider Uncertainty When Evaluating Supply Chain DesignAkshay_Raja_94150% (2)

- Chap 12 Inventory ManagementDocumento25 páginasChap 12 Inventory Managementapi-3827845100% (2)

- Chapter 4-Inventory Management PDFDocumento19 páginasChapter 4-Inventory Management PDFNegaAinda não há avaliações

- Various Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostDocumento28 páginasVarious Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostAditya Dashputre100% (2)

- Sample Test Questions For EOQDocumento5 páginasSample Test Questions For EOQSharina Mhyca SamonteAinda não há avaliações

- MPR Lot Sizing Rules (L4L)Documento30 páginasMPR Lot Sizing Rules (L4L)ajeng.saraswatiAinda não há avaliações

- Gayatri SCM PPT Just in Time JitDocumento13 páginasGayatri SCM PPT Just in Time JitgayatriAinda não há avaliações

- Chapter 4: The Master Schedule Discussion Questions and ProblemsDocumento3 páginasChapter 4: The Master Schedule Discussion Questions and ProblemsAmeen Mohamed AlameenAinda não há avaliações

- Inventory Replenishment ModelsDocumento3 páginasInventory Replenishment Modelsh_badgujarAinda não há avaliações

- SCM - Chapter 01Documento68 páginasSCM - Chapter 01Talha6775Ainda não há avaliações

- Chap 13 Inventory ManagementDocumento43 páginasChap 13 Inventory ManagementAcyslz50% (2)

- Chapter 3 Resource PlanningDocumento70 páginasChapter 3 Resource PlanningHieu TruongAinda não há avaliações

- Practice Problems of Inventory ManagementDocumento8 páginasPractice Problems of Inventory ManagementChaerul Amien0% (1)

- Chapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsDocumento13 páginasChapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsomkarAinda não há avaliações

- Supply Chain Management: Managing Economies of Scale in The Supply Chain: Cycle InventoryDocumento10 páginasSupply Chain Management: Managing Economies of Scale in The Supply Chain: Cycle InventorySamima AkteriAinda não há avaliações

- A Project On The Economic Order QuantityDocumento26 páginasA Project On The Economic Order QuantityFortune Fmx MushongaAinda não há avaliações

- Inventory ControlDocumento26 páginasInventory ControlhajarawAinda não há avaliações

- Inventory ManagementDocumento27 páginasInventory ManagementsaloniAinda não há avaliações

- Inventory Management (2021)Documento8 páginasInventory Management (2021)JustyAinda não há avaliações

- Inventory ModelDocumento8 páginasInventory ModelCharlyn FloresAinda não há avaliações

- Accounting For Overheads and Marginal Costing 1Documento51 páginasAccounting For Overheads and Marginal Costing 1Uditha LakshanAinda não há avaliações

- Ch08 - InventoryDocumento112 páginasCh08 - InventoryAdam Yans JrAinda não há avaliações

- Krajewski TIF Chapter 16Documento49 páginasKrajewski TIF Chapter 16Saja BassamAinda não há avaliações

- Worksheet 17 CBDocumento8 páginasWorksheet 17 CBTrianbh SharmaAinda não há avaliações

- Assignment 2: Problem 1Documento3 páginasAssignment 2: Problem 1musicslave960% (1)

- Dps 502 Inventory Management Feb 23 2012Documento153 páginasDps 502 Inventory Management Feb 23 2012jaminkwadAinda não há avaliações

- Special Inventory MGMT ModelsDocumento42 páginasSpecial Inventory MGMT ModelsPradeep SethiaAinda não há avaliações

- Unit 5 Acceptance Sampling Plans: StructureDocumento18 páginasUnit 5 Acceptance Sampling Plans: Structurevinay100% (2)

- Module-5 Inventory ModelsDocumento30 páginasModule-5 Inventory ModelsGopi SAinda não há avaliações

- Here's How Kanban WorksDocumento3 páginasHere's How Kanban WorksShiva Krishna BhagavatulaAinda não há avaliações

- (N D Vohra Unsolved Q-4 Page-594) (Solution: 6 Years)Documento15 páginas(N D Vohra Unsolved Q-4 Page-594) (Solution: 6 Years)Lokesh GagnaniAinda não há avaliações

- Just in TimeDocumento24 páginasJust in TimeMrinal KalitaAinda não há avaliações

- Inventory Classification SystemDocumento9 páginasInventory Classification Systempooja11110Ainda não há avaliações

- Inventory Mangement - Final PartDocumento25 páginasInventory Mangement - Final PartMostafa Salah ElmokademAinda não há avaliações

- Practice of Cost Volume Profit Breakeven AnalysisDocumento4 páginasPractice of Cost Volume Profit Breakeven AnalysisHafiz Abdulwahab100% (1)

- Chapter 4Documento15 páginasChapter 4Arun Kumar SatapathyAinda não há avaliações

- Assignment 02 SolutionDocumento4 páginasAssignment 02 SolutionSlhz Chua100% (1)

- Allocation and ApportionmentDocumento11 páginasAllocation and ApportionmentpRiNcE DuDhAtRa100% (2)

- MRP, Jit, ErpDocumento26 páginasMRP, Jit, ErpRupendra TripathiAinda não há avaliações

- Inventory ManagementDocumento6 páginasInventory Managementrachim04Ainda não há avaliações

- Inventory BY U Saiprasanraj Asst - Professor Iv B.Tech Mechanical 2018-19Documento18 páginasInventory BY U Saiprasanraj Asst - Professor Iv B.Tech Mechanical 2018-19sai ramanaAinda não há avaliações

- Cost-Volume-Profit Analysis: Part-A QuestionsDocumento10 páginasCost-Volume-Profit Analysis: Part-A QuestionsAtiq RehmanAinda não há avaliações

- Teamcenter: Engineering Data Management System: AgendaDocumento14 páginasTeamcenter: Engineering Data Management System: AgendaIgor OrtizAinda não há avaliações

- Samsung: SLIM Short Cycle Time and Low InventoryDocumento2 páginasSamsung: SLIM Short Cycle Time and Low InventoryYuandong JiangAinda não há avaliações

- TRW HW OverviewDocumento8 páginasTRW HW OverviewnagasankarAinda não há avaliações

- A Report On Application of Kaizen in Poultry FarmDocumento12 páginasA Report On Application of Kaizen in Poultry FarmMaulik Padh100% (1)

- Lean Case Study - LeatherDocumento9 páginasLean Case Study - LeatherSk Mosaib AhamedAinda não há avaliações

- Be 313 - Week 4-5 - Unit Learning BDocumento25 páginasBe 313 - Week 4-5 - Unit Learning Bmhel cabigonAinda não há avaliações

- Ashok Leyland 3Documento4 páginasAshok Leyland 3Harshith GowdaAinda não há avaliações

- Rapid Plant Assessment Table 1 - Rating Sheet: Ratings Measure Score 1 3 5 7 9 11Documento14 páginasRapid Plant Assessment Table 1 - Rating Sheet: Ratings Measure Score 1 3 5 7 9 11Naga ChaitanyaAinda não há avaliações

- EOQ ProblemsDocumento3 páginasEOQ Problemstomtomtom77750% (4)

- CPIM Part 1 Section C PDFDocumento2 páginasCPIM Part 1 Section C PDFSaurabhAinda não há avaliações

- Group TechnologyDocumento5 páginasGroup TechnologyDivyeshAinda não há avaliações

- Pull System, JITDocumento12 páginasPull System, JIThendmeAinda não há avaliações

- Ch01 - Introduction To Project ManagementDocumento52 páginasCh01 - Introduction To Project ManagementKovMuAinda não há avaliações

- Director Manufacturing Supply Chain in Boston MA Resume James HamreDocumento2 páginasDirector Manufacturing Supply Chain in Boston MA Resume James HamreJamesHamreAinda não há avaliações

- CH11 Solution 9eDocumento25 páginasCH11 Solution 9eAbdullah Muhsin100% (2)

- Chapter 2 Engineering Costs and Cost EstimatingDocumento33 páginasChapter 2 Engineering Costs and Cost EstimatingcamableAinda não há avaliações

- British Plastics and Rubber Nov-Dec 2013Documento48 páginasBritish Plastics and Rubber Nov-Dec 2013Clint FosterAinda não há avaliações

- Uncoordinated Supply Chain: by Prof. M. K. Tiwari Dept of IE&M IIT KharagpurDocumento125 páginasUncoordinated Supply Chain: by Prof. M. K. Tiwari Dept of IE&M IIT Kharagpurravi_radanAinda não há avaliações