Escolar Documentos

Profissional Documentos

Cultura Documentos

Control Plan

Enviado por

Amit PatelDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Control Plan

Enviado por

Amit PatelDireitos autorais:

Formatos disponíveis

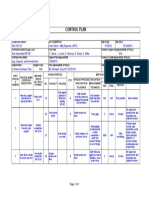

CONTROL PLAN

Control Plan Number Key Contact/Phone Date (Orig.) Date (Rev.)

ABC101-23

Part Number/Latest Change Level

John Stone - Mfg Engineer, x5412

Core Team

1/1/2010 N/A

12/11/2011

Customer Engineering Approval/Date (If Req'd.) Customer Quality Approval/Date (If Req'd.)

Sub-Assembly 987-00

Part Name/Description

C. Stone, J. Leard, D. Moores, G. Boyd, S. Miller

Supplier/Plant Approval/Date

Leg, Support, and Armrest Asm

Supplier/Plant Supplier Code

12/9/2011

Other Approval/Date (If Req'd.)

N/A

Other Approval/Date (If Req'd.)

In-House (Kansas City)

PART/ PROCESS NAME/ PROCES OPERATION S DESCRIPTION NUMBER

N/A

MACHINE, DEVICE JIG, TOOLS FOR MFG.

Ed Stumpek, Eng VP (12/10/11)

CHARACTERISTICS CTQ? NO. PRODUCT PROCESS METHODS PRODUCT/PROCESS EVALUATION/ SPECIFICATION/ MEASUREMENT TOLERANCE TECHNIQUE Parts oriented correctly (reference drawing 987-00 with any questions) SAMPLE SIZE FREQ.

N/A

REACTION PLAN

CONTROL METHOD

Place leg, support, and armrest in assembly fixture

Fixture 98701F1

1D

Parts placed properly in fixture per drawing 98700

Error proofed parts cannot be mis-oriented

N/A

N/A

Error proofed

None required

2D

Final screw depth

Screw heads subflush

Flush gage

Hourly

P-Chart

Drive two screws to secure side support

Electric screwdriver 987-01A1 2P

Drive torque on screw

Automatically monitored with electric Torque between 10 inscrewdriver lb and 13 in-lb alarm will sound if torque is out of range

100%

N/A

100% monitoring

Re-inspect all product since last inspection and rework if needed If torque alarm sounds, stop production, verify proper screws, check pilot hole diameter. If correct, contact maintenance and engineering. Re-inspect all product since last inspection and rework if needed

Drive three screws to secure arm rest

Pneumatic screwdriver 987-01A2

2D

Screws seated subflush

Screw heads subflush

Slide flushness gage over screw locations - must move freely

Hourly

P-Chart

Page 1 of 1

Você também pode gostar

- Apqp Status LogDocumento1 páginaApqp Status Logsathyabalaraman67% (3)

- Control Plan & FmeaDocumento9 páginasControl Plan & FmeaManu SharmaAinda não há avaliações

- Advanced Product Quality PlanningDocumento35 páginasAdvanced Product Quality Planninggerry3854100% (2)

- Apqp PlanDocumento3 páginasApqp Plananon-448387100% (1)

- Process Failure Mode Effects AnalysisDocumento20 páginasProcess Failure Mode Effects Analysissriramachandira100% (1)

- Core Tools Forms V5dDocumento119 páginasCore Tools Forms V5dIng. Alberto AguilarAinda não há avaliações

- Ppap, R&R, MsaDocumento8 páginasPpap, R&R, MsaArun SaigalAinda não há avaliações

- SPC SpreadsheetDocumento8 páginasSPC Spreadsheetikesh mAinda não há avaliações

- APQP FormsDocumento23 páginasAPQP FormsJOECOOL670% (1)

- PPAP Training MaterialDocumento9 páginasPPAP Training MaterialSumeet Saini0% (1)

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocumento14 páginasIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- Supplier PPAP ManualDocumento28 páginasSupplier PPAP ManualBESAinda não há avaliações

- APQP TemplateDocumento7 páginasAPQP TemplateBob ZepfelAinda não há avaliações

- DRBFM WorksheetDocumento1 páginaDRBFM WorksheetHareth MRAIDIAinda não há avaliações

- Fsqm-080 Ppap ChecklistDocumento14 páginasFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- APQP Phases and ActivitiesDocumento1 páginaAPQP Phases and Activitiesaorto3919Ainda não há avaliações

- Process Parameter SheetDocumento1 páginaProcess Parameter SheetNur AmiraAinda não há avaliações

- APQPDocumento25 páginasAPQPHeera Singh100% (3)

- GM Machining CP REV 03Documento17 páginasGM Machining CP REV 03Suraj RawatAinda não há avaliações

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocumento3 páginasRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanAinda não há avaliações

- 02-Team Feasibility CommittmentDocumento1 página02-Team Feasibility CommittmentVinod SaleAinda não há avaliações

- Guidelines For Making PFMEA - A PDFDocumento10 páginasGuidelines For Making PFMEA - A PDFKalimuthu PsAinda não há avaliações

- APQPDocumento3 páginasAPQPsam1hi5Ainda não há avaliações

- Control Plan: Prelaunch Prototype ProductionDocumento2 páginasControl Plan: Prelaunch Prototype ProductionBharathAinda não há avaliações

- Supplier APQP Training SupplementDocumento78 páginasSupplier APQP Training SupplementjcperezAinda não há avaliações

- Apqp Advanced Product Quality PlanningDocumento27 páginasApqp Advanced Product Quality PlanningRajesh KumarAinda não há avaliações

- Design FMEA (DFMEA) TutorialDocumento18 páginasDesign FMEA (DFMEA) Tutorialpiero_rsAinda não há avaliações

- CD6 Prototype Control PlanDocumento3 páginasCD6 Prototype Control Planmpedraza-1Ainda não há avaliações

- APQPDocumento2 páginasAPQPjitenderbawalia0% (1)

- Manual - APQP 20121017 PDFDocumento135 páginasManual - APQP 20121017 PDFBerk NoyanAinda não há avaliações

- Ppap-Template 4th EditionDocumento23 páginasPpap-Template 4th EditionAshutosh SinghAinda não há avaliações

- Pfmea ExampleDocumento5 páginasPfmea Exampleesivaks2000Ainda não há avaliações

- The 5 Core ToolDocumento17 páginasThe 5 Core ToolRajesh GhoshAinda não há avaliações

- CP20200804-A Model Control Plan - FoundationsDocumento6 páginasCP20200804-A Model Control Plan - Foundationsmanno200Ainda não há avaliações

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocumento6 páginasAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- Layout Inspection Report XH5DR June 20 2012Documento17 páginasLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Format No-Blank/Dir: Detail Inspection ReportDocumento18 páginasFormat No-Blank/Dir: Detail Inspection ReportRock RockyAinda não há avaliações

- Incoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Documento11 páginasIncoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Sandip Jawalkar100% (1)

- Supplier Apqp Gated ReviewDocumento1 páginaSupplier Apqp Gated Reviewtanto_deep_15Ainda não há avaliações

- SAMPLE - Process FlowDocumento2 páginasSAMPLE - Process Flowakav123Ainda não há avaliações

- APQP FormDocumento103 páginasAPQP FormJERFSON AUGUSTOAinda não há avaliações

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocumento16 páginasQC 080000-2005 (2nd Ed) IECQ-HSPMISO VintecomAinda não há avaliações

- PPAPDocumento51 páginasPPAPGuru PrasadAinda não há avaliações

- Control PlanDocumento1 páginaControl Plan786tip786Ainda não há avaliações

- Example Control PlanDocumento1 páginaExample Control PlanRohmat SesAinda não há avaliações

- Uncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial SystemsDocumento4 páginasUncontrolled Copy, Verify Revision Before Using.: Atlantic Inertial Systemsnetelsrt1298Ainda não há avaliações

- Control Plan FormatDocumento6 páginasControl Plan Formatazadsingh1Ainda não há avaliações

- Request For Material Sample Approval (Msa) : Daiken CorporationDocumento1 páginaRequest For Material Sample Approval (Msa) : Daiken CorporationarifinAinda não há avaliações

- Laporan Hasil Inspkesi-00Documento23 páginasLaporan Hasil Inspkesi-00adisutardiAinda não há avaliações

- Ppap For Neel MetalDocumento40 páginasPpap For Neel MetalshuklahouseAinda não há avaliações

- Control Plan: Prototype Pre-Launch ProductionDocumento1 páginaControl Plan: Prototype Pre-Launch ProductionGeovanny HernándezAinda não há avaliações

- Wheel Chair (Spec)Documento1 páginaWheel Chair (Spec)Ibrohim Mashiro AsshofaAinda não há avaliações

- PFMEA FormatoDocumento2 páginasPFMEA FormatoJorge Lopez AguilarAinda não há avaliações

- Appr Oved B Y: - Di Rect or - P Roject SDocumento3 páginasAppr Oved B Y: - Di Rect or - P Roject SkedubhajjiAinda não há avaliações

- Summary Report For Foundation Design: Calculation Sheet of FoundationDocumento1 páginaSummary Report For Foundation Design: Calculation Sheet of FoundationUlfa HafizdyaAinda não há avaliações

- Allied Manufacturing ProcessesDocumento2 páginasAllied Manufacturing ProcessesAmit PatelAinda não há avaliações

- Jeevan Vikas ConsultatnsDocumento1 páginaJeevan Vikas ConsultatnsAmit PatelAinda não há avaliações

- ICICI Prudential Tax Plan (G) : Axis Long Term Equity Fund (G) HDFC Long Term Advantage Fund (G)Documento1 páginaICICI Prudential Tax Plan (G) : Axis Long Term Equity Fund (G) HDFC Long Term Advantage Fund (G)Amit PatelAinda não há avaliações

- YshDocumento1 páginaYshAmit PatelAinda não há avaliações

- Jeevan Vikas ConsultatnsDocumento1 páginaJeevan Vikas ConsultatnsAmit PatelAinda não há avaliações

- Computer Aided DesignDocumento2 páginasComputer Aided DesignKeyur TAinda não há avaliações

- Symbol Series Coupon Rate YTM at LTP (%) Face Value LTP Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin IiflfinDocumento3 páginasSymbol Series Coupon Rate YTM at LTP (%) Face Value LTP Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin Iiflfin IiflfinAmit PatelAinda não há avaliações

- Coning OilDocumento1 páginaConing OilAmit PatelAinda não há avaliações

- United States Patent (191: Beales Et Al. (45) Date of Patent: Sep. 23, 1997Documento13 páginasUnited States Patent (191: Beales Et Al. (45) Date of Patent: Sep. 23, 1997Amit PatelAinda não há avaliações

- JAIIB Legal Aspects of Banking Mod ABDocumento116 páginasJAIIB Legal Aspects of Banking Mod ABFouzan SoniwalaAinda não há avaliações

- Heaer Cost CoparisionDocumento2 páginasHeaer Cost CoparisionAmit PatelAinda não há avaliações

- LogDocumento1 páginaLogAmit PatelAinda não há avaliações

- 014 ToolsteelDocumento36 páginas014 ToolsteelSamrat SinghAinda não há avaliações

- Dura CylDocumento2 páginasDura CylAmit Patel100% (1)

- How To Read Hydraulic SymbolsDocumento17 páginasHow To Read Hydraulic SymbolsanonimppAinda não há avaliações

- JAIIB Legal Aspects of Banking Mod ABDocumento116 páginasJAIIB Legal Aspects of Banking Mod ABFouzan SoniwalaAinda não há avaliações

- Vasai Cable Service NoDocumento1 páginaVasai Cable Service NoAmit PatelAinda não há avaliações

- LogDocumento1 páginaLogAmit PatelAinda não há avaliações

- How To Read Hydraulic SymbolsDocumento17 páginasHow To Read Hydraulic SymbolsanonimppAinda não há avaliações

- Indian Railway Seat LayoutDocumento1 páginaIndian Railway Seat LayoutHarshmani Gupta100% (1)

- Tol ChartDocumento1 páginaTol ChartAmit PatelAinda não há avaliações

- ABC ManualDocumento54 páginasABC ManualAmit PatelAinda não há avaliações

- Engine Radiator CalculatorDocumento25 páginasEngine Radiator Calculatorscsurratt0% (1)

- Aluminum PropertiesDocumento15 páginasAluminum PropertiesAmit PatelAinda não há avaliações

- Dust BINDocumento1 páginaDust BINAmit PatelAinda não há avaliações

- Aluminum PropertiesDocumento15 páginasAluminum PropertiesAmit PatelAinda não há avaliações

- ABC ManualDocumento54 páginasABC ManualAmit PatelAinda não há avaliações

- Stripping MCDocumento1 páginaStripping MCAmit PatelAinda não há avaliações

- Ew Materials and New Design Criteria For Heat Exchangers: Metall-PraxisDocumento5 páginasEw Materials and New Design Criteria For Heat Exchangers: Metall-PraxisAmit PatelAinda não há avaliações