Escolar Documentos

Profissional Documentos

Cultura Documentos

Guide For Vessel

Enviado por

tutuionutTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Guide For Vessel

Enviado por

tutuionutDireitos autorais:

Formatos disponíveis

Guide

for

Vessel Sizing

.

0 Certified

ISSUE DATE DESCRIPTION BY CHKD APPD

ID. NO.

O:\QSYSDOC\GPIT008.DOC

SHEET

1 of 19

DOC.NO.

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

2 of 40

DOC

Table of Contents

1. Scope .................................................................................................................................... 4

2. Introduction .......................................................................................................................... 4

3. Selection Criteria for Vapor-Liquid Separators .................................................................... 4

3.1 Orientation of the Vessel............................................................................................................. 4

3.2 Feed Inlet ..................................................................................................................................... 5

3.2.1 Inlet Nozzle ......................................................................................................................................... 5

3.2.2 Inlet device .......................................................................................................................................... 5

3.3 Internals ....................................................................................................................................... 6

3.4 Vessel Head ................................................................................................................................. 7

4. Design Criteria for Vapor / Liquid Separators ..................................................................... 7

4.1 Definition of Levels .................................................................................................................... 7

4.2 Vertical Vessels........................................................................................................................... 8

4.2.1 Diameter of a Vertical Vessel .............................................................................................................. 8

4.2.2 Height of a Vertical Vessel .................................................................................................................. 8

4.3 Horizontal Vessels .................................................................................................................... 10

4.3.1 Size of a Horizontal Vessel ............................................................................................................... 10

4.3.2 Feed Inlet Device for Horizontal Vessels .......................................................................................... 13

Either a 90 elbow, or a half-open pipe can be used as inlet device for a horizontal vessel. A 90 elbow is

preferred as they are easier to fabricate. The following requirements are applicable for 90 elbow inlets: ... 13

- The diameter of the elbow must be the same as the nozzle diameter........................................................ 13

4.3.3 Boot ................................................................................................................................................... 13

4.4 Additional Criteria .................................................................................................................... 15

4.4.1 Degassing .......................................................................................................................................... 15

4.4.2 Foaming ............................................................................................................................................. 16

4.5 Sizing of Nozzles ...................................................................................................................... 16

4.5.1 Feed Inlet Nozzle ............................................................................................................................... 16

4.5.2 Vapor Outlet Nozzle .......................................................................................................................... 16

4.5.3 Liquid Outlet Nozzle ......................................................................................................................... 17

4.5.4 Manway ............................................................................................................................................. 17

4.5.5 Vents and Drains ............................................................................................................................... 17

4.5.6 Nozzle Identification ......................................................................................................................... 18

4.6 Mist Eliminators ........................................................................................................................ 18

4.6.1 Sizing of Demister Pads .................................................................................................................... 18

4.6.2 Demister in Vertical Vapor / Liquid Separators ................................................................................ 19

5. Design of Liquid / Liquid Separators ................................................................................. 19

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

3 of 40

DOC

5.1 Liquid-Filled Separators............................................................................................................ 20

5.2 Liquid-Liquid Separators with Vapor Compartment ................................................................ 21

6. Computer Programs ............................................................................................................ 23

6.1 Depsep ....................................................................................................................................... 23

6.2 Separator ................................................................................................................................... 23

6.3 Excel Functions ......................................................................................................................... 23

6.3.1 Horizontal Vessel Liquid Volume ..................................................................................................... 23

6.3.2 Horizontal Vessel Liquid Level ......................................................................................................... 23

6.3.3 Vertical Vessel Liquid Volume ......................................................................................................... 24

6.3.4 Vertical Vessel Liquid Level ............................................................................................................. 24

6.3.5 Segmental Area from Elevation ......................................................................................................... 24

7. Appendices ......................................................................................................................... 24

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

4 of 40

DOC

1. Scope

This document shall be used for the process design of vessels, however, for specific

projects, these design rules may be superseded or modified by client requirements.

Applicable design rules for a specific project shall be specified in the Design Basis

and / or the General Information and Instructions (GII) for the project.

2. Introduction

In general the function of a vessel in a process unit is to either provide hold-up time

or to make a separation between the various phases of a mixed process stream. In this

design guide rules are given for the dimensioning of vessels, which are used for the

separation of mixed process streams. They can be divided into two categories:

- Vapor / liquid separators, which are used to separate the vapor and liquid part of

a mixed stream.

- Liquid / liquid separators, which are used to separate the two liquid phases of a

mixed stream.

For both types of separators the design rules will be given in this design guide.

3. Selection Criteria for Vapor-Liquid Separators

The configuration of a vapor/liquid separator depends on a number of factors. Before

making a vessel design one has to decide on the configuration of the vessel with

respect to among others:

- Orientation

- Type of feed inlet

- Type of internals

- Type of heads

Factors that help to make the chioce between the various alternatives are discussed in

this chapter.

3.1 Orientation of the Vessel

The selection of the orientation of a gas-liquid separator depends on several factors.

Both vertical and horizontal vessels have their advantages. Depending on the

application one has to decide on the best choice between the alternatives.

Advantages of a vertical vessel are:

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

5 of 40

DOC

- a smaller plot area is required (critical on offshore platforms)

- it is easier to remove solids

- liquid removal efficiency does not vary with liquid level because the area in the

vessel available for the vapor flow remains constant

- generally the vessel volume is smaller

Advantages of a horizontal vessel are:

- it is easier to accommodate large liquid slugs;

- less head room is required;

- the downward liquid velocity is lower, resulting in improved de-gassing and foam

breakdown;

- additional to vapor / liquid separation also a liquid / liquid separation can be

achieved (e.g. by installing a boot).

The preffered orientation for a number of typical vapor / liquid separation

applications are:

Application Preferred orientation

Reactor Effluent Separator (V/L) Vertical

Reactor Effluent Separator (V/L/L) Horizontal

Reflux Accumulator Horizontal

Compressor KO Drum Vertical

Fuel Gas KO Drum Vertical

Flare KO Drum Horizontal

Condensate Flash Drum Vertical

Steam Disengaging Drum Horizontal

3.2 Feed Inlet

3.2.1 Inlet Nozzle

The feed nozzle size and the type of feed inlet device (if any) have an impact on the

vapor / liquid separation that can be achieved. The feed nozzle is normally sized to

limit the momentum of the feed. The limitation depends on whether or not a feed

inlet device is installed.

3.2.2 Inlet Device

Various inlet devices are available to improve the vapor / liquid separation. Among

others the following inlet devices may be installed:

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

6 of 40

DOC

- A deflector baffle

- A slotted tee distributor

- A half-open pipe

- A 90 elbow

- A tangential inlet with annular ring

- A schoepentoeter

For verticla drums, preferably a deflector baffle or a half open pipe shal be selected.

In case of a slug flow regime in the inlet piping, or if a high liquid separation

efficiency is required, a tangential inlet nozzle with annular ring can be used.

However, in case a high liquid removal efficiency is required, the application of a

wire mesh demister is preferred.

For horizontal drums normally a 90 elbow or a slotted diverter is installed. In some

cases a submerged inlet pipe is installed, but this shall not be done in the case of a

two-phase feed.

Normally the selected inlet device for a horizontal drum shall be:

- a 90 elbow or a slotted diverter in case of an all liquid or vapor-liquid feed

- a submerged pipe when the feed is a subcooled liquid and the mixing of liquid

and blanket gas is to be minimized

- two 90 elbow inlets in case of high vapor loads

3.3 Internals

After passing through the feed inlet, the vapor stream will still contain liquid in the

form of droplets. The maximum soze of these entrained droplets depends on the

vapor upflow velocity. A separation device can reduce this entrainment significantly.

Wire mesh demister are the most commonly used as separation device. They are used

for two reasons:

- To minimize entrainment

- Of the drum services having such a requirement, suction drum for reciprocating

compressors are the most notable examples

- To reduce the size of a vessel

- The allowable vapor velocity in a drum can be increased significantly by using a

wire mesh demister. So, when sizing is governed by vapor-liquid separation

criteria, this will result in a smaller diameter of the vessel

Major disadvantages of wire mesh demister are:

- They are not suitable for fouling services

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

7 of 40

DOC

- Their liquid removal decreases significantly at reduced throughput

Although the size of the vessel often can be reduced by applying a wire mesh

demister, there are also many services where there is normally no demister installed.

Reflux accumulators, for example, seldom have mist eliminators.

There are several other types of mist eliminators such as vanes, cyclones, and fiber

beds. They are used when conditions are not favorable for wire mesh screens.

Selection criteria for these types of internals are the required efficiency, capacity,

turndown, ratio, maximum allowable pressure drop and fouling resistance. These

types however will not be further addressed in this design guide.

3.4 Vessel Head

Most vessels have 2:1 elliptical heads, welded to the shell of the vessels. However, in

some cases other types of heads are used. The major alternatives are:

- Flat heads

- In case of small vertical vessels (diameter less than approximately 30) often a

flaged top head is used, which also serves to provide access to the vessel.

Depending on the pressure rating, this type of head can either be flat or elliptical,

and shall be selected in consultation with the mechanical engineer

- Hemispherical heads

- A hemispherical head should be considered for an extremely large, high-pressure

vessel

- A dished head be considered in the case of a large diameter, low-pressure vessel

4. Design Criteria for Vapor / Liquid Separators

4.1 Definition of Levels

In the sizing of vessels the the proper definition of hold-up time and liquid levels is

important. For the design of vessels the following shall be used:

Liquid hold-up time Working volume between High Liquid Level

(HLL) and Low Liquid Level (LLL)

HLL Upper end of the control span

LLL Lower end of the control span

HLA High Level Alarm, normally at 90% of the control span

LLL Low Level Alarm, normally at 10% of the control span

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

8 of 40

DOC

4.2 Vertical Vessels

4.2.1 Diameter of a Vertical Vessel

The design of a vapor-liquid separator is based on the terminal settling velocity of a

liquid droplet of specified size, settling under the influence of gravity. This velocity

is given by:

v

v l

v

v l P

K

C

gD

v

=

1 1

3

) ( 4

(4.1)

where

v

1

terminal settling velocity (m/s),

l

liquid density (kg/m

3

),

v

vapor density (kg/m

3

),

D

p

droplet diameter (m),

g gravitational constant (9.81 m/s

2

),

C dimensionless drag coefficient,

K

t

separation factor, or gas handling capacity )m/s

2

.

The vapor handling capacity (K

t

) depends on the type of service of the vessel.

Typical values are:

Application K

t

Horizontal KO drum 0.25 fps 0.08 m/s

Vertical KO drum without demister 0.15 fps 0.05 m/s

Vertical KO drum with demister 0.25 fps 0.08 m/s

Flare KO drum (essentially dry vapor) 0.25 m/s

Flare KO drum (wet vapor) 0.10 m/s

The separator shall be large enough to handle the gas flow rate under the most severe

process conditions. For systems, which have a foaming tendency, sugh as glycol and

amine solutions, a derating factor of 0.7 0.8 shall be used for K

t

. A derating factor

of 0.7 0.8 shall also be used for compressor suction knockout drums.

See paragrap 4.6 for the sizing of the demister mat.

4.2.2 Height of a Vertical Vessel

The total vessel height is the sum of the following contributions:

1. The height required for the Low Liquid Level (LLL)

The level instrument determines the LLL. For mechanical reasons, the nozzel of this

instrument should be at least 150 mm above the bottom tangent line. The level

instrument requires an additional 50 mm. Therefore the LLL is about 200 mm above

the bottom TL of a vessel. In case of doubt the instrument engineer shall be consulted

on the minimum required LLL.

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

9 of 40

DOC

2. The height required for the liquid hold-up

The liquid hold-up is defined as the volume between the High Liquid Level (HLL)

and the Low Liquid Level (LLL). This volume consists of the standard hold-up plus

additional volume in case of slug or trip-alarm levels. Typical hold-up times are:

Service Recommended hold-up

Feed to distillation column, reactor, heater 5-15 min.

Reflux vessel 3-5 min.

Flare KO drum 20-30 min.

Condensate Flash drum 3-5 min.

Fuel gas KO drum 1)

1) As a minimum a Fuel Gas KO drum shall be sized to contain a slug of liquid

equivalent to the content of 6 mtr inlet piping.

If slugs of liquid can be expected, additional volume shall be provided to ensure that

the required vapor / liquid separation can still be achieved.

3. The clearance between the High Liquid Level and the inlet nozzle.

The clearance between the HLL and the inlet nozzle shall be 0.3 times the vessel

diameter, with a minimum of 0.3 m.

4. The diameter of the inlet nozzel.

The diameter of the inlet device depends on the inlet flow and on the type of inlet

device. See section 4.5.1 for the sizing criteria of the inlet nozzle.

5. The clearance between the inlet device and the top TL.

The required clearance between the inlet nozzle and the top TL depends on the presence

of a demister.

- Without a demister the clearance shall be 0.7 times the vessel diameter with a

minimum of 0.9 m.

- With a demister the clearance shall be:

0.45 times the vessel diameter, with a minimum of 0.9 m to the demister, plus, 0.1 m

for the demister, plus

0.15 times the vessel diameter, with a minimum of 0.15 m for the clearance between

the demister and the top TL

The sizing is for a vertical vessel with and without a demister is summarized in figure

4.1.

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

10 of 40

DOC

4.3 Horizontal Vessels

4.3.1 Size of a Horizontal Vessel

The calculation of the diameter and the length of a horizontal vessel can not be

separated. The cross-section area of the vapor space is based on a maximum

allowable vapor velocity given by equation 4.1. The sizing of a horizontal vapor /

liquid separator is based on a trial-and-error method. The sizing method consists of

the following steps:

1. Calculate the required liquid volume (V

Liq

) based on the selected liquid dold-up

time. The liquid is given by:

VL

iq

=

Liq

V, Liq

where:

VL

iq

the liquid volume for hold-up (m

3

)

Liq

the liquid hold-up (s)

V, Liq

the liquid volumetric flow rate (m

3

/s)

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

11 of 40

DOC

Figure 4.1

2. As a first estimate, assume that the liquid volume is 60 % of the total volume.

Select an L/D ratio and calculate the vessel diameter. The vessel diameter is given

by:

D =

( )

3

1

6 . 0

4

1

|

|

|

.

|

\

|

D

L

V

Liq

t

(4.3)

where:

D the diameter of the vessel (m),

L/D the ratio between the length and the diameter (-).

If there are no other factors, which determine the L/D ratio of a vessel, the design

pressure is normally used to select this ratio. Recommended L/D ratioss are:

Vessel design pressure (Barg) Recommended L/D

0<P

design

<17 2.5

17< P

design

<35 3.0 4.0

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

12 of 40

DOC

P

design

<35 4.0 6.0

3. Select the Low Liquid Level (LLL). Typically the LLL is set at 0.2 m, but it shall

be checked with the mechanical engineer whether is feasible. Calculate the cross-

section area is given by:

( )

t

2

sin

=

Tot

LLL

A

A

, and

|

.

|

\

|

=

2

cos 1

2

1

D

H

LLL

(4.4)

where:

A

LLL

the cross-sectional area below the LLL (m

2

);

A

Tot

the cross-sectional area of the vessel, D

2

(m

2

)

the angle between the center and the liquid-vapor

interface at the vessel surface (-)

H

LLL

the height of the low liquid level (m)

In Excel a special function is available for this calculation.

4. Calculate the total cross-sectional area required for the liquid by adding to the

cross-sectional area below the LLL the area required for the liquid hold-up. The

total liquid cross-sectional area is given by:

A

Tot, Liq

= A

LLL

+

L

V

Liq

(4.5)

5. Calculate the HLL, using similar formulas as in step 4, or the special function in

Excel. Determine the remaining vapor cross-sectional area.

6. Calculate maximum allowable vapor velocity using

v

max

= K

t

v

v l

(4.6)

where:

v

max

maximum vapor velocity (m/s),

l

liquid density (kg/m

3

),

v

vapor density (kg/m

3

),

K

t

separation factor or gas handling

capacity (m/s).

For horizontal vessels K

t

shall be taken as 0.25 fps (0.08 m/s).

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

13 of 40

DOC

7. Check the actual vapor velocity.

Based on the vapor space above the HLL, the actual vapor space must be

calculated and compared against the maximum allowable vapor velocity. In case

of a large required vapor area, two vapor inlet nozzles shall be considered,

thereby reducing the required vapor space by 50 %.

Based on the application some additional criteria aply:

A. Limitations on HLL

The HLL shall not be higher than 80 % of the diameter with a minimum heigh of

the vapor space of 0.3 m. If a demister is installed, the minimum height of the

vapor space is 0.6 m.

B. Space for inlet device

The vapor space must be sufficiently high to accommodate the feed inlet device.

At least 150 mm shall be available between the bottom of the inlet device and

the HLL .

4.3.2 Feed Inlet Device for Horizontal Vessels

Either a 90 elbow, or a half-open pipe can be used as inlet device for a horizontal

vessel. A 90 elbow is preferred as they are easier to fabricate. The following

requirements are applicable for 90 elbow inlets:

- The diameter of the elbow must be the same as the nozzle diameter.

- An impingement baffle should be installed opposite to the elbow to protect the

drum shell. The baffle diameter should be twice the inlet nozzle diameter. A

thickness of for the baffle plate is recommended.

- The minimum distance between the elbow and the HLL is 150 mm (6).

- The elbow should be installed as close as possible to the tangent line considering

reinforcement and fabrication requirements (150 mm).

- Short radius elbows shall be used with 3 straight pipe inside the drum.

4.3.3 Boot

When there is a chance that the liquid contains some water or other immiscible fluid

a boot can be provided to collect the heavier fluid phase. A boot will only be selected

if the following criteria are satisfied:

- De-oiling of the heavy liquid phase is not important

- The ratio of the volumetric flow rates of the heavy and light liquid phase is

smaller than 0.2

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

14 of 40

DOC

In all other cases overflow/underflow weirs shall be used for proper liquid/liquid

separation.

The sizig of the boot diameter shall satisfy the following criteria:

- The boot diameter shall not be more than 0.5 times the vessel diameter

- the minimum boot diameter depends on the diameter of the vessel and shall be

as listed below:

Vessel Diameter (mm) Min. Boot Diameter (mm)

D < 900 300

900<D<1400 400

D>1400 500

- The aheavy liquid draw-off velocity shall not exceed 80% of the rising velocity of

the light liquid. Because of the small size of the droplets, in most cases the Stokes

law can be applied to calculate the rising velocity of the droplets. This results in:

( )

c

l h d

d

D g

v

q

=

2

18

(4.7)

where

v

d

rising velocity of the droplet (m/s)

g gravitational constant (9.81 m/s

2

)

D

d

the droplet diameter (m)

l

the density of the light liquid phase (kg/m

3

)

v

the density of the heavy liquid phase (kg/m

3

)

c

the dynamic viscosity of the continuous phase (Pa s)

The following criteria for droplet diameter (D

d

) of the light phase are recommended:

Density (kg/m

3

) Droplet diameter (m)

>850 125 (0.0005 inch)

<850 90 (0.0003 inch)

Moreover, the design settling velocity should be limited to 10 inch per minute even if

a higher rate is calculated.

The length of a boot shall be based on the following criteria:

- Typically, allow about 5 minutes hold up for the heavy phase

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

15 of 40

DOC

- The length of the boot (i.e the distance between the bottom of the vessel and the

bottom tangent line of the boot) should be at least 900 mm to allow a proper

interface level control and to accommodate all the nozzles for the control

instruments

- The low liquid level for the liquid-liquid interface should be 200 mm above the

bottom tangent line. The high liquid level should be 200 mm below the bottom of

the vessel. This results in a distance between the low and high level of the liquid-

liquid interface of at least 500 mm

Additional vessel requirements when providing a boot:

- The light liquid phase outlet shall extend 100 to 150 mm above the bottom of the

vessel, and be equipped with a vortex breaker

- The light liquid phase outlet shall be located downstream of the boot and as close

as possible to the tangent line of the vessel

- The boot shall be located on the opposite side from the inlet, as close as possible

to the tangent line. The distance is not determined by process reasons, but by the

saddle support. Therefore, contact with the mechanical department is required

4.4 Additional Criteria

4.4.1 Degassing

When good degassing of liquid is required, the dimensioning of the vessel shall also

satisfy criteria for the separation of gas bubbles out of the liquid phase. Because of

the small size of the bubbles, in most liquids the Stokes law can be applied to

calculate the rising velocity of the bubbles. This results in:

( )

q

v l v

v

D g

v

=

2

18

(4.8)

where

v

v

rising velocity of the bubble (m/s)

g gravitational constant (9.81 m/s

2

)

D

v

the bubble diameter (m)

l

the density of the light liquid (kg/m

3

)

v

the density of the vapour (kg/m

3

)

the dynamic viscosity of the liquid (Pa s)

It is generally assumed that proper liquid degassing is achieved when bubbles of 200

micron and larger are removed. In this case formula 4.8 can be simplified to:

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

16 of 40

DOC

( )

q

v l

v

x v

=

8

10 2 . 2

(4.9)

For vertical vessels it shall be ensured that the downward liquid velocity in the vessel

doesnt exceed the calculated rising velocity of the bubbles.

For horizontal vessels it shall be ensured that the residence time below the low liquid

level will allow the selected minimum size bubble to travel the distance between the

vessel bottom and the loe liquid level.

4.4.2 Foaming

In case the handled has a tendency to foam, the design shall take this into

consideration. Although is no solid basis to do so, the following can be used as a

guide:

- For horizontal vessels, add the height of the foam above the high liquid level, to

allow for the reduced vapor space for vapor/liquid disengagement. (typically 0.3

mtr or 1 ft)

- For vertical vessels, Shell limits the downwards liquid velocity to:

( )

q

v l

l

x v

=

4

10 4 . 1 (4.10)

4.5 Sizing of Nozzles

4.5.1 Feed Inlet Nozzle

The internal nozzle diameter may be taken equal to that of the feed pipe, but also the

following momentum criteria shall be satisfied:

No inlet device:

2

m m

v < 1000 (4.11)

Half open pipe:

2

m m

v < 1500 (4.12)

Where:

m

the density of the mixture (M

G

+ M

L

) / (Q

G

+ Q

L

) (kg/m

3

)

v

m

the velocity of the mixture (Q

G

+ Q

L

) / (1/4H D

2

) (m/s)

Other momentum criteria are applicable for high vacuum units or other units where

the inlet velocity can be very high because of the low gas density.

4.5.2 Vapor Outlet Nozzle

The diameter of the gas nozzlet should normally be equal to that of the outlet pipe,

but also the following criterion shall be satisfied:

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

17 of 40

DOC

2

G G

v

< 3750

where:

G

the vapor density (kg/m

3

)

v

G the

vapor velocity (m/s)

In High Vacuum Units this criterion may result in a high outlet velocity, leading to a

pressure drop which is too high. In that case, the gas outlet nozzle shall be sized such

that the pressure drop requirements between column and downstream system are met.

4.5.3 Liquid Outlet Nozzle

The diameter of the outlet nozzle shall be chosen in relation to the outlet line size

selected, and is often based on a liquid velocity of 1 m/s. As liquid circulating above

the liquid outlet nozzle may result in vortex formation, design shall include measures

to avoid this. This can be done in two ways:

- Above adequate liquid height above the outlet nozzle. For checking the required

minimum liquid height above the outlet nozzle see graphs in Appendix I.

- Install a vortex breaker

- Normally vortex breakers are provided on outlet nozzles that serve as outlet to

pump.

4.5.4 Manway

The size of a manway is usually 24, unless internal devices require larger size for

installation. If the vessel diameter is 30 or less, a flaged head may be considered in

stead of a manway. For mechanical reasons, manway should be smaller that one-half

of the vessel inside diameter.

4.5.5 Vents and Drains

As defined in the Engineering Guide for the Preparation of Engineering Floe

Diagrams (BN-EG-UE208), para 5.2.4 the size of vents and drains on vessels shall

be:

Vessel volume Drain Connection Vent Connection

Up to 17 m3 2 2

17 to 200 m3 3 3

200 to 400 m3 3 4

400 to 700 m3 4 6

700 m3 and above 6 8

Additional to vents and drains vessels may be provided with steam out and utility

connections. Normally these connections are 2:.

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

18 of 40

DOC

4.5.6 Nozzle Identification

If not specifically defined for the project, the nozzles on a vessel shall be identified as

follows:

Process nozzles N1, N2, N3 etc.

Instrument nozzles K1, K2, K3, etc., where multiple nozzles for a single

instrument shall be identifiedK1A\B\C etc

Manways M1, M2 etc.

Relief Valves RV1, RV2 etc.

Vents V1, V2 etc.

Drains D1, D2 etc.

Steam out connections SO

Utility connections UC

4.6 Mist Eliminators

In case a high liquid separation efficiency is required, a mist eliminator can be

installed to ensure the removal of smaller liquid droplets. Also a mist eliminator can

be installed to reduce the size of a vertical vapor/liquid separator. Normally a

demister pad is installed as mist eliminator.

Important: In case a vessel is provided with a demister pad, the relief valve

protecting the vessel shall be mounted upstream of the demister pad to

reduce the change of blockage in the relief valve inlet and to reduce

pressure drop.

4.6.1 Sizing of Demister Pads

The demister pad is sized based on a maximum allowable vapor velocity through the

pad, given by vendor rules. A typical sizing rule for demister pads is given by

equation 4.13 however for separators operating under vacuum conditions vendor

information shall be consulted.

v

v l

t

K v

=

max

(4.13)

where:

v

max

Maximum vapor velocity through the demister (m/s),

l

liquid density (kg

/

m

3

),

v

vapor density

(kg

/

m

3

),

K

t

separation factor, typically 0.11 m/s (0.35 fps).

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

19 of 40

DOC

The demister thickness is normally 100 mm or 4.

4.6.2 Demister in Vertical Vapor / Liquid Separators

For vertical vessels the following applies for the use of demister pads.

Horizontally installed demister pads:

- The minimum clearance between the top of the vessel and the demister pad is the

larger of 12 or half the length of the longer side of the pad.

- The design of the vessel remains the same as for a horizontal vessel without mist

eliminator, except for the minimum length, which is not specified from inlet to

outletnozzle but from inlet to demister pad.

- In case separation efficiency of the vessel should be very high, two vertical and

one horizotal demister can be installed in the vapor phase. The vessel requires an

inlet nozzle at each end, terminated by an elbow or a half-open pipe, and one

vapor outlet nozzle at the center of the vessel. This setup reduces the required

cross-sectional vapor area by 50%. However, with small low-pressure vessels, the

savings from the smaller diameter may be offset by the cost of the vertical

demisters and the extra inlet.

For vertically installed demister pads:

- The minimum thickness of the demister pad is 6.

- The demister pad should extend from the top of the vessel to 0.1 m above the

bottom. The area between the mat and the bottom of the vessel shall allow free

pasage of liquid.

- The distance between the inlet device and the front face of the demister mat shall

be at least 0.6 m or 0.5 times the vessel diameter D.

Typical cleint rules for this distance are:

SHELL: The distance shall be at least D.

EXXON: The verticla demister shall be located immediately downstream of the inlet

nozzle.

- The distance between the downstream side of the outlet nozzle and the rear face of

the demister mat shall be at least 0.5D.

5. Design of Liquid / Liquid Separators

Normally, liquis / liquid separation is achieved in a horizontal vessel, providing

adequate residence time to properly separate the required droplet size from both the

liquid phases.

- Completely filled vessels with liquid draw-off via nozzles at the top and bottom

of the vessel

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

20 of 40

DOC

- Vessels also providing vapor space, with overflow and underflow baffles, which

are separating the liquid / liquid separation compartment from compartments for

liquid draw-off

The former type of separators is used when there is no chance of vapor formation,

while the latter is used when there is a chance of vapor formation.

Rules for the design of calescor type liquid / liquid separators, where the separation is

enchaced by internals (e.g. plate packs, wire mesh), are not given in this design

guide. Design rules for this type of separator shall be based on vendor information.

5.1 Liquid-Filled Separators

The sizing of a liquid filled liquid / liquid separator is based on the required

residence time for:

- separating small droplets of light fluid from the heavy phase fluid

- separating small droplets of heavy fluid from the light phase fluid

Based on the type of application, one of the two above metioned criteria may be

skipped.

The sizing of this type of liquid / liquid separators is based on trial end error and

requires the following steps:

1. Select vessel dimensions and interface levels (min. and max.)

Initial vessel dimensions can be selected based on an overall liquid residence

time, e.g. 15 minutes. Initial high and low rface levels can be selected to get a

hold-uptime for both phases, with the interface at the normal level.

2. Calculate the droplet settling velocity for both phases

Because of the small size of the droplets , in most cases the Stokes law ca nbe

applied to calculate the settling velocity of the droplets. This results in:

( )

c

l h d

d

D g

v

q

=

2

18

(5.1)

where

V

d

settling velocity of the droplet

g ravitational constant (9.81 m/s

2

)

D

d

the droplet diameter (m)

h

the density of the heavy fluid

(kg/m

3

)

l

the

density of the light fluid (kg/m

3

)

c

the dynamic viscosity of the continuous phase (Pa s)

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

21 of 40

DOC

3. Calculate the required residence time for both phases

The required residence time must be calculated for both phases, to allow the selected

droplet size to travel between the interface and the top or bottom of the vessel. These

residence times must be compared with the actual residence time of both phases at

the interface. Because of the shape of the vessel, it is required to check the required

residence time of both phases against the actual at various interface levels, e.g. the

low and high interface level.

Based on the outcome of the calculations a new set of (high and low) interface levels

Cn be selected, or a new size vessel.

5.2 Liquid-Liquid Separators with Vapor Compartment

A liquid / liquid separator with a vapor compartment is well known, and often used

as the accumulator of an ejector based vacuum system. The sizing of these horizontal

vessels includes the sizing based on vapor / liquid separation as described before and

the sizing of the liquid / liquid separation. In this section only the sizing for liquid /

liquid separation is discussed. In case there is only a very small amount of vapor

flowing through the vessel, the High Level shall be taken at max. 80% of the

diameter of the vessel.

The liquid / liquid separators with a vapor compartment have three liquid

compartments, one for the liquid / liquid separation and one for the hold-up of the

separated light and heavy phase. These compartments are separated by overflow and

underflow baffles, which ensure a proper hold up time of the two phases in the

separating compartment.

Also the sizing of this type of liquid / liquid separator is based on trial and error and

requires the following steps:

1. Select vessel dimensions

Initial vessel dimensions can be selected based on an overall liquid residence

time, e.g. 15 minutes wit a HLL at 80% of the vessel diameter.

2. Select the heavy phase overflow baffle height and calculate the resulting

interface.

By selecting the height of the heavy phase overflow baffle the liquid / liquid interface

can be calculated based on a pressure balance, using the following equation:

H

1

x

h

= H

h

x

h

+ (H

2

-H

h

) x

l

where:

H

1

the height of the heavy phase overflow baffle

H

2

the height of the light phase overflow baffle

H

h

the height of the heavy phase in the separation compartment

h

the density of the heavy fluid

(kg/m

3

)

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

22 of 40

DOC

l

the

density of the light fluid (kg/m

3

)

As a starting value for H

1

take it approximately 200 mm below H

2

.

3. Position the baffles

The overflow baffles must be positioned to get adequate hold in the overflow

compartments for proper control of the outgoing fluid. Normally a hold up of

approximately this shall be checked to minimize pressure drop.

The distance between heavy phase underflow and overflow normally is 200 mm,

however this shall be checked to minimize pressure drop.

4. Check the liquid / liquid separation

To check the liquid / liquid separation the droplet dettling velocity for both phases

must be calculated. Because of the small size of the droplets, in most cases the

Stokes law can be applied to claculate the settling velocity of the droplets. This

results in:

( )

c

l h d

d

D g

v

q

=

2

18

(5.2)

where

v

d

settling velocity of the droplet (m/s)

g gravitational constant (9.81 m/s

2

)

D

d

the droplet diameter (m)

h

the density of the heavy fluid (kg/m

3

)

l

the density of the light fluid (kg/m

3

)

c

the dynamic viscosity of the continuous phase (Pa s)

Based on the calculated interface level and settling velocities the required residence

time for the light and heavy fluid must be calculated and compared with the actual

residence times.

Based on the outcome og the calculations some of the assumed values have to be

adjusted. In case there are only minor differences between the actual and required

residence time, adjustment of the overflow and underflow baffles (in height and / or

location) will be sufficient, in the case of larger differences, the overall size of the

vessel will have to be adjusted.

Because of the fixed overflow baffles, the interface level will change with changes in

fluid densities. As this affects the separation, the design shall be checked for possible

changes in these densities. For the same reason it is recommended to have the top of

the heavy fluid overflow baffle adjustable (e.g. +/- 100 mm).

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

23 of 40

DOC

5. Check vapor / liquid separation

As a final check on the dimensions, the vapor / liquid separation must be checked

based on the vapor residence time and settling velocity of the light fluid droplets to

be removed from the vapor.

6. Computer Programs

Various computer applications have been developed for the sizing of vapor / liquid

separators. These are:

6.1 Depsep

This program has been developed to size vapor / liquid separators based on the

Shell rules, as defined in Shell DEP no. 31.22.05.11-Gen. Of February 1991.

The program is located on the network L drive, in the directory

L/Process/Bbvprog/Depsep.235. The program can be started from this directory.

A typical output is given in Appendix IV.

6.2 Separator

This program, originally a Lotus 123 spreadsheet, has been developed to size vapor /

liquid separators based on Badger and Shell rules, as defined in the Badger

Standard Data Book, section 7.1 of July 1976 and Shell DEP no. 31.22.05.11-Gen. of

February 1991. The program is now available as a standard Excel template.

Some typical outputs are given in Appendix V.

6.3 Excel Functions

In Excel a number of special functions have been developed to calculate vessel

characteristics. Among other the folowing functions have been developed:

6.3.1 Horizontal Vessel Liquid Volume

Calculates the volume of liquid in a horizontal vessel based on vessel diameter,

vessel length, liquid level and type of head.

6.3.2 Horizontal Vessel Liquid Level

Calculates the liquid level in a horizontal vessel based on:

- Vessel Diameter

- Vessel Length

- Liquid Volume

- Type of Head

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

24 of 40

DOC

6.3.3 Vertical Vessel Liquid Volume

Calculates the volume of liquid in a vertical vessel based on:

- Vessel Diameter

- Vessel Length

- Liquid Level

- Type of Head

6.3.4 Vertical Vessel Liquid Level

Calculates the liquid level in a horizontal vessel based on:

- Vessel Diameter

- Vessel Length

- Liquid Volume

- Type of Head

6.3.5 Segmental Area from Elevation

Calculates the cross sectional area of a horizontal vessel below a given level based

on:

- Vessel diameter

- Level height

7. Appendices

I Graphs

II Typical Vessel Calculations

III Typical Data Sheet

IV DEPSEP Output

V SEPARATOR Output

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

25 of 40

DOC

Typical Vessel Calculations

PROCESS CALCULATION

GENERAL

Title Demo Project Design Guides

Client Design Guide Signature AGO

Unit Vapor / liquid separation Location Nowhere

Design of a vertical vapor / liquid separator

Liquid Vapor

Flow 20000 12000 kg/hr Note Bold numbers are input values

Density 650 3.5 kg/m

3

Volume 30.77 3428.57 m3/hr

Selected vessel configuration No demister

No inlet device

VESSEL DIAMETER

Selected K value 0.15 fps

0.0457 m/s

Max. vapor velocity 0.62 m/s

Min. cross sectional area 1.53 m2

Min. diameter 1.40 m Use 1.400 mtr

VESSEL HEIGHT

Step 1 Set the Low Liquid Level

LLL

Step 2 Set the height for liquid hold-up

Required liquid hold-up 5 min.

2.56 m3

LLL->HLL 1.67 mtr Use 1.700 mtr

Step 3 Set clearance HLL to inlet nozzle

1 Min. distance 0.3 mtr

2 0.3 x diam. 0.42 mtr Use 0.420 mtr

Step 4 Inlet nozzle

Sizing basis inlet nozzle:rho v

2 1000

rho mix 9.25 kg/m3

v

2 108.10

v 10.40 m/s

Total volume 3495.34 m3/hr

0.96 m3/s

Amin nozzle 0.092 m2

Dmin 0.343 Use 0.356 mtr

Step 5 Inlet nozzle to Top TL

1 Min. distance 0.9 m

2 0.7 x diam. 0.98 m Use 1.000 mtr

Total TL to TL diastance 3.676 mtr

Use Vessel TL / TL 3.700 mtr

Vessel diameter 1.400 mtr

Nozzle sizes

Feed nozzle 14 inch minimum

Vapor outlet nozzle

Sizing basis: rho v

2 3750

rho vapor 3.50 kg/m3

v

2 1071.43

v 32.73 m/s

Total volume 3428.57 m3/hr

0.95 m3/s

Amin nozzle 0.029 m2

Dmin 0.192 mtr Use 8 inch

Liquid outlet nozzle

Sizing basis: v max 1 m/s

Total volume 30.77 m3/hr

0.01 m3/s

Amin nozzle 0.009 m2

Dmin 0.104 mtr Use 5 inch

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

26 of 40

DOC

PROCESS CALCULATION

GENERAL

Title Demo Project Design Guides

Client Design Guide Signature AGO

Unit Vapor / liquid separation Location Nowhere

Design of a horizontal vapor / liquid separator

Liquid Vapor

Flow 20000 12000 kg/hr Note Bold numbers are input values

Density 650 3.5 kg/m

3

Volume 30.77 3428.57 m3/hr

Vessel configuration No demister

No inlet device

Step 1 Required volum for liquid hold-up

Required liquid hold-up 5 min.

2.56 m3

Step 2 Set the diameter and L/D ratio

HLL as percentage of diameter 50.00 % (estimate)

Selected L/D 2.5

Vessel diameter 1.377 m tr Use 1.500 mtr

Vessel TL/TL 3.443 mtr Use 3.750 mtr

Step 3 Set the Low Liquid Level

LLL 0.2 mtr

Area below LLL 0.14 m2

Step 4 Calculate required area below HLL

Area required for liquid hold up 0.68 m2

Area required below HLL 0.82 m2

Step 5 Calculate required HLL for liquid hold up

HLL required for liquid hold up 0.710 mtr

Step 6 Calculate the allowable vapor velocity

Selected K value 0.25 fps

0.0762 m/s

Max. vapor velocity 1.04 m/s

Step 7 Calculate the actual vapor velocity based on HLL

Area available above HLL 0.94 mtr

Actual vapor velocity 1.01 m/s

Nozzle sizes

Sizing basis inlet nozzle: rho v2 1500 (half open pipe)

rho mix 9.25 kg/m3

v2 162.16

v 12.73 m/s

Total volume 3459.34 m3/hr

0.96 m3/s

Amin nozzle 0.075 m2

Dmin 0.310 mtr Use 14 inch

Vapor outlet nozzle

Sizing basis: rho v2 3750

Rho vapor 3.50 kg/m3

v2 1071

v 32.73 m/s

Total volume 3428.57 m3/hr

0.95 m3/s

Amin nozzle 0.029 m2

Dmin 0.192 mtr Use 8 inch

Liquid outlet nozzle

Sizing basis: v max 1 m/s

Total volume 30.77 m3/hr

0.01 m3/s

Amin nozzle 0.009 m2

Dmin 0.104 mtr Use 5 inch

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

27 of 40

DOC

PROCESS CALCULATION

GENERAL

Title Demo Project Design Guides

Client Design Guide Signature AGO

Unit Vapor /Liquid / Liquid separation Location Nowhere

Design of a horizontal vapor / liquid separator

Liquid Vapor

Flow 20000 12000 kg/hr Note Bold numbers are input values

Density 650 3.5 kg/m

3

Volume 30.77 3428.57 m3/hr

Vessel configuration No demister

No inlet device

Step 1 Required volum for liquid hold-up

Required liquid hold-up 5 min.

2.56 m3

Step 2 Set the diameter and L/D ratio

HLL as percentage of diameter 50.00 % (estimate)

Selected L/D 2.5

Vessel diameter 1.377 m tr Use 1.500 mtr

Vessel TL/TL 3.443 mtr Use 3.750 mtr

Step 3 Set the Low Liquid Level

LLL 0.2 mtr

Area below LLL 0.14 m2

Step 4 Calculate required area below HLL

Area required for liquid hold up 0.68 m2

Area required below HLL 0.82 m2

Step 5 Calculate required HLL for liquid hold up

HLL required for liquid hold up 0.710 mtr

Step 6 Calculate the allowable vapor velocity

Selected K value 0.25 fps

0.0762 m/s

Max. vapor velocity 1.04 m/s

Step 7 Calculate the actual vapor velocity based on HLL

Area available above HLL 0.94 mtr

Actual vapor velocity 1.01 m/s

Nozzle sizes

Sizing basis inlet nozzle: rho v2 1500 (half open pipe)

rho mix 9.25 kg/m3

v2 162.16

v 12.73 m/s

Total volume 3459.34 m3/hr

0.96 m3/s

Amin nozzle 0.075 m2

Dmin 0.310 mtr Use 14 inch

Vapor outlet nozzle

Sizing basis: rho v2 3750

Rho vapor 3.50 kg/m3

v2 1071

v 32.73 m/s

Total volume 3428.57 m3/hr

0.95 m3/s

Amin nozzle 0.029 m2

Dmin 0.192 mtr Use 8 inch

Liquid outlet nozzle

Sizing basis: v max 1 m/s

Total volume 30.77 m3/hr

0.02 m3/s

Amin nozzle 0.009 m2

Dmin 0.104 mtr Use 5 inch

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

28 of 40

DOC

PROCESS CALCULATION

GENERAL

Title Demo Project Design Guides

Client Design Guide Signature AGO

Unit Vapor /Liquid / Liquid separation Location Nowhere

Design of a horizontal liquid / liquid separator

Light fluid Heavy fluid

Flow 50000 50000 kg/hr

Density 650 880 kg/m

3

Viscosiy 0.0004 0.0009 Pa s

Volume 76.9 56.8 m3/hr

Step 1 Select vessel dimensions and interface levels (min. and max.)

Volume for 11 min. hold up 24.5 m3

2.5

D min 2.32 mtr Use 2.3 mtr

L min 5.80 mtr 5.8 mtr

Volume for 3 min. hold up of largest flow 3.85 m3

HIL selected 1.28 mtr Volume below HIL 15.64 m3

NIL selected 1.15 mtr Volume below NIL 13.64 m3

LIL selected 1.02 mtr Volume below LIL 11.64 m3

Volume between LIL and HIL 4.00 m3

Step 2 Calculate the droplet settling velocity for both phases

Droplet to be separated 100 micron

0.01 mtr

light fluid heavy fluid

droplet droplet

Settling velocity 1.31914E-03 3.1306E-03 m/s

Check on Reynolds 0.10 0.69

Step 3 Calculate the required residence time for both phases

Residence time continuous phase required at Low Interface Level 733 409 sec

Actual residence time continuous phase 738 603 sec

Residence time continuous phase required at Normal Interface Level 827 367 sec

Actual resicende time continuous phase 864 509 sec

Residence time continuous phase required at High Interface Level 920 326 sec

Actual residence time continuous phase 991 416 sec

Note: Bold numbers are input values

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

29 of 40

DOC

Step 4 Check the liquid / liquid separation

Separation compartment

Volume below light fluid overflow baffle 12.72 m3

Volume below interface 10.33 m3

Light fluid volume in separation compartment 2.39 m3

Heavy fliud volume in separation compartment 10.33 m3

Droplets to be separated 100 micron

0.0001 mtr

light drop heavy drop

Settling velocity 2.1173E-03 4.7639E-03 m/s

Check on Reynolds 0.15 1.19

Travelling distance 1.58 0.34 mtr

Residence time continuous phase required 745 72 sec

Actual residence time continuous phase 744 112 sec

Step 5 Check vapor / liquid separation

Settling velocity light phase droplet in vapor 0.87 m/s

Travelling distance (top of vessel to light fluid overflow baffle) 0.48 mtr

Residence time vapor phase required 0.55 sec

Actual residence time 232 sec

Note: Bold numbers are input values

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

30 of 40

DOC

PROCESS DATA SHEETS FOR:

B211

Benzeen Destillaat Vat

UNIT: 1100

CLIENT: BASF - Antwerp

PROJECT: 2215.20

LOCATION: Antwerp - Belgium

CLIENT REF.: 1696

This document contains proprietary information belonging to Washington Group International its parent and/or affili ated companies and shall

be used only for the purpose for which it was supplied. It shall not be copied, reproduced or otherwise used, nor shall such information be

furnished in whole or in part to others, except in accordance with the terms of any agreement under which it was supplied or with the prior

written consent of Washington Group International and shall be returned upon request.

CLIENT

BASF

0 16/01/2002 Certified

ISSUE DATE DESCRIPTION BY CHKD APPD

ID. NO.

Washington Group

Romania S.R.L.

SHEET

1 of 5

DOC.NO.

2215-PDS-MS1102

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

31 of 40

DOC

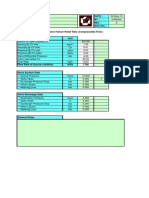

Process Data sheet for: TOWER / VESSEL / REACTOR

B211

CASE1 Controlling: Yes

1

2

OPERATING / MECHANICAL DATA

3 Service Benzeenkolom Reflux Vat

4 Orientation Horizontal

5 Description DRUM Units

6 Average liquid density 716 kg/m

3

7 Operating temepratures - max. / normal / min. 161 C

8 Operating pressure - max. / normal / min. 6.3 bar(g)

9 - normal / min. vac. conditions mbar(a)

10 Design temperature, max. min. 200 C

11 Design pressure, internal 12 bar(g)

12 Design vacuum condition, pressure / temperature 500 120 mbar(a) C

13 Steam-out condition, pressure / temerature 9 180 bar(g) C

14 Pressure drop over trays / packing bar

15 Packing type

16 Packing bulk density kg/m

3

17 Number / height per packed bed

mm

18 Total packed height mm

19 Trays, type

20 Trays, number / spacing mm

21 Total operating liquid volume, trays / packing m

3

22 Tracing type / min. holding temperature C

23 Hazardous service Benzane

24 Sour service / wet H2S severity category

25 Special service conditions

26 Max. H2 partial pressure bar(g)

27 Max. H2S partial pressure bar(g)

28 Inside diameter of shell 3400 mm

29 Length between tangent lines 9000 mm

30 Type of heads Korbbogen

31 Insulation type Fire protection

32 Stress relieve for process reasons No

33 Max. liquid volume, bottom 41 m

3

34

MATERIAL SPECIFICATION / GENERAL

35

36 Shell Killed CS

37 Internal cladding

38 Internals, removable

39

40 Corrosion allowance, internal / external 1.0 mm

41 Corrosion allowance, removable internals mm

42 Internal cllading / weld overlay mm

43 Internal coating

44 Internal refractory lining mm

45

46

47

48

49

50

51

52

NOTES

53

54

55

56

57

58

59

60

61

ID. NO.

SHEET

2 of 5

DOC.NO.

2215-PDS-MS1102

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

32 of 40

DOC

Process Data sheet for: TOWER / VESSEL / REACTOR

B211

CASE1 Controlling: Yes

1

2

OPERATING / MECHANICAL DATA

3 Service Benzeenkolom Reflux Vat

4 Orientation Horizontal

5 Description DRUM Units

6 Average liquid density 716 kg/m

3

7 Operating temepratures - max. / normal / min. 161 C

8 Operating pressure - max. / normal / min. 6.3 bar(g)

9 - normal / min. vac. conditions mbar(a)

10 Design temperature, max. min. 200 C

11 Design pressure, internal 12 bar(g)

12 Design vacuum condition, pressure / temperature 500 120 mbar(a) C

13 Steam-out condition, pressure / temerature 9 180 bar(g) C

14 Pressure drop over trays / packing bar

15 Packing type

16 Packing bulk density kg/m

3

17 Number / height per packed bed

mm

18 Total packed height mm

19 Trays, type

20 Trays, number / spacing mm

21 Total operating liquid volume, trays / packing m

3

22 Tracing type / min. holding temperature C

23 Hazardous service Benzane

24 Sour service / wet H2S severity category

25 Special service conditions

26 Max. H2 partial pressure bar(g)

27 Max. H2S partial pressure bar(g)

28 Inside diameter of shell 3400 mm

29 Length between tangent lines 9000 mm

30 Type of heads Korbbogen

31 Insulation type Fire protection

32 Stress relieve for process reasons No

33 Max. liquid volume, bottom 41 m

3

34

MATERIAL SPECIFICATION / GENERAL

35

36 Shell Killed CS

37 Internal cladding

38 Internals, removable

39

40 Corrosion allowance, internal / external 1.0 mm

41 Corrosion allowance, removable internals mm

42 Internal cllading / weld overlay mm

43 Internal coating

44 Internal refractory lining mm

45

46

47

48

49

50

51

52

NOTES

53

54

55

56

57

58

59

60

61

ID. NO.

SHEET

3 of 5

DOC.NO.

2215-PDS-MS1102

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

33 of 40

DOC

Process Data sheet for: TOWER / VESSEL / REACTOR B211

1

Mark Service Size Remarks

2 PROCESS CONNECTIONS

3

4 A1 Inlet 500 Hall open pipe with open end

5 A2 Pump Min. Flows 200

6 A4 PSV discharge 250

7 B1 Reflux Outlet 300 Vortex breaker

8 B2 Product Outlet 500 Vortex breaker

9 B3 Vapor Out 150

10 D Drain 80

11 E Equalizing Line 50

12 SO Steam Out 50

13 V Vent 80

14 INSTRUMENT CONNECTIONS

15

16 L1 Level gauge

17 L2 Level gauge

18 L3 Level Control

19 L4 Level Control

20 P1 Pressure Control

21 P2 Pressure Gauge

22 OTHER CONNECTIONS

23

24 M Manhole 600

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

NOTES

53

54

55

56

57

58

59

60

61

ID. NO.

ISSUE

-F

SHEET

4 of 5

DOC.NO.

2215-PDS-MS1102

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

34 of 40

DOC

Process Data sheet for: TOWER / VESSEL / REACTOR

B211

CASE1 Controlling: Yes

1

REMARKS

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

ID. NO.

ISSUE

-F

SHEET

5 of 5

DOC.NO.

2215-PDS-MS1102

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

35 of 40

DOC

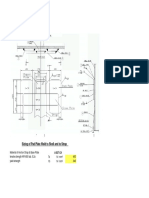

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

36 of 40

DOC

DEPSET Output

DEPSET, Gas/Liquid Separator Design (v. 1.11) BADGER B.V.

SIGN : AGO

TITLE : Nowhere

SUBJECT : Separating vapor & liquid

DATE : 01-Aug 2000 TIME : 11.35 AM

JOB NO : Design Gu

UNIT : V-1000

SHEET : 1 of 2

VESSEL CONFIGURATION:

Horizontal vessel

No inlet device

No demister

Flowmargin 0%

Eliptical vessel heads

De-foaming is not required

De-degassing is not required

PROCESS DATA: Vapor

Mass flow [kg/s] 3.33

Volume flow [m3/s] 0.9514

Density [kg/m3] 3.50

Viscosity [cP] 0.001

Slug volume

Required liquid holdup for control purposes

Liquid Water Mixed

5.56 0.00 8.89

0.0086 0.0000 0.9600

650.00 967.00 9.26

0.100

0.0 m3 (0 s holdup)

300 s (5.00 min)

PROGRAM DEFAULTS: LZA(LL)

Minimum distances [m]

Intervention time [s]

Required Length / Diameter

LA(L) LA(H) LZA(HH) FOAM

0.200 0.000 0.000 0.000

0 0

2.500 -

NOZZLES: Inlet

Nominal diameter used [inch] 16.0

Required accord. DEP [inch] 16.0

Inside diameter [m] 0.381

Outside diameter [m] 0.406

Velocity [m/s] 8.42

Calc. rho*vel2 [Pa] 657

Max. rho*vel2 [Pa] 1000

Pressure drop [kPa] 0.33

Total pressure drop is 1.00 kPa

Vapor Liquid

8.0 5.0

8.0 5.0

0.203 0.128

0.219 0.141

29.48 0.66

3041

3750

0.67

LIQUID DROPLET IN VAPOR:

Max. liquid droplet diam. 36 micron

Max. liquid droplet diam. 37 micron

At low level, LA(L)

At high level, LA(H)

!! WARNING ARE PRINTED ON SHEET 2 !!

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

37 of 40

DOC

DEPSET, Gas/Liquid Separator Design (v. 1.11) BADGER B.V.

SIGN : AGO

TITLE : Nowhere

SUBJECT : Separating vapor & liquid

DATE : 01-Aug 2000 TIME : 11.35 AM

JOB NO : Design Gu

UNIT : V-1000

SHEET : 1 of 2

VESSEL CONFIGURATION:

Horizontal vessel

No inlet device

No demister

Flowmargin 0%

Eliptical vessel heads

De-foaming is not required

De-degassing is not required

PROCESS DATA: Vapor

Mass flow [kg/s] 3.33

Volume flow [m3/s] 0.9514

Density [kg/m3] 3.50

Viscosity [cP] 0.001

Slug volume

Required liquid holdup for control purposes

Liquid Water Mixed

5.56 0.00 8.89

0.0086 0.0000 0.9600

650.00 967.00 9.26

0.100

0.0 m3 (0 s holdup)

300 s (5.00 min)

PROGRAM DEFAULTS: LZA(LL)

Minimum distances [m]

Intervention time [s]

Required Length / Diameter

LA(L) LA(H) LZA(HH) FOAM

0.200 0.000 0.000 0.000

0 0

2.500 -

NOZZLES: Inlet

Nominal diameter used [inch] 16.0

Required accord. DEP [inch] 16.0

Inside diameter [m] 0.381

Outside diameter [m] 0.406

Velocity [m/s] 8.42

Calc. rho*vel2 [Pa] 657

Max. rho*vel2 [Pa] 1000

Pressure drop [kPa] 0.33

Total pressure drop is 1.00 kPa

Vapor Liquid

8.0 5.0

8.0 5.0

0.203 0.128

0.219 0.141

29.48 0.66

3041

3750

0.67

LIQUID DROPLET IN VAPOR:

Max. liquid droplet diam. 36 micron

Max. liquid droplet diam. 37 micron

At low level, LA(L)

At high level, LA(H)

!! WARNING ARE PRINTED ON SHEET 2 !!

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

38 of 40

DOC

DEPSET, Gas/Liquid Separator Design (v. 1.11) BADGER B.V.

SIGN : AGO

TITLE : Nowhere

SUBJECT : Separating vapor & liquid

DATE : 01-Aug 2000 TIME : 11.35 AM

JOB NO : Design Gu

UNIT : V-1000

SHEET : 1 of 2

VESSEL CONFIGURATION:

Horizontal vessel

No inlet device

No demister

Flowmargin 0%

Eliptical vessel heads

De-foaming is not required

De-degassing is not required

PROCESS DATA: Vapor

Mass flow [kg/s] 3.33

Volume flow [m3/s] 0.9514

Density [kg/m3] 3.50

Viscosity [cP] 0.001

Slug volume

Required liquid holdup for control purposes

Liquid Water Mixed

5.56 0.00 8.89

0.0086 0.0000 0.9600

650.00 967.00 9.26

0.100

0.0 m3 (0 s holdup)

300 s (5.00 min)

PROGRAM DEFAULTS: LZA(LL)

Minimum distances [m]

Intervention time [s]

Extra distance BTL-LZA (LL) for mounting of

LA(L) LA(H) LZA(HH) FOAM

0.200 0.000 0.000 0.000

0 0

levelgauge nozzle is 0.000 m.

NOZZLES: Inlet

Nominal diameter used [inch] 16.0

Required accord. DEP [inch] 16.0

Inside diameter [m] 0.381

Outside diameter [m] 0.406

Velocity [m/s] 8.42

Calc. rho*vel2 [Pa] 657

Max. rho*vel2 [Pa] 1000

Pressure drop [kPa] 0.33

Total pressure drop is 1.00 kPa

Vapor Liquid

8.0 5.0

8.0 5.0

0.203 0.128

0.219 0.141

29.48 0.66

3041

3750

0.67

VESSEL HEIGHT:

High level LZA(HH)

X1 (LZA(HH) inlet)

X2 (OD inlet)

X3 (inlet top)

Used DEP default

1.900 m

0.420 m 0.420 m

0.406 m 0.406 m

1.260 m 1.260 m

!! WARNING ARE PRINTED ON SHEET 2 !!

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

39 of 40

DOC

DEPSET, Gas/Liquid Separator Design (v. 1.11) BADGER B.V.

SIGN : AGO

TITLE : Nowhere

SUBJECT : Separating vapor & liquid

DATE : 01-Aug 2000 TIME : 11.35 AM

JOB NO : Design Gu

UNIT : V-1000

SHEET : 1 of 2

MAXIMUM DROPLET SIZES: at LA (H)

Liquid in vapor outlet [micron] 112

at LA (L)

112

RESULTS:

Volumetric gas load factor

Maximum allowable gas load factor

Min. vessel cross-sectional area for gas flow

Liquid control volume between LA (L) and LA (H)

Selected diameter 1.400 m

Cros-sect. Area 1.539 m2

Gas cap height 2.086 m

Vessel volume 6.85 m3

Vessel H / D 2.847 -

Vessel height 3.986 m

Holdup LZA (HH) 342 s

0.070 m3/s

0.070 m/s

1.000 m2

2.617 m3

SIZING CRITERIA [m]

Gas handling capacity : 1.128

Liquid de-gassing : N.A.

Liquid de-foaming : N.A.

Normal level 1.050 m

CONTROL LEVELS:

LZA(LL)

USED:

Distance [m] 0.200

Level [m] 0.200

Incremental holdup [s] 36

Cumulative holdup [s] 36

MINIMUM REQUIRED: (from DEP)

Distance [m] 0.200

Level [m] 0.200

Incremental holdup [s] 0

Cumulative holdup [s] 0

LA(L) LA(H) LZA(HH) WITH FOAM

0.000 1.700 0.000 0.000

0.200 1.900 1.900 1.900

0 306 0

36 342 342

0.000 0.000 0.000 0.000

0.200 0.200 0.200 0.200

0 300 0

0 300 300

WARNINGS:

The selected diameter is not equal to the minimum diameter provided

The Shell DEP prefers an inlet device for vertical vessels

The selected diameter and/or level distances are not optimal

SEPARATOR Output

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

40 of 40

DOC

PROCESS CALCULATION

VAPOR / LIQUID SEPARATOR DESIGN

Title Process Design Guide Project B0030

Client RE & C Signature AEO

Unit U100 Location The Hague, Netherlands

Item Name Vapor Liquid Separator Item number MS-101

Flows and properties

Vapor Liquid

2)

Water

2)

Mass flow rate 12000 20000 kg/h

Density 3.5 650 kg

Viscosity 0.001 1 cP

Vessel sizing and design

Estimates for preliminary sizing:

Orientation Vertical L/D 2.5 -

Demister Yes LLL from TL 200 mm

Inlet device Yes HLL from TL 600 mm

Head type Eliptical Hold-up LLL-HLL 5 min

Water droplet Micron

Inlet nozzle v

2

1500 kg/m.s2 (max, default = 1500)

Vapor Out v

2

3750 kg/m.s2 (max, default = 3750)

Liq. Out velocity 1 m/s (max, default = 1)

Minimum Diameter calculated from estimates: Minimum Length calculated from estimates:

Based on: Based on:

Vap/Liq. Sep. 1082 mm Hold-up LLL+HLL 3696 mm

Hold-up LLL+HLL 1478 mm

Water droplet size - mm

Degassing

922 mm

Defoaming 1519 mm

Selected dimensions User selected dimensions

Diameter 1550 mm Change: 1400 mm (1400 mm used)

Height 3900 mm Change: mm (3900 mm used)

LLL 310 mm Change: 200 mm (200 mm used)

HLL 930 mm Change: 1900 mm (1900 mm used)

Results from selected dimensions

Vessel dimensions summary:

Hold-up LLL+HLL 5.1 min Selected Diameter: 1400 mm

Total Volume 6.7 m

3

Selected Length: 3900 mm

L/D Calculated: 2.79 -

Liquid Velocity 0.01 m/s

Vapor Velocity 0.62 m/s

Selected LLL 200 mm

K-value Calcd 0.15 ft/s (=0.05 m/s) Selected HLL 1900 mm

Max 0.25 ft/s (=0.08 m/s) HLL Feed 443 mm (minimum)

Feed Demister 900 mm (minimum)

Demister size 100 mm (used)

Demister - TTL 222 mm (minimum)

Droplets/Bubbles:

Liquid in Vapor 118 Micron (no demister)

Vapor in Liquid 126 Micron

Water in Liquid - Micron Feed nozzle

14 inch (= 336.6 mm)

Vapour out nozzle 8 inch (= 202.7 mm)

Pressure drop 0.01 bar Liquid 5 inch (= 128.2 mm)

Notes:

1) Reference: BADGER Standard Databook Section 7.1 (July 1976) and Design Vessel Sizing (August 2000)

2) The Water phase is reffered to only as 2

nd

liquid phase. In case of e.g. a steam drum, use Liquid phase column for water data

PROCESS CALCULATION

ID. NO.

E:\01.Docs\Books\Guide for vessel.doc

ISSUE

1

SHEET

41 of 40

DOC

VAPOR / LIQUID SEPARATOR DESIGN

Title Process Design Guide Project B0030

Client RE & C Signature AEO

Unit U100 Location The Hague, Netherlands

Item Name Vapor Liquid Separator Item number MS-101

Flows and properties

Vapor Liquid

2)

Water

2)

Mass flow rate 12000 20000 kg/h

Density 3.5 650 kg

Viscosity 0.001 1 cP

Vessel sizing and design

Estimates for preliminary sizing:

Orientation Horizontal L/D 2.5 -

Demister None LLL from TL 200 mm

Inlet device None HLL from TL 600 mm

Head type Eliptical Hold-up LLL-HLL 5 min

Water droplet Micron

Inlet nozzle v

2

1500 kg/m.s2 (max, default = 1500)

Vapor Out v

2

3750 kg/m.s2 (max, default = 3750)

Liq. Out velocity 1 m/s (max, default = 1)

Minimum Diameter calculated from estimates: Minimum Length calculated from estimates:

Based on: Based on:

Vap/Liq. Sep. 1406 mm Hold-up

LLL+HLL

4094 mm

Hold-up LLL+HLL 1638 mm

Water droplet size 730 mm

Degassing

575 mm

Defoaming 851 mm

Selected dimensions User selected dimensions

Diameter 1650 mm Change: 1600 mm (1600 mm used)

Length 4200 mm Change: mm (4200 mm used)

LLL 200 mm Change: 300 mm (300 mm used)

HLL 600 mm Change: 800 mm (800 mm used)

Results from selected dimensions

Vessel dimensions summary:

Hold-up LLL+HLL 6.9 min Selected

Diameter:

1600 mm

Total Volume 9.5 m

3

Selected Length: 4200 mm

L/D Calculated: 2.63 -

Liquid Velocity 0.01 m/s

Vapor Velocity 0.95 m/s

Selected LLL 300 mm

K-value Calcd 0.23 ft/s (=0.07 m/s) Selected HLL 800 mm

Max 0.25 ft/s (=0.08 m/s) HLL Feed Vert. Vessel only

Feed Top TL Vert. Vessel only

Vert. Vessel only

Vert. Vessel only

Droplets/Bubbles:

Liquid in Vapor 33 Micron (no demister)

Vapor in Liquid 68 Micron

Water in Liquid - Micron Feed nozzle

14 inch (= 336.6 mm)

Vapour out

nozzle

8 inch (= 202.7 mm)

Pressure drop 0.01 bar Liquid 5 inch (= 128.2 mm)

Notes:

1) Reference: BADGER Standard Databook Section 7.1 (July 1976) and Design Guidelline Vessel Sizing (August 2000)